Robot Type 1 45 cm - belt gear - direct drive - R0

-

I finished rebuild the axis 1, the following three images show the status:

I implemented the following ideas:

- once I used concrete to build something and put the rest into a bucket, the resulting block is usable to be a weight for printer stability (40 kg). I plan to use concrete to surround the printer later, it's easy and cheap

- using 25 mm shaft with F205 flanged ball bearings at two points (top one upside down)

- shaft - axis 2 connection by SH25 shaft connectors

- reducing wiring mess

- the aluminium plate's task is only to drive the rotation now. The rotation constraint is by the shaft and ball bearings. I may replace the aluminium plate later with a 3d printerd teethed pulley, because it no longer needs to be very stiff.

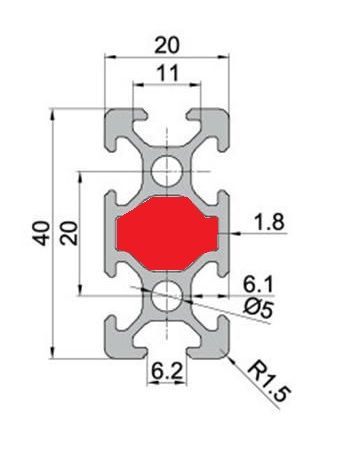

- the aluminium extrusions are Bosch profile 45 based

open problems

- belt tension of the gear toward big wheel is sufficient, but I search a better solution

- the stepper is in the way for the counterweight of axis 2. I'll put it lower with a new adapter

- the endstop trigger and the endstop violate the two-point-rule, they could rotate unintentionally. I'll have to fix it better, but it's low prio

Next step is axis 2. I always try to build the robot without special tools to allow to build is easy for others. But in this case it will be more demanding, as I plan to connect 6205 ball bearings (they are 25 shaft inner diameter) with 60x20x2 aluminium arms. I'll describe how I make it in the next blog.

-

@joergs5 said in Robot Type 1 45 cm - belt gear - direct drive - R0:

I plan to use concrete to surround the printer later, it's easy and cheap

On my CNC I filled the 2040 aluminum extrusions with a mix of fine sand (meant for sandblasting) and epoxy resin. (90% sand, 10% resin IIRC)

It's not easy to fill, better use slow curing resin or very thin concrete?

or very thin concrete?

-

@o_lampe I would say, it depends... For reducing vibrations, it's better if the sand has some room and can take the energy of the vibration by moving itself, so no epoxy. Otherwise the whole construction starts to vibrate (but at a different frequency). The idea of concrete around the printer was to hinder the printer from moving. There are different methods and goals. One of the advantages of your method is that it looks nicer.

-

The idea of concrete around the printer was to hinder the printer from moving. There are different methods and goals.

Well, it's not an either / or decision, you can do both.

-

@o_lampe I totally agree. If I continue as before, my robot prototype will end as a heavy weight commercial robot clone. But that's ok. It will be stiff enough to take a CNC milling head.

-

This post is deleted!