RRF3.2Beta4.1 Heightmap vs. Spindle/Driver Mapping

-

@Frederik

Add an M291 between the M409 and the if statement. I have updated the macro below with thisM291 P{move.calibration.initial.deviation} S3Based upon these values

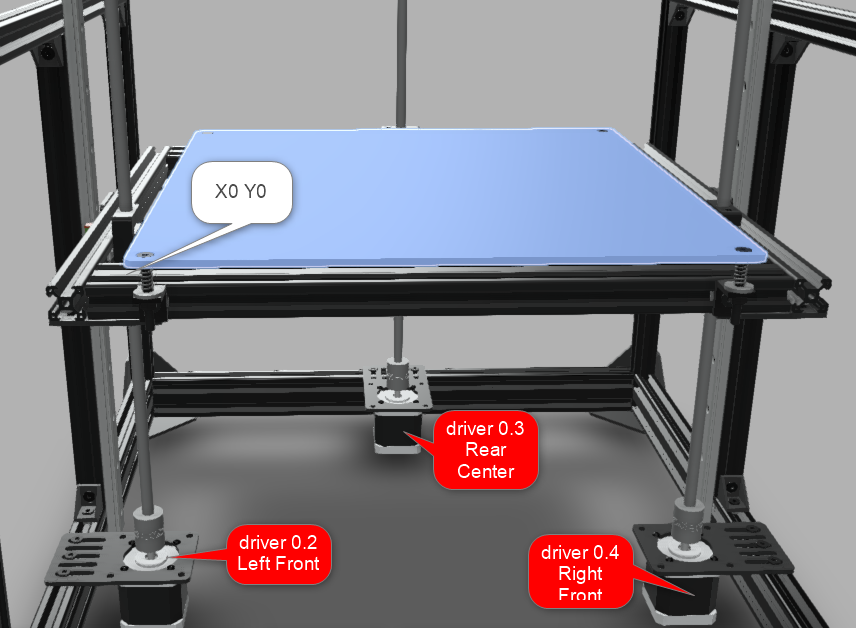

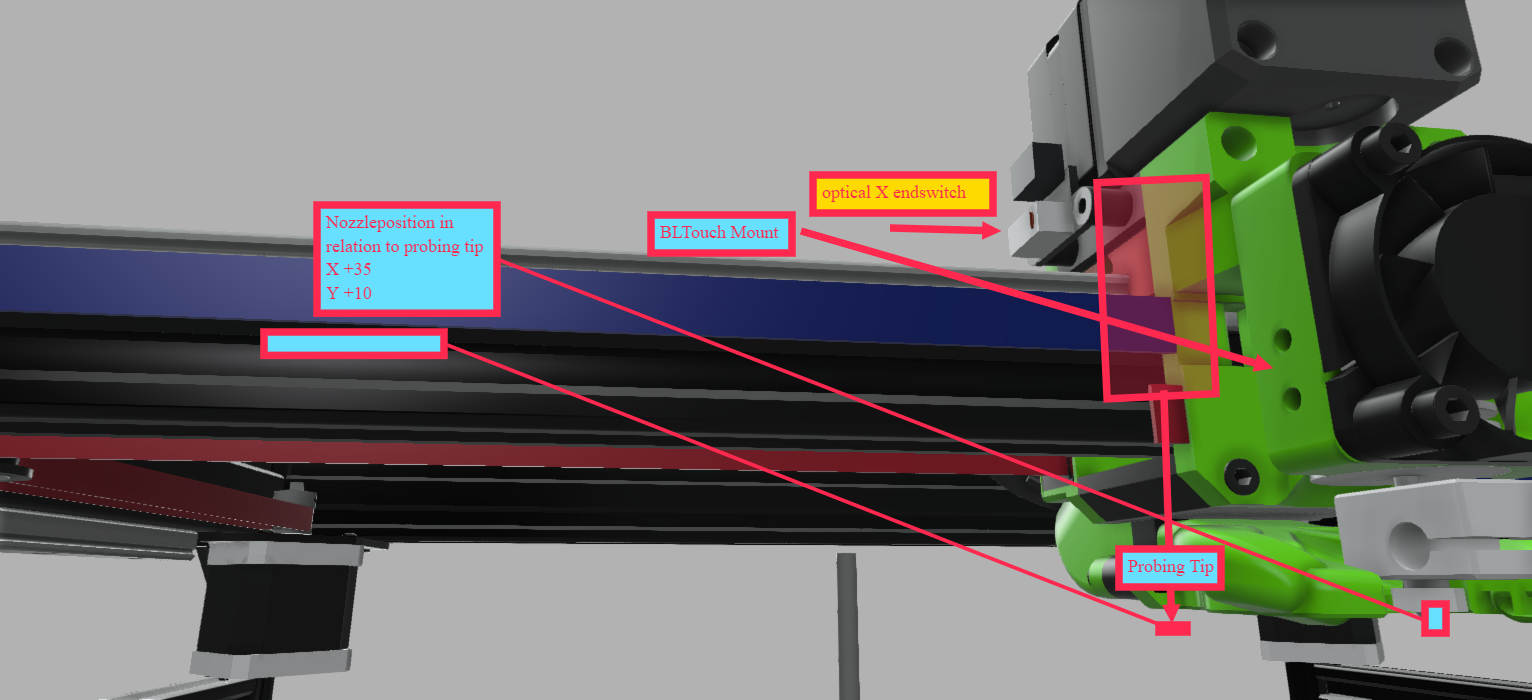

M208 X0 Y0 Z0 S1 ; set axis minima M208 X415 Y395 Z400 S0 ; set axis maxima G10 P0 X0 Y0 Z0 ; set tool 0 axis offsetsthe nozzle should be considered at x0 y0 and the BLTouch at x-38 y-10 in the comment below.

