general (heated) enclosure questions for ABS printing

-

iirc cardboard has an R value about 4 times that of plywood. i.e. cardboard is better - on paper, pun intended..

-

or you could get Acrylic. that is used on some corexy printer for abs printing.

if you screw it to the printer itself, you make the enclosure as small as possible.

good example here is the voron 2.4

e.g https://www.reddit.com/r/voroncorexy/comments/hvtxoa/voron_24_350mm_serial_request_thinksteve2774/Second: Filament spool inside or outside the enclosure?

outside

-

Acrylic, even regular plexi will work. You should also be able to order Coroplast panels online - that would be even better.

I don't have hints to give you other than https://fermio.xyz. While their stuff is mostly for Vorons, maybe they will be able to hook you up if you won't find a direct shop in your city or anywhere else within Germany.

If you are stuck, I can get you some recommendations from Poland

-

@bearer said in general (heated) enclosure questions for ABS printing:

iirc cardboard has an R value about 4 times that of plywood. i.e. cardboard is better - on paper, pun intended..

I wanted to start with cardboard anyway. If it sucks, I can still use it as template... -

@Veti said in general (heated) enclosure questions for ABS printing:

or you could get Acrylic. that is used on some corexy printer for abs printing.

if you screw it to the printer itself, you make the enclosure as small as possible.I have some acrylic 500x500 sheets too, but my DBOT has seen some modifications and the mgn12 riders stick out everywhere

-

According to google acrylic ranges from 0 to 0.9 in R value so plywood would be a better insulator. (Some cite plexiglass as better than cardboard, but that seems to refer to multilayer much like double(++) glazed windows for buildings.

You'll probably be able to improve the cardboard by lining with aluminum foil on the inside to reflect heat back to the printer.

Another thing is if your ambient temperature is warm you might not need too much insulation, more protection against draft and varying temperature.

-

ghetto enclouse guide

https://youtu.be/YTEj7uQZ7yQ?t=3474 -

@o_lampe said in general (heated) enclosure questions for ABS printing:

First the material for the enclosure: 6mm plywood or corrugated cardboard? Which is the better isolator?

cardboard is better insulator for the same thickness but I doubt you have 6mm cardboard, also with plywood you can make more "usable" case with doors, shelves... but cardboard is super fast to work with and if you double it it will hold temp better than thee plywood. line the inside with the alu foil it reflects the heat and is pretty useful and cheap, especially if you have alu tape.

Second: Filament spool inside or outside the enclosure?

most filaments you want to print with in enclosure absorb moisture so you want to dry them. if you have a dedicated drybox then keeping filament in the drybox with ptfe tube from drybox to your enclosure is ideal, if you do not have drybox then better to keep filament in the enclosure, warm and dry

-

Corrugated cardboard is cheap/free but plywood will help make the printer's frame more rigid. You can't see through it, though.

You can get PIR foam insulation that won't burn in the event your printer catches fire. It's a great insulator and cheap. We have an old stratasys printer at the makerspace that has PIR foam insulating the walls. Incidentally, you can print on PIR foam and never have to worry about bed leveling- just bury the nozzle about 1mm into the foam on the first layer and use a raft. You also don't need to heat the bed. ABS and PLA will stick to it, and probably any other type of filament you use.

Acrylic will let you see what's going on inside the printer, but one of the major lessons from the great acrylic 3D printer frame disaster of 2015 is that acrylic cracks under the pressure of screws. If you want clear stuff, polycarbonate doesn't crack. Like plywood, it will rigidify the frame it's attached to.

