E 3d BIGBOX Duel head

-

@phaedrux

I went to system tab and files are listed there. which i did not know. I was going to Display tab and changing things there. But now that i have changed the file Config.g.bak file and restarted everything and now works for homing without jumping after i reversed the wires for the stepper motor. so now all homes well with no issues.Now the PID for the heaters does not seem to work or heat up when bed and tool0 are set to a temp for active.

here are the files which are being used now.

; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Tue May 25 2021 18:51:26 GMT-0400 (Eastern Daylight Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"big box 1" ; set printer name ;M669 K1 ; select CoreXY mode ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S1 ; physical drive 0 goes forwards M569 P1 S1 ; physical drive 1 goes forwards M569 P2 S1 ; physical drive 2 goes forwards M569 P3 S1 ; physical drive 3 goes forwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z400.00 E420.00 ; set steps per mm M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2) M906 X800 Y800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X460 Y210 Z200 S0 ; set axis maxima ; Endstops M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop M574 Z2 S2 ; configure Z-probe endstop for high end on Z ; Z-Probe ;M558 P1 C"zprobe.in" H5 F120 T6000 ; set Z probe type to unmodulated and the dive height + speeds M558 P5 C"e0stop" H5 F120 T3000 ; Z probe connected to E0 endstop input M558 H30 ;*** Remove this line after delta calibration has been done and new delta parameters have been saved G31 P500 X5 Y5 Z2.5 ; set Z probe trigger value, offset and trigger height M557 X15:215 Y15:195 S20 ; define mesh grid ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M575 P1 S1 B57600 ; enable support for PanelDue M501 ; load saved parameters from non-volatile memory M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss -

@testpro said in E 3d BIGBOX Duel head:

M558 H30 ;*** Remove this line after delta calibration has been done and new delta parameters have been saved

You should remove that line I think. You don't have a delta. That's for sure.

@testpro said in E 3d BIGBOX Duel head:

But now that i have changed the file Config.g.bak file

What exactly do you mean by that?

@testpro said in E 3d BIGBOX Duel head:

Now the PID for the heaters does not seem to work or heat up when bed and tool0 are set to a temp for active.

What do you mean by that? How are you trying to set a temp? Have you done a PID tune and saved it with M500?

Send M98 P"config.g" and report any errors.

-

@phaedrux

1 yes i will remove the M558 H30 from program.2 i changed the config.g.bak file to not have the corexy setup.

3 on the dashboard tab in software it list tools like tool0 and bed and if you click where is states active for either tool0 or bed it sets a temperature and then click on the heater 1 or heater 0 to make them active, standby or off. they toggle as you click.

ok so far we are doing good the printer now homes with no skipping.

next issues are the heater bed does not heat up fast enough (you gave me something on that, so i will back tract and get that done.)

Leveling the bed

getting material to extrude

calibration of extruder with bed

how to print the stl file

thank you for all your help so far learning a lot but there is more to go.

any insights on these?

-

@testpro said in E 3d BIGBOX Duel head:

i changed the config.g.bak file to not have the corexy setup.

The .bak file is the backup of the main config.g file. It gets created each time the config.g file is changed so that you can undo your change if need be from the backup.

All edits should happen to config.g since it's the file that gets loaded at startup.

You can try following along with this guide

https://duet3d.dozuki.com/Guide/Ender+3+Pro+and+Duet+Maestro+Guide+Part+4:+Calibration/40

-

@phaedrux will under systems i have a config.g.bak file and a config.override.g file and a config.json file

but there is not config.g file by itself. this is wrong right?second the extruder and bed pid turned fine and thank you for that. but now when i feed in a 1.75 ABS filament and it goes in just fine problem is it is not coming our the end. i think maybe the heat is to low?

i used a IR temp gun to read temp of aluminum block (with out fan running) and it reads in the 30's on the surface and when i turned tool0 temp up to 275 c the surface temp is reading 43 C so i know the heater is working but how do i know it has the correct temperature reading. How would i go about making sure what the reading states is actually correct?still working on level of bed and calibrate nozzle with bed for printing.

-

@testpro said in E 3d BIGBOX Duel head:

i have a config.g.bak file and a config.override.g file and a config.json file

but there is not config.g file by itself. this is wrong right?Sounds like the config.g is missing and it's probably falling back to config.g.bak. Right click on config.g.bak and download a copy of it as a backup. Then create a new file called config.g and then copy and paste the contents of config.g.bak into it. Then you'll be back to normal.

