Heater Tuning M307

-

The Instructions for Manual Tuning are not updated.

(for example there's a line that says Tuning the A Parameter

but that's deprecated now)...I've done the Autocalibration without good results (overshooting about 15 degree C).

after a little bit manual correction the Temperature now overshoots about

9-10 degree CSure.. playing around works always, but,

How to tune correctly with R, C, D?

at the Moment:

M307 H1

Heater 1 model: heating rate 2.000, cooling time constant 200.0, dead time 6.50, max PWM 1.00, calibration voltage 25.3, mode PID

Computed PID parameters: setpoint change: P13.7, I0.381, D62.5, load change: P13.7, I0.787, D62.5 -

What firmware version are you using? The tuning algorithm was updated in 3.2.

For tools, use M303 T0 S220 to tune the heater as a tool with feed forward for the part cooling fan.

For bed heaters continue to use M303 H0 S60 etc.

Since you're asking about the R parameter I assume it's v3.2

-

3.3 beta 2, i've already done the Autocal. with M303 H1 P1 S230

my mostly used Temp. 230C.

but the Autocal itself has a lot of overshooting...

so i tried to tune it manually... a little better results but not as wanted.is M303 T0 S230 better than to calibrate the heater itself?

-

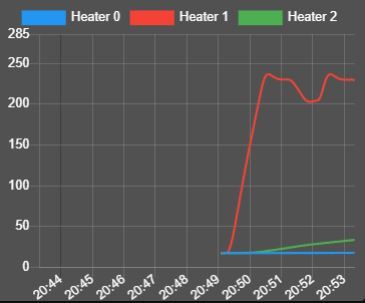

Can you share a photo of the heater graph from tuning?

And also some details about the heater setup? And Photos?

@NeueKlasse said in Heater Tuning M307:

is M303 T0 S230 better than to calibrate the heater itself?

Usually yes because it can take account of the part cooling fan.

-

Following Picture is from Heating up to 230 degree, (overshoots to 238) then i set it to 205 degree to cool down a little bit (Standby Temp) and Heat up to 230 again (overshoots to 238). it's not bad but i don't want that

i don't want that overshooting behavior, the Overshooting get's worse when the

Second hotend is at temperature too (that's normal, i know, but how to solve that?)Setup: 2x Mosquito Hotends with 50W Cartridge @24V

-

Can you post your full config?

50W heater is pretty powerful.

