ST3Di Modelsmart 280 - Duet Maestro repair/upgrade

-

ok thats inline with a 100k ntc thermistor.

but which one is not as easy to determine.

can you put the thermistor at 100C using a known good temperature measuring tool?

i.e here is a beta 3950 resistance table.

https://www.keenovo.com/NTC-Thermistor-R-T-Table.pdf -

@Veti said in ST3Di Modelsmart 280 - Duet Maestro repair/upgrade:

ok thats inline with a 100k ntc thermistor.

but which one is not as easy to determine.

can you put the thermistor at 100C using a known good temperature measuring tool?

i.e here is a beta 3950 resistance table.

https://www.keenovo.com/NTC-Thermistor-R-T-Table.pdfI'm not sure how I'd go about that especially with what I have available at the moment. Am I daft thinking i could try suspend it in some boiling water and measure it then?

-

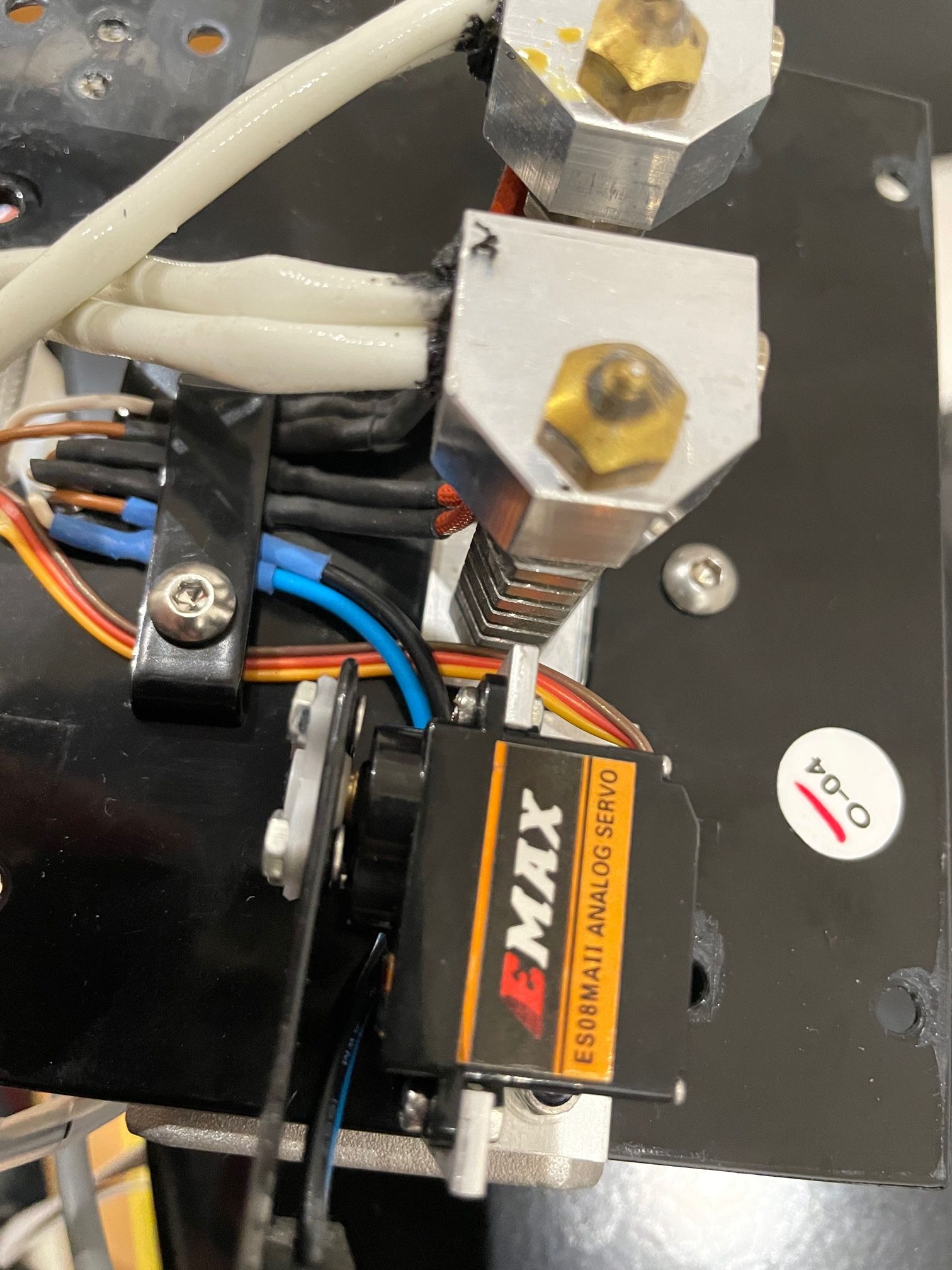

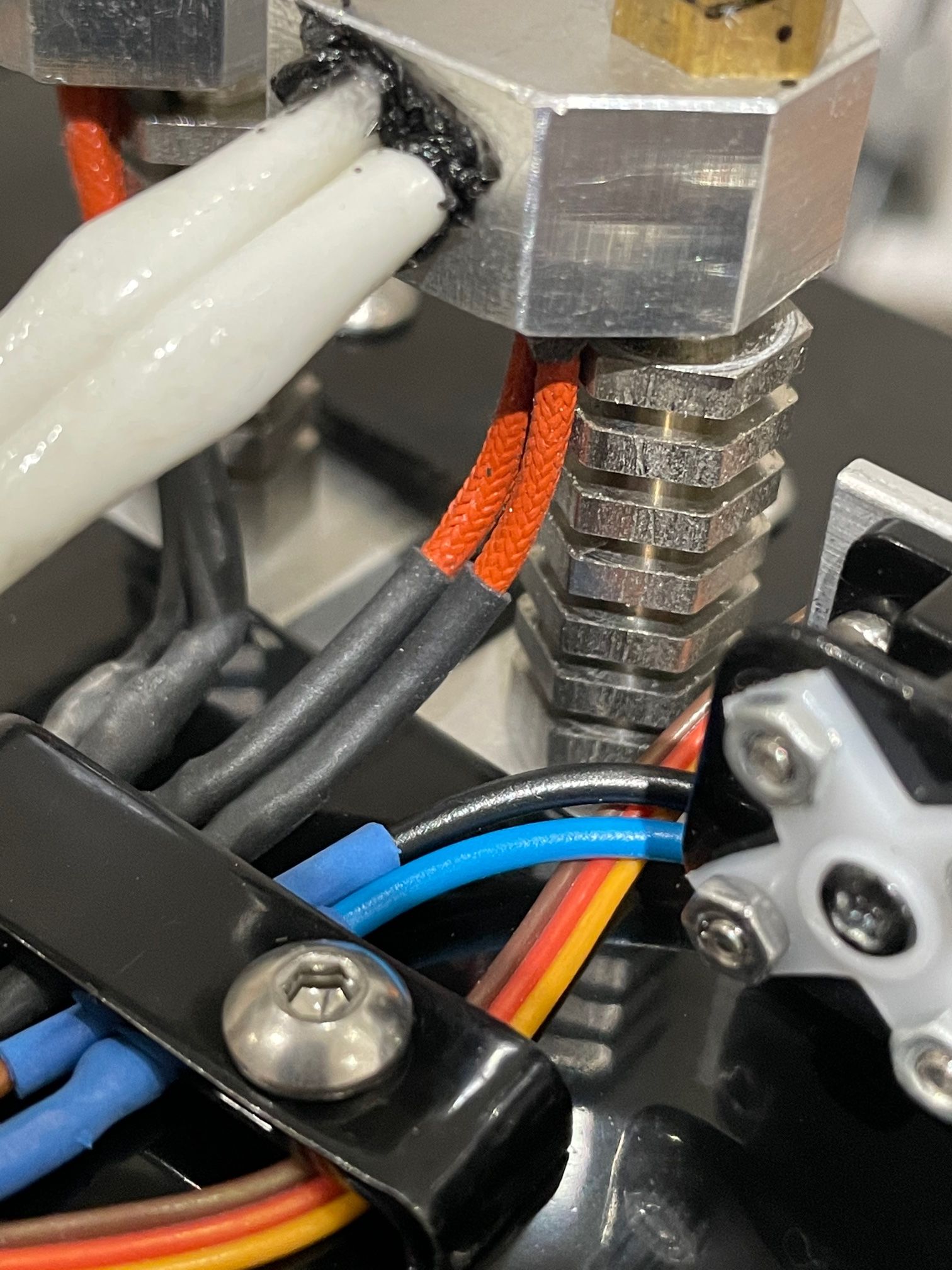

can you post a picture of the thermistor in the hotend?