Any future edits should happen in config.g -

I'm not exactly sure what kind of a temp sensor you have in there for the nozzle and bed heaters. Your config right now is using the defaults from the config tool, which will be a bit off.

It's been a long thread and I can't recall exactly, but was there a working config that came with it when you started?

Can you post a photo of the electronics case showing the Duet? There may be a temp sensor daughterboard. Getting a photo of the hotend showing the temp sensor wiring may give a clue as well.

IR temp guns don't work very well on reflective surfaces. So it might not get a good reading on the hotend.

Does it show an accurate temp at room temperature?

When you did a PID tune of the hotend did it heat up as expected and complete?

-

@phaedrux Fair enough and all ready done

-

@phaedrux

yes it has been a long file here but i came here after deciding to replace the Rumba with the duet board and no it was not working well at all. my boss went through 5 rumba boards over 5 years before he gave it to me. Now just trying to get it to work.the heaters are working fine at this point. the PID Tune helped out a lot.

So now working on extruders feed rate and got it working to the point of you ask for 110 mm of filament it gives you the 110 mm. but during this process i believe the tool 0 carriage is now no good to anyone.i have taken off the end piece (brass piece with a whole in it) so the filament can run through so i can set the feed in steps when the aluminum fined long piece just melted out of the carriage. the other side can be used but this side is shot. so now i am afraid i am going to need a part if it can be found.

the hot temp was at 240 C for about 20 minutes but now i am thinking i should of had the small fan on that was attached to the aluminum fined piece.

so now switching over to the other side shortly and see if it feeds better now but i will have that fan on .

-

@testpro said in E 3d BIGBOX Duel head:

the hot temp was at 240 C for about 20 minutes but now i am thinking i should of had the small fan on that was attached to the aluminum fined piece.

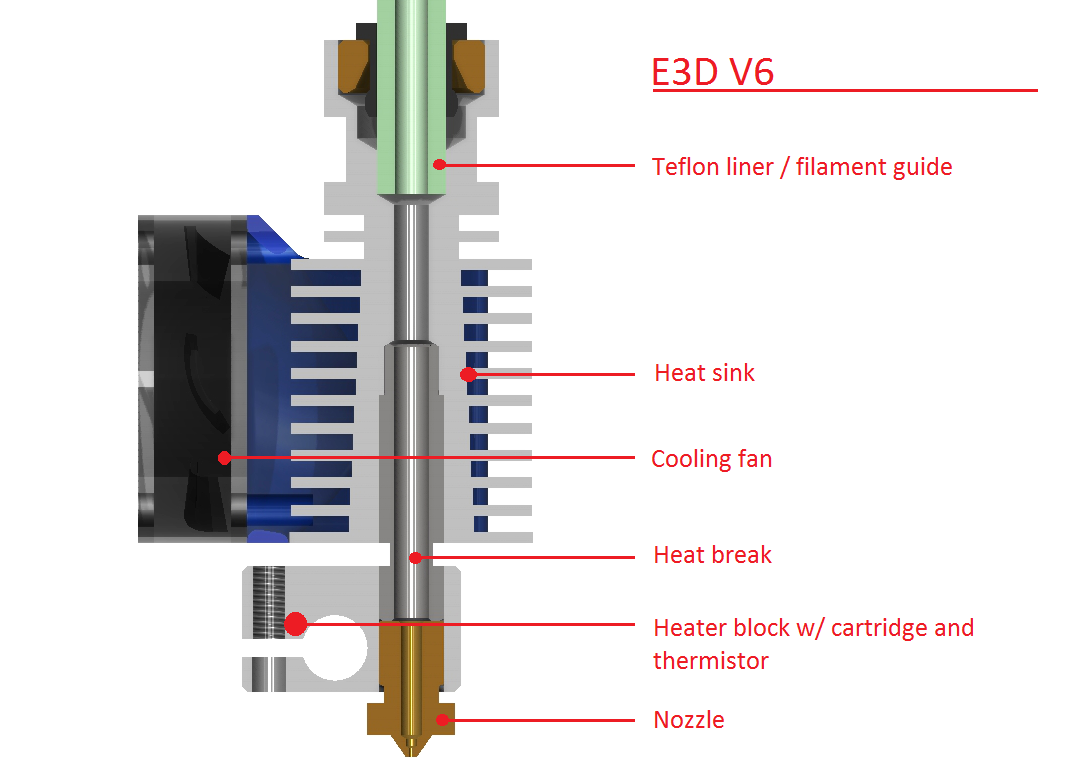

Yes, most definitely should have the heatsink fan running whenever the hotend is at temp. That fined piece is keeping the cold end of the extruder cool and needs the fan for proper operation.

