Error: bad Command XXX W/RRF 3.2 and leveling issue

-

@martin7404 I considered a second bearing as a backup if a single bearing did not work out,

but it did. I wanted to keep it as light as posable. Its the same bearing as the tool changer uses with the same length cantilever to the nozzle but the Muldex carriage is much lighter so it should be no problem. Their probe is much closer though. -

@dc42 said in Error: bad Command XXX W/RRF 3.2 and leveling issue:

My guess is that the print heat is tilting a little

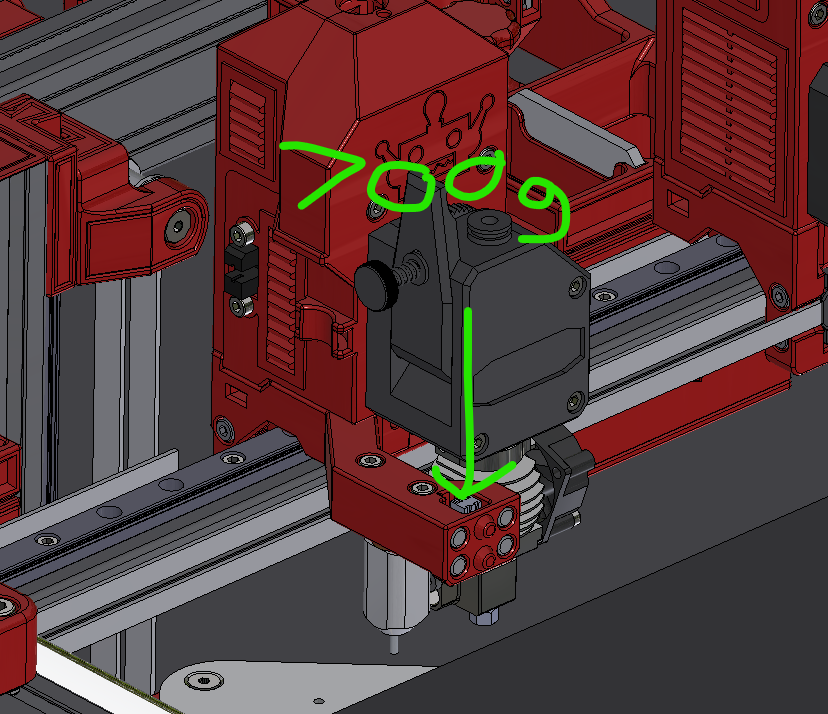

To test your theory that the head is tilting , I put a 700g steel bar as shown in the picture to cause the bearing to tip forward and to remove any potential bearing slop. But, the level is still the same. Back right corner low, front left corner high.

-

In this case I might backup my config and start with a fresh basic set for testing.

-

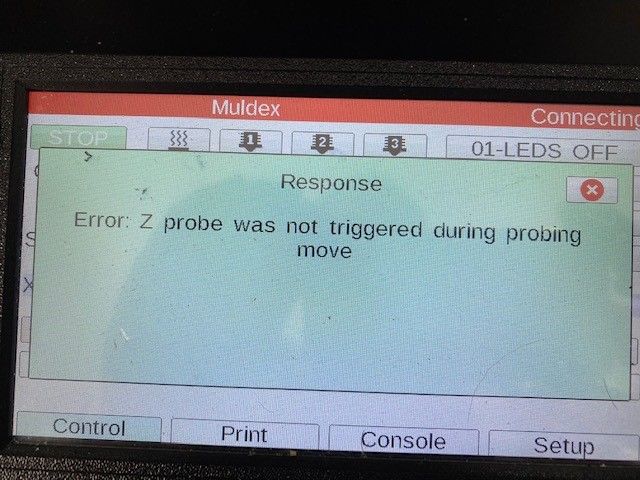

One other error to put on the list from updating to 3.2. About once in every twenty to fifty startups I get this error, it causes the machine crash into the Y endstops. The error takes place as its homing Y, way before it ever gets to the G30. Never seen this error on 3.1.1.

I still get "bad error" command every time I reset and T2 fan still comes on every other time power is reset.

-

@Phaedrux said in Error: bad Command XXX W/RRF 3.2 and leveling issue:

In this case I might backup my config and start with a fresh basic set for testing.

There have been a couple instances where I waisted a lot of time trying to figure a issue out thinking it was user error because I am new to RRF only to find that it was a bug in RRF. Are you sure the issue has to be on my end?

-

@3DPrintingWorld said in Error: bad Command XXX W/RRF 3.2 and leveling issue:

Are you sure the issue has to be on my end?

I am sure of very little in general.

The only gauge I have is how widespread a problem is reported.

Setting up a simplified basic config would help to eliminate some variables in your current config. I know it takes some time to set up, but I wouldn't ask if it hasn't proven fruitful int the past.

-

hey @martin7404 , just spoke to Gui and he experimented with his Z axis acceleration and turned it up to 1000 but noticed he started to see inconsistency's with the level. He lowered it back down to 600 and the issue went away. He's thinking that he was getting missteps from the reduction and having such low voltage on the steppers,(300) so not to damage anything should the probe fail.

