MFM 0: tooLittleMovement

-

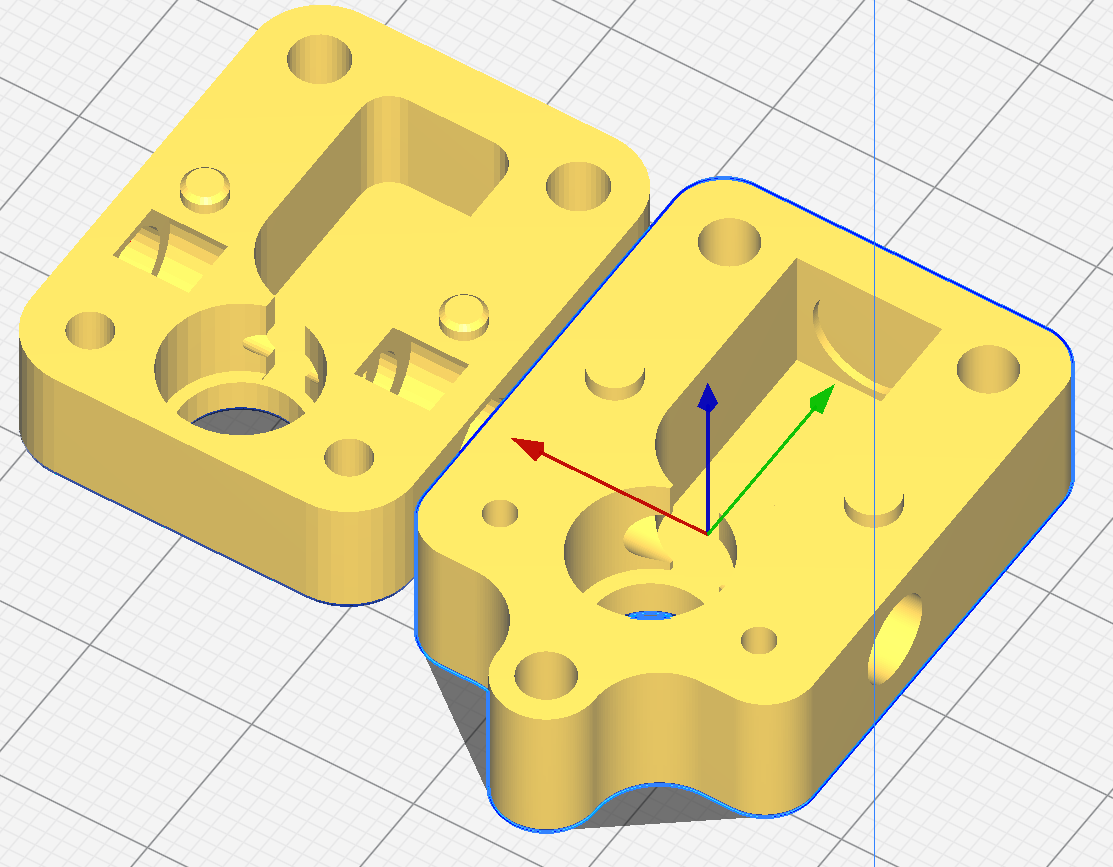

I'd guess at this being a mechanical issue. It certainly seems to have been with mine. I redesigned the case, re-printed and it's been perfect so far.

I've just posted my updated design over here in another thread if you're interested in trying it out. I don't have a resin printer, so put a bit of work into getting it tweaked for FDM. STL if you want 'em.

My recent thread here:

For what it's worth, 3.4RC2 cured the "sensor error" stops I was getting, but not the movement ones. The updated housing is going strong and the sensor has been flawless. Had a few "sensor error" drops from crimps that had lost some spring early on, but fresh ones did nothing to solve the "too little movement".

My current M591 D0

Duet3D rotating magnet filament monitor v3 on pin e0stop, enabled, sensitivity 26.67mm/rev, allow 70% to 130%, check printing moves every 6.0mm, version 3, mag 131 agc 69, measured sensitivity 26.57mm/rev, min 98% max 103% over 10401.0mm

That's on a print with 2800 x 6.5mm retracts!

-

@lo-fi

Thanks for your reply. I'm eager to see what you changed in the housing design that made the difference. I was thinking my problem may be the springs tension on the bearing starting to weaken as my sensor was working pretty well. I'm going to devote time to this over the weekend, I'll report back what I find. -

My design goals:

-

Keep the filament path clear of anything but the PTFE inserts, hob and idler.

-

Align the PTFE so the filament is lightly pressed against the hobb even before the idler comes into play

-

Add slightly more clearance for the hob and idler

-

Add an indent to keep the idler spring in the correct position

-

Achieve a tight fit for the plastic collets holding the PTFE

I used the official idler mounting, though I think I can tweak that a little too as the two halves required quite a bit of fettling to let the bearing spin freely but still hold it securely when glued together around it.

I think the key things that made the difference are keeping the filament path clear, stable and moving the hobb even without the idler. I don't think the idler spring is strong enough to do the job on its own if the filament enters or exits at a funny angle and wants to move away from the hobb.

Worth noting that I got the V1 magnetic assembly in my kit. I'd have to get my hands on the V2 (or get a good set of dimensions) to tweak the design for that.

-

-

@lo-fi

You put a lot of thought and effort into this. I have the v2 assembly, I can't remember if the housings are compatible. I have a .3mm nozzle x I could use to get more resolution but i'm not sure that's necessary. What was your print settings for this? Did you go with solid infill? I would definitely like the stl if my v2 will work with this. -

Nope, guess I wasn't paying attention. v1 and v2 are too different. Would duet supply the drawing if we requested it?

-

@idodgeads yes I have added a picture here:

https://docs.duet3d.com/en/Duet3D_hardware/Accessories/Rotating_Magnet_Filament_Monitor#hobbed-assembly -

undefined Phaedrux referenced this topic

undefined Phaedrux referenced this topic

-

@t3p3tony that's brilliant, thanks for all the hard work on the new docs! Is there any way I can buy just the V2 hobbed assembly? I wouldn't mind trying it, just out of interest.

So just a 1mm difference in the placement of the top bearing and width of the hob. Not a problem. I've updated the models, @Idodgeads . I'm going to print to check before sending files over.

The 0.3mm nozzle might make a few details sharper, though I don't think anything critical either way. 0.1mm layer height will probably get better a result, but my 0.2 print seems to be doing OK. -

@lo-fi yes for the work you are doing on the housings, sure. drop a line to info@duet3d.com.

Thanks should go mainly to @droftarts for the new docs!

-

@t3p3tony

Thanks for making this available. I just got two new build surfaces in this week so I'm ready

to test print. -

@lo-fi Super interested in trying your sensor housing when it's complete. I am having the same issues others appear to be having.

-

@brotherchris I had two good test prints last night and have been in touch with T3P3Tony about getting a V2 rotating assembly, so hopefully won't be long and I can test out both variations.

I'll throw you a heads-up when I'm happy with and have done a little testing myself