Creating a new IDEX 3D Printer with Duet 2 WIFI

-

; homeall.g

; called to home all axesM106 P0 S0 ; Part cooling Fan off

G91 ; relative positioningG1 H2 Z5 F6000 ; lift Z relative to current position

G1 H1 X-650 Y-550 U650 F5000 ; first pass XYU

G1 H2 X5 Y5 U-5 F6000 ; go back a few mm

G1 H1 X-20 Y-20 U20 F360 ; second pass XYG90 ; absolute positioning

G1 X0 Y0 U600 F8000 ; first bed probe point -> move X to the middle of the Bed, U outside and home ZG30

; homeu.g

; called to home the U axis

;

; generated by RepRapFirmware Configuration Tool v3.1.4 on Tue Aug 25 2020 12:07:49 GMT+0200 (Mitteleuropäische Sommerzeit)

G91 ; relative positioning

G1 H1 U215 F1800 ; move quickly to Y axis endstop and stop there (first pass)

G1 H2 U-5 F6000 ; go back a few mm

G1 H1 U215 F360 ; move slowly to Y axis endstop once more (second pass)

G90 ; absolute positioning; homex.g

; called to home the X axis

;

; generated by RepRapFirmware Configuration Tool v3.1.4 on Tue Aug 25 2020 12:07:49 GMT+0200 (Mitteleuropäische Sommerzeit)

G91 ; relative positioning

G1 H1 X-215 F1800 ; move quickly to Y axis endstop and stop there (first pass)

G1 H2 X5 F6000 ; go back a few mm

G1 H1 X-215 F360 ; move slowly to Y axis endstop once more (second pass)

G90 ; absolute positioning

homex.g; homey.g

; called to home the Y axis

;

; generated by RepRapFirmware Configuration Tool v3.1.4 on Tue Aug 25 2020 12:07:49 GMT+0200 (Mitteleuropäische Sommerzeit)

G91 ; relative positioning

G1 H1 Y-215 F1800 ; move quickly to Y axis endstop and stop there (first pass)

G1 H2 Y5 F6000 ; go back a few mm

G1 H1 Y-215 F360 ; move slowly to Y axis endstop once more (second pass)

G90 ; absolute positioning

homey.g; homez.g

; called to home the Z axis

;G91 ; relative positioning

G1 H2 Z5 F6000 ; lift Z relative to current position

G1 X20 Y20 U0 F800 H2 ; lift Z relative to current position

G1 H1 Z-400 F400 ; move Z DOWN until the endstop is triggered

G92 Z0 ; set Z position to axis minimum (you may want to adjust this)

homez.g; pause.g

; called when a print from SD card is paused

;M83 ; relative extrusion

G1 E-2 F3600 ; retract 2mm

G91 ; relative movement

G1 Z2 F500 ; raise head 2mm

G90 ; absolute movement

G1 H1 X-200 U200 F6000 ; park both heads

pause.g; tfree0.g

;G28 X U ; home the X and U carriages

M83 ; relative extruder movement

G1 E0 F3600 ; retract 2mm

M106 S0 ; turn off our print cooling fan

G91 ; relative axis movement

G1 Z3 F500 ; up 3mm

G90 ; absolute axis movement

G1 S2 X0 F6000 ; park the X carriage at -48mm;tfree1.g:

;G28 X U ; home the X and U carriages

M83 ; relative extruder movement

G1 E0 F3600 ; retract 2mm

M106 S0 ; turn off our print cooling fan

G91 ; relative axis movement

G1 Z3 F500 ; up 3mm

G90 ; absolute axis movement

G1 S2 U0 F6000 ; park the U carriage at +248mm;tfree2.g:

M83 ; relative extruder movement

G1 E0 F3600 ; retract 2mm

M106 S0 ; turn off our print cooling fan

G91 ; relative axis movement

G1 Z3 F500 ; up 3mm

G90 ; absolute axis movement

G28 X U ; home the X and U carriages;tfree3.g:

M83 ; relative extruder movement

G1 E0 F3600 ; retract 2mm

M106 S0 ; turn off our print cooling fan

G91 ; relative axis movement

G1 Z3 F500 ; up 3mm

G90 ; absolute axis movement

G28 X U ; home the X and U carriages

M579 U1; tpost0.g

M106 R2 ; restore print cooling fan speed

M116 P0 ; wait for tool 0 heaters to reach operating temperature

M83 ; relative extruder movement

G1 E2 F3600 ; extrude 2mm;tpost1.g:

