Strange delta calibration and mesh compensation

-

so yeah nothing helped

- deleted the trigger heights from bed

- ran 13 cycles with 6-factor on 17 points

- ran 7 cycles with 7-factor on 17 points

Still the same result as the delta radius is adjusted

Any other ideas?

-

@t3p3tony said in Strange delta calibration and mesh compensation:

If after running G32 a number of times and then doing a mesh compensation you are still getting the bowl shape in mesh bed levelling then try temporarily dropping the number of points to 7 (6 in a ring around the outside of the bed, 3 in front of each tower and 3 roughly between the towers, and 1 in the center).

please try that.

-

yeah but what if the measured trigger height result in bad parameters from the beginning?

-

@taconite also, for now, the radius being adjusted is not necessarily wrong as maybe some element of the model you are using to determine the theoretical radius is off

-

@t3p3tony

Tried 7 iterations with just 7 pointsM665 L414.000:414.000:414.000 R235.772 H464.295 B150.0 X0.033 Y-0.455 Z0.000

M666 X0.028 Y-0.064 Z0.037 A0.00 B0.00deviation is a lot higher than with more points

Calibrated 6 factors using 7 points, (mean, deviation) before (-0.006, 0.235) after (-0.000, 0.235)before that it was more in this direction

Calibrated 6 factors using 17 points, (mean, deviation) before (0.000, 0.088) after (0.000, 0.088)

-

@taconite said in Strange delta calibration and mesh compensation:

Where are the images you are displaying coming from? I assumed you were plotting the heightmap.csv externally for some reason but now not so sure.

From the documentation you linked earlier it looks like your rod length could be a cause.

-

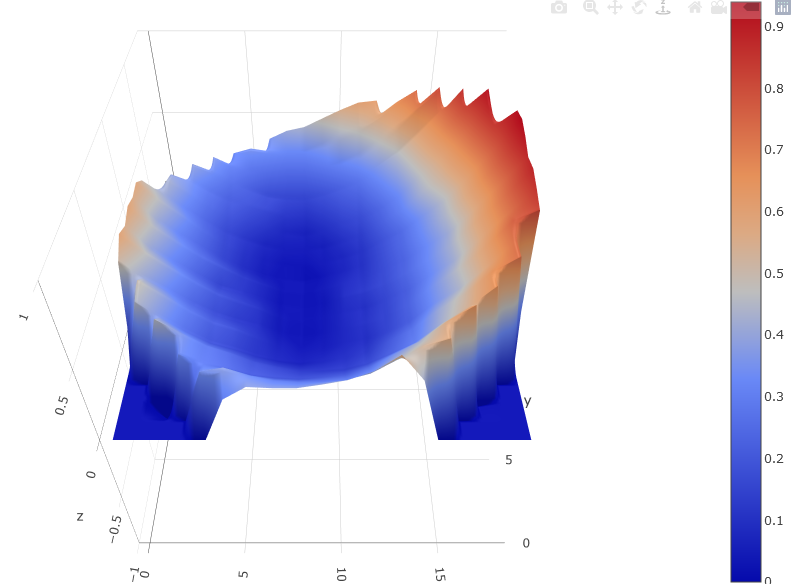

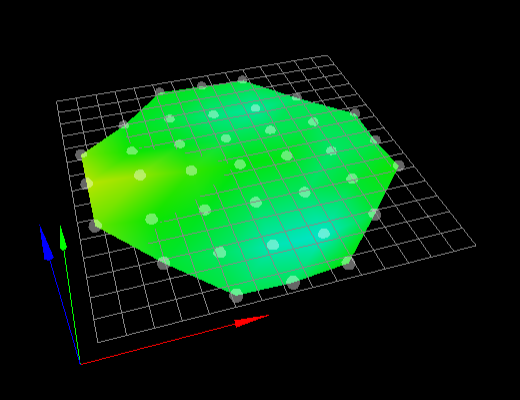

I use this page to view the mesh because I am getting the maximum deviation

http://lokspace.eu/3d-printer-auto-bed-leveling-mesh-visualizer/But 7 Factor was not working as well and I tried to manipulate it manually and it did not improve.

-

@taconite ahh i see. ok so try shortening the rod lengths with 6 factor and 7 probe points until you get a flatter bed shape.

-

@t3p3tony

Isn't that super tedious? In which intervals should I change the rod length? It should not be off by mm -

@taconite I suspect a problem with your Z probe and/or the joints of your printer. What type of Z probe are you using, and what sort of joints?

-

@dc42 thank you for your reply

Z-Probe: inductive sensor, M18, similar to what I was using on other printers

Joints: They are Ball-joints, Igus, KCRM-05 they have a little play which I compensated with springsEDIT: the nozzle is replaced by the sensor so it sits at X0 Y0

-

no it gets really strange. I decreased the size of the probing radius (calibration and mesh compensation) and with the "original" values I get this L414 R236

Calibrated 6 factors using 7 points, (mean, deviation) before (-0.000, 0.006) after (0.000, 0.005)

M665 L414.000:414.000:414.000 R238.041 H465.172 B150.0 X0.146 Y0.015 Z0.000

M666 X-0.003 Y-0.210 Z0.214 A0.00 B0.00

-

@taconite ahh ok so if you probe too close to the edge of the delta radius then that may cause issues, (the arms are almost straight down or straight out).

You are now getting much better results, and can see if you get much improvement with 17 points over 7. I have a slightly smaller bed on my delta and use 10 points (6 outer ring, 3 in an inner ring. 1 in the center).