Wavy surface problem.

-

@tpra Maybe I try this in a future....

-

@hiroaki said in Wavy surface problem.:

@o_lampe Hello. It's done! How does it look ?

That looks excelent! Can you tell a bit more about the slicer settings?

Nozzle 0.4 I guess and RRF2.? -

@o_lampe Hello.

Is it ?

Actually I not really satisfied...

That's FIRMWARE_NAME: RepRapFirmware for Duet 2 WiFi/Ethernet FIRMWARE_VERSION: 2.05.1

Nozzle is 0.4mm dia.

Layer thickness is 0.15mm

I made the G code by Simplify 3D.

This machine has 1.8Degree stepper motors. Not 0.9...

Regards -

@hiroaki said in Wavy surface problem.:

Is it ?

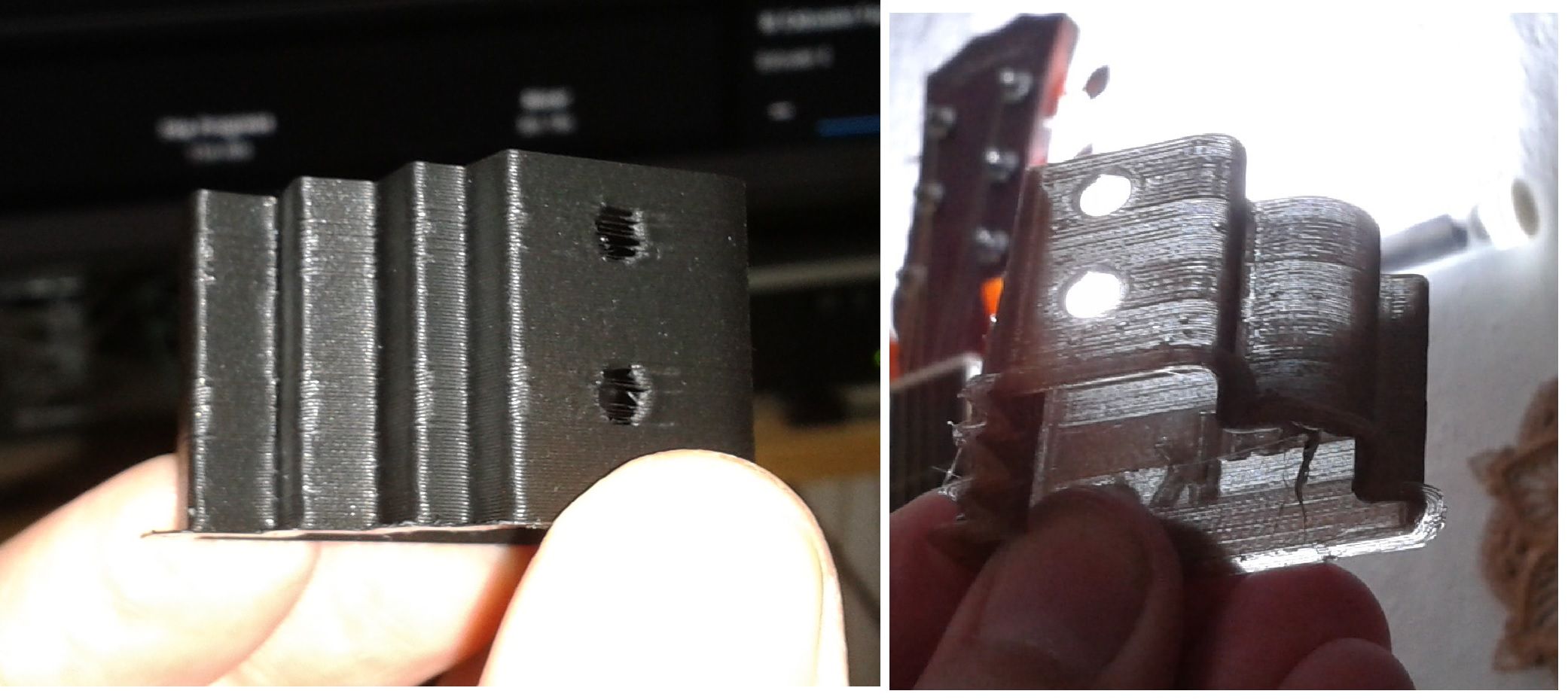

Actually I not really satisfied...It also shows vertical lines, same as your 'problematic' printer. But other prints looked really bad around the holes:

-

@o_lampe I think you can egt better result if you increase the retruction ammount. Mine is at this moment 5mm.

