3D printin issues on a core XY equiped with a duet wifi

-

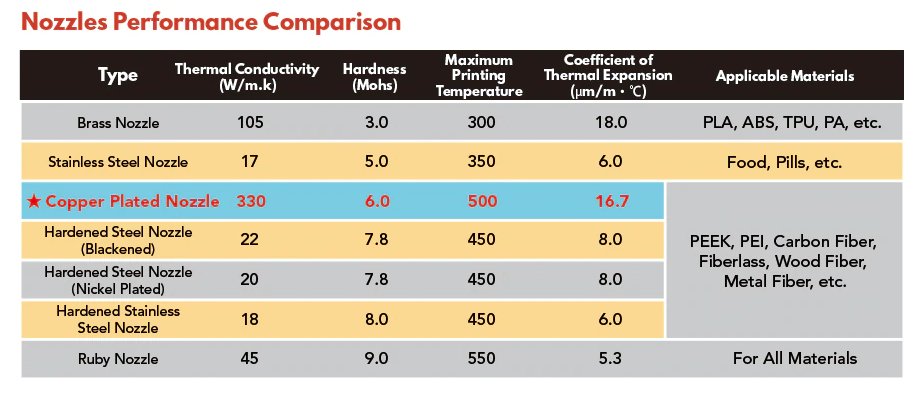

@Veti It's not a brass nozzle ; reinfoced steel. I plan on having a look at it after it's gone thru a spool of filament.

-

@campeancalin said in 3D printin issues on a core XY equiped with a duet wifi:

reinfoced steel.

that is ok for wear, but very bad for temperature transfer.

i would suggest that you print a temperature tower.

-

I have a little problem with the PID tunning. Once I've changed the values , it gives me the following error message:

M307 H1 S285Error: M307: bad model parameters

-

; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S250 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M308 S2 P"e1temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 2 as thermistor on pin e1temp

M950 H2 C"e1heat" T2 ; create nozzle heater output on e1heat and map it to sensor 2

M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit -

@campeancalin M303 is used to PID tune, not M307

-

@jay_s_uk Thank you

-

@campeancalin said in 3D printin issues on a core XY equiped with a duet wifi:

M143 H0 S250 ; set temperature limit for heater 0 to 120C

can you bed really reach 250C? the bed does not look like the special e3d high temperature bed. and those can reach 250, but should not be operated above 200C

-

@Veti No. I've PID tunned it for a max temp of 100 C

-

@campeancalin PID doesn't set a max temperature, the M143 does.

-

@campeancalin

Looking at the pictures, either you are over-extruding or your first layer is too low (which means you are trying to fit too much material in too little space). That causes material to push up higher than it should, and if the nozzle runs into those lumps it tends to cause layer shifts.And if you don't have one already, get a filament drier, CF filled filaments absorb moisture like crazy and need to be dried. If you look closely you might be able to see the filament bubbling as it comes out of the nozzle. Drying the filament for at least 24 hours will make a huge difference to both print quality and material strength.

-

How many walls are you using? Are you using concentric infill?

It's typical to use only a few walls and solid or rectilinear infill for the rest. Using too many walls can lead to over extrusion building up.