Z axis movement does not accompany the leveling map

-

Please, I would like help to identify a problem.

Duet 2 wifi RRF2.05, PL08N probe, Z motors together (not independent).

The G32 and G29 work well and the leveling map is created, however, when printing, the Z motors do not move to keep up with the leveling. They are static all the time, moving only in the retract and in the layer change.

Printing runs normally, except for the movement of the Z following the leveling map. This causes parts of the impression to be very squashed because the table is not perfect.

This problem occurs only on 1 of the 3 machines that I own. In the others, the Z follows the leveling and everything works normally.

I attach my config.g here for anyone who can help me.

Thanks. -

Can you post your homeall.g, homez.g, bed.g, and your slicer start gcode section so we can see the full sequence of gcodes from power on to print start?

M557 X10:210 Y65:210 P4:4 ; Define mesh grid

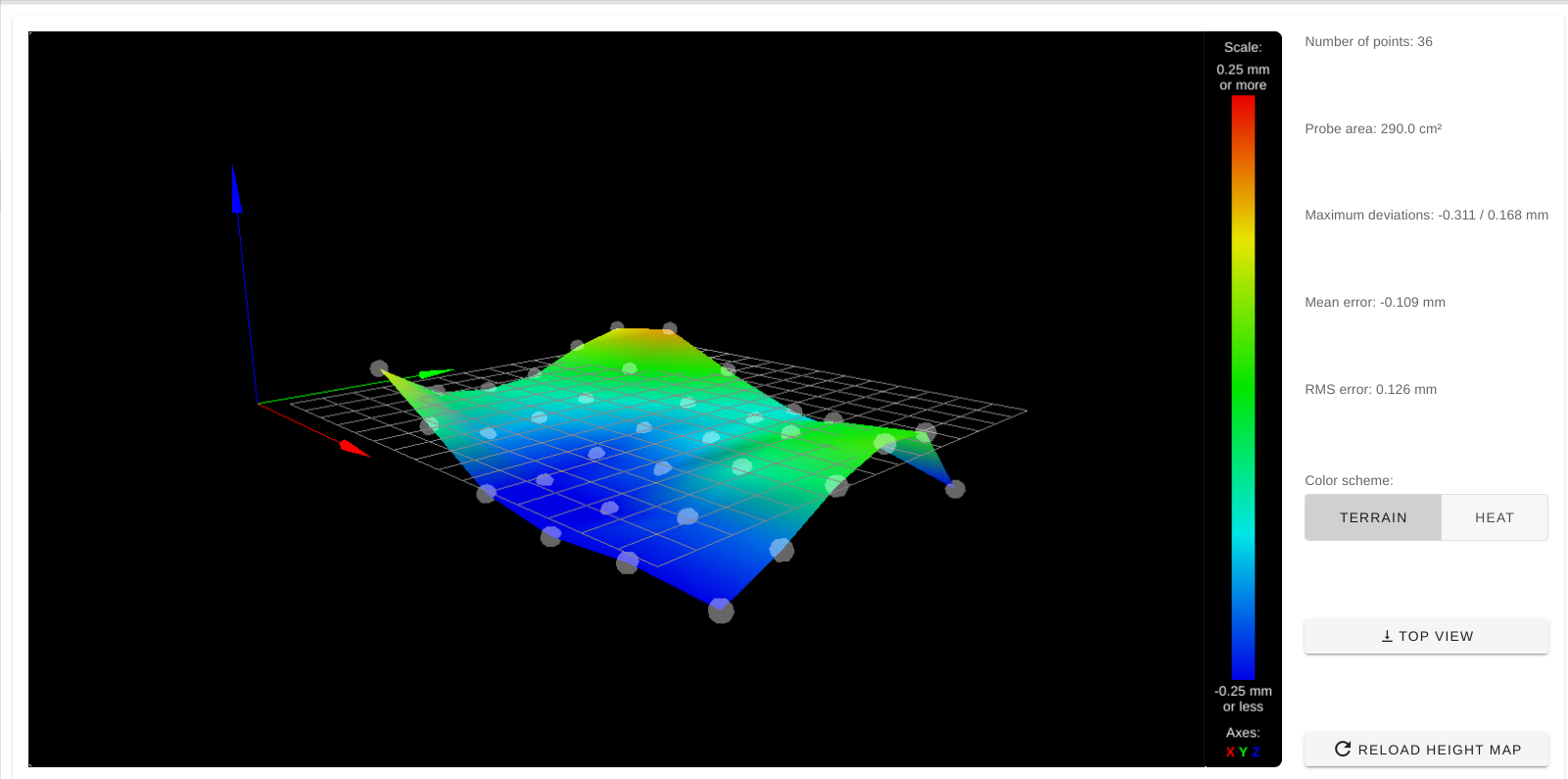

In your config the grid is only 4 x4 points which maybe doesn't capture the full shape of the bed?Can you also post a photo of the heightmap display?

M290 S-0.08 ; babystep the BED UPI also notice you are doing babystepping in the config.g at startup. Maybe not the best place for that since the z axis has not even been homed at that point.

-

@phaedrux, thanks for helping.

I made some changes to the machine, turned off the second extruder and set up independent motors in Z. This time, the movement of Z is noticeable, as the printing occurs, however, it seems not to be enough, because in one part of the bed, the impression is still well squeezed. Here are the files you requested.HomeAll.g