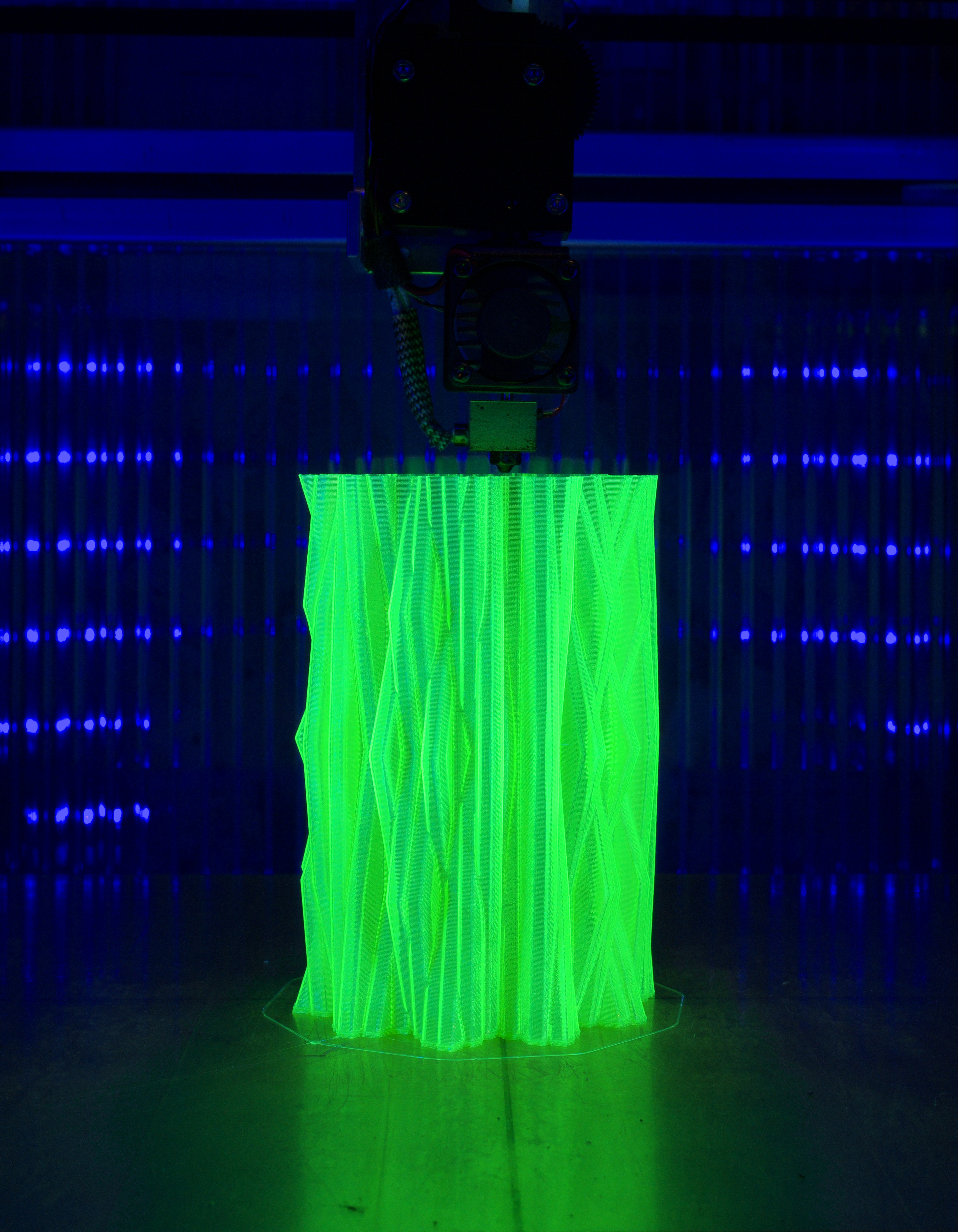

I used 8mm thick dual layer polycarbonate for the side walls of my printer- it just fits into the slots in the t-slot frame. Great insulation, but no help with printer rigidity. It does have a unique look, and if you light up the inside of the printer, it produces some nice optical effects:

Dual layer PC is commonly used to make greenhouses, so it's readily available, not too expensive, and very light weight.

-

OK, first step is done. The top and front will be clear PVC.

I've put the white side inside, for better view.