when my printhead is homed at x0 y0 (left front corner) the bltouch is around x-3 y-2

the nozzle x35 y8

This

G31 P1000 X0 Y0 Z0.81 ; BLTouch offsetshould be updated to this

G31 P1000 X-38 Y-10 Z0.81 ; BLTouch offset

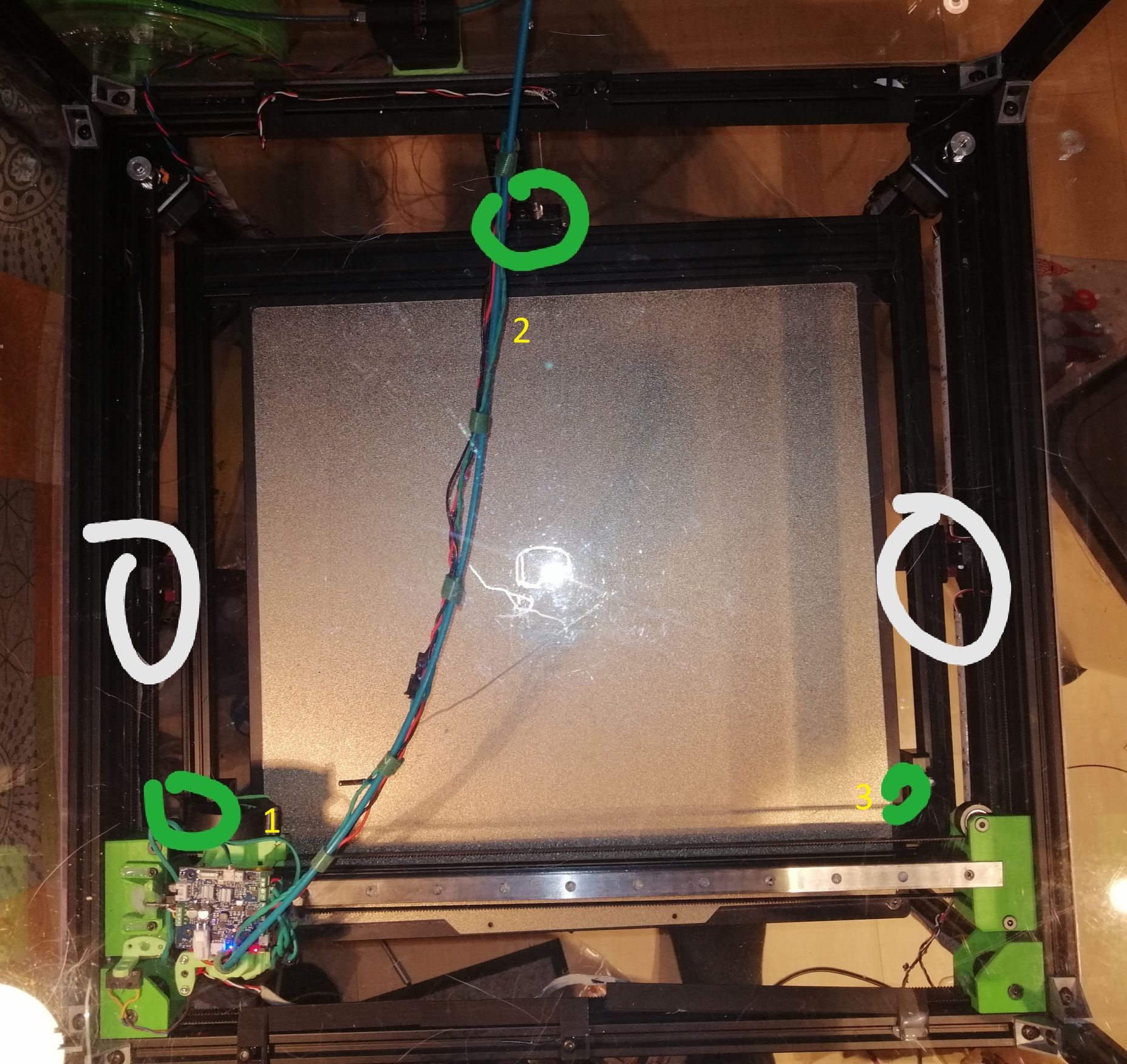

For M671 move the tool head to the position indicated by the (1) of x0 y(align the nozzle to the spindle). Measure from the center of the nozzle to the center of the spindle and subtract that number from x0. The Y value will be the Y position as indicated by the DWC tool position.Next move tool head to position 2 of x(align the nozzle to the spindle) y395. Measure from the center of the nozzle to the center of the spindle and add that number to y395. The X value will be the X position as indicated by the DWC tool position.

Next move tool head to position 3 of x415 y(align the nozzle to the spindle). Measure from the center of the nozzle to the center of the spindle and add that number to x415. The Y value will be the Y position as indicated by the DWC tool position.

Update the M671 with the values collected from the above steps.

M671 X0:215:450 Y80:450:80 S5 ; Position of LeadscrewsNext copy your first G30 command from the 3point calibration

G30 P0 X40 Y80 Z-99999to the console and send it the printer. Once the command has finished record the tool position as indicated by the DWC. Use this x and y value in a G1 x## y## command at the beginning of the 3point calibration followed by G30 to set the z height.

Update the 3point calibration macro to something like

M203 Z100 ; set a low z max speed to increase accuracy. Run multiple G30 S-1 to determine the speed needed to achieve the accuracy you need. G28 while true G1 X## Y## ; enter the tool position as indicated by the DWC after running the first G30 command in the 3point calibration G30 ; sets the first point of the 3point calibration as Z0 G30 P0 X40 Y80 Z-99999 ; Probe near the front left lead-screw G30 P1 X215 Y395 Z-99999 ; Probe near the rear lead screw G30 P2 X415 Y80 Z-99999 S3 ; Probe near the front right lead-screw M409 K"move.calibration.initial.deviation" ;displays deviation in console M400 ; wait for move to complete M291 P{move.calibration.initial.deviation} S3 ;displays deviation value if move.calibration.initial.deviation <= 0.001 ; change the 0.001 to your needed value echo "Passed" M203 Z1000 ; set this z max speed to match your config file. Note if you cancel this macro by selecting the cancel button on the M291 message box this command will not run. You will need to run this command from the console to restore the max z speed break continueFollows these steps above to double check all your setting are correct. Lets the 3point calibration macro run until the deviation no longer decreases and post the results.

@Phaedrux

This is my understanding of the calibration process for 3 motor Z axis calibration.

If something is not correct please update it. This is the process I used to set mine up and it works perfectly.Edit: {

Added M203 to start and end of macro to increase probe accuracy.@3dML said in RRF3.2Beta4.1 Heightmap vs. Spindle/Driver Mapping:

@Frederik

I have found that slowing down the maximum Z speed can help with tolerance.}

-

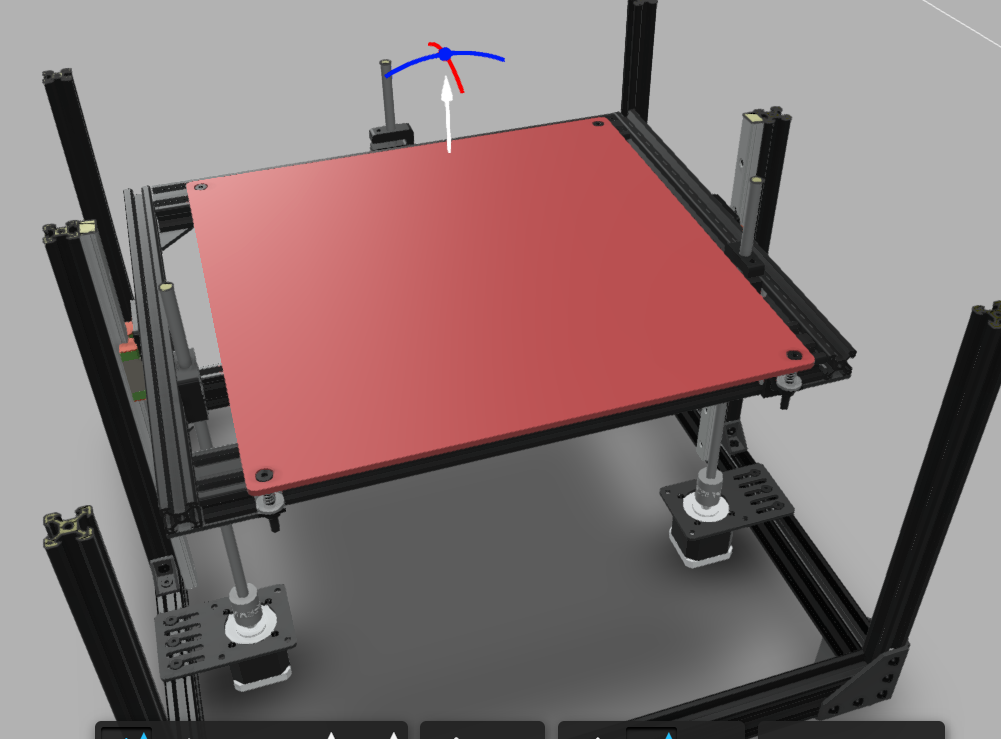

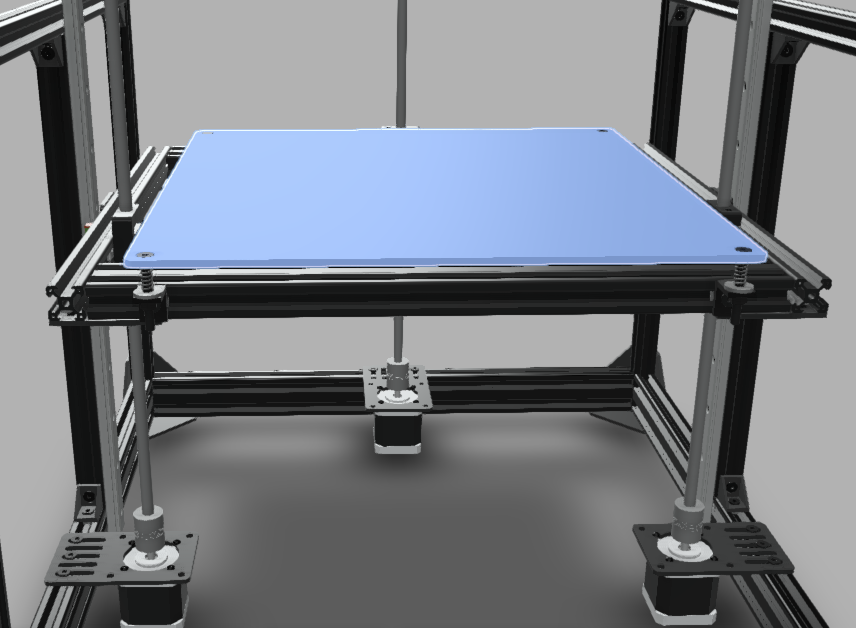

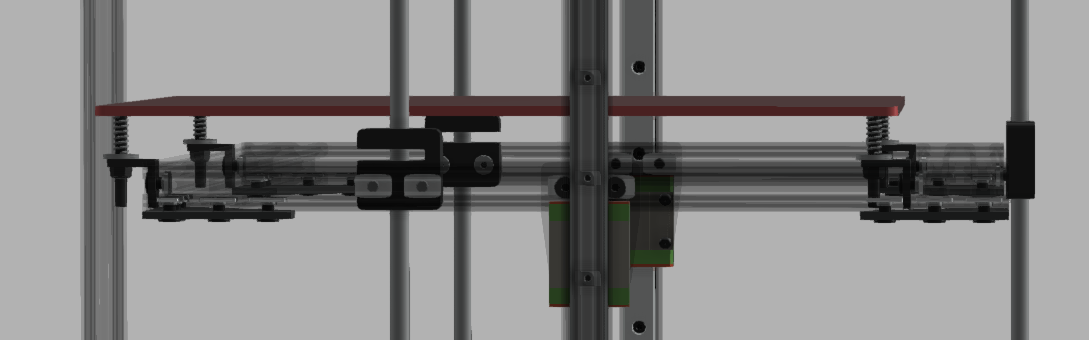

this is the online fusion 360 CAD Model of my build. perhaps it helps to show the position oh everything and offsets ....

https://myhub.autodesk360.com/ue2c6242f/g/shares/SH56a43QTfd62c1cd9689aec54c27a170106

-

@Frederik

The drawing looks correct. My above post still applies.Based on these values

M208 X0 Y0 Z0 S1 ; set axis minima M208 X415 Y395 Z400 S0 ; set axis maxima G10 P0 X0 Y0 Z0 ; set tool 0 axis offsetsall offsets are relative to nozzle position with the tool at x0 y0.

