Do Linear Rails Perform Well Under Cantilever Loads?

-

@Turbo said in Do Linear Rails Perform Well Under Cantilever Loads?:

@achrn I think? the center of gravity or the bed and anything attached to it, is where the belt lies. I can (shouldn't, but i can) actually print without the linear guides due to the balance, but the ringing is comical.

In that case I don't think there can be any (significant) moment on the guides, they are just being guides. I definitely wouldn't want to set up any opportunity for two linear guides to be fighting each other.

-

@achrn you could install two guides "fighting each other", but then better as in a CNC machine one as fixed bearing and floating bearing solution. But imho in this case there is not much win, because there is not much load.

-

-

@Turbo from my view, this is correct.

-

@JoergS5 Awesome, thanks for the input. I suppose i now need to convert my other printer to a linear rail z axis with my extra rails

-

@Turbo I like them, but there are quality differences. I discovered one yesterday which is rusted, it is worth to maintain them a bit.

-

@JoergS5 I find that keeping a thin layer of lubricant on the rails helps with rusting. But yeah I actually have some surface rust on some other rails that sat for some months I was gone and no one cleaned them at all. These are LDO Rails from Printed Solid's shop. 400mm. Good Stuff

-

Hi,

There many different designs out there in the real world, some good, some bad.

I had a DBot for a while but didn't like it's design, so I took it apart and started over.

I tried 4 guide rods (12mm dia) with two lead screws (8mm dia, 8mm pitch), one Z stepper, like my FT-5.

I tried 4 guide rods (12mm dia) with three lead screws (8mm dia, 8mm pitch) and three Z steppers for auto-leveling.

I now have 4 linear guides and two lead screws (12mm dia 2mm pitch), one Z stepper.

That is working pretty well but I'm still getting some minor Z banding (I think that is what it is).

My next experiment, if I get the motivation, is to try two lead screws (8mm dia, 8mm pitch) with attached steppers, to eliminate the belt in the current single stepper design which places a sideways load on the lead screws.

I may even try three of the lead screw/stepper combos and give auto-leveling another go.

I'm having fun.

Frederick

-

@fcwilt sounds like a fun project. Ever since I saw the Voron2, I've loved the idea of a belted Z axis, and it is really nice. No z banding to worry about assuming everything else it running smooth. Maybe consider what ive done and go belted. No lead screws to mess with

-

@Turbo said in Do Linear Rails Perform Well Under Cantilever Loads?:

@fcwilt sounds like a fun project. Ever since I saw the Voron2, I've loved the idea of a belted Z axis, and it is really nice. No z banding to worry about assuming everything else it running smooth. Maybe consider what ive done and go belted. No lead screws to mess with

I'm always up for trying different things.

How many belts? How many steppers?

Thanks.