I noticed that my accel was only 35 mms^2 so not a issue for me... I think I slowed it down at one point to test something but forgot to put it back. I thought I would let you know If you turned the acceleration way up, it might be the cause for inconsistent leveling.

-

@3DPrintingWorld I checked , my Z stepper voltage is 900 left from 5:1 reduction steppers. And my acceleration Z is 35 , I did not change that from initial setup

-

One more thing for G29

SO I made the following made bed probing with G29 and left the machine with motors energized idle for the night. In the morning I made G29 s2 and G32 with S3 and S-1, then again, then G29 S1 to activate mesh correction and G32 Again. What I see during the night for some reason the left side have 0.1mm + deviation, and with or without G29 mesh correction activated or not, there is almost no difference in G32 results2/16/2021, 9:53:33 AM G32 bed probe heights: -0.007 -0.007 0.008, mean -0.002, deviation from mean 0.007 2/16/2021, 9:53:09 AM g32 Leadscrew adjustments made: 0.008 -0.010 -0.029, points used 3, (mean, deviation) before (-0.009, 0.011) after (-0.000, 0.000) 2/16/2021, 9:50:59 AM g29 s1 2/16/2021, 9:50:37 AM G32 bed probe heights: -0.002 -0.015 0.005, mean -0.004, deviation from mean 0.008 2/16/2021, 9:50:13 AM g32 Leadscrew adjustments made: -0.011 -0.003 0.016, points used 3, (mean, deviation) before (-0.000, 0.008) after (0.000, 0.000) 2/16/2021, 9:49:40 AM g29 s2 2/16/2021, 9:49:10 AM G32 bed probe heights: -0.009 0.014 0.001, mean 0.002, deviation from mean 0.009 2/16/2021, 9:48:47 AM g32 Leadscrew adjustments made: 0.129 0.001 -0.028, points used 3, (mean, deviation) before (0.043, 0.052) after (-0.000, 0.000) 2/16/2021, 9:47:36 AM G32 bed probe heights: 0.080 0.005 0.003, mean 0.029, deviation from mean 0.036 2/16/2021, 9:47:12 AM g32 Leadscrew adjustments made: -0.194 -0.050 -0.020, points used 3, (mean, deviation) before (-0.098, 0.058) after (0.000, 0.000) 2/15/2021, 6:12:01 PM 224 points probed, min error -0.109, max error 0.084, mean 0.005, deviation 0.035 Height map saved to file 0:/sys/heightmap.csv -

@3DPrintingWorld I am interested if the test with the steel bar get any effect

-

@martin7404 I guess you would need more power with a little less reduction, I just tried to keep it low as possible incase of a crash. I would turn up the acceleration, that was a typo. Its saves a couple seconds homing.

-

@martin7404 so you are saying, if mesh bed is on or off it doesn't make a difference?

-

I just went to PRF 3.2 again and it is the same

2/16/2021, 1:27:27 PM G32 bed probe heights: 0.004 -0.006 -0.020, mean -0.007, deviation from mean 0.010 2/16/2021, 1:27:02 PM g32 Leadscrew adjustments made: 0.067 0.023 -0.004, points used 3, (mean, deviation) before (0.032, 0.022) after (-0.000, 0.000) 2/16/2021, 1:25:25 PM G32 bed probe heights: 0.040 0.024 0.011, mean 0.025, deviation from mean 0.012 2/16/2021, 1:25:01 PM g32 Leadscrew adjustments made: -0.160 -0.085 -0.057, points used 3, (mean, deviation) before (-0.106, 0.032) after (-0.000, 0.000) 2/16/2021, 1:15:15 PM G29 30 points probed, min error -0.122, max error 0.006, mean -0.044, deviation 0.036 Height map saved to file 0:/sys/heightmap.csv -

@martin7404 The weight did not have any effect on leveling, It was still out of level. The Z height was .25mm lower but I think that's because the arm that holds the BL touch was flexing from the weight I put on it.

-

@3DPrintingWorld Yes NO difference if G29 is on or off

-

@martin7404 Is your bed actual level or is it just saying that it is?

-

Using steel 10.5 gauge and panel due to steps I am within what G29 probing says les than 0.15

-

@martin7404 Ok, not perfect but acceptable. Seems like your configuration is working properly. This about of error could be caused by the head tilting. A second bearing could help with that but would also increase the weight.

If you used the same base config as me, I don't understand my issues. I'm thinking about ordering a new board just to see because I don't see how it can be on my end.

-

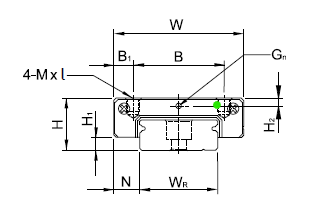

@martin7404 Instead of two bearings, what about a option to upgrade to the wide series, mgw9h. This should reduce the tilt, and would result in less binding then two bearings mounted on different planes would.

-

@3DPrintingWorld said in Error: bad Command XXX W/RRF 3.2 and leveling issue:

mgw9h

Yes , but you have to switch to 4020 profile for the X and the mass would not be less

I took a look at hiwin pdf's . So LDO rails must light clearance type ZF (4 to 10 microns clearence between block adn rail) so 0.06-0.07 mm on 25 mm cantilever seems normal too. Maybe we can switch to light to slight preload blocks