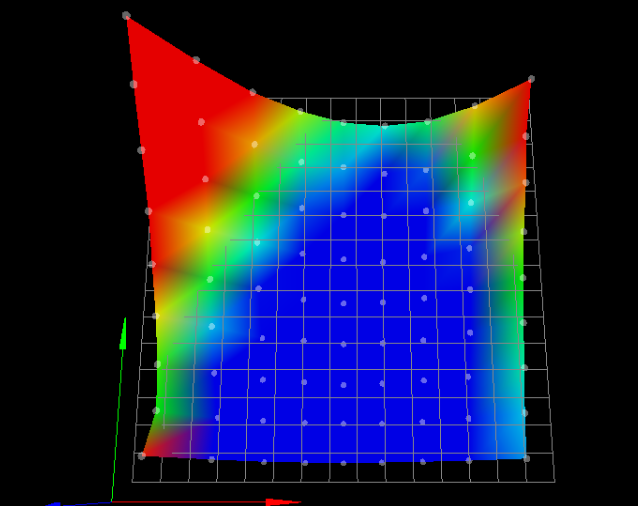

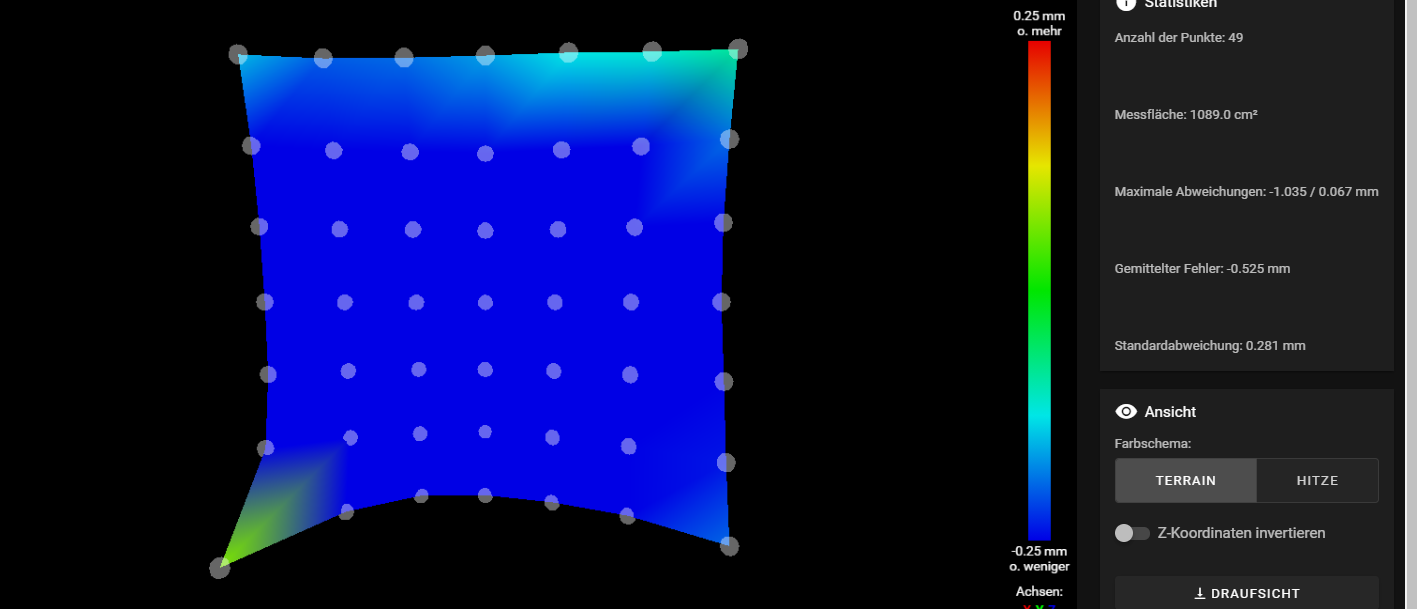

Base on that drawing and your height map I'd say the bed has a large sag along the Y axis.

In this image your 3point calibration deviation is close to 0 but the sag in the bed is causing the skew in the Heightmap. -

@3dML ok, i will post the values as soon as im finished. i will send the manufacturer a photo, perhaps its was damaged during shipping

-

-

@Frederik

Post a picture of the current mount you are using to mount the bed to the z sub-frame. If you are using the mounts I think you are they may be be the cause of sum of the sag. -

@3dML Good Morning,

Merry Christmas

The last if loop after modifying the accel values of Z to 20 and max speed to 100

M98 P"0:/macros/1 test if loop - Z deviation new" Leadscrew adjustments made: 0.351 -1.187 0.554, points used 3, (mean, deviation) before (0.049, 0.626) after (0.000, 0.000) {"key":"move.calibration.initial.deviation","flags":"","result":0.626} Leadscrew adjustments made: 0.346 -0.771 0.107, points used 3, (mean, deviation) before (-0.010, 0.392) after (-0.000, 0.000) {"key":"move.calibration.initial.deviation","flags":"","result":0.392} Leadscrew adjustments made: 0.093 -0.459 0.023, points used 3, (mean, deviation) before (-0.066, 0.200) after (0.000, 0.000) {"key":"move.calibration.initial.deviation","flags":"","result":0.200} Leadscrew adjustments made: 0.077 -0.390 -0.087, points used 3, (mean, deviation) before (-0.095, 0.158) after (0.000, 0.000) {"key":"move.calibration.initial.deviation","flags":"","result":0.158} Leadscrew adjustments made: -0.032 -0.217 -0.052, points used 3, (mean, deviation) before (-0.084, 0.067) after (0.000, 0.000) {"key":"move.calibration.initial.deviation","flags":"","result":0.067} Leadscrew adjustments made: -0.170 -0.222 -0.008, points used 3, (mean, deviation) before (-0.125, 0.068) after (0.000, 0.000) {"key":"move.calibration.initial.deviation","flags":"","result":0.068} Leadscrew adjustments made: -0.142 -0.175 -0.105, points used 3, (mean, deviation) before (-0.137, 0.022) after (-0.000, 0.000) {"key":"move.calibration.initial.deviation","flags":"","result":0.022} Leadscrew adjustments made: -0.15 actual 2 -0.165 -0.158, points used 3, (mean, deviation) before (-0.157, 0.004) after (0.000, 0.000) {"key":"move.calibration.initial.deviation","flags":"","result":0.004} Leadscrew adjustments made: -0.164 -0.177 -0.151, points used 3, (mean, deviation) before (-0.163, 0.008) after (-0.000, 0.000) {"key":"move.calibration.initial.deviation","flags":"","result":0.008} Leadscrew adjustments made: -0.182 -0.158 -0.160, points used 3, (mean, deviation) before (-0.168, 0.008) after (-0.000, 0.000) {"key":"move.calibration.initial.deviation","flags":"","result":0.008} Leadscrew adjustments made: -0.165 -0.169 -0.172, points used 3, (mean, deviation) before (-0.168, 0.002) after (0.000, 0.000) {"key":"move.calibration.initial.deviation","flags":"","result":0.002} PassedMy NOZZLE !!! is now x0 Y0, like you mentioned, and bltouch x-35 y-15 d, i would thay after looking at the different values, the measurements are getting overall closer and more consistent