M106 R2 ; restore print cooling fan speed

M116 P1 ; wait for tool 1 heaters to reach operating temperature

M83 ; relative extruder movement

G1 E2 F3600 ; extrude 2mm;tpost2.g:

M106 R2 ; restore print cooling fan speed

M116 P2 ; wait for tool 2 heaters to reach operating temperature

M83 ; relative extruder movement

M567 P2 E1:1 ; set tool mix ratio

M568 P2 S1 ; turn on mixing

G1 E2 F3600 ; extrude 2mm from both extruders;tpost3.g:

M106 R2 ; restore print cooling fan speed

M116 P2 ; wait for tool 2 heaters to reach operating temperature

M83 ; relative extruder movement

M567 P2 E1:1 ; set tool mix ratio

M568 P2 S1 ; turn on mixing

G1 E2 F3600 ; extrude 2mm from both extruders

M579 U-1; bed.g

; called to perform automatic bed compensation via G32

;

; generated by RepRapFirmware Configuration Tool v3.1.3 on Fri Jun 19 2020 21:08:48 GMT+0200 (Mitteleuropäische Sommerzeit)M561 ; clear any bed transform

G28

G29 ; probe the bed and enable compensation -

M584 X0 Y1:4 U3 Z2 E5:6 ; set drive mappingWhy Y1:4? Two Y axis motors? Or no? (M569 you defined 6 motors).

; Endstops M574 X1 S1 P"!xstop" ; configure active-high endstop for low end on X via pin xstop M574 Y1 S1 P"!ystop" ; configure active-high endstop for low end on Y via pin ystop M574 U2 S1 P"!e0stop" ; configure active-high endstop for low end on U via pin ustop ; Z-Probe M558 P1 C"!^zprobe.in" H5 F120 T6000 ; Set Z probe type to inverted, unfiltered piezo and the dive height + speeds G31 P700 X0 Y0 U0 Z-0.2 M557 X-98:98 Y-98:98 S70 ; Define mesh gridDo you need a M574 for the Z-Probe? I think yes but double check. Right now Z-probe endstop configuration (M574) is undefined.

M557 - S70 seems large compared to the bounds (098 to 98)? Can you do, say, M557 X-100:100 Y-100:100 S20? S70 is unusual

To use Mirror or Copy, your print file GCODE must select T2 or T3. You can use standard Cura, slice the file, and then replace all instances of Cura-created T0, (or even T1) with T2 or T3 so long as you take care in where you slice the object on the build plate. This is still tricky.

Do not use BCN3D Cura for Mirror/duplication mode (copy, etc) as BCN3D uses a custom version of Marlin. In their mirror/copy GCODE files, they send a custom GCODE command to tell the machine to mirror or copy. They also modify the area you can place models in their Cura software to ensure the machine does not crash.

I recommend solving one problem at a time.

First solve Bed leveling

Then solve Blower fans (these are the part cooling fans, not the heatsink fans correct?) -

@sebkritikel Thanks for the answer.

I really forgot to point out. I have one motor for each axle.

I read somewhere on the site that if I create an additional X axis, then I must also create a Y axis. maybe I was wrong.

Possibly the Z axis positioning sensor is incorrectly set but it works.

the bed rises up hits the extruder and falls down so we get point 0. I would also like to have the sensor check the entire bed for evenness.

You're right, the radiator blower is working properly.

blower fan printed parts does not start -

I also forgot to say that I decided to use positioning in the center of the bed -

@DE-TechArt said in Creating a new IDEX 3D Printer with Duet 2 WIFI:

I read somewhere on the site that if I create an additional X axis, then I must also create a Y axis. maybe I was wrong

No, you don't need to create an additional Y axis, unless you actually have two Y axes. A standard IDEX has one Y axis and two X axes. The second X axis in RRF is normally called the U axis.

-

@DE-TechArt said in Creating a new IDEX 3D Printer with Duet 2 WIFI:

; homeall.g

; called to home all axesM106 P0 S0 ; Part cooling Fan off

G91 ; relative positioningG1 H2 Z5 F6000 ; lift Z relative to current position

G1 H1 X-650 Y-550 U650 F5000 ; first pass XYU

G1 H2 X5 Y5 U-5 F6000 ; go back a few mm

G1 H1 X-20 Y-20 U20 F360 ; second pass XYG90 ; absolute positioning

G1 X0 Y0 U600 F8000 ; first bed probe point -> move X to the middle of the Bed, U outside and home ZG30

