TOOL T0 IS NON ACTIVATED IN config.g

-

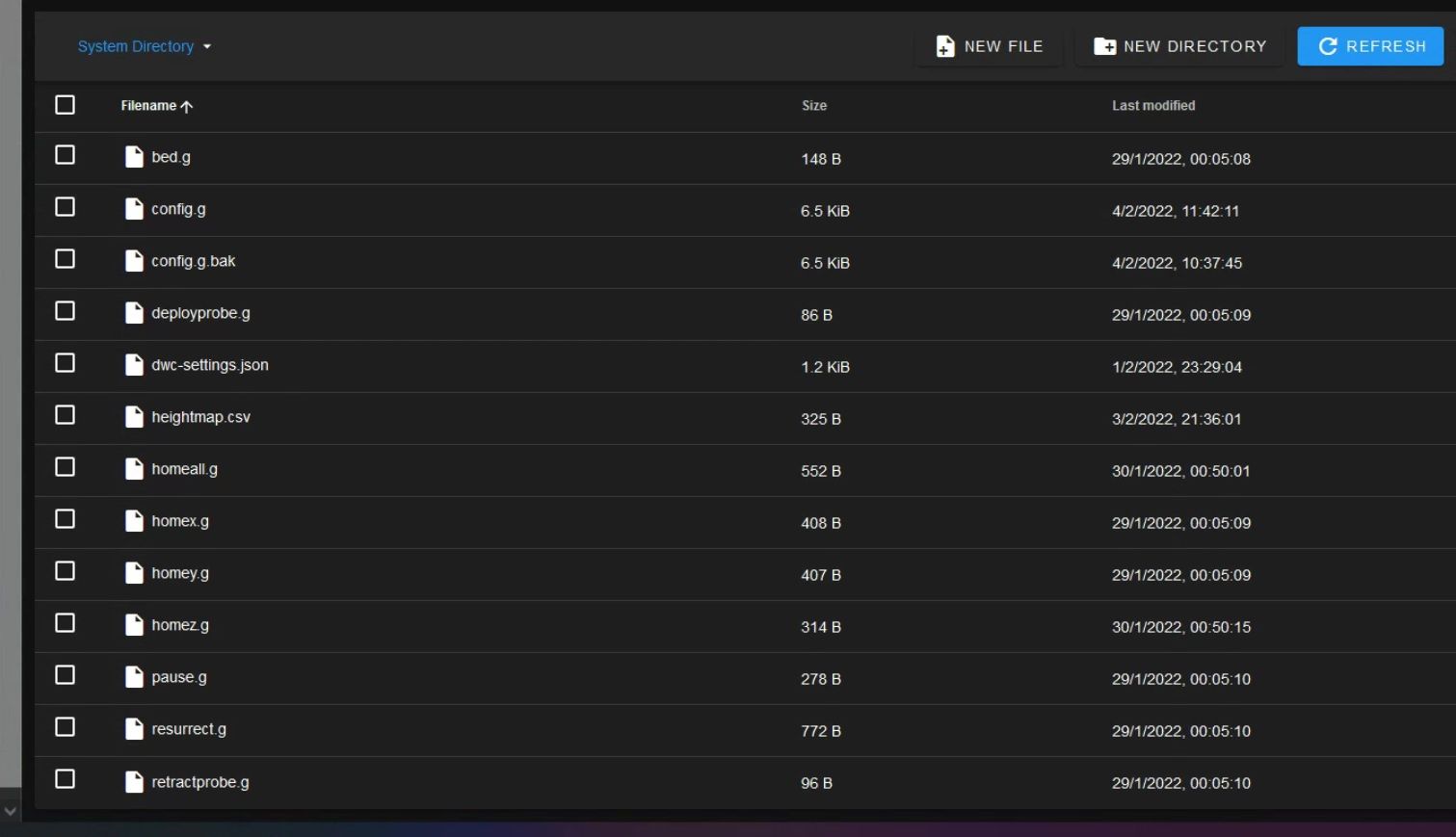

Recently on my system (Duet3 + SBC), at boot the T0 tool is not active, even if specified in the config.g. (see below) This happens only in SBC mode, the same config.g in STAND ALONE mode, works perfectly.

