seeing if i can get assistance with bed connectins

-

@frnknstn ill double check and make sure i have the wires correct

-

@frnknstn That is strange, not even the tool fan? ... Is your config still as listed above ?

Try a M98 P"0:/sys/config.g" and check the console

-

@frnknstn You might want to uncomment your tool config at the end of config.g and end with a T0

-

@gixxerfast ; General preferences

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves; Network

M550 P"duet3" ; Set machine name

M552 S1 ; Enable network

;*** Access point is configured manually via M587

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable Telnet

M575 P1 S1 B57600 ; Panel Due; Printer geometry

M669 K1 ; Select CoreXY mode

M208 X0:330 Y0:285.75 Z0:350 ; Axis Limits

M564 H0 ; allow unhomed movement;------- drives from top---------------------------------------------------

; B -------+------ A

; | P.02 | P.03 |

; -------+------- Z-Drives

; | P0.1 | P0.4 |

; -------+-------

; Front; Drive Mappings

M569 P0.0 S1 V0 ; Drive 0: E Axis

M569 P0.1 S1 V0 ; Drive 1: Z-LeftFront Axis

M569 P0.2 S0 V0 ; Drive 2: Z-LeftRear Axis

M569 P0.3 S1 V0 ; Drive 3: Z-RightRear Axis

M569 P0.4 S0 V0 ; Drive 4: Z-RightFront Axis

M569 P1.0 S1 V0 ; Drive 5: Expansion: B motor (X-axis)

M569 P1.1 S1 V0 ; Drive 6: Expansion: A motor (Y-axis); Motor remapping for dual Z and axis Limits

M584 X1.0 Y1.1 Z0.1:0.2:0.3:0.4 E0.0 ; Motor mapping

M671 X-76.2:-76.2:406.4:406.4 Y0:374.65:374.65:0 S20 ; Z leadscrews positions Left Front - Let Rear - Right Rear - Right Front; Microstepping and Speed

M350 X32 Y32 E16 Z16 I1 ; Configure microstepping with interpolation

M92 X200.00 Y200.00 Z200.00 E400.00 ; Set steps per mm 1.8 motors; Speeds, Acceleration and Jerk

M566 X400.00 Y400.00 Z25.00 E600.00 P1 ; Set maximum instantaneous speed changes (mm/min)

M203 X12000.00 Y12000.00 Z1000.00 E3600.00 ; Set maximum speeds (mm/min)

M201 X3000.00 Y3000.00 Z100.00 E3600.00 ; Set accelerations (mm/s^2); Motor currents

M906 X1200.00 Y1200.00 Z1200.00 E700.00 I60 ; Set motor currents (mA) and motor idle factor in percent

M84 S600 ; Set idle timeout; Endstops for each Axis

M574 X2 S1 P"io0.in" ; Set X endstop controlled by switch

M574 Y2 S1 P"io1.in" ; Set Y endstop controlled by switch; Z-Probe

M558 P8 C"io3.in" H5 F120 T60000 ; set Z probe type to unmodulated and the dive height + speeds

G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height

M557 X15:215 Y15:195 S20 ; define mesh grid; Stallgaurd Sensitivy (maybe use to pause print after crash)

M915 X S2 F0 H200 R0 ; Set X axis Sensitivity 1.8 motors

M915 Y S2 F0 H200 R0 ; Set y axis Sensitivity 1.8 motors; Input Shaper and Accelerometer

;M955 P0 C"io4.out+io4.in"

;M593 F46.75 S0.2

;M593 F19 P4 S0.3 ; experimental; Z Probe Offset (Probe behind Afterburner)

G31 P500 X0 Y0 Z1.5; Heaters

M308 S0 P"temp_0" Y"thermistor" A"Bed" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0

M950 H0 C"out_0" T0 ; create bed heater output on out0 and map it to sensor 0

M307 H0 A350 C139 D5.5 B0 ; set model parameters for heater 1 and use PID mode

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120CM308 S1 P"temp_1" Y"thermistor" A"Hotend" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin temp1

M950 H1 C"out_1" T1 ; create nozzle heater output on out1 and map it to sensor 1

M307 H1 B0 R1.680 C233.0:193.0 D6.75 S1.00 V23.7 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S280 ; set temperature limit for heater 1 to 280C; Fans