; homez.g

; called to home the Z axis

;G91 ; relative positioning

G1 H2 Z5 F6000 ; lift Z relative to current position

G1 X20 Y20 U0 F800 H2 ; lift Z relative to current position

G1 H1 Z-400 F400 ; move Z DOWN until the endstop is triggered

G92 Z0 ; set Z position to axis minimum (you may want to adjust this)

homez.g; bed.g

; called to perform automatic bed compensation via G32

;

; generated by RepRapFirmware Configuration Tool v3.1.3 on Fri Jun 19 2020 21:08:48 GMT+0200 (Mitteleuropäische Sommerzeit)M561 ; clear any bed transform

G28

G29 ; probe the bed and enable compensationYour bed.g looks fine, however at the end of my homeall.g and homez.g I have "G29 S1" to load my heightmap.

Have you been able to run a full bed probing? G29? I think you need to change your M557, as you have your bounds set to a 196mm length for each axis, divided by 70mm spacing..... Or try -95 to 95, with a spacing of 19mm (S19). 70mm is too large I think, especially for your bed size, to give a good bed leveling result, excluding the fact it does not divide nicely into 196.

-

Hey. I'm new to 3D printers. but I want to create my own. body and kinimatics are. Can you help me set up the control board?

-

@sebkritikel No, I was unable to run a full bed probing. I don't quite understand how I can run this. for a start, I think that four points will be enough -95 and 95

-

@sergei I think on my example you and others can create your own project.

-

@DE-TechArt said in Creating a new IDEX 3D Printer with Duet 2 WIFI:

@sebkritikel No, I was unable to run a full bed probing. I don't quite understand how I can run this. for a start, I think that four points will be enough -95 and 95