-

Yes, here are the config.g

; Configuration file for Duet 3 (firmware version 3) ; executed by the firmware on start-up ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"ChironBMG" ; set printer name ; Network Settings DHCP M552 S1 ; Enable Network Connection M552 P0.0.0.0 ; (0 = DHCP) ;Set Network Adress M553 P255.255.255.0 ; Netmask ; Maxima / Drives M569 P0.0 S0 ; physical drive 0.0 goes forwards X M569 P0.1 S1 ; physical drive 0.1 goes forwards Y M569 P0.2 S1 ; physical drive 0.2 goes forwards ZL M569 P0.3 S1 ; physical drive 0.3 goes forwards ZR M569 P0.4 S0 ; physical drive 0.4 goes forwards E1 M569 P0.5 S1 ; physical drive 0.5 goes forwards E2 M584 X0.0 Y0.1 Z0.2:0.3 E0.4:0.5 ; set drive mapping M671 X-40:450 Y0:0 S3 ; leadscrew positions and max correction in mm M350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation M92 X80.00 Y100.00 Z400.00 E413.00:413.00 ; set steps per mm M566 X1600.00 Y1600.00 Z100.00 E150.00:150.00 ; set maximum instantaneous speed changes (mm/min) M203 X18000.00 Y18000.00 Z600.00 E1200.00:1200.00 ; set maximum speeds (mm/min) M201 X800.00 Y800.00 Z60.00 E5000.00:5000.00 ; set accelerations (mm/s^2) M906 X1200 Y1200 Z900 E700:700 I20 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X-19 Y-2 Z0 S1 ; set axis minima M208 X406 Y410 Z400 S0 ; set axis maxima ; Endstops M574 X1 S1 P"!io3.in" ; configure active-high endstop for low end on X via pin io3.in M574 Y1 S1 P"!io4.in" ; configure active-high endstop for low end on Y via pin io4.in M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Filament Sensors M591 P1 C"io5.in" S0 D0 ; filament monitor connected to E0 extruder M591 P1 C"io6.in" S0 D1 ; filament monitor connected to E1 extruder ; Z-Probe M558 P5 A2 I1 C"^io7.in" H2 F200 T15000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X7.5 Y-26 Z1.12 ; set Z probe trigger value, offset and trigger height M557 X19:391 Y15:379 S93:91 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out1" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 A126.3 C485.1 D1.5 S1.0 V25.0 B0 M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"temp1" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin temp1 M950 H1 C"out2" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 A340 C140.0 D5.5 S1.0 V0.0 B0 M308 S2 P"temp2" Y"thermistor" T100000 B4138 ; configure sensor 2 as thermistor on pin temp2 M950 H2 C"out3" T2 ; create nozzle heater output on out2 and map it to sensor 2 M307 H2 A340 C140.0 D5.5 S1.0 V0.0 B0 ; Fans M950 F1 C"out8" Q500 ; create fan 1 on pin out8 and set its frequency M106 P1 C"Extruderfan" S1 H1:2 T70 ; set fan 1 name and value. Thermostatic control is turned on M950 F2 C"out9" Q500 ; create fan 2 on pin out9 and set its frequency M106 P2 C"Partcoolingfan" S0 H-1 ; set fan 2 name and value. Thermostatic control is turned off M950 F3 C"!out4+out4.tach" Q5000 ; create fan 3 on pin out4 and set its frequency M106 P3 C"Cabinetfan" S200 H-1 ; set fan 4 name and value. M950 F4 C"!out5+out5.tach" Q5000 ; create fan 4 on pin out5 and set its frequency M106 P4 C"Powersupplyfan" S200 H-1 ; set fan 4 name and value. ; Tools M563 P0 S"Left Nozzle" D0 H1 F2 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M563 P1 S"Right Nozzle" D1 H2 F2 ; define tool 1 G10 P1 X14.43 Y0 Z0 ; set tool 1 axis offsets G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C ; Miscellaneous M912 P0 S-13 ; MCU Temperature Adjustment M575 P1 S1 B57600 ; enable support for PanelDue M564 H0 ; allow axis movement before homing, needed for Z axis M501 ; Load Parameterset T0 P0 ; Set Tool 0 without any Toolchange Scriptsand the config-override.g

; config-override.g file generated in response to M500 at 2021-03-05 08:12 ; This is a system-generated file - do not edit ; Heater model parameters M307 H0 R0.260 C485.100:485.100 D1.50 S1.00 V25.0 B0 M307 H1 R2.000 C200.000:200.000 D6.50 S1.00 V25.3 B0 M307 H2 R2.000 C200.000:200.000 D6.50 S1.00 V25.4 B0 ; Workplace coordinates G10 L2 P1 X0.00 Y0.00 Z0.00 G10 L2 P2 X0.00 Y0.00 Z0.00 G10 L2 P3 X0.00 Y0.00 Z0.00 G10 L2 P4 X0.00 Y0.00 Z0.00 G10 L2 P5 X0.00 Y0.00 Z0.00 G10 L2 P6 X0.00 Y0.00 Z0.00 G10 L2 P7 X0.00 Y0.00 Z0.00 G10 L2 P8 X0.00 Y0.00 Z0.00 G10 L2 P9 X0.00 Y0.00 Z0.00 M486 S-1 -

What exactly does the hotend look like? I see two heaters and two tools, but a single part cooling fan.

-

Standard BMG X2 double Mosquito Setup, 2 Extruderfans, 2 Partcoolingfans

each Fan pair over a Distributionboard from 1 Fanoutput -

I would suggest re-tuning again, but this time using a lower PWM factor to reduce the overshoot. 50w on a hotend is a lot of power in a small area. By the time the temperature rise has registered with the sensor the temperature has already shot past. Try P0.7 maybe.