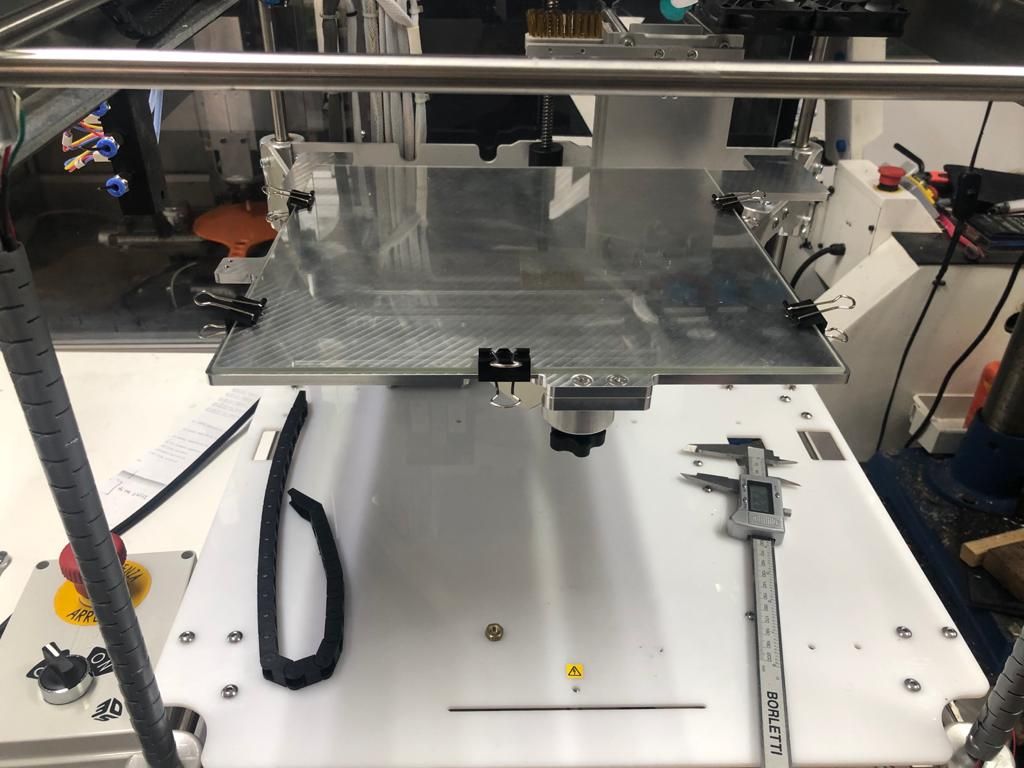

problem attuning bed heater

-

M303 autotuning procedure for bed heater never ends.

failing to calibrate it automatically every time I start heating the bed I get this error.Error: Heater 0 fault: temperature rising much more slowly than the expected 1.6°C/sec

; Heaters

;Piatto riscaldato

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138

M950 H0 C"bedheat" T0

M307 H0 B1 S1.00

M140 H0

M143 H0 S110 -

make sure you have m501 in config, and m500 after autotune

-

@konte1978 Make sure you have the correct B value in M308.

-

; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.1.4 on Fri Jul 17 2020 20:24:58 GMT+0200 (CEST); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P" CUBE PRO TRIO" ; set printer name; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M569 P4 S1 ; physical drive 4 goes forwards

M569 P9 S1 ; physical drive 9 goes forwards

M584 X0 Y1 Z2 E3:4:9 ; set drive mapping

M350 X16 Y16 Z16 E16:16:16 I1 ; configure microstepping with interpolation

M92 X87.35 Y87.43 Z1076.77 E82.09:82.09:82.09 ; set steps per mm

M566 X900.00 Y900.00 Z12.00 E120.00:120.00:120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X15000.00 Y15000.00 Z1200.00 E600.00:600.00:600.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z250.00 E250.00:250.00:250.00 ; set accelerations (mm/s^2)

M906 X1500 Y1500 Z800 E1200:1200:1200 I30 ; set motor currents (mA) and motor idle factor in per cent (ho modficato la corrente dei motori dell'estrusore da 800 a 1200)

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; Imposta valore minimo deli assi

M208 X290 Y295.3 Z205 ; imposta il valore massimo degli assi ho tolto il valore S0 ALLA FINE DELLA RIGA; Endstops

M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop

M574 Z1 S1 P"zstop" ; configure active-high endstop for low end on Z via pin zstop; Z-Probe

M558 P0 H5 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed

M950 S0 C"duex.pwm5" ; creare il servo pin 0 per BLTouch

M558 P9 C"^zprobe.in" H5 F120 T6000 A10 R0.75 S0.02 ; set Z probe type to bltouch and the dive height + speeds

G31 P25 X-11.70 Y-51.2 Z2.75 ; impostare il valore del trigger della sonda Z, l'offset e l'altezza del trigger

M557 X12.3:290 Y24.80:295 S20 ; define mesh grid; Heaters

;Piatto riscaldato

;M570 H0 P90 T20 ; sto cercando di far aspettare fino che il piatto si riscaldi prima che mi dia errore