It's doublewalled cardboard, so I expect good results for narda -

WOW,

I just read the dozuki "how to setup a chamber heater and temp-sensor".

Didn't know it was that difficult?!

Difficult to understand the dozuki, I had to flip through several deprecated M codes and I still don't know, how to really set a temperature.

Is it still M141 Sxx? Since M141 Hx is now M950, but M950 description doesn't give clue about setting a target temp.

I'm sure in the end, it's just a few simple lines in config. g and in the slicer startcode.Time to find the "migrate to RRF3.x" page, where all the M-code differences are listed.

IMHO it would be best to split up the dozuki in independent RRF2.x and RRF3.x sections

-

@o_lampe Here's an example from the configurator:

; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C M308 S2 P"e1temp" Y"thermistor" T100000 B4138 ; configure sensor 2 as thermistor on pin e1temp M950 H2 C"e1heat" T2 ; create chamber heater output on e1heat and map it to sensor 2 M307 H2 B0 S1.00 ; disable bang-bang mode for the chamber heater and set PWM limit M141 H2 ; map chamber to heater 2 M143 H2 S280 ; set temperature limit for heater 2 to 280Chttps://duet3d.dozuki.com/Wiki/Connecting_and_configuring_a_chamber_heater

-

My corexy uses an extrudued frame with a plexiglass enclosure it works well with a pair of halogen terrainium lamps as heaters.

For controlling heat inside the "chamber" i found i wanted a quick way to know what the inside temp was compared to ambient and to control it in the same simple fashion so i went with a dual channel STC-3008 it allows me to control the A/C lamps totally independant of the Duet, meaning the chamber can act as a filamanet dryer even with the duet turend off I have a DHT22 for measuring humidity so i know what everything is doing. and as i make the chamber as dryer i keep the filamanet inside the chamber too.

beaware that some extruders and printers using printed parts will soften as chamber temps rise.

-

@JayJay What are the lamps pointing at?

-

@Phaedrux

Thanks again for shortening my learning curve

BTW: your CoreXY has a similar Z-axis than I have, but I had a hard time finding a longer closed loop GT2 belt.

That's why two of the ballscrews are in this stupid place where they limit my printable area.

Your blog only says, it's a gates gt2 belt. Do you know a good online source, where they stock different length's belts? -

Bear in mind that plywood, cardboard, and acrylic are all flammable materials. Polycarbonate is flame resistant and has a better insulation than acrylic. It is easier to cut & drill too, requiring no special bits/blades. It is however more expensive.

For a heater I use an electronics enclosure heater. I use a Stego 04641.9-00. They're $150-300 new, but can be had on ebay for a fraction of that price. These are technically designed to do exactly what we want/need them to do.

Filament inside the printer means that it will preheat it meaning your hotend doesn't have to work as hard, or can potentially go faster. It can also theoretically dry out the filament some. It will however require opening the printer to do filament changes.

-

@macguyver

Thanks for the recommendations, but at the moment, I'll have to use, what's laying around.I'm currently living like Grizzly Adams in the woods, where there's no hardware shop around and the postman will arrive next spring

-

@o_lampe That's even more reason to be careful and do it right because living out in the woods often means that the fire trucks wont arrive in time to do anything but cool down the ashes of what used to be your cabin in the woods. A smoke alarm and a self deploying range top fire extinguisher are also good ideas.

-

@macguyver

My chamber heater element has a safety-thermostat at 167°F/75°C.

I hope that'll do the trick.

Usually, I never leave my printer unattended.

Currently I'm more concerned about my waterpipe freezing , than getting roasted in a cozy campfire. -

@o_lampe said in general (heated) enclosure questions for ABS printing:

gates gt2 belt. Do you know a good online source, where they stock different length's belts?

I believe I got a few different belts from a few different sources. Some were from AliExpress. Some from ebay. Some from 3d Print shops online. It's a lot easier to find quality stuff online now than it was when I was looking.

It may say gates GT2 but I don't think any of the closed loop belts I have are genuine.