Or If your printer is borden, the teflon tube between extruder and nozzul has too much friction or too long.

So when extruder motor stops to stop extruding, it contines extruding.

The following guys had a video how to tune your printer I think.

https://www.youtube.com/watch?v=TDxpVSXmKiE -

So in my desperate quest about those motor vibrations, i switched to Klipper.

It was not that easy, but it solved all my problems. Maybe it's because trinamic chopper values, maybe it's because input shaper somehow deals with steppers vibrations, i don't know.

My tests are not enough serious / scientifically made to pull a conclusion.All i can tell is i spent a lot of time and money on this, and i litteraly searched in every possible direction.

TBH the firmware is the really last thing i suspected.

I know VFA's are something you see in very special cases, but imho rrf default trinamic chopper values should be revised and modified to be closer to what Klipper use.

And it's not like i tried with only one stepper type, i tried a lot of different common steppers on the market. -

You should be able to go back to RRF and command the drivers to use klipper's default settings

-

@luke-slaboratory said in Wavy surface problem.:

You should be able to go back to RRF and command the drivers to use klipper's default settings

Never. Just because of all the time and money lost to fix that.

There has been a LOT of people saying they had this problem. It has always been ignored, with blurry answers or gently explaining the guy that it is a mechanical problem or ghosting when it is obviously not ghosting (htf could ghosting have an amplitude that doesn't decrease ?)...Now the problem is solved, why bother with correcting something that's out for years with a major mistake in it ?

I'm currently switching all my other duets to klipper and will never go back. If you add the input shaper, the difference with rrf is stellar. Now my printer prints just like it should.I wish i had built a rigourous test process and took pictures to show that i'm not crazy...

-

@tpra said in Wavy surface problem.:

So in my desperate quest about those motor vibrations, i switched to Klipper.

It was not that easy, but it solved all my problems. Maybe it's because trinamic chopper values, maybe it's because input shaper somehow deals with steppers vibrations, i don't know.

My tests are not enough serious / scientifically made to pull a conclusion.All i can tell is i spent a lot of time and money on this, and i litteraly searched in every possible direction.

TBH the firmware is the really last thing i suspected.

I know VFA's are something you see in very special cases, but imho rrf default trinamic chopper values should be revised and modified to be closer to what Klipper use.

And it's not like i tried with only one stepper type, i tried a lot of different common steppers on the market.I've just had a look at the TMC2660 default config from Klipper and it seems to be the same that RRF defaults to... Did you already finetuned input shaping?

I'm also interested in this because my 0.9º Moons motors are WAY louder than my noname motors in a crap Marlin board. They are bearable, but I've already changed the X/Y motors two times: first were the typical steppteronline motors, that sounded like a chainsaw. Then a pair of smallish 0.9º Moons, that were quite noisy too, and finally another pair of beefier 0.9º Moons that are bearable, but not as silent as I'm used to. All of them were low induction.

-

@zipzap Hello. I appreciate your post. I have just received Gater genuine belt and tried!

The result was much better !

I guess the teeth side of the belt has to be cloth to have enough slipperiness. -

@hiroaki Sorry "Gates "

-

have you run them through the EMF calculator? if you're driving them fast with low VMOT, they can get noisy as the stepper drivers are unable to deliver a smooth curve to the motors.

@Hiroaki proper 2gt is almost always better

I'm a klipper afficionado - just was suggesting since some people prefer RRF's configs and other features.