M950 F0 C"out7" Q500 ; Parts cooling create fan 0 on pin out7 and set its frequency

M106 P0 T45 H0M950 F1 C"out8" Q500 ; Extruder create fan 1 on pin out8 and set its frequency

M106 P1 T25 H1; Fans Electronic compartment & Exhaust

;M950 F1 C"out3" Q100 ; Creates Case Fan 1

;M106 P1 T40 S150 H0 ; Case Fan 1 Settings (Turns on at 60°C tool temp) at low speed

;M950 F2 C"out4" Q100 ; Creates Case Fan 2

;M106 P2 T40 S150 H0 ; Case Fan 2 Settings (Turns on at 60°C tool temp) at low speed

;M950 F5 C"out7" Q100 ; Creates Case Fan 2

;M106 P5 T95 S50 H0 ; Exhaust fan; Filament Runout sensor

;M950 J4 C"io5.in" ; Input 4 filament sensor

;M581 P4 T2 S1 R1 ; Filament Sensor P4 triggers inactive-to-active edge (S1) tigger2.g (T2) only when printing (R1)

;M591 D0 P1 C"io5.in" S1 ; Filament Sensor; Tools

M563 P0 D0 H1 F0 S"Extruder" ; Define tool 0

G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0CThis is where its at right now

-

-

@frnknstn said in seeing if i can get assistance with bed connectins:

M106 P0 T45 H0

This one: M106 P0 T45 H0 ---> M106 P0 S0 H-1 right? You don't want the part cooling fan with thermostatic control. You want the Slicer to handle that one

-

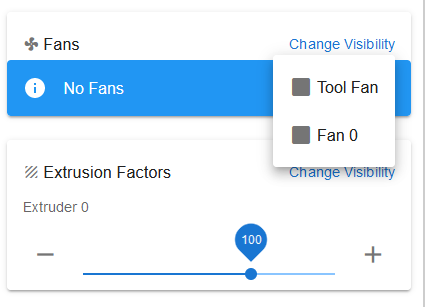

@alankilian .png](/assets/uploads/files/1639424752390-bff710fe-017d-46e8-9dca-b7f6ce8fd525-screenshot-3.png) image url)

image url)I dont see anything

-

This post is deleted! -

@alankilian right, that dont do anything if turned all the way up

-

@frnknstn Did you fix this?

"This one: M106 P0 T45 H0 ---> M106 P0 S0 H-1 right? You don't want the part cooling fan with thermostatic control. You want the Slicer to handle that one"