-

@Veti said in ST3Di Modelsmart 280 - Duet Maestro repair/upgrade:

can you post a picture of the thermistor in the hotend?

I'll try. I've a work call now but will do it after.

thanks for your help.

-

How was the original board configured - maybe you can borrow some info from there?

-

Best I can manage at the moment. I'll have to take the shroud off etc.

-

@bearer said in ST3Di Modelsmart 280 - Duet Maestro repair/upgrade:

How was the original board configured - maybe you can borrow some info from there?

Pics.

-

This other board was below the touch screen.

-

Ouch / RIP. No immediately obvious easy way to get anything from that, the main cpu on the motion controller had seen better days indeed.

(there is what looks like a 8 pin soic flash chip, but might not be worth while extracting it if settings are in the other cpu's flash / eeprom)

-

@bearer It didn't smell too great when that happened

-

@Veti said in ST3Di Modelsmart 280 - Duet Maestro repair/upgrade:

ok thats inline with a 100k ntc thermistor.

but which one is not as easy to determine.

can you put the thermistor at 100C using a known good temperature measuring tool?

i.e here is a beta 3950 resistance table.

https://www.keenovo.com/NTC-Thermistor-R-T-Table.pdfI have an infrared thermometer gun (for the pizza oven). How about in the oven and use that to read the surface temp of it?

-

if the oven temp is stable then it should work if left long enough for temperature to equalize on the board and oven; i prefer to use water with crushed ice and boiling water for a 2 point calibration as its more stable and water conducts the temperature better than air (but water does have its own challenges)

-

Also as you'll tweak the print profile it doesn't matter if you print at 210 or 215 as long as you get consistent results - i.e. precision is more important than accuracy unless running a print farm.

-

@bearer said in ST3Di Modelsmart 280 - Duet Maestro repair/upgrade:

Also as you'll tweak the print profile it doesn't matter if you print at 210 or 215 as long as you get consistent results - i.e. precision is more important than accuracy unless running a print farm.

That's a good point. It will be run as a lone printer.

-

@Blacksheep99 said in ST3Di Modelsmart 280 - Duet Maestro repair/upgrade:

I have an infrared thermometer gun (for the pizza oven). How about in the oven and use that to read the surface temp of it?

that will work for the bed, but for the hotend there will be a temperature difference between the nozzle and the surface.

maybe its possible to replace the thermistor with a known one. thats why i asked for a picture.

@bearer said in ST3Di Modelsmart 280 - Duet Maestro repair/upgrade:

Also as you'll tweak the print profile it doesn't matter if you print at 210 or 215 as long as you get consistent results - i.e. precision is more important than accuracy unless running a print farm.

yes the problem is that the difference between a semitec 104gt2 and a b3950 setting is more than 20C at 200C

-

@Veti said in ST3Di Modelsmart 280 - Duet Maestro repair/upgrade:

@Blacksheep99 said in ST3Di Modelsmart 280 - Duet Maestro repair/upgrade:

I have an infrared thermometer gun (for the pizza oven). How about in the oven and use that to read the surface temp of it?

that will work for the bed, but for the hotend there will be a temperature difference between the nozzle and the surface.

maybe its possible to replace the thermistor with a known one. thats why i asked for a picture.

@bearer said in ST3Di Modelsmart 280 - Duet Maestro repair/upgrade:

Also as you'll tweak the print profile it doesn't matter if you print at 210 or 215 as long as you get consistent results - i.e. precision is more important than accuracy unless running a print farm.yes the problem is that the difference between a semitec 104gt2 and a b3950 setting is more than 20C at 200C

I'll take the hotend out tonight and see if it can be ID'd.

-

Not sure these help?