-

@luke-slaboratory said in Wavy surface problem.:

have you run them through the EMF calculator? if you're driving them fast with low VMOT, they can get noisy as the stepper drivers are unable to deliver a smooth curve to the motors.

Yes, I know it's normal for the steppers to be noise at high speed. My travel speed is 300mm/s, and they are as noisy as they are supposed to be at that speed at 24V. The problem is with more normalish speeds, like 50-60mm/s. I know it can be steppter's resonance, but only with this Moons' pair and a lowish current I've managed to tame it to acceptable noise, while with my other printer I have to look at bltouch light moving to be sure it's printing (it has older TMC plug-in chips and a crap 8 bit Marlin board).

-

@egon-net

2660's aren't the quietest drivers, but it might be worth to check out per-motor register tuning? I'm thinking of the same as I can't seem to get my 60mm LDO motors to be at all quiet, but those are high-inductance.

Could it be full frame resonance? Maybe add some weight to the base and see if that changes the natural freq and quiets it down at slow speeds

-

@luke-slaboratory said in Wavy surface problem.:

@egon-net

2660's aren't the quietest drivers, but it might be worth to check out per-motor register tuning? I'm thinking of the same as I can't seem to get my 60mm LDO motors to be at all quiet, but those are high-inductance.

Could it be full frame resonance? Maybe add some weight to the base and see if that changes the natural freq and quiets it down at slow speeds

My old printer has the TMC2130 drivers IIRC, in spreadCycle mode and just shy of 1A. Can't configure anything else, and they are scary silent (can't hear them out of the enclosure if not moving fast)

My new printer is built like a brick (3060/306060 extrusions bolted directly) and all metal. Maybe being too rigid means any vibration gets amplified by it...

-

My old printer has the TMC2130 drivers IIRC, in spreadCycle mode and just shy of 1A. Can't configure anything else, and they are scary silent (can't hear them out of the enclosure if not moving fast)

My new printer is built like a brick (3060/306060 extrusions bolted directly) and all metal. Maybe being too rigid means any vibration gets amplified by it...

I tried to optmize the TMC parameters with an oscilloscope monitoring the current measuring resistor, but couldn't get any better than default.

-

@egon-net just using extrusion without extra mass+damping definitely will vibe everything extra.

My printers are 2040-4040, and without damping and extra mass are loud from just mechanical vibrations.

