Help with Temperature Sensor Issues

-

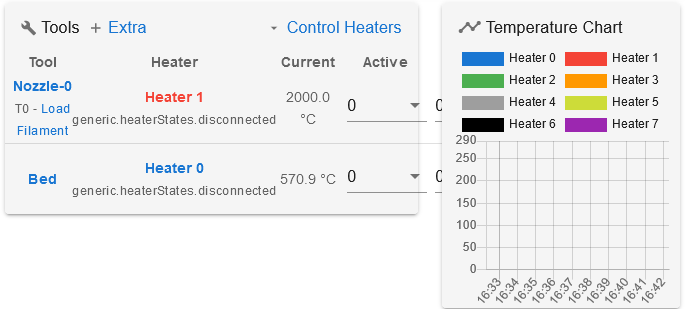

I bought the RTD Daughter Board (Max 31865) for Duet 2 Wifi and I am getting incorrect readings.

Everything is hooked up hardware wise for the Bed (a PT100 sensor) and the Nozzle sensor (another PT100 sensor). I followed the guide for the hardware. Tried following the firmware guide. The version of firmware I'm using is 2.03 (I need this version for specific endstop settings).

Any advice to get the two PT100 sensors working? I've posted my config.g below.

; Configuration file for Duet WiFi (firmware version 2.03) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.10 on Mon Mar 14 2022 15:32:07 GMT-0700 (Pacific Daylight Saving Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"" ; set printer name ; Network M551 P"" ; set password M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S0 ; physical drive 0 goes backwards M569 P1 S1 ; physical drive 1 goes forwards M569 P2 S0 ; physical drive 2 goes backwards M569 P3 S1 ; physical drive 3 goes forwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z400.00 E420.00 ; set steps per mm M566 X900.00 Y900.00 Z12.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z250.00 E250.00 ; set accelerations (mm/s^2) M906 X800 Y800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X223 Y223 Z205 S0 ; set axis maxima ; Endstops M574 X1 Y2 Z2 S0 ; set active low and disabled endstops ; Z-Probe M558 P0 H5 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed M557 X15:215 Y15:195 S20 ; define mesh grid ; Heaters M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M305 P0 X201 ; configure PT100 for heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M305 P1 X200 ; configure PT100 for heater 1 M143 H1 S290 ; set temperature limit for heater 1 to 290C ; Fans M106 P0 S0 I0 F500 H-1 ; set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off M106 P1 S1 I0 F500 H1 T45 ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on ; Tools M563 P0 S"Nozzle-0" D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined -

@ripeds_o3p said in Help with Temperature Sensor Issues:

The version of firmware I'm using is 2.03 (I need this version for specific endstop settings).

I don't understand. Any endstop settings can be duplicated in recent firmware.

What version of DWC are you using?

; Heaters M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M305 P0 X200 ; configure PT100 for heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M305 P1 X201 ; configure PT100 for heater 1 M143 H1 S280 ; set temperature limit for heater 1 to 280CThis is what I get from the config tool for using PT100. Seems basically the same as yours, so I don't think the config is the issue.

Are you sure the PT100 board is seated correctly?

-

@phaedrux DWC 3.3.0.

(As for endstops, my apologies, but that's too long of a story. All I can say is in my experience, I needed specific endstop type options that I couldn't find in later versions. Just to get my UM2 to home all properly. Maybe someone more experienced in using the tool or knows how to code wouldn't have that issue, but I did. It works great now.)

From what I can see with the daughter board it looks seated okay. In the area from the photos I've seen in the guide.

Should I try removing the daughter board and placing it back in it's spot? I can try that tomorrow if you think it'll help.

-

@ripeds_o3p said in Help with Temperature Sensor Issues:

DWC 3.3.0.

I think the problem is that you're using an ancient firmware with the latest DWC. That's going to be problematic.

You can try uploading this zip file to go back to a version of DWC compatible with your chosen firmware. https://github.com/Duet3D/RepRapFirmware/releases/download/2.05.1/DuetWebControl-SD-2.0.7.zip

If you post your current config.g I can tell you what the equivalent endstop config would be for RRF3.

-

@phaedrux I'm going to break this response into three parts.

DWC firmware rollback: Thank you.

RRF3 settings for endstops: Sure, I'll try it again sometime in the future if you're able to recreate the endstop settings in the latest version. Here's the current version of my config.g .