-

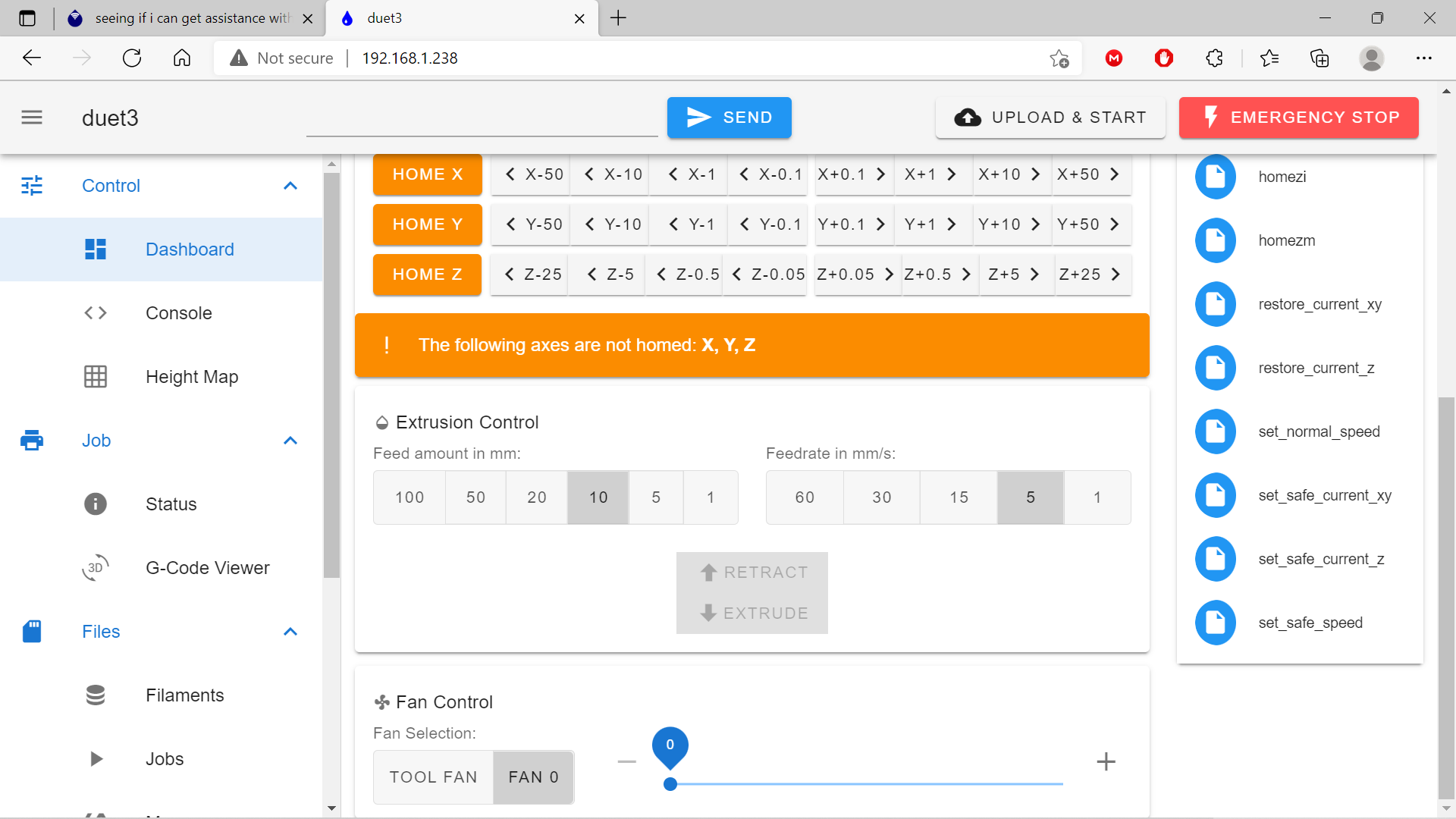

I changed the comment now i get fan 0 at the bottom. but i still have no action

-

@frnknstn OK, that's one. Now we must check your tool config ...

and later your wiring...

-

@gixxerfast glad you guys are helping. new to this and trying to learn. appreciate your patients

-

@frnknstn said in seeing if i can get assistance with bed connectins:

@gixxerfast glad you guys are helping. new to this and trying to learn. appreciate your patients

You're doing GREAT!

We've all been where you are right now.

-

@frnknstn

Now replaceM563 P0 D0 H1 F0 S"Extruder" ; Define tool 0with

M563 P0 D0 H1Just to test and reset the board

Add a T0 at the very end of config.g as well

Shouldn't make much difference but ...