G91 ; relative positioning

G1 Z5 F2400 S2 ; lift Z relative to current positionG1 X-305 F2400 S1;

G1 Y-305 F2400 S1; move quickly to X or Y endstop and stop there (first pass)

G1 X5 Y5 F2400 ; go back a few mm

G1 X-10 Y-10 F360 S1 ; move slowly to X axis endstop once more (second pass)

G92 X-6 Y-4

G1 S1 X0 F180

M98 Phomez.ghomez.g

G91

G1 Z8 F1800 S2

G1 X110 Y45 F9600

G30 ; Do a single probe to home our Z axis

G90 ; Make sure we are in absolute modebed.g

M561 ; clear any bed transform

G28 ; home

G30 P0 X10 Y110 Z-99999 ; probe near a leadscrew, half way along Y axis

G30 P1 X210 Y110 Z-99999 S2 ; probe near a leadscrew and calibrate 2 motors

G1 S1 X0 Y0slicer start gcode (prusa slicer linux 2.3)

M190 S[first_layer_bed_temperature]

G32

G29 S1

G1 X2 Y2 Z2 F1000

G4 S120

M109 S[first_layer_temperature] T0:1

M400

G1 Z0 F1000

G1 Y10 E15 F500

G1 Y50 E4 F500

Thank you very much.

-

I would add G28 Z to the end of your bed.g to re-establish the Z0 point after the tilt correction.

You'd also need to redo your heightmap at least once at that point.

After redoing the heightmap can you grab a screen shot of the displayed heightmap and post it here?

-

I put G28 Z at the end of bed.g

; bed.g

; called to perform automatic bed compensation via G32

;

; generated by RepRapFirmware Configuration Tool v2 on Sun Aug 04 2019 18:49:41 GMT-0300 (Horário Padrão de Brasília)

M561 ; clear any bed transform

G28 ; home

G30 P0 X10 Y110 Z-99999 ; probe near a leadscrew, half way along Y axis

G30 P1 X210 Y110 Z-99999 S2 ; probe near a leadscrew and calibrate 2 motors

G1 S1 X0 Y0

G28 ZI made G32 and then G29 to generate the map

Thanks!