-

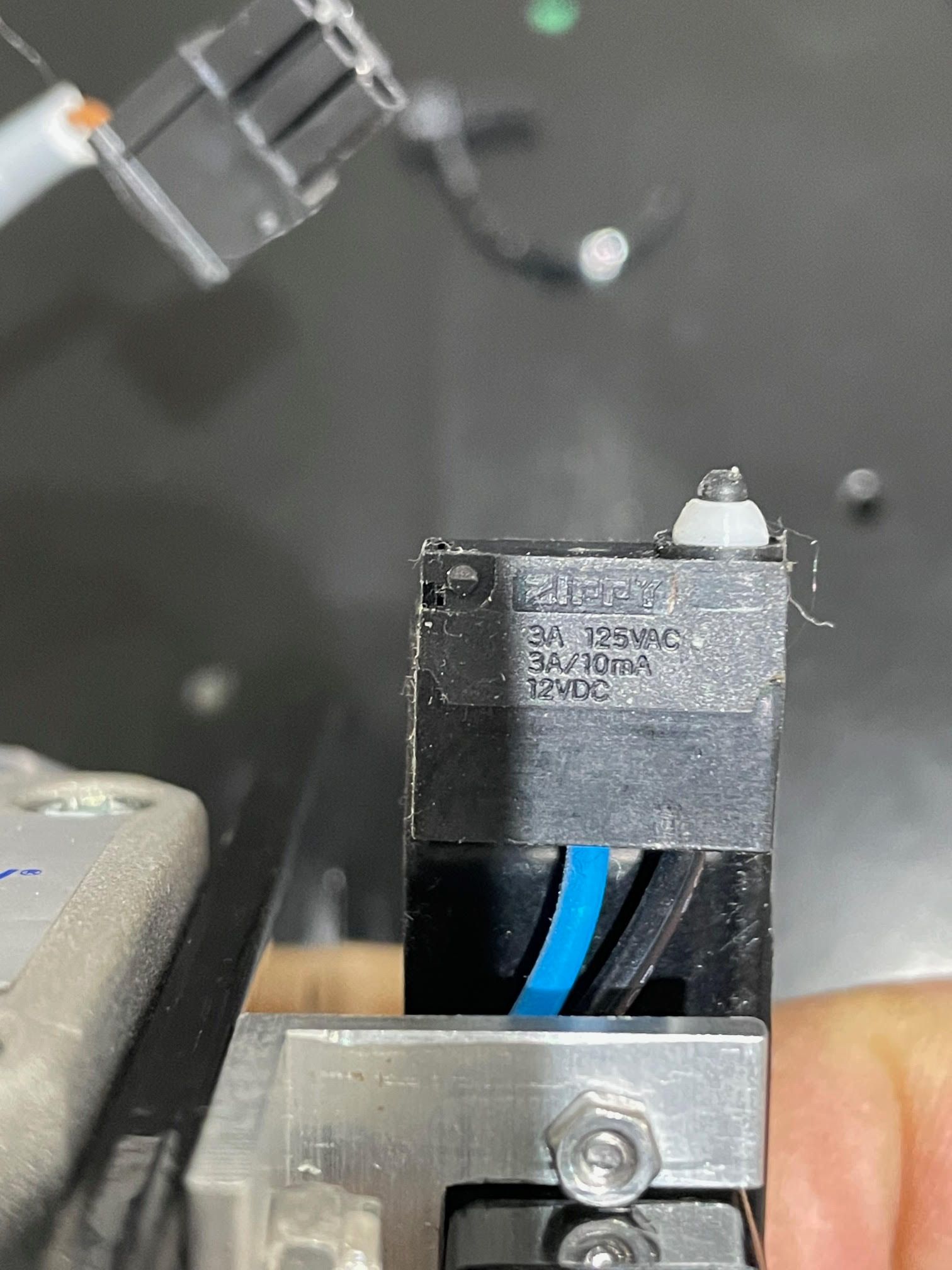

The endstop/probe. 12v, is that an issue?

-

It could just be a simple microswitch that is rated to handle 12 volts in which case it won't matter if you only use 3.3 volts. You'll need to just use an ohm meter on the wire ends to see if it that style switch. If it only has two wires I would suspect it's just a normal microswitch.

-

@JamesM said in ST3Di Modelsmart 280 - Duet Maestro repair/upgrade:

It could just be a simple microswitch that is rated to handle 12 volts in which case it won't matter if you only use 3.3 volts. You'll need to just use an ohm meter on the wire ends to see if it that style switch. If it only has two wires I would suspect it's just a normal microswitch.

Thanks. I would think/hope you're right.