-

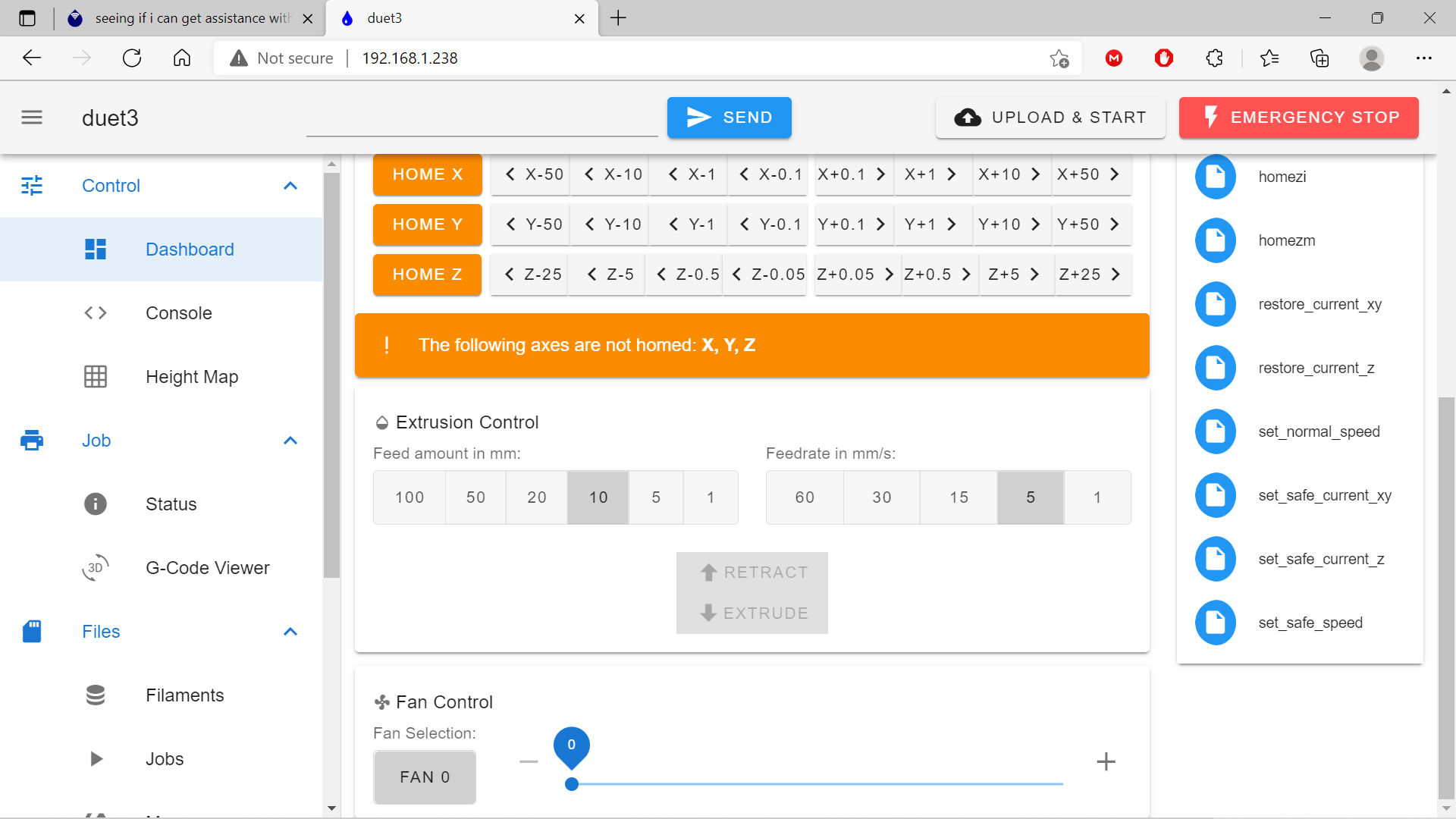

@gixxerfast it is changed

-

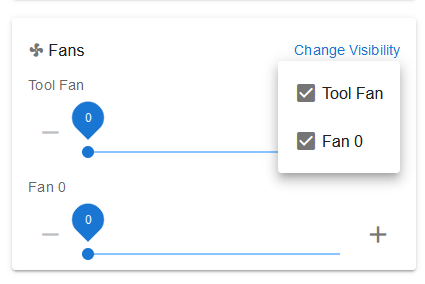

-

it put Tool fan under fans. No movement yet though

-

@frnknstn Oh, yes. #2 done. Now try to max that one and see if any fan spins.

Drag it to max

-

@gixxerfast no movement.