If I type "T0" after boot, by console in paneldue or DWC it works perfectly. I also tried pausing before the T0 command... How could I fix it?; Configuration file for Duet 3 (firmware version 3.3.0 DWC 3.3.0) ; Note: Duet3 ( SBC RASPBERRY ) ; Data di aggiornamento: 04/02/2022 ; ; ---------- General preferences --------- G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M575 P1 S1 B57600 ; enable support for ; ; ---------- Drives ---------- M569 P0.0 S1 ; X physical drive 0.0 goes forwards M569 P0.1 S1 ; Y physical drive 0.1 goes forwards M569 P0.2 S1 ; Z1 physical drive 0.2 goes forwards M569 P0.3 S1 ; Z2 physical drive 0.3 goes forwards M569 P0.5 S0 ; E1 physical drive 0.5 goes backwards ; M584 X0.0 Y0.1 Z0.2:0.3 E0.5 ; set drive mapping Z0.2:0.3 ; M350 X32 Y32 Z32 E16 I1 ; configure microstepping with interpolation M92 X320.00 Y320.00 Z1600.00 E92.60 ; set steps per mm M566 X1200.00 Y1200.00 Z60.00 E900.00 ; set JERK (maximum instantaneous speed changes) M566=mm/min M205=mm/sec M203 X12000.00 Y12000.00 Z2000.00 E1200.00 ; set maximum speeds (mm/min) M201 X1200.00 Y1200.00 Z120.00 E3000.00 ; set accelerations (mm/s^2) M906 X1500 Y1500 Z1000 E1200 I30 ; set motor currents (mA) and motor idle factor 30% M84 S30 ; Set idle timeout 30sec ; ; ---------- Axis Limits ---------- M208 X0 Y0 Z0 S1 ; set axis minima M208 X235 Y300 Z290 S0 ; set axis maxima ; ; ---------- Endstops --------- M574 X1 S1 P"!io1.in" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin !io1.in M574 Y1 S1 P"!io2.in" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin !io2.in ;M591 P2 C"io3.in" S1 D0 ; filament monitor connected to E0_stop ; ; ---------- Z-Probe ---------- M950 S0 C"io7.out" ; create servo pin 0 for BLTouch M558 P9 C"io7.in" H5 F500 T6000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X-4.5 Y-22 Z2.85 ; set Z probe trigger value, PIU' ALTO E' Z PIU' SI AVVICINA AL LETTO M557 X1:240 Y2:300 S69 ; define mesh grid (GRIGLIA maglia 4 x 4 con 60mm di spazio) ; ; ----------- HO - HEATERS BED ---------- M308 S0 P"temp0" Y"thermistor" T100000 B4138 A"BED" ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out1" T0 ; create bed heater output on out1 and map it to sensor 0 M307 H0 A149.0 C639.9 D1.4 V24.2 B0 ; autotaratura copiato da sys duet wifi M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 ; ; ----------- H1 - HEATERS NOZZLE ---------- M143 H0 S110 ; set temperature limit for heater 0 to 110C M308 S1 P"temp1" Y"thermistor" T100000 B4138 A"ESTRUSORE" ; configure sensor 1 as thermistor on pin temp1 M950 H1 C"out2" T1 ; create nozzle heater output on out2 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S275 ; set temperature limit for heater 1 to 275C ; ; ---------- FAN 0 VENTOLA RAFFREDDAMENTO STAMPA (out7) 24v ---------- M950 F0 C"out7" Q500 ; create FAN_0 on pin out7 at 500hz M106 P0 C"VENTOLA Filo" S0 H-1 ; set FAN_0 name and value. Thermostatic control is turned off ; ; ---------- FAN 1 VENTOLA ESTRUSORE (out8) 24v ---------- M950 F1 C"out8" Q500 ; create FAN_1 on pin out8 and set its frequency at 500hz M106 P1 C"VENTOLA Extr." H1 L0.3 X1.0 B0.3 T70:250 ; PARAMETRICA Termostatica ( da 30% a 100% con temp. da 70°C a 240°C ) ; ; ---------- FAN 2 VENTOLA MCU PWM (out5) 12v --------- M308 S3 Y"mcu-temp" A"MCU" ; configure sensor 3 as thermistor for MCU ; M950 F2 C"out9" Q100 ; create FAN_2 on pin out9 and set its frequency at 100hz M950 F2 C"!out5+out5.tach" ; Fan 2 su out5, use PWM (needs ! inverted), using out5.tach ; M106 P2 T25:35 H3 ; FUNZIONANTE M106 P2 L0.1 X1.0 B0.3 T26:35 H3 ; set FAN_2 value T26:32°C velocità ventola L-10% X-90% ; ; ---------- FAN 3 LUCE LED su RISCALDATORE (out3) ---------- M950 F3 C"out3" Q1000 ;Fan 3 is connected to HEAT E1, si può inserire la frequanza PWM. Es. Q1000 è 1000Hz M106 P3 C"LUCE LED" S0.1 ;LED ON AL 10% ;M106 P3 S0.0 ;PER SPEGNERE LED ; ; ---------- FAN 4 RELE' ACCENSIONE (out4) 12v ---------- M950 F4 C"out4" Q500 ;Fan 4 is connected to HEAT E1, si può inserire la frequanza PWM. Es. Q1000 è 1000Hz M106 P4 C"RELE'" S0.0 ;IMPOSTATA IL PIN 4 AL 0% ;M106 P3 S0.0 ;PER SPEGNERE LED ; ; ---------- FAN 5 VENTOLA PWM RASPBERRY (out6) 12v --------- M308 S5 P"temp2" Y"thermistor" T100000 B4138 A"RASPBERRY" ; Configura il sensore 5 (S5) come riscaldatore sul pin temp2 con nome ALIMENTATORE M950 F5 C"!out6+out6.tach" ; Fan 5 uses out4, PWM fan, and using out4.tach as a tacho input M106 P5 T30:45 H5 ; set fan 5 (F5) attiva da 40 a 50°C secondo il riscaldatore 5 (H5) ; ; Tools M563 P0 S"Dragonfly BMS" D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; ; ---------- MISCELLANEUS ---------- M912 P0 S-5.2 ; parametro per tatare la temperatura della MCU (-5.2°C) G29 S1 ; Carica la mappa di compensazione dalla SD Card M911 S11.5 R11.9 P"M913 X0 Y0 G91 M83 G1 Z3 E-2 F500" ;Autosalvataggio stampa per mancanza di corrente, sospende a 25.0v e riparte a 25.8v M300 S2500 P3000 ; Emette suono a S=2500Hz per P=3 secondi T0 ; select first tool ACTIVE ; ---------- END SCRIPT ----------- -