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S110 ; set temperature limit for heater 0 to 120C

;Estrusore numero 1

M308 S1 P"spi.cs1" Y"rtd-max31865" ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S290; set temperature limit for heater 0 to 120C

;Estrusore numero 2

M308 S2 P"spi.cs2" Y"rtd-max31865" ; configure sensor 2 as thermistor on pin e1temp

M950 H2 C"e1heat" T2 ; create nozzle heater output on e1heat and map it to sensor 2

M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H2 S270

;Estrusore numero 3

M308 S3 P"spi.cs3" Y"rtd-max31865" ; M308 S3 P"duex.e2temp" Y"thermistor" T100000 B4725 ; configure sensor 3 as thermistor on pin duex.e2temp

M950 H3 C"duex.e2heat" T3 ; create nozzle heater output on duex.e2heat and map it to sensor 3

M143 H3 S270 ; set temperature limit for heater 0 to 120C

M307 H3 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

; Riscaldatore della camera

M141 H4 ; il riscaldatore 4 è il riscaldatore della camera

M950 H4 C"duex.e3heat" T4 ; configura l'uscita per il riscaldamento della camera sull pin e della scheda duex

M308 S4 P"duex.e3temp" Y"thermistor" T100000 B5500 C7.06Ee-8 ; configure sensor 4 as thermistor on pin duex.e2temp

M143 H4 S70 ; set temperature limit for heater 0 to 120C

M301 H4 B1 ; utilizzare il controllo bang-bang per il riscaldatore della camera; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 C"ESTRUSORI" S0 H3:2:1 T120 ; set fan 0 name and value. Thermostatic control is turned on

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 C"NOZZLE" S0 H1:2:3 T45 ; set fan 1 name and value. Thermostatic control is turned on

M950 F2 C"fan2" Q500 ; create fan 2 on pin fan2 and set its frequency

M106 P2 C"LUCI LED" S0 H-1 ; set fan 2 name and value. Thermostatic control is turned off

M950 F3 C"duex.fan6" Q500 ; create fan 3 on pin duex.fan6 and set its frequency

M106 P3 C"VENTOLA 6" S0 H-1 ; set fan 3 name and value. Thermostatic control is turned off

M950 F4 C"duex.fan7" Q500 ; create fan 4 on pin duex.fan7 and set its frequency

M106 P4 C"VENTOLA 7" S0 H-1 ; set fan 4 name and value. Thermostatic control is turned off; Tools

M563 P0 S"estrusore 1" D0 H1 F0:1 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M563 P1 S"estrusore 2" D1 H2 F0:1 ; define tool 1

G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C

M563 P2 S"estrusore 3" D2 H3 F0:1 ; define tool 2

G10 P2 X0 Y0 Z0 ; set tool 2 axis offsets

G10 P2 R0 S0 ; set initial tool 2 active and standby temperatures to 0C; Sensori di folamento degli estrusori se imposto l'ultima S0 disabilita il confronto tra filamento aspetatto e quello realmente estruso,S1 abilita il controllo

M591 D0 P5 C"e0stop" R5:190 E3.0 S0 ; ho configurato il filamento del primo estrusore sull'uscita e0stop valori sensibilità filamneto originale R40:120

M591 D1 P5 C"connlcd.encb" R5:190 E3.0 S1 ; ho configurato il filamento del secondo estrusore sull'uscita stop10(ECN_B) valori sensibilità filamneto originale R40:120

M591 D2 P5 C"e1stop" R5:190 E3.0 S1 ; ho configurato il filamento del terzo estrusore sull'uscita e1stop valori sensibilità filamneto originale R40:120; Custom settings are not defined

M575 P1 S1 B57600 ;per abilitare lcd paneldue

M501 -

@Stephen6309 i don't know the B value in M308, how can i get it?

-

it should be in your thermistor documentation

-

@Veti said in problem attuning bed heater:

t should be in your thermistor documentation

unfortunately I have no documentation, I made the mistake of getting it on amazon

https://www.amazon.it/dp/B07RJHYRP5/ref=cm_sw_r_wa_api_fabc_hm15Fb6K3JJWZ?_encoding=UTF8&psc=1

-

@konte1978 Write to the seller and ask for the beta value.

-

most likely they used the very common B3950 thermistor

-

I entered the b-value of B3950 and launched the calibration. Nothing changes, I do not know if it is the fault of the 8mm plate that I used for the printing pact. increase of the test. -

-

What firmware version are you using?

Your screen shot shows the tuning process is running.

Does it ever finish? How long are you waiting?

Does it ever throw an error message?

When it's complete you need to send M500 to save the results. -

@Phaedrux Hi I'm using RepRapFirmware for Duet 2 WiFi / Ethernet version 3.2-RC2.

the test goes on even for 30 minutes without giving any error -

The new heater tuning algorithm in 3.2 can take a long time. Just let it finish.

https://forum.duet3d.com/topic/19761/new-heater-tuning-algorithm