ovals instead of circles

-

Good evening everyone, I'm here to submit a printing problem. I would like to know if it has happened to any of you that when you print vertically, these circles, when finished printing, turn out to be oval.

Board: Duet 2 WiFi (2WiFi)

Firmware: RepRapFirmware for Duet 2 WiFi / Ethernet 3.2 (2021-01-05)

Duet WiFi Server Version: 1.25

Slicer - Simplify3d and Cura 4.8 -

That's normal because we print "sliced" stl. The circle resolution is limited on Z axis to your layer height so it will be always print as an oval instead of a circle. That should not happed if printed on the XY plane. On that plane usally you'll get smaller circle than the design caused by stl resoultion (triangle counts) and also for plastic being overextruded on the inside of a circular movement.

Here's a trick to compensate for this problem at design: https://re3d.zendesk.com/hc/en-us/community/posts/360057694271-Printing-the-Most-Circular-Circle-along-the-Z-axis

-

thanks for the answer, but it seems a bit strange to me since I have always printed and I do not say that the circles were perfect but not oval for sure, I will investigate more thoroughly

-

How oval are you seeing? Photo of the previewed STL and the resulting print?

-

OK I'll post it all tomorrow afternoon

-

-

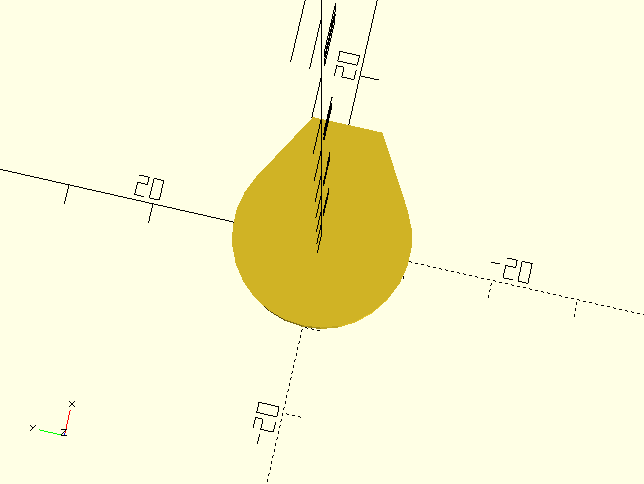

The piece I did it with fusion 360

-

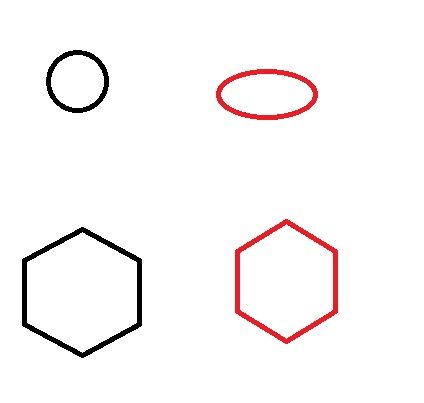

@Leblond Make holes something like this:

The flat at the top helps to prevent the filament from falling into the hole.

The openscad code for this example:

hull() {

cylinder(h=5,d=20);

translate([12,-4,0]) cube([1,8,5]);

} -

The plate on top helps prevent filament from falling into the hole. I knew this, as far as I know with care there are tricks to avoid the plate, maybe I have the wrong settings I just have to understand where I was wrong, but to make you understand better I designed this to make you understand ..

-

and it never happened to me, at least until recently

-

It looks like you've got some bad ringing and maybe too hot temps? Too high jerk?

-

probable, in fact I put my hand back to the configuration and I lowered the jerk from 1000 to 600, then once another piece is printed if I get improvements I post a photo

-

even the temperatures will have to lower by 5 degrees, petg mold at 230 degrees the print bed 75 degrees