if you run

M98 P"config.g"what result do you have?

-

@danzaywer said in TOOL T0 IS NON ACTIVATED IN config.g:

if you run

M98 P"config.g"what result do you have?

Reload the config.g without errors and Tool 0 becomes correctly active ...

This does not happen on the first boot just turned on.

-

@gianluca Do you have a sys/config-override.g file?

Eventually there is a command which disable the tool... -

@cosmowave I don't see M501 in config.g, @Gianluca can try to add T-1 prior of T0 and see what happen? or try to put T0 in an external macro and call it at the end of config.g. Anyways i believe this is SBC firmware glitch

-

@cosmowave said in TOOL T0 IS NON ACTIVATED IN config.g:

@gianluca Do you have a sys/config-override.g file?

Eventually there is a command which disable the tool...I havn't config-override.g file

-

@danzaywer said in TOOL T0 IS NON ACTIVATED IN config.g:

@cosmowave I don't see M501 in config.g, @Gianluca can try to add T-1 prior of T0 and see what happen? or try to put T0 in an external macro and call it at the end of config.g. Anyways i believe this is SBC firmware glitch

T-1 prior of T0 does not work, T0 is always off on first boot ...

I try with M501...

Could it be because my Raspberry P4 starts from USB and not from MicroSD? -

@gianluca I think You don't need M501 if you not have any setting stored with M500. Have you tried M98 P"SelectT0.g" and put "T0" into it? Obviouslyit it is "Una pezza a colore".......

-

@danzaywer said in TOOL T0 IS NON ACTIVATED IN config.g:

@gianluca I think You don't need M501 if you not have any setting stored with M500. Have you tried M98 P"SelectT0.g" and put "T0" into it? Obviouslyit it is "Una pezza a colore".......

mystery ... the T0 doesn't work, even with a call from a macro from config.g (only on first boot) ... But if I run an emergency stop, or call the macro, T0 becomes active good.

-

@gianluca I'm wondering if using M300 to play a 3 second beep just before the "T0" command in your config.g is having an effect? Try commenting that M300 out just to see. Or you could try putting a pause of (say) 4 seconds after the M300 and before the "T0" e.g. G4 S4.

-

@deckingman said in TOOL T0 IS NON ACTIVATED IN config.g:

@gianluca I'm wondering if using M300 to play a 3 second beep just before the "T0" command in your config.g is having an effect? Try commenting that M300 out just to see. Or you could try putting a pause of (say) 4 seconds after the M300 and before the "T0" e.g. G4 S4.

The M300 is not the problem, and 4 sec. delay did not solve the problem. I solved by update the firmware from 3.3 to 3.4 b7.

The beta version worked better than a stable one