-

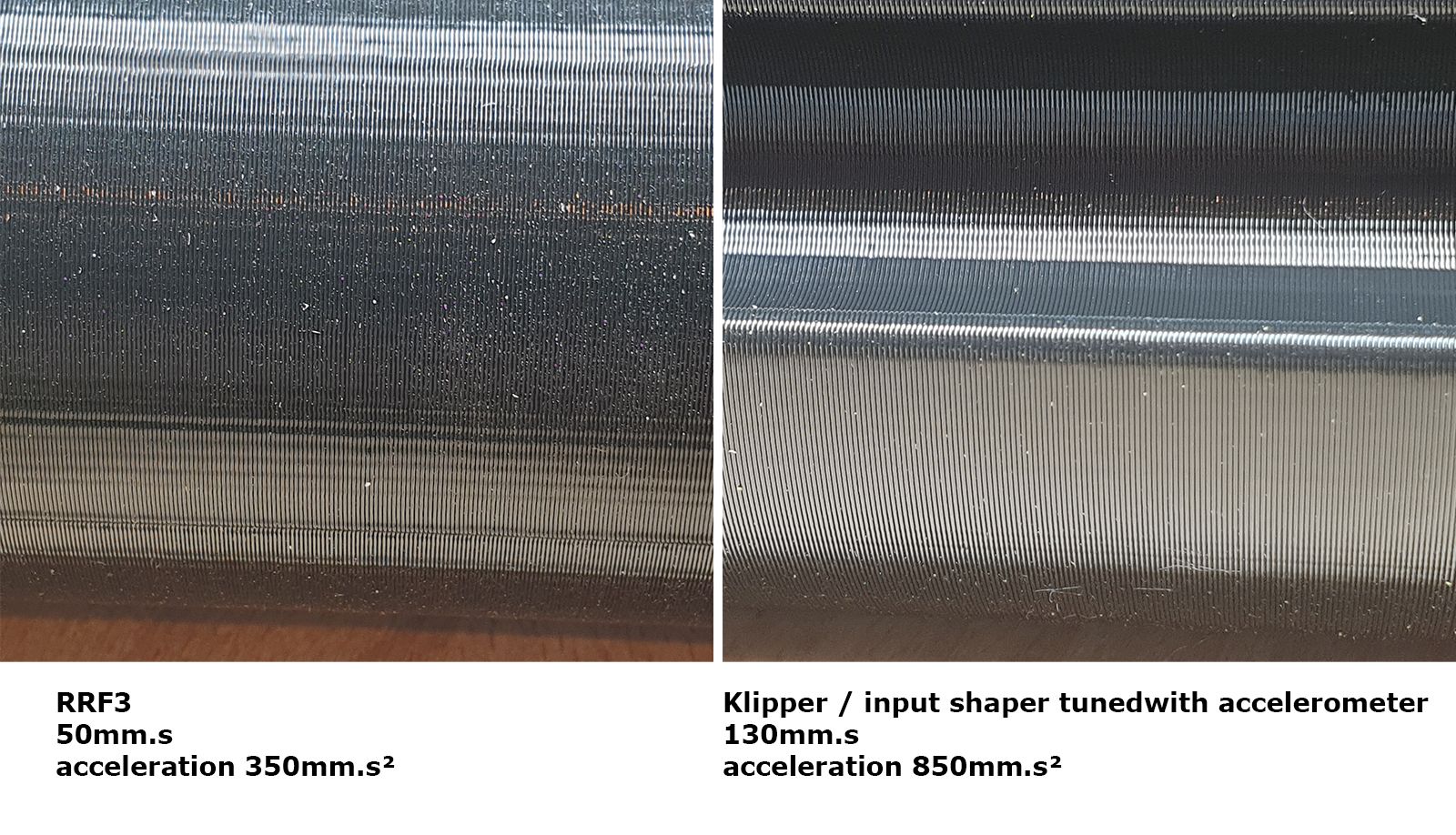

So. I made a picture comparison to be really clear about VFAs, ie very fine artifacts.

(please look at it real size, else moire effect is pronounced)First it's something that you'll only on a carefuly tuned printer. Else it will be "hidden" by other things.

It is super super visible with shiny filaments like petg (or colorfabb ngen in my case).

It looks like very fine tiny vertical "waves", like ghosting, but with a constant amplitude.I still absolutly don't know what produces it exactly.

However, in the picture attached :- both parts sliced from the exact same stl

- both parts sliced with the same slicer profile in prusaslicer, just a lot faster for the klipper test

- settings copied from the duet config when i switched to klipper (i mean no recalibration process)

- pid's were obviously re-made after firmware switch

-

@tpra said in Wavy surface problem.:

So. I made a picture comparison to be really clear about VFAs, ie very fine artifacts.

(please look at it real size, else moire effect is pronounced)First it's something that you'll only on a carefuly tuned printer. Else it will be "hidden" by other things.

It is super super visible with shiny filaments like petg (or colorfabb ngen in my case).

It looks like very fine tiny vertical "waves", like ghosting, but with a constant amplitude.I still absolutly don't know what produces it exactly.

However, in the picture attached :- both parts sliced from the exact same stl

- both parts sliced with the same slicer profile in prusaslicer, just a lot faster for the klipper test

- settings copied from the duet config when i switched to klipper (i mean no recalibration process)

- pid's were obviously re-made after firmware switch

I'd try again with Klipper at 50mm/s2, since I've noticed that VFA is way more noticeable with slower speed, just to be sure.

-

@luke-slaboratory said in Wavy surface problem.:

@egon-net just using extrusion without extra mass+damping definitely will vibe everything extra.

My printers are 2040-4040, and without damping and extra mass are loud from just mechanical vibrations.

It already weights 30+ kg... It's quite tall.