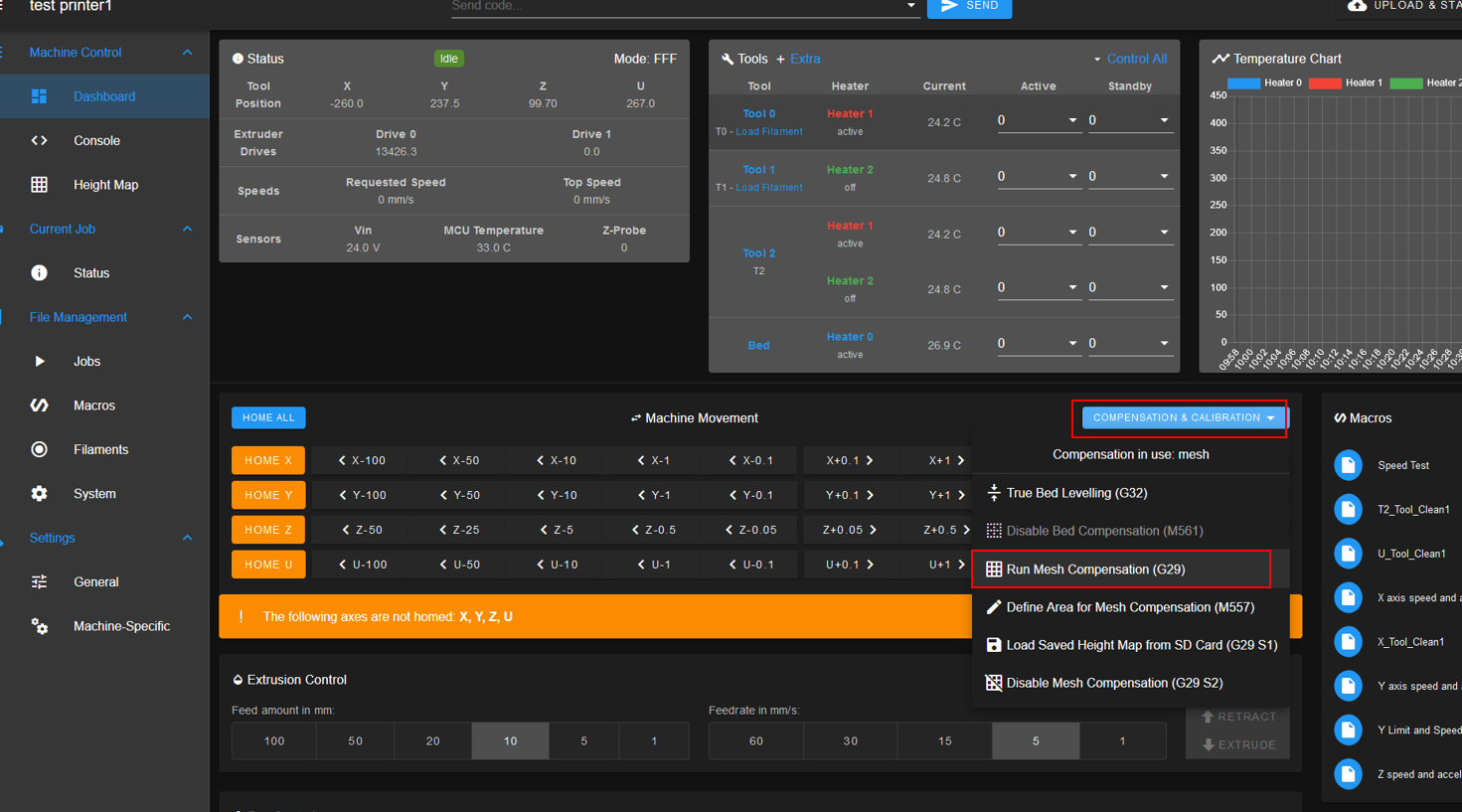

I think you will want a greater fidelity... but lets start with something that divides nicely into your bounds... For reference, on my IDEX machine I have "M557 X-220:160 Y-200:200 S20:25 ; define mesh grid" and many other times you will see folks with spacing of 20-25mm.

https://duet3d.dozuki.com/Wiki/Using_mesh_bed_compensation

Simply put - what happens when you type and send G29 in the console? Can also click here:

Have you corrected the additional Y-axis comments DC42 brought up? You have your X-axis, which is the T0 (left I assume) hotend. You have the U-axis, which is the T1 (right I assume) hotend. You have one Y-axis - that is driven by only one motor correct? Should be "M584 X0 Y1 U3 Z2 E5:6 ; set drive mapping " correct?

Happy to help!

-

@sebkritikel Thank you for the tips. as I said, without your help I cannot cope.

G31 P700 X0 Y0 U0 Z0

M557 X-98:98 Y-98:98 S20:25 ; Define mesh grid

I changed the G-code and now the mesh bed probes are working. all that remains is to adjust the speed and acceleration.The next problem is getting the printer to work in parallel and mirrored.

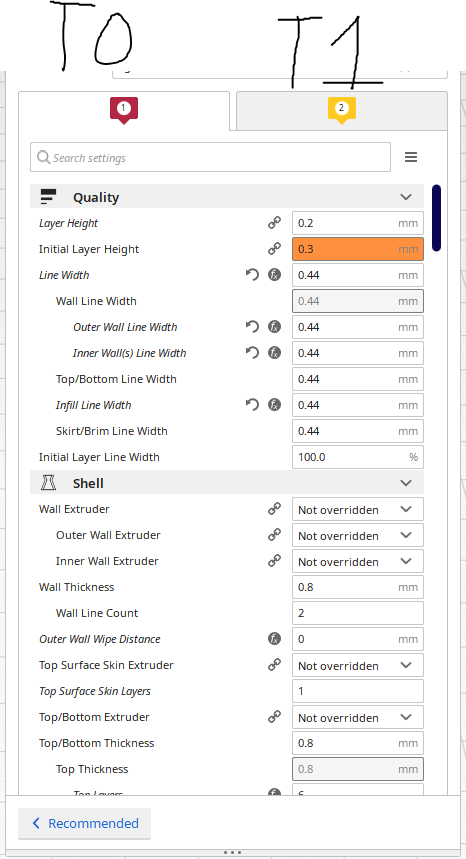

it is not clear to me where in cura should I indicate T1 T2 and T3?

Just in the starter G-Code? I think it's not very convenient to edit the parameters of the 3d printer every time -

I also changed set drive mapping

M584 X0 Y1 U3 Z2 E5:6 ;and added at the end Homeall.g and homez.g

G29 S1 -

@DE-TechArt said in Creating a new IDEX 3D Printer with Duet 2 WIFI:

@sebkritikel Thank you for the tips. as I said, without your help I cannot cope.

G31 P700 X0 Y0 U0 Z0

M557 X-98:98 Y-98:98 S20:25 ; Define mesh grid

I changed the G-code and now the mesh bed probes are working. all that remains is to adjust the speed and acceleration.The next problem is getting the printer to work in parallel and mirrored.

it is not clear to me where in cura should I indicate T1 T2 and T3?