-

@phaedrux

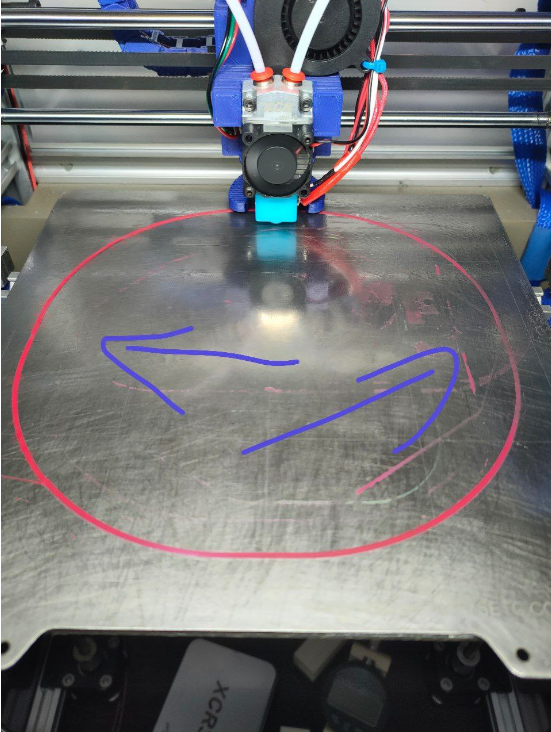

I pasted an adhesive tape on the engines of the Z and realized that they are moving as the car moves across the bed. The problem now is that this correction of the Z is not enough, because in the higher areas the first layer is still very squeezed, practically without leaving any filament. If I use the babystep, the lower areas do not stick enough on the bed.