; General preferences G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves ; Network M550 P"duet3" ; Set machine name M552 S1 ; Enable network ;*** Access point is configured manually via M587 M586 P0 S1 ; Enable HTTP M586 P1 S0 ; Disable FTP M586 P2 S0 ; Disable Telnet M575 P1 S1 B57600 ; Panel Due ; Printer geometry M669 K1 ; Select CoreXY mode M208 X0:330 Y0:285.75 Z0:350 ; Axis Limits M564 H0 ; allow unhomed movement ;------- drives from top--------------------------------------------------- ; B -------+------ A ; | P.02 | P.03 | ; -------+------- Z-Drives ; | P0.1 | P0.4 | ; -------+------- ; Front ; Drive Mappings M569 P0.0 S1 V0 ; Drive 0: E Axis M569 P0.1 S1 V0 ; Drive 1: Z-LeftFront Axis M569 P0.2 S0 V0 ; Drive 2: Z-LeftRear Axis M569 P0.3 S1 V0 ; Drive 3: Z-RightRear Axis M569 P0.4 S0 V0 ; Drive 4: Z-RightFront Axis M569 P1.0 S1 V0 ; Drive 5: Expansion: B motor (X-axis) M569 P1.1 S1 V0 ; Drive 6: Expansion: A motor (Y-axis) ; Motor remapping for dual Z and axis Limits M584 X1.0 Y1.1 Z0.1:0.2:0.3:0.4 E0.0 ; Motor mapping M671 X-76.2:-76.2:406.4:406.4 Y0:374.65:374.65:0 S20 ; Z leadscrews positions Left Front - Let Rear - Right Rear - Right Front ; Microstepping and Speed M350 X32 Y32 E16 Z16 I1 ; Configure microstepping with interpolation M92 X200.00 Y200.00 Z200.00 E400.00 ; Set steps per mm 1.8 motors ; Speeds, Acceleration and Jerk M566 X400.00 Y400.00 Z25.00 E600.00 P1 ; Set maximum instantaneous speed changes (mm/min) M203 X12000.00 Y12000.00 Z1000.00 E3600.00 ; Set maximum speeds (mm/min) M201 X3000.00 Y3000.00 Z100.00 E3600.00 ; Set accelerations (mm/s^2) ; Motor currents M906 X1200.00 Y1200.00 Z1200.00 E700.00 I60 ; Set motor currents (mA) and motor idle factor in percent M84 S600 ; Set idle timeout ; Endstops for each Axis M574 X2 S1 P"io0.in" ; Set X endstop controlled by switch M574 Y2 S1 P"io1.in" ; Set Y endstop controlled by switch ; Z-Probe M558 P8 C"io3.in" H5 F120 T60000 ; set Z probe type to unmodulated and the dive height + speeds G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height M557 X15:215 Y15:195 S20 ; define mesh grid ; Stallgaurd Sensitivy (maybe use to pause print after crash) M915 X S2 F0 H200 R0 ; Set X axis Sensitivity 1.8 motors M915 Y S2 F0 H200 R0 ; Set y axis Sensitivity 1.8 motors ; Input Shaper and Accelerometer ;M955 P0 C"io4.out+io4.in" ;M593 F46.75 S0.2 ;M593 F19 P4 S0.3 ; experimental ; Z Probe Offset (Probe behind Afterburner) G31 P500 X0 Y0 Z1.5 ; Heaters M308 S0 P"temp_0" Y"thermistor" A"Bed" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out_0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 A350 C139 D5.5 B0 ; set model parameters for heater 1 and use PID mode M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"temp_1" Y"thermistor" A"Hotend" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin temp1 M950 H1 C"out_1" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 B0 R1.680 C233.0:193.0 D6.75 S1.00 V23.7 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M950 F0 C"out7" Q500 ; Parts cooling create fan 0 on pin out7 and set its frequency M106 P0 S0 H-1 M950 F1 C"out8" Q500 ; Extruder create fan 1 on pin out8 and set its frequency M106 P1 T25 H1 ; Fans Electronic compartment & Exhaust ;M950 F1 C"out3" Q100 ; Creates Case Fan 1 ;M106 P1 T40 S150 H0 ; Case Fan 1 Settings (Turns on at 60°C tool temp) at low speed ;M950 F2 C"out4" Q100 ; Creates Case Fan 2 ;M106 P2 T40 S150 H0 ; Case Fan 2 Settings (Turns on at 60°C tool temp) at low speed ;M950 F5 C"out7" Q100 ; Creates Case Fan 2 ;M106 P5 T95 S50 H0 ; Exhaust fan ; Filament Runout sensor ;M950 J4 C"io5.in" ; Input 4 filament sensor ;M581 P4 T2 S1 R1 ; Filament Sensor P4 triggers inactive-to-active edge (S1) tigger2.g (T2) only when printing (R1) ;M591 D0 P1 C"io5.in" S1 ; Filament Sensor ; Tools M563 P0 D0 H1 G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C T0