The hot block with the nozzle, sensor, and heater are separated from the heatsink by a heat break. That heat break keeps the heat from traveling up, but some still gets across. Hence the need for the heatsink and fan.

It looks like it melted the mount. I can't tell if that's a printed part or not. If it is, you could possibly print yourself a replacement with the second remaining tool. Would need to dig up the source files for that version of bigbox from E3D.

-

@phaedrux ok making more since now. i am switching over to the other hot end and i am almost done.

now that i have feed rate down i should be able to extrude some material to see if it is working ok.the carriage is a printed part. the carriage is a one piece lower half and separate top half but a dual carriage. i would settle for a single carriage at this point. do you know where i could look for the drawing files on this part?

thannks -

Might be in here, but I'm not sure about different versions. https://www.thingiverse.com/thing:1521722/files

-

@phaedrux well we have it switched over to the other head and it heating just fine it is up to 275 but my external T type thermocouple is stating 252.0 C. the extruder pulls in the filament but nothing is coming out the other end. i do know it is hot enough but after the filament is pushed down in it will not come out the nozzle! so i am at a loss at this point? so what do i need to read now

-

@phaedrux from what i can see these are the files i have found them as well.

the files has the dual and single carriage for my E3D BIG Box so i am most likely going with a single for now to make easy for now and get it working properly.this also brings up another concern. i have resin 3d printer the Sonic mighty 4K and i have a friend with a filament printer called De Vinci both are capable of printer single or double carriage but would i get a better part with resin? that is a question

still need to figure out why filament is not flowing out of extruder issue.

thinking about starting new threads on extruder issue and once i get this figured out and working i will be posting the code here what do you think?

-

@testpro said in E 3d BIGBOX Duel head:

i do know it is hot enough but after the filament is pushed down in it will not come out the nozzle! so i am at a loss at this point? so what do i need to read now

It's possible the nozzle is clogged if this is a used machine that's seen some use. Can you push the filament down by hand to try and force it through? Swapping the nozzle might be the easiest option if it is clogged.

@testpro said in E 3d BIGBOX Duel head:

would i get a better part with resin?

Possibly. Though the part would have been designed for filament printing and you likely wouldn't gain much. Printing with a more temp resistant plastic might be a better move.

-

@phaedrux ok the nozzle was new so no issue there but it seems like it is not getting hot enough and so i put a stand alone T type thermocouple in the hot block slit next to heater and i am showing 250 C so it is hot enough but that filament will not come out of the nozzle. I set the feed rate like the one for the ender posts on calibration. something is just not right here. might be the feed rate. the label on side of filament states 220C 1.75 DIa.

the resin and filament are about the same in high end temp. so no gain or loss there. it will be smoother

-

It still sounds like you have a clog. At that temperature you should be able to push the filament through by hand with ease.

Try doing a cold pull

-

@phaedrux Yes and you are correct the past owner did a fine job of jamming filament into the extruder without the fan on so when it did melt, it melted all the way up onto the extruder (where air fins are). once i removed the extruder and hit it with a hand held propane torch it became unclogged. put it back to together and new it extrudes.

ok the next things to be done are leveling the bed and calibrating the head with the bed and then our first print.

any ideas on these?

-

Some calibration steps here: https://duet3d.dozuki.com/Guide/Ender+3+Pro+and+Duet+Maestro+Guide+Part+4:+Calibration/40

-

@phaedrux thanks for the form but i am still having issues even with the form. i have leveled the bed so the most i am out between all four corners is 0.53 mm. I think this is good.

i have ran the bed level program and it takes 110 points for a mesh map? well it completed and stated i needed to make the Z=0 datum? So my Z probe or Z sensor needs to be calibrated to 0, is this a focal point of the sensor?

by the way how would i go about loading a drawing to print in this software?

do i need to send the stl file into a slicer and if so which one? i have leachee and chuto box