Is there still anything to do or is my hotbed doomed? -

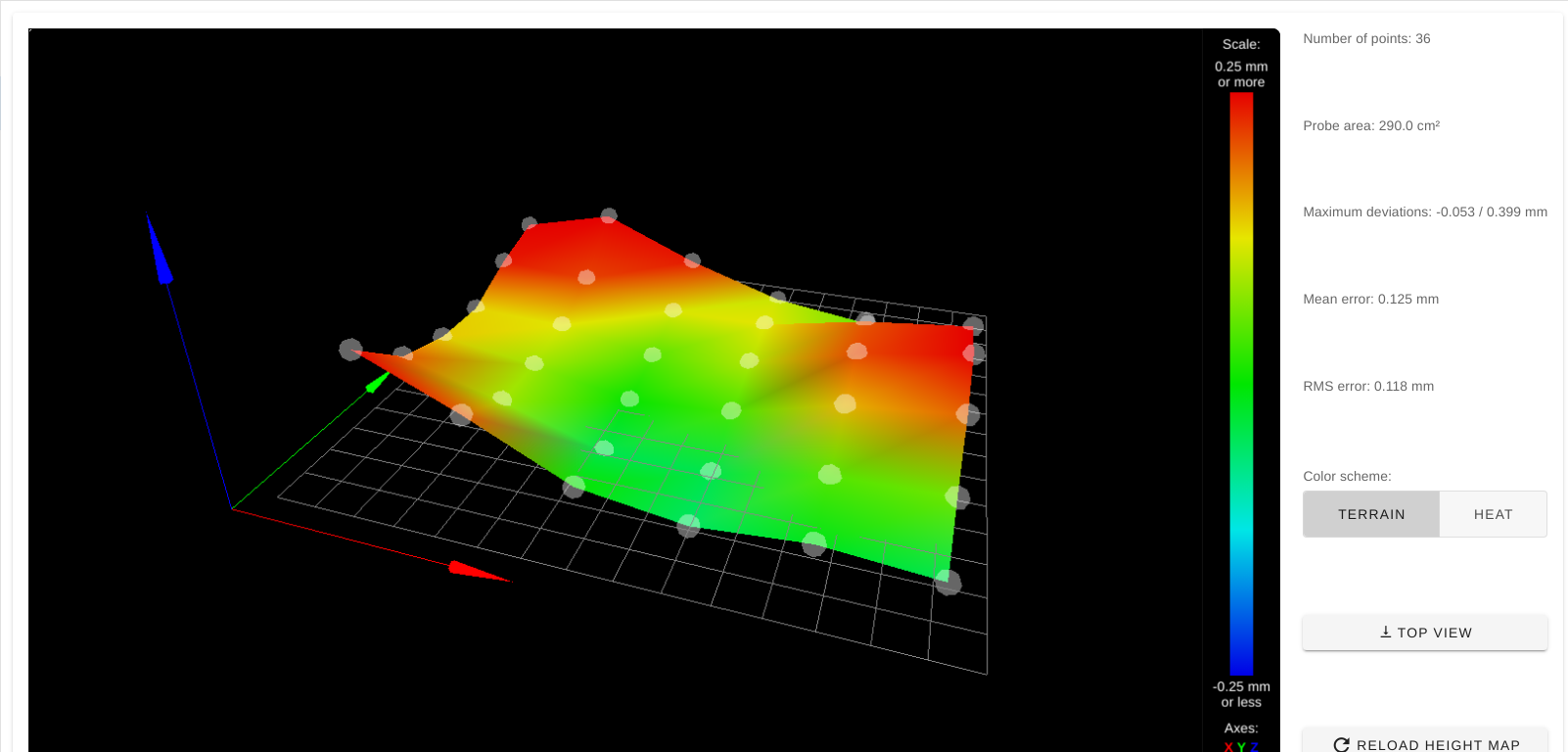

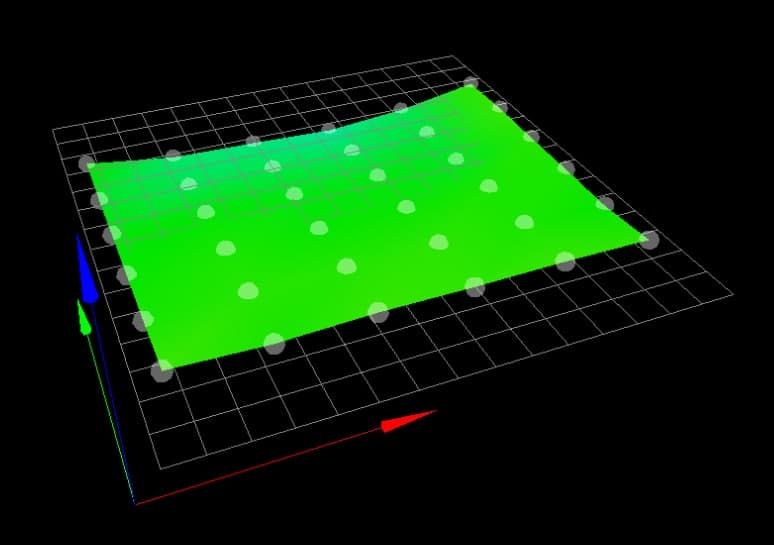

I would try using a higher density of points when generating the heightmap. The interpolation between points may not be accurate enough.

The other thing is to try and reduce the distance between probe and nozzle as much as possible and ensure the measured XY offset between nozzle and probe is accurate.

-

@phaedrux said in Z axis movement does not accompany the leveling map:

I would try using a higher density of points when generating the heightmap. The interpolation between points may not be accurate enough.

The other thing is to try and reduce the distance between probe and nozzle as much as possible and ensure the measured XY offset between nozzle and probe is accurate.Got it, I'm going to do the test by increasing the mesh to 20:20.

As for the sensor offset, this is a little more difficult. In my case the PL08N is behind the car. Elsewhere closer to the nozzle it would hit one of the xy engines, or I would lose useful printable area. The table is small, 220x220mm. I'll see what I can do. Thanks. -

