Hot-End Thermistor Temperature calibration

-

@wombat37 I do have a suggestion for thermistor calibration, near the 200C working temperature. If you build a little offline metal block, with a heater, your thermistor, and a little extra well in it, and insulate it thoroughly so that the only exposed bit is the well, so you can see into it, you could use 63/37 eutectic solder as a melting point standard. You would just slowly step the temperature up a bit at a time, with a piece of the solder sitting in the bottom of the well. The solder will melt at 183C, so you can calibrate your thermistor to get that right.

Basically, you would set alpha, the base resistance of the thermistor, to get room temperature right, and then adjust beta to get the 183C point right. Then, move the thermistor back to you printer, and it should be pretty close to right over the entire usage range. This method will make it best at room temp, and near 183C, with somewhat larger errors in between those two points, and at higher temps, but it's probably a lot better than just using the book value of beta.

-

I used pure metallic tin last time - which worked well (m.p 231.9°C). I can also look at the boiling points of silicone oil or something like dodecane. Solder probably won't be very pure and as an alloy, its composition may vary. Also, it may not have a sharp melting point like pure substance. However, we're not during purity analysis (melting points can be used as a measure of purity) here so a few degrees error probably won't hurt.

Looks like there is some interest in this topic, so I will keep looking into this. I'll post up an algorithm over the next few days and see what people think of that and get some more ideas.

-

@wombat37 I think if you buy the real 63/37 eutectic, it is fairly tightly controlled since it is a mil spec. Also, since the temperature is at a minimum there, it is flat over a moderate range of compositions (quadratics are nice). If you have pure tin, though, that is fine, too. It's just a bit less available than 63/37. If you want to get fancy, do tin and solder, and then you can fit the cubic coefficient, too!

Boiling points are harder, since a lot of things superheat before they boil.

-

I didn't realize that these solders were eutectic. Most alloys typically melt over a range of temperature.

Regarding tin, it's not too expensive to get reasonable purity - perhaps less than the solder you recommend:

I agree about boiling points being a bit erratic because of superheating. However, many things supercool so care has to be taken to determine melting points as well.

I feel it would be enough to use just one calibration point (in addition to ice or steam) for the digital thermometer for a narrow range of operating temperatures - say, something in the 180 to 260°C range. I don't really care if the temperature below that is accurate - it's never used except to tell me that the hot-end is now cold enough to touch. There's an easy way to find that out anyway. We can still do the cubic coefficient determination by taking more measurements with the thermocouple probe. Solving 3rd-order equations may be a bit challenging for RRF macros, though.

-

@wombat37 Yes, on your comment about not needing extra calibration points. Extras would be just for fun. The working temperature range is fairly narrow, and pure tin is close enough to the middle of it to give really good results. Supercooling is, of course, why one uses either melting points (with slow upward stepping), or equilibrium freezing points, where you keep the melt partly melted and partly crystalline. That method is usually considered to be the gold standard, either via the water triple point at 0.01C, the gallium freezing point at 29.7646C, or various higher-temperature metals. These are uses as reference points on the official ITU temperature scale.

I think the thermistor calibration built in accepts the cubic Hart-Steinhart coefficient already, so it is no extra work to put it in, if you want. You have to do the solution for the coefficients on your computer, not in RRF.

-

@mendenmh I had a great idea that came to me overnight and maybe this is what you had in mind all along. Solder and tin can come in reels of wire. This wire could be pushed directly into the hot end. If the temperature of the hot end was (very) slowly increased, there would come a point at which the metal would melt and the wire could be extruded. This would be at the melting point of the wire and so the temperature of the hot-end would now be known - at the exact location it's needed. Hopefully because the alloy is eutectic this measurement will be very precise and repeatable. I'm also thinking that, unlike filament, the molten metal will have low viscosity and will quickly drip out of the nozzle.

I've been hung up on how to calibrate and use thermocouple probes etc. to make temperature measurements but this extrusion approach would eliminate all that crap and provide a very direct, cheap and simple means of performing a single point temperature calibration without needing any additional equipment and would work for any type of temperature sensor on any printer.

Of course, all depends on the details.

I'm thinking of something along the lines of:

- Cut a short length of solder wire of suitable diameter - say 100mm x 1.5mm

- Heat up the hot end

- Remove any filament from the hot-end and perhaps fit a new nozzle

- Set the hot-end temperature to about 20°C below the melting point of the solder

- Push one end of the solder wire into the hot-end through the heat-break

- Attach a weight to the other end to assert a sustained force on the wire

- Run a macro to increase the hot-end temperature at a slow rate - say 1°C/min

- Look for molten solder emerging from the nozzle and note the temperature reading when it does.

- Use the read temperature and the known melting point of the solder to make a correction to the hot-end temperature calibration

- Catch the liquid metal in a suitable dish or tray

- If we could find other solder/metals/alloys that melt at different temperatures we could as you say, determine the cubic coefficient, C, for a thermistor

- If we wanted to automate this, we could locate an electrode immediately beneath the nozzle to detect the presence of molten metal at that point and feed that event back into the running macro.