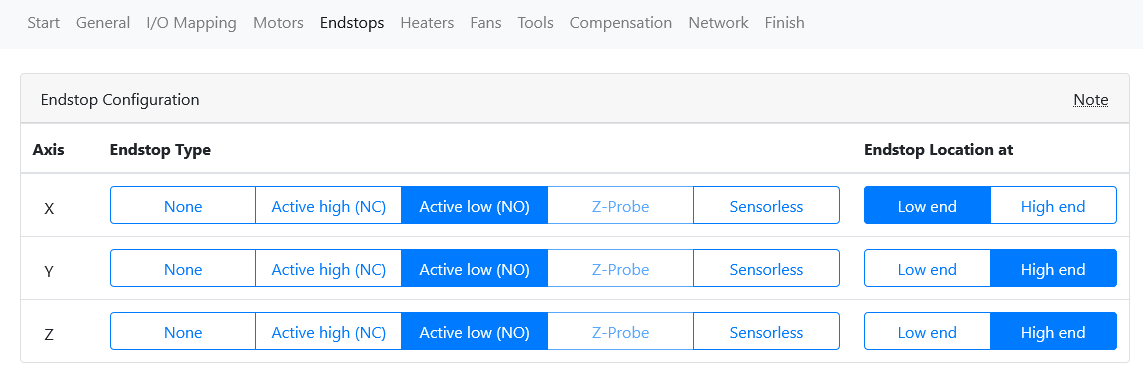

This is a picture of the endstop settings I needed.

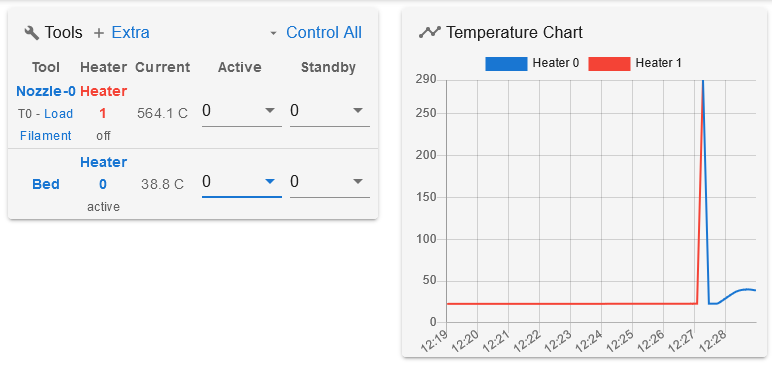

I also quoted the code for it.; Endstops M574 X1 Y2 Z2 S0 ; set active low and disabled endstopsBack to the temperature sensors: So I decided to check the daughterboard. I tugged on the wires and one came loose (one for the bed sensor). I fixed it, tightening it back into place. One of the sensors reads accurately now. It took some tinkering to learn it is the bed sensor that works. The nozzle sensor reads in the 500s.

Still unsure why. The wires are generally the same length and size (bed sensor & nozzle sensor). I'll post a new picture.

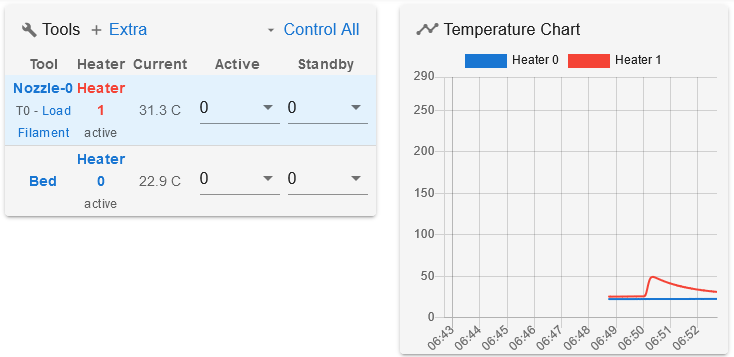

This is the bed temperature after a quick test of raising the temp to 40 degrees celsius just to see if it works. -

Are you sure they are PT100 sensors?

See the troubleshooting section here for how to test the board itself.

https://docs.duet3d.com/User_manual/Connecting_hardware/Temperature_connecting_PT100

For the endstop, the get active low, you need to choose the active low endstop pin option from the I/O mapping page.

And you get this:

; Endstops M574 X1 S1 P"!xstop" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin !xstop M574 Y2 S1 P"!ystop" ; configure switch-type (e.g. microswitch) endstop for high end on Y via pin !ystop M574 Z2 S1 P"!zstop" ; configure switch-type (e.g. microswitch) endstop for high end on Z via pin !zstopThe

!in front of the pin name makes the pin active low. Or rather, it inverts the signal. This is equivalent toS0 -

@phaedrux

PT100 issue: I plugged the sensor directly into the Duet before getting a reading of 2000 Celsius. This was before using the daughterboard. I'm pretty sure I'm reusing the original sensor I got with my secondhand Ultimaker 2 which is supposed to be a PT100. That's what this machine is known to ship with.I guess I could just redo the tips of the wires meant for the terminal. I'm using ferrules. It could be a bad connection.Perhaps the wire is bad? Or maybe this PT100 sensor itself?Shoot, I think I may have spare PT100 around here. That could be worth a try.

Endstops: Thank you.

-

Fixed!

Turns out the wrong wires were plugged into the terminal (wasn't for a PT100 but a different component). sigh

I lost a few labels to my wires when pushing them through the designated holes in the printer (for cable management). Out to the Duet board. Add in the fact that it has been a few weeks since I last tinkered with the printer and that's the recipe for this mistake.

-

undefined Phaedrux marked this topic as a question

undefined Phaedrux marked this topic as a question

-

undefined Phaedrux has marked this topic as solved

undefined Phaedrux has marked this topic as solved