@phaedrux

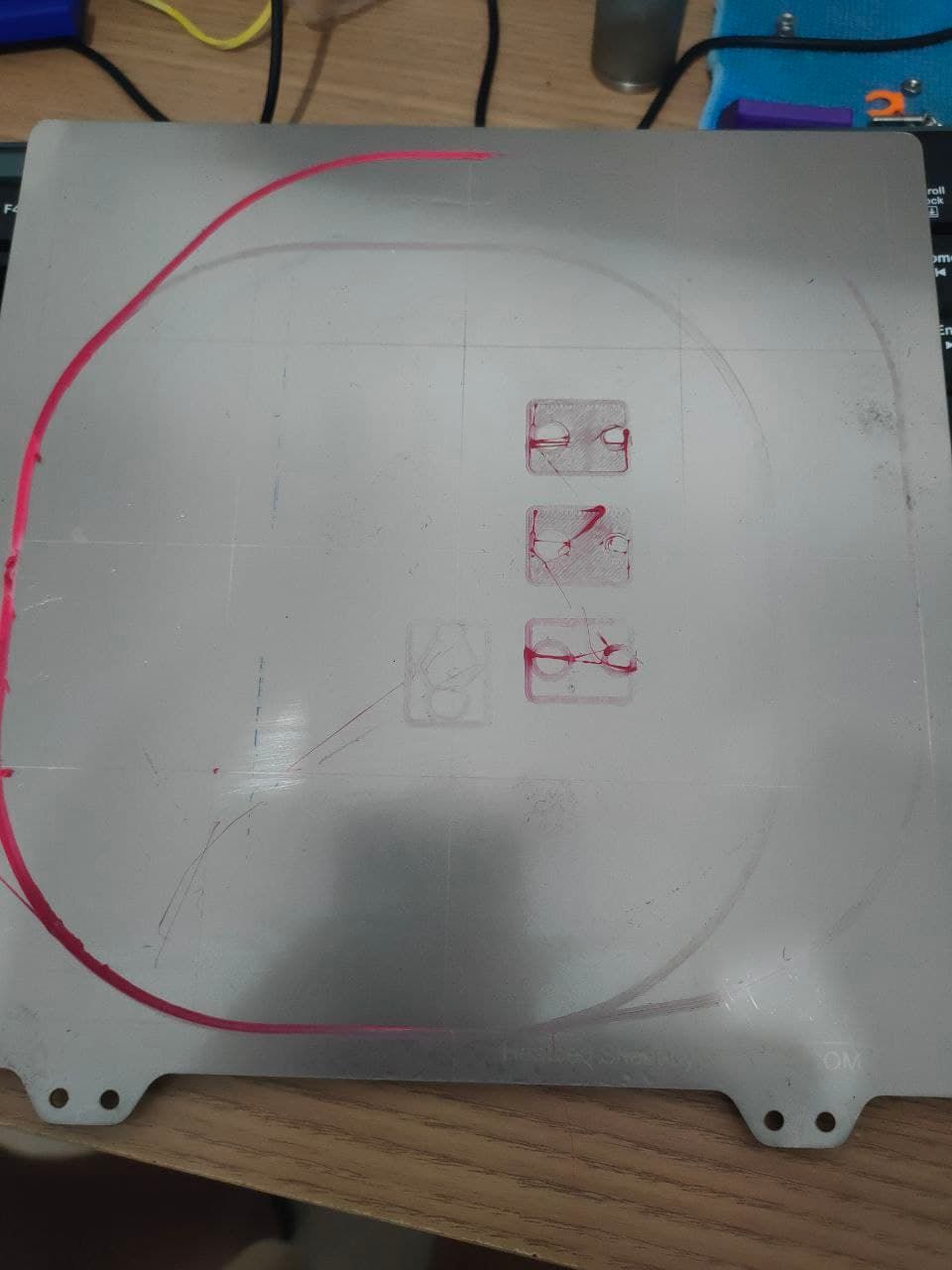

I replaced the hotbed with a much flatter one but the behavior of crushing the print on the right side of the steel plate remains. As if the G32 is going up one side more than the other.

If I don't run G32 and G29, and go down 2 steps of the right screw manually before printing, everything is perfect.

A question:

Would I be able to move just one Z motor using gcode? -

Does it seem like it's correcting in the wrong direction?

You may be running afoul of this guidance:

You must use the M671 command to define the X and Y coordinates of the leadscrews. The M671 command must come after the M584 command and must specify the same number of X and Y coordinates as the number of motors assigned to the Z axis in the M584 command; and these coordinates must be in the same order as the driver numbers of the associated motors in the M584 command. The M671 command must also come after any M667 or M669 command.

https://duet3d.dozuki.com/Wiki/Bed_levelling_using_multiple_independent_Z_motors

Post your config.g please.