Some questions:

- Will the rosin in the solder affect the result?

- Will the solder corrode/dissolve the metal in the nozzle and affect the result and/or destroy the nozzle? What type of nozzle would be best? Brass, copper, steel, stainless steel, titanium - they all seem to be available.

- Will solder be left in the nozzle after the test making it useless for later work with filament? Could it be removed by a wash of filament? Perhaps we would need a dedicated nozzle for these temperature tests.

- What diameter nozzle orifice would be best? 1mm?

I may try out some quick tests as a sort of proof of concept exercise. But this looks like a good way to go and thank you for your input that led to this.

-

@mendenmh Thank you for your detailed explanation...it exceeds by far my humble knowledge

I have just received a PT1000 (2 wire) from trianglelabs, that I intend to use as a direct replacement of my current HT-NTC100K B3950 thermistor. Once correctly configured in config.g, I hope to not to have to battle again with B and C Thermistor coefficients.Regarding the calibration resistor, I have currently installed a Duet 2 Wifi (although I keep a Duet 3 Mini5+ as reserve). I have not exchanged the former for the latter because It seems there is not much to gain with the change.

The PT1000 arrived with three 1K 0.1% SMD resistors to replace the default 4,7K pullup on the Duet2, but unless I am convinced that is absolutely mandatory I would prefer not to try to solder on the board, specially as I don't have SMD soldering experience.

I have heard somewhere on this forum that even on a stock Duet 2 Wifi the reduced resolution is more than enough for FDM printer purposes. If not, I could consider to replace the board with the Duet 3 Mini since its pullup resistor happens to be a more adequate 2.2 K.

I don't have any 2K calibration resistor at hand, I would have to order it on RScomponents or similar and for the use I am going to give it I would prefer to try to go without it.

-

@ignacmc I did not replace the resistors on my Duet2 v1.02, either. However, I did note that there was a significant (few degrees at room temp) error on ADC channel 0, but not on channel 1. I swapped the choice of channels, and everything works very well. This is probably an effect known as charge injection, which affects scanning ADCs. If the previous voltage read was very different from the next, some of the reading will bleed over due to stored charge on the sampling capacitor. Reducing the feedback resistor prob ably helps this. Apparently the differential between channels when I moved the pt1000 to channel 1 was small enough that it was fine. This would mostly show up as a fixed offset, anyways. I really like having a temperature sensor that I can both trust over the whole range, and interchange, if needed, without recalibrating.

-

@mendenmh I am going to directly install the PT1000 and configure it. Then I will cross my fingers expecting not to have the same problem as you

Thanks for your advice and your expertise in this kind of sensors. As a Mechanical Engineer I am stepping on foreign ground, haha!

Thanks for your advice and your expertise in this kind of sensors. As a Mechanical Engineer I am stepping on foreign ground, haha! -

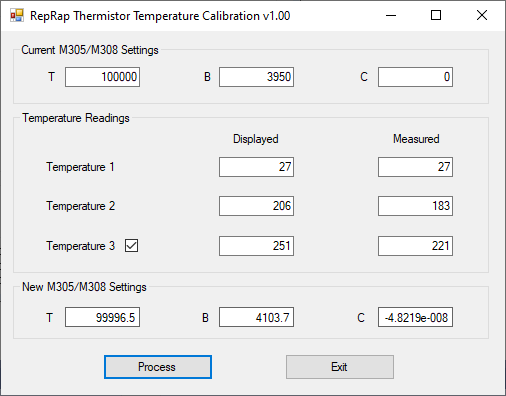

@wombat37 Following on from my last posting, I have now completed my tests and believe that I now have a quick, easy, cheap, reliable and accurate method of calibrating hot end thermistor temperature control (with all three Steinhart Hart coefficients) that should work with any printer without any disassembly or modification or even the need for a thermometer.

With a cheap unbranded thermistor I believe that I can achieve accuracy within 1°C across the full working range.

I'm currently in the process of writing up a white-paper on this. If anyone is interested in beta-testing this method, let me know.

-

I’m interested

only worked out the first 2 of the 3 using this method

https://forum.duet3d.com/post/191523 -

@digid I don't measure the thermistor resistances explicitly, rather, I back-calculate what they are from the displayed temperatures and the current T, B and C entries in the M308 g-code statement. This requires solving the roots of cubic equations (complex numbers are not nice). Then I have to solve some 3-term simultaneous equations to get the new Steinhart Hart coefficients for entry into the M308 statement. It's not very straightforward - however, the software is easy to use

I'll get the white paper and software to you shortly.

-

@wombat37

I didn’t measure R with a meter , I solved it using the thermistor values in config and what the actual temperature was at the hot end with a thermocouple . The spreadsheet there should explain how I did it . Doing it that way you take into account all the stacking errors at the temp range of interestLook forward to trying your method

Cheers