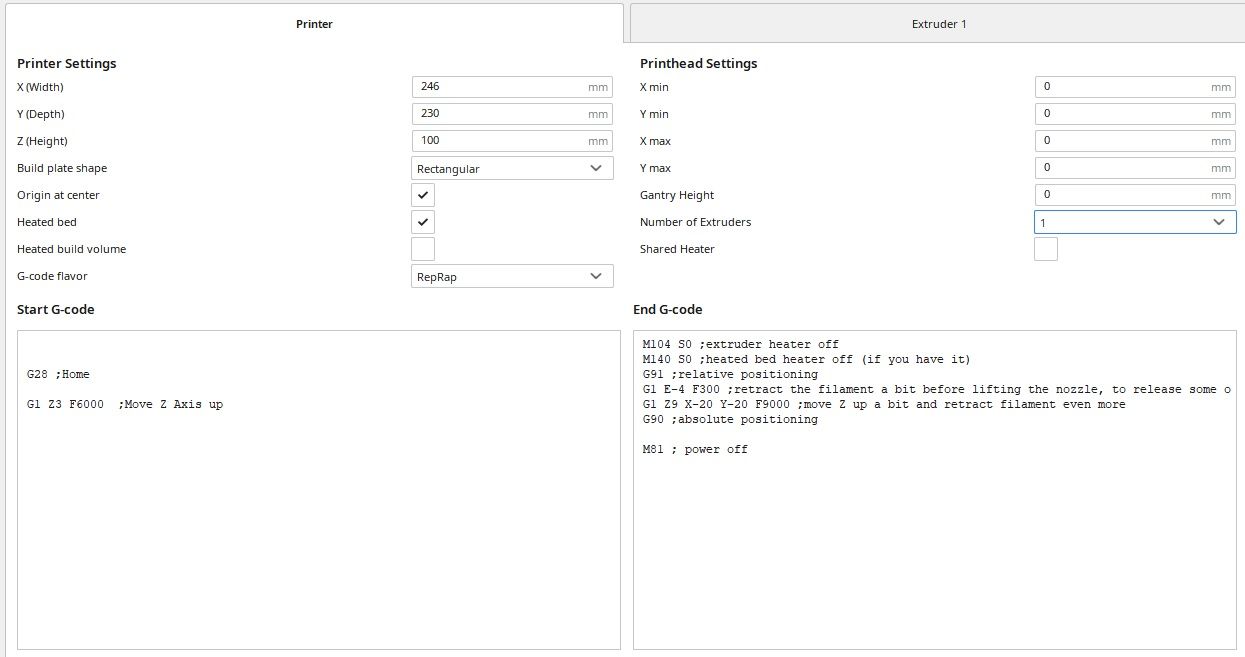

Just in the starter G-Code? I think it's not very convenient to edit the parameters of the 3d printer every timeFor standard dual extrusion, this is how I use Cura

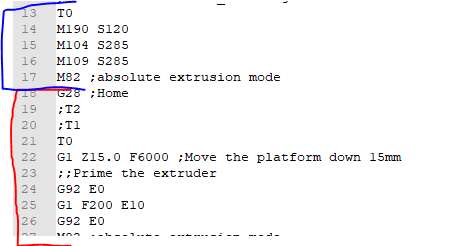

The start GCODE is very important for me. Cura is not a perfect software, and has some quirks. Before the start GCODE, Cura actually calls the tool for the start of the print, see below - T0 is called before my start script

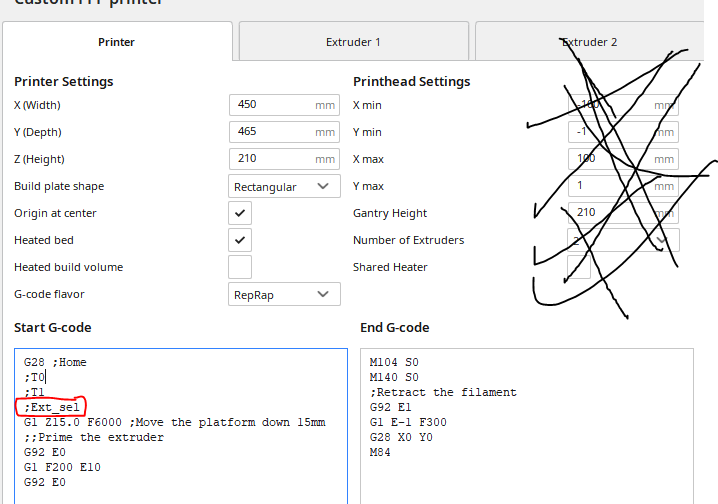