Frederick

-

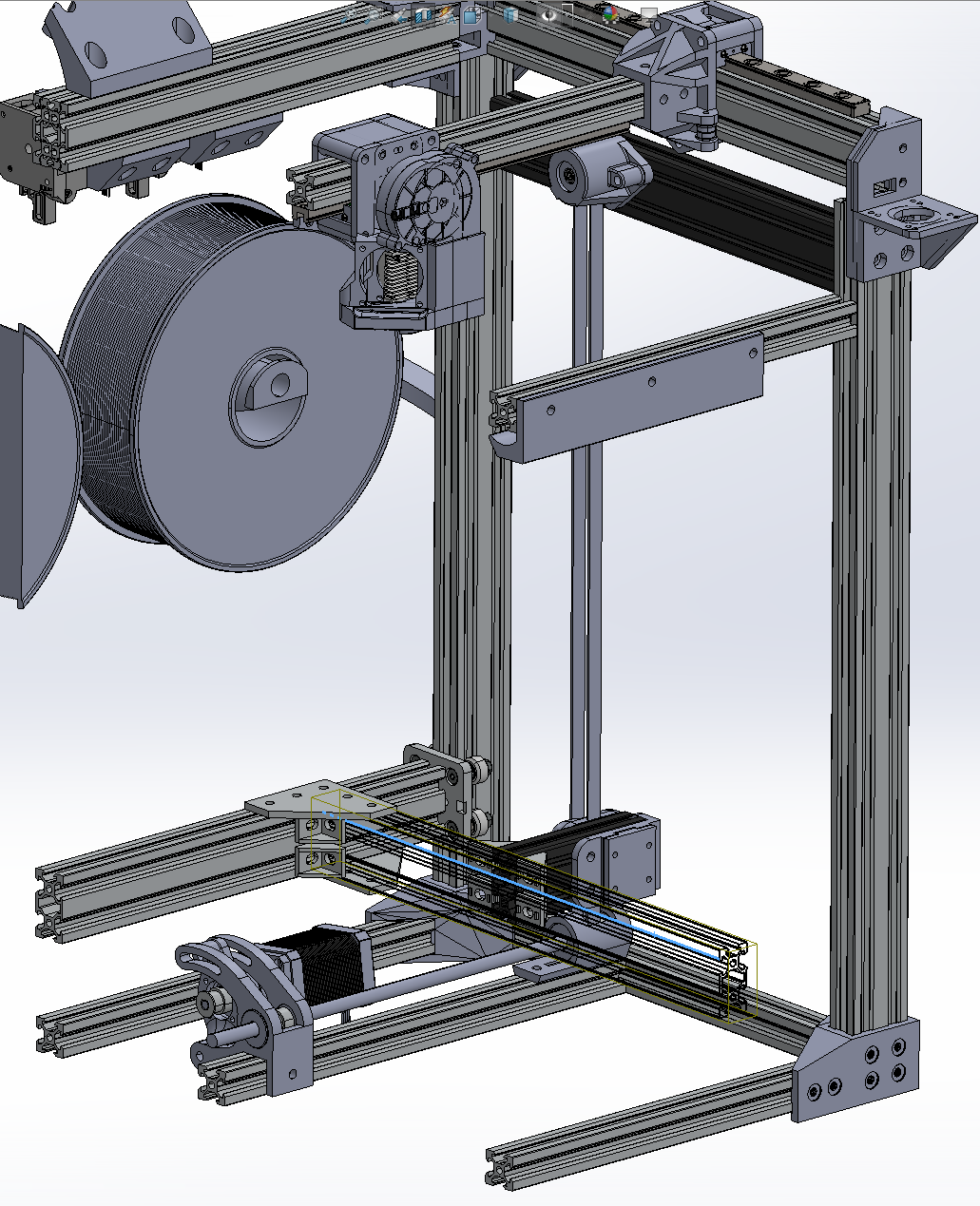

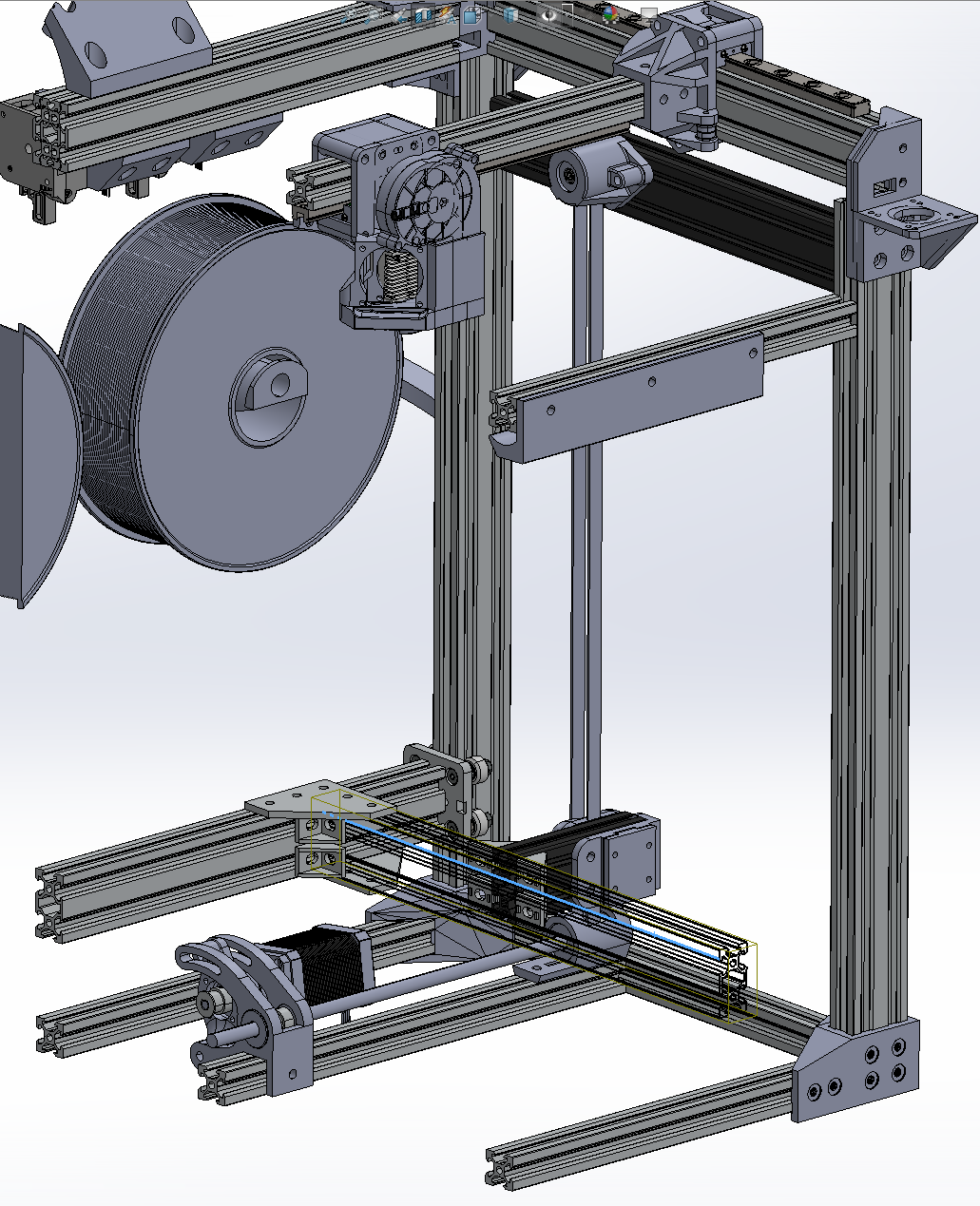

@fcwilt two belts. One stepper, which is geared 5:1, and a large rod to sync them up.

Here's a section view of one side.

-

Interesting?

What size belts?

Where did you get that kind of stepper?

Part #?

Thanks much.

Frederick

-

- Gt2 9mm width x 2. Dont know the exact length offhand

- Motor part # --> 17hs15-1684s-pg5

*Link to motor --> https://www.omc-stepperonline.com/nema-17-stepper-motor-bipolar-l38mm-w-gear-raio-51-planetary-gearbox-17hs15-1684s-pg5.html

-

@Turbo said in Do Linear Rails Perform Well Under Cantilever Loads?:

- Gt2 9mm width x 2. Dont know the exact length offhand

- Motor part # --> 17hs15-1684s-pg5

*Link to motor --> https://www.omc-stepperonline.com/nema-17-stepper-motor-bipolar-l38mm-w-gear-raio-51-planetary-gearbox-17hs15-1684s-pg5.html

Thanks VERY much for that info.

I may have to try this as it is unlike any other approach I have used.

Frederick

-

@Turbo said in Do Linear Rails Perform Well Under Cantilever Loads?:

@achrn @JoergS5 So what im getting from this is that so long as I'm off-putting the main load onto something else, and primarily using the rails just as an alignment factor, it's fine. Sound about right?

(I think you've already reached this conclusion, but...) From the 3D picture, and assuming the linear rails have replaced the four wheel carriage that's back central in that view, yes, I think that rail is actually carrying next to no loads in any direction - it's just stopping the platform swinging round on the belt. (Though it obviously doesn't swing free since the belt is restrained top and bottom). My initial understanding (assumption) was that you had the belt only on one side (i.e. as if the diagram shows the whole drive mechanism) - then there would have been a significant moment on the carriage.

-

@Turbo said in Do Linear Rails Perform Well Under Cantilever Loads?:

@fcwilt two belts. One stepper, which is geared 5:1, and a large rod to sync them up.

Here's a section view of one side.

Hi,

I've decided to go ahead and try belts of my Z axis.

Do you have any link(s) to more images or 3D models of your printer that I could look at?

Thanks.

Frederick

-

@fcwilt It's not my design, but this was the designers printer before he moved and gave it to me. He also gave me the CAD files, so if you PM me, I'm sure i can email or discord you the related files.

-