Trouble diagnosing high-temperature extruder (65W) heater faults

-

Hey,

I'm setting up my printer for high temperature printing (<500C) and I've step-by-step been replacing one part at a time on my extruder: first using a PT1000 sensor, then moving to a plated copper heater cartridge, then switching to a E3D NozzleX extruder, then a titanium heat break, and finally a water cooled extruder heat sink. These changes all went fine and I've been able to run the printer successfully for a few weeks after these changes. However the printer with this configuration struggled to maintain high temperatures; I assumed it was due to an underpowered heater cartridge.

Now I replaced the heater cartridge from using a 40W to using a 65W cartridge, to be able to keep temperatures more stable, and sure enough when the printer reaches the set temperature, it keeps that temperature perfectly. However, while heating up (even to a low temperature like 250C) the heater consistently faults with no apparent error message. If I reset the fault and resume heating, the heater eventually reaches 250C fine. I've been diagnosing the errors with 250C for now just to get repeatable measurements and to not play around with potentially dangerously high temperatures, but of course I'll be looking for a solution that also works up to 500C.

Things I have checked:

- My PSU is a reputable brand (Meanwell) and rated to 350W.

- I'm using 3 extruders like this with a Duet 3 Tool Board, and since my system is 24V, the tool board should be able to handle a 120W heater according to the specs, so that should be fine I think?

- I've PID auto-tuned the heater several times and it always completes successfully (model parameters are currently e.g.

M307 H1 R2.554 C349.500:118.400 D7.30 S1.00 V23.3 B0for one of the 3 extruders) - The extruder has a pretty powerful PCF (as you can guess from the above heater params) but the faults don't ever occur due to turning on the PCF; they happen even when the PCF is completely turned off.

- Running with

M929 S3logs absolutely nothing when the heater fault occurs. - Each heater is limited to 500C with e.g.

M143 H1 S500 - I have not changed

M570at all, maybe I should for this case? Feels dangerous...

Any ideas?

-

@dflemstr how are you PID tuning ?

M303 H1 or M303 T0

-

@pcr The latter (

M303 T0)! -

What does your heater graph look like while the temp is raising? Photo?

What firmware version?

-

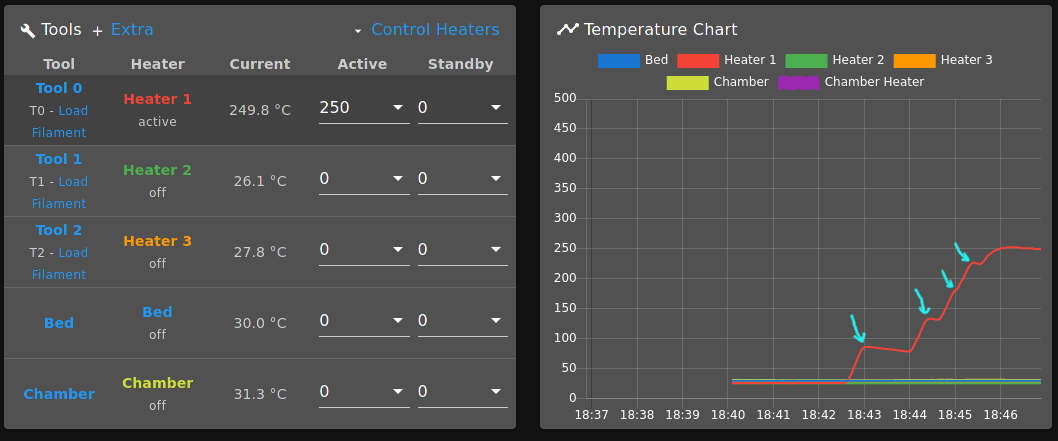

@phaedrux Here's a graph of me heating up Heater 1 to 250C:

I've very unscientifically marked with teal arrows where the heater faults occur, and at that point I run

M562 P1followed by re-activating the tool withT0 P0(or clicking on "Heater 1" in the UI). Eventually the tool heats up and is rock solid at 250C, no problems whatsoever.Some version info:

$ M115 FIRMWARE_NAME: RepRapFirmware for Duet 3 MB6HC FIRMWARE_VERSION: 3.3 ELECTRONICS: Duet 3 MB6HC v1.01 or later FIRMWARE_DATE: 2021-06-15 21:45:56 $ M115 B20 Duet TOOL1LC firmware version 3.3 (2021-06-15 16:12:58) -

undefined Phaedrux marked this topic as a question

undefined Phaedrux marked this topic as a question

-

Can you please share your full config.g and describe how your toolboards are wired? Specifically, are the temp sensors on the mainboard or toolboard?

It's possible you are experiencing some of the limitations described here: https://duet3d.dozuki.com/Wiki/Duet_3_firmware_configuration_limitations

-

-

Also, does M98 P"config.g" produce any errors?

-

@phaedrux Nope, the config file loads completely successfully both with

M98or at board reset -

undefined dflemstr has marked this topic as solved

undefined dflemstr has marked this topic as solved