Magnetic Filament Sensor - false alarms

-

I did check the magnet and it sits firmly on the shaft.

So, I am out of ideas, what else I could do.

Duet 3 is probably the best 3D printer board available on the market, combined with Toolboard it offers unique functionality. I love it. It is so good that I have temptation to replace my CNCs Duet 2 with Duet 3, especially if I keep SBC mode in mind.

Magnetic Filament Sensor is exactly 65EUR of disappointment + wasted time and filament on failed prints, especially if it not clear where is the issue. Hardware, software, user error?

It defiantly has great potential, but it should be reliable, I guess I will try to return it and get the refund, and print out simple microswitch filament run out sensor.

-

@o_lampe said in Magnetic Filament Sensor - false alarms:

@dc42

Maybe it's not the right place to discuss it here, but a optical mouse sensor reading the surface of a rough idler roller would have a much higher resolution than a magnet&hall combo. And the rough surface of the roller avoids slipping, too.Just my 2 Cent

Have you seen https://forum.duet3d.com/topic/18497/indirect-laser-monitor-remix-ii-working ?

-

@gunrak said in Magnetic Filament Sensor - false alarms:

So, I am out of ideas, what else I could do.

Please post the GCode file you are printing. I have a machine using a tool board with magnetic filament monitor, so I will try printing your part on it.

-

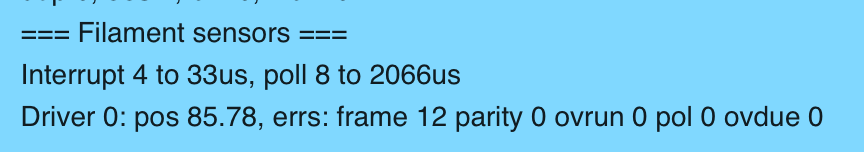

I did upgrade to RRF 3.3beta1, just to see if this will make any difference.

Errors are still there, but a bit less than yesterday printing the same file:

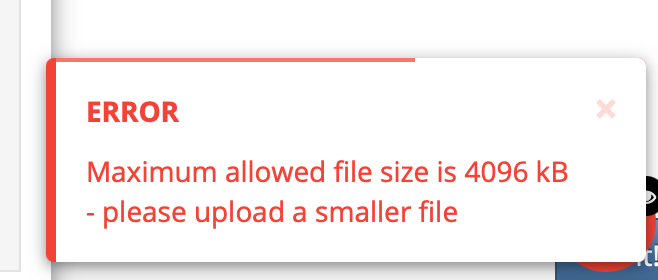

and .zip is not allowed to upload.

Uploaded to DropBox: https://www.dropbox.com/s/tnevy8i5yhnym6x/f119e32e-cf3a-46c6-97b3-237b4b389e3c_0.8n_0.4mm_PLA__3h34m.gcode?dl=0

-

Hi,

Please help our client or do you accept the sensor under warranty?

-

I am trying to run your client's print, but it's too large for the bed of my printer. I will try a workaround tomorrow.

-

@gunrak, I see the following command in your print file:

;Enable Stealthcop Tuning move G1 E0.2 F100Does this mean that you have configured the extruder driver in StealthChop mode? I advise against that, because StealthChop can't adapt to rapid fluctuations in load.

-

You are right, I was experimenting with StealthChop, and apparently I forgot to remove it from my other computers slicer's Start G-Code. StealthChop is not enabled in config.

I still did not give up, and other day was experimenting, my thought was that maybe sensor is to close to extruder. I have Hemera and stepper motor is right there and I thought maybe that was causing interference so I went from 4cm to 8cm long PTFE tube now sensor is mounted further away from stepper motor.

All other settings stayed the same, but this time I printed with PETG instead of PLA, still 0.8mm nozzle, diferent part. Absolutely nothing changed, exactly the same pattern as before.

-

@gunrak, have you see this thread https://forum.duet3d.com/topic/21958/magnetic-sensor-reports-negative-min-value ?

The sensor should be as close to the extruder as possible. Otherwise, when the extruder retracts, the filament tends to bunch up in the bowden tube between the sensor and the extruder, instead of back-feeding through the sensor.

-

@dc42 it was a while since I posted. After I read thread you mentioned I mounted sensor as close as possible to extruder and since then I did not receive any failure or false alarm (printed couple spooles).

Thank you for help and patience. Issue solved.