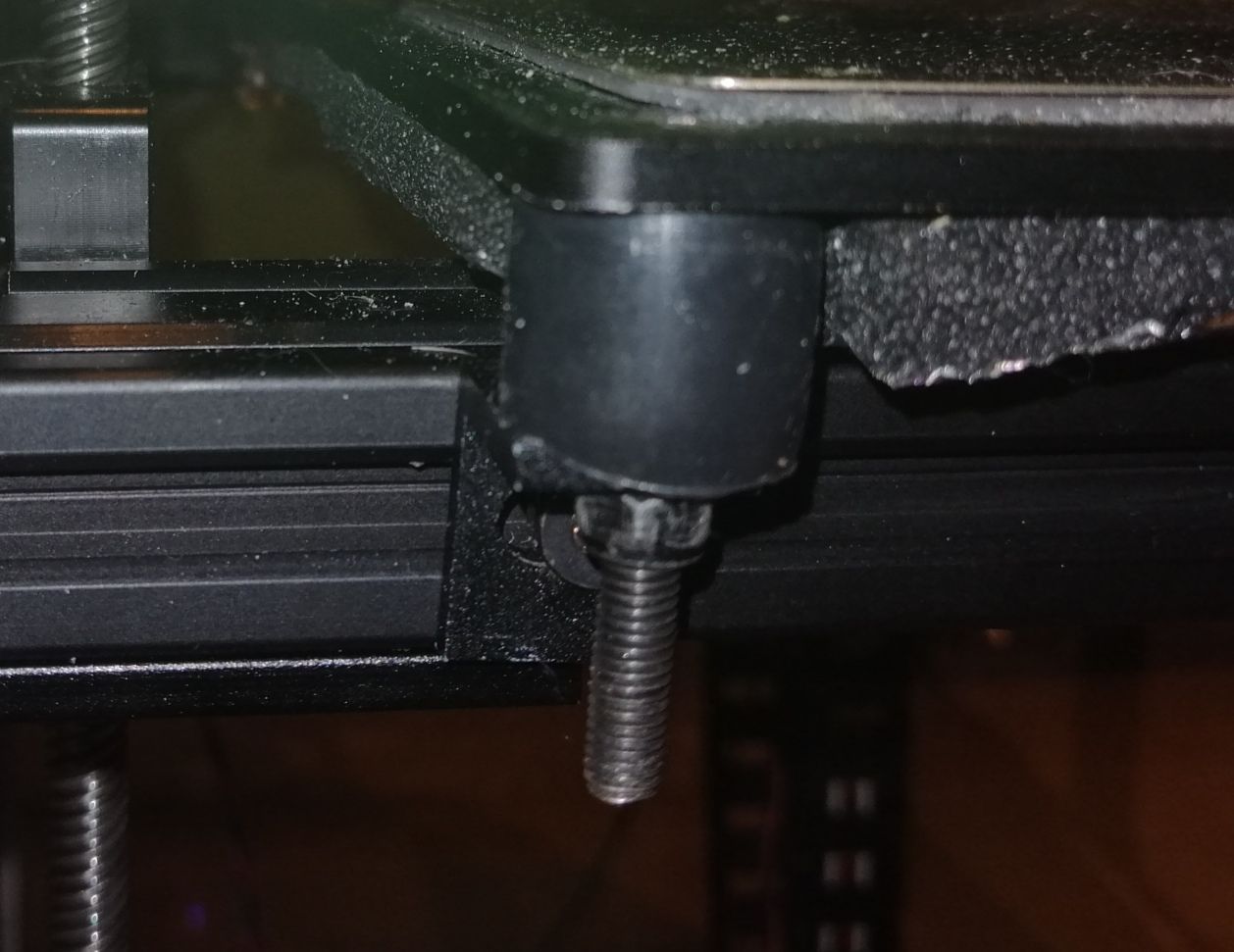

Yesterday i changed the mounting from silicone spacers back to the standard springs from the Kit. now its mounted 1:1 like the CAD above wiht 4 springs at the corners

-

@3dML

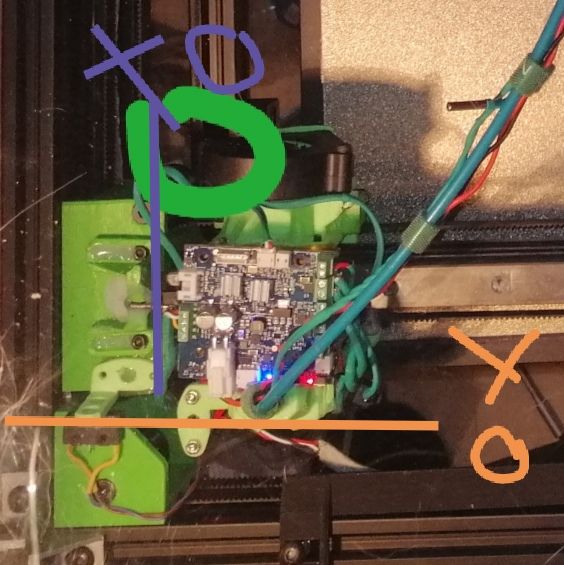

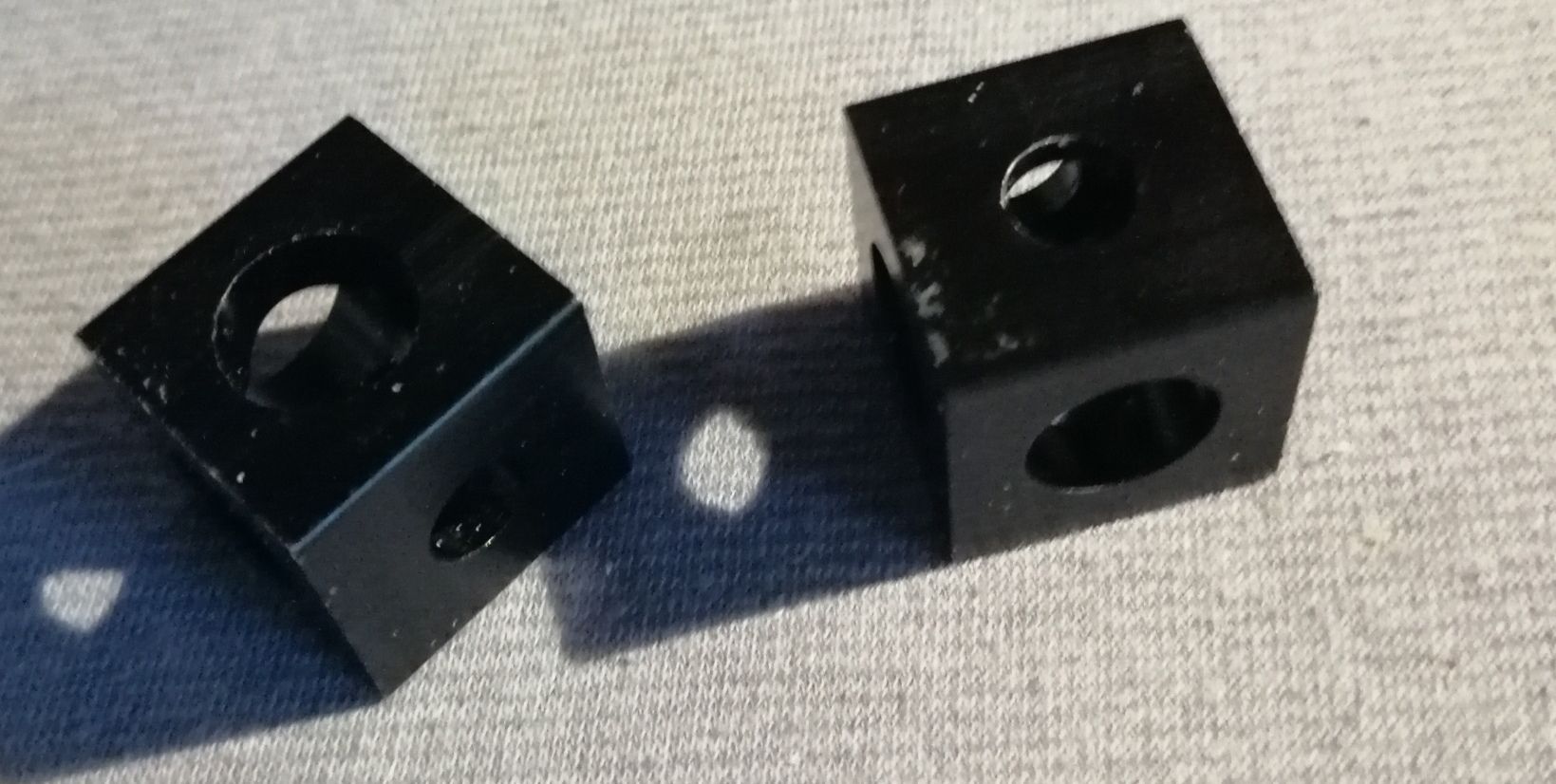

the old mounting:

img_20201224_101915.jpg)

at the moment mounted with this original springs:

![IMG_20201224_101939.jpg]

![IMG_20201224_101939.jpg]The openbuild blocks:

the subframe assembly from the side:

on top is a Prima Creator Magnetic Flex Steel Plate

and the Keenovo Silicone Heatpad below + isolating padding -

@Frederik

My guess is excessive force got applied to the center of the bed at some point and the nature of the L brackets with a single bolt allowed them to swivel inward creating the bend in the bed along the Y axis. I don't have any experience with that style of bed mount so not sure what would be the best recommendation for mounting. -

@3dML The Bed was shipped with DHL Express from Portugal to Germany. Perhaps it got damaged along the way?

What are the most thermal stable and least problematic solutions for the bed ?

i wanted to print a 3 or 4 point kinematic mount like the Hevort V2 without the need of a subframe . only 3x sfu1204 Spindles and a mgn12 or 15 rail behind to eliminate the ply of the floating mount (without FK/BK Blocks).

option 1: borosilikat plate 400x400mm without flex plate or similar

option 2. Aluminium Plate, 10-20mm thick with precision ground surface to +0.025 to -0.025 and flex plate or something like thatoption 3 the same precision plate , only with a DIY coating with Ultem Pellets (PEI) solved in dichloromethane

-

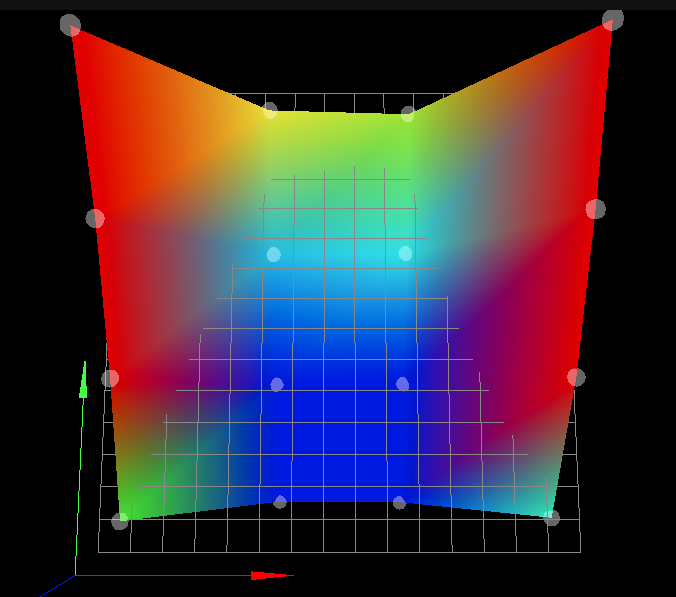

the corresponding .csv values:

xmin,xmax,ymin,ymax,radius,xspacing,yspacing,xnum,ynum

10.00,400.00,10.00,390.00,-1.00,43.30,42.20,10,10

0.238, -0.344, -0.824, -1.021, -1.114, -1.004, -0.833, -0.581, -0.169, 0

-0.003, -0.475, -0.694, -0.875, -0.938, -0.924, -0.785, -0.514, -0.146, 0

0.029, -0.307, -0.608, -0.732, -0.866, -0.804, -0.649, -0.469, -0.089, 0

0.132, -0.153, -0.518, -0.618, -0.739, -0.704, -0.600, -0.338, -0.053, 0

0.280, -0.028, -0.245, -0.518, -0.637, -0.599, -0.485, -0.265, 0.003, 0

0.421, 0.117, -0. 114, -0.345, -0.470, -0.528, -0.417, -0.231, 0.083, 0

0.631, 0.253, -0.006, -0.208, -0.333, -0.352, -0.258, -0.115, 0.202, 0

0.842, 0.446, 0.163, -0.082, -0.162, -0.266, -0.206, 0.006, 0.268, 0

1.037, 0.647, 0.309, 0.086, -0.064, -0.107, -0.045, 0.151, 0.456, 0

0, 0, 0, 0, 0, 0, 0, 0, 0,Thats the last map after i tested a few little things, i thought could help to validate the measurements and improve the probing further:

firmware upgrade to 3.2RC2

Then only for safety

M997 B121

M997 B0- new macros with every BLTouch command including the EEProm Conversion request from open drain to 5v and vice versa

additional, i measured how deep the set crew is on top of the BLTouch and tryed if the ^ on the input pin made a difference in accuracy or error count (error on every probing try or only on every 10th...).

- loosen the mounting screws to the subframe, so that the bed was only held by its own weight on top of the springs to release every little bit of mounting stress like you mentioned above (perhaps a force was applied in the center...).

next, i will rotate the bed 90° and 180 ° to see if the Heightmap in DWC is changing accordingly.

If it doesn't change, i try and change driver 0.3 and 0.4 (Hardware wiring) and check what happens with the compensation map

-

Set the Heater to 120°C, because I thought the thermal expansion could help a little bit, or it flexed while printing PLA with 50°C Bed Temp.

-

Trying to bring it down on the left lower, upper and right corners with the mounting screws and shim it on the right lower corner

- new macros with every BLTouch command including the EEProm Conversion request from open drain to 5v and vice versa

-

i made a few tests with different bed mounts.

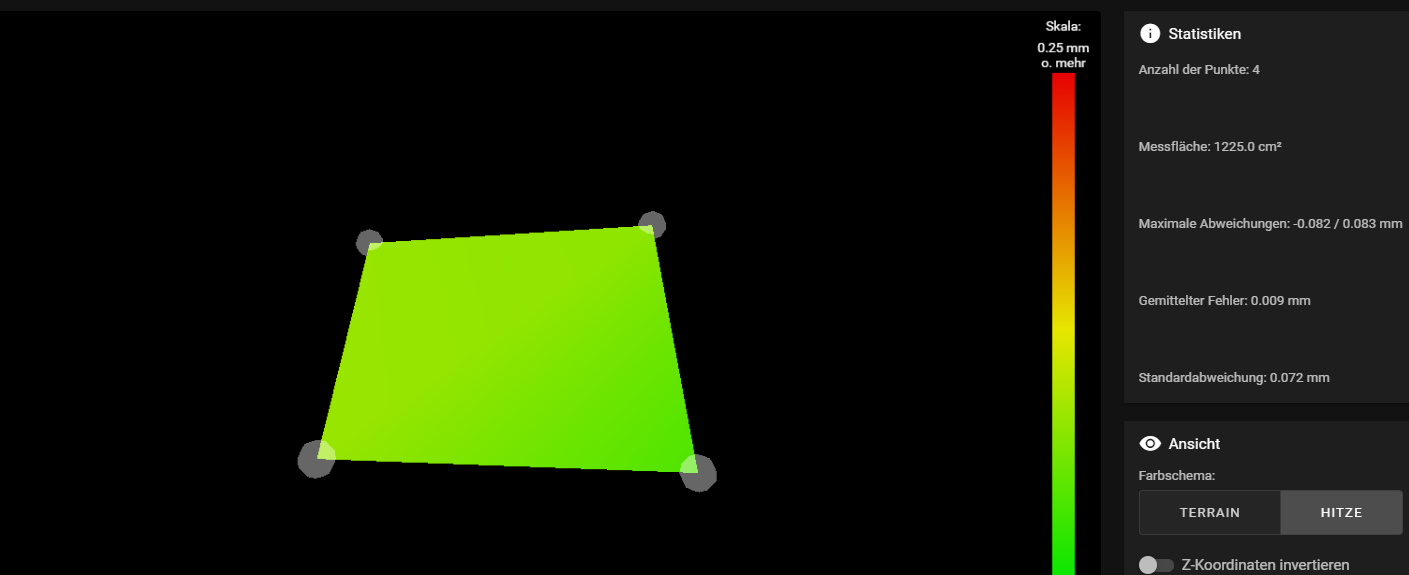

when i probe 4 points on the outer corners i get these values:

RepRapFirmware height map file v2 generated at 2020-12-28 19:39 xmin,xmax,ymin,ymax,radius,xspacing,yspacing,xnum,ynum 10.00,380.00,10.00,380.00,-1.00,350.00,350.00,2,2 0.083, -0.042 -0.082, 0.077and the corresponding graphic in DWC:

when probing more points i get this values:

RepRapFirmware height map file v2 generated at 2020-12-28 19:52 xmin,xmax,ymin,ymax,radius,xspacing,yspacing,xnum,ynum 10.00,380.00,10.00,380.00,-1.00,55.00,55.00,7,7 0.067, -0.716, -1.026, -1.035, -0.892, -0.648, -0.194 -0.543, -0.832, -0.956, -1.031, -0.845, -0.609, -0.239 -0.586, -0.778, -0.884, -0.869, -0.774, -0.577, -0.268 -0.531, -0.686, -0.745, -0.789, -0.716, -0.558, -0.302 -0.446, -0.559, -0.581, -0.624, -0.567, -0.474, -0.275 -0.328, -0.423, -0.451, -0.486, -0.405, -0.334, -0.193 -0.150, -0.201, -0.192, -0.164, -0.126, -0.115, -0.083

-

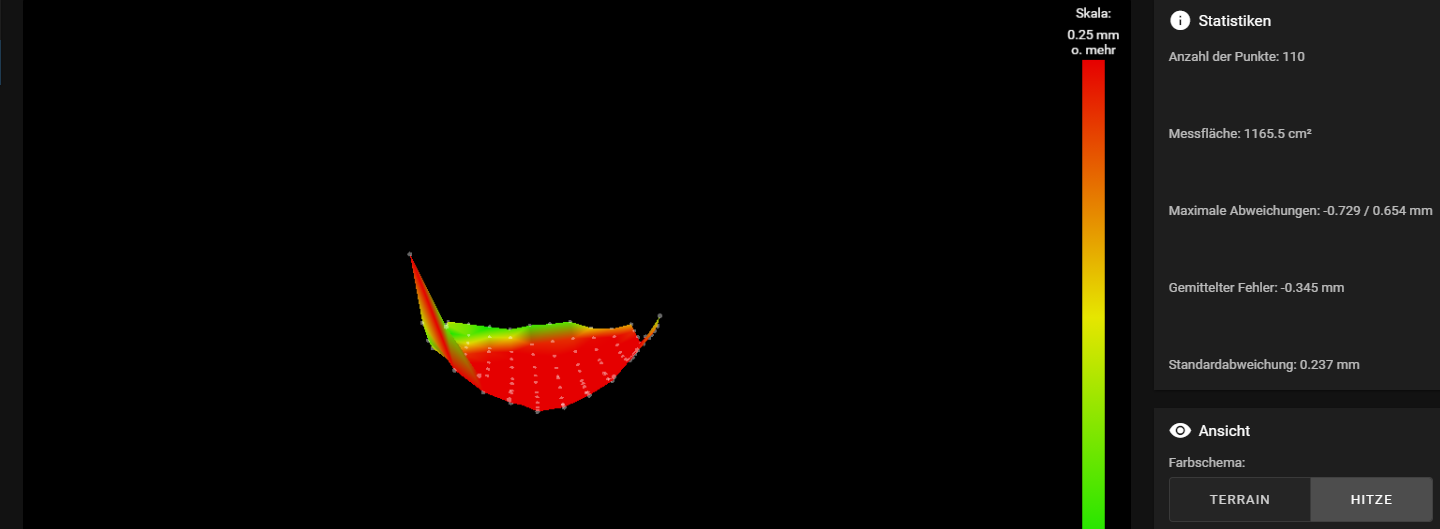

and this a second map generated right after the first two:

the values from heightmap.csv:

RepRapFirmware height map file v2 generated at 2020-12-28 20:15 xmin,xmax,ymin,ymax,radius,xspacing,yspacing,xnum,ynum 10.00,380.00,10.00,360.00,-1.00,37.00,35.00,11,11 0.654, 0.049, -0.369, -0.588, -0.709, -0.703, -0.634, -0.514, -0.327, -0.081, 0 0.105, -0.311, -0.518, -0.634, -0.707, -0.710, -0.635, -0.561, -0.365, -0.162, 0 -0.046, -0.310, -0.495, -0.571, -0.688, -0.729, -0.654, -0.570, -0.404, -0.206, 0 -0.118, -0.321, -0.484, -0.575, -0.659, -0.693, -0.621, -0.582, -0.434, -0.243, 0 -0.121, -0.301, -0.431, -0.529, -0.636, -0.618, -0.610, -0.552, -0.451, -0.276, 0 -0.113, -0.293, -0.383, -0.503, -0.560, -0.549, -0.601, -0.555, -0.456, -0.266, 0 -0.110, -0.225, -0.334, -0.405, -0.512, -0.547, -0.524, -0.474, -0.436, -0.339, 0 -0.051, -0.171, -0.239, -0.339, -0.444, -0.478, -0.474, -0.456, -0.409, -0.342, 0 0.002, -0.133, -0.213, -0.276, -0.329, -0.369, -0.348, -0.359, -0.339, -0.285, 0 0.086, -0.059, -0.100, -0.133, -0.233, -0.228, -0.225, -0.246, -0.260, -0.226, 0 0.116, 0.061, 0.006, -0.048, -0.033, -0.045, -0.047, -0.141, -0.179, -0.155, 0 -

The heightmap shows a bowl shape. The 4 point map shows that the bed is basically level.

Now the question is whether the mesh compensation is enough to compensate for the shape of the bed surface.

bedlevel_nozzle_0.4_200x200-0.3-0.8.stl

Print a test file once with compensation active and again with it disabled and see if the first layer is better with it active.

-

@Phaedrux thanks for the file. i will test it and report back whats happening .

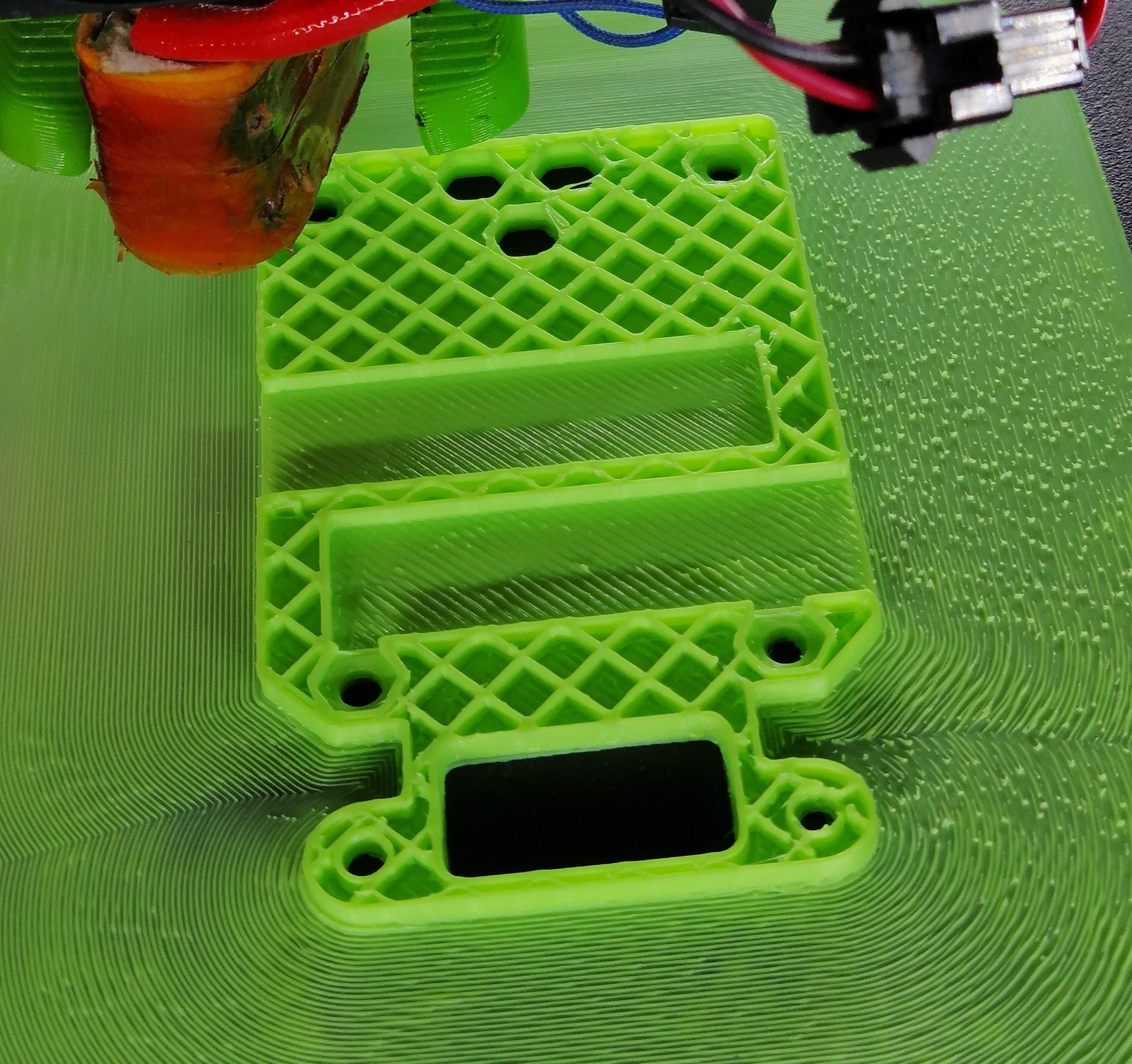

the last time i tried a 350x350 X as test, i had to abort the print after i saw that the printed line was getting squished more and more...and before the nozzle starts digging in the bed i stopped the test. that was perhaps 10 cm from the center

parts up to perhaps 8x8cm from the center where i home Z are no problem, but as soon as i try bigger parts with 15x 8 i already can see the height changes in the actual layer

You can see it goog here in the picture below. The actual part is 6.5cm wide

-

That amount of brim is going to show some heavy over extrusion no matter what.

-

@Phaedrux the picture was only to visualize the problem. The right side is where the height starts to decrease, and another 3-5 cm to the right the nozzle would hit the bed. Note: I was not at the printer and had no other Pic showing the differences:)

-

@Phaedrux there are a lot of things that I had to improve. at the moment I think a combination of pressure advance 0.45 and FW Retract 6.5mm with 45mm/s solved my extrusion problem quite well.

for information:

the Bowden tube between my Bondtech and the start of the Heat block in the mosquito is 1065mm.

when I am running a g32 and start a print with ~ 75x75mm in the center...everything looks good.

the next thing I will test is your test file with and without compensation activated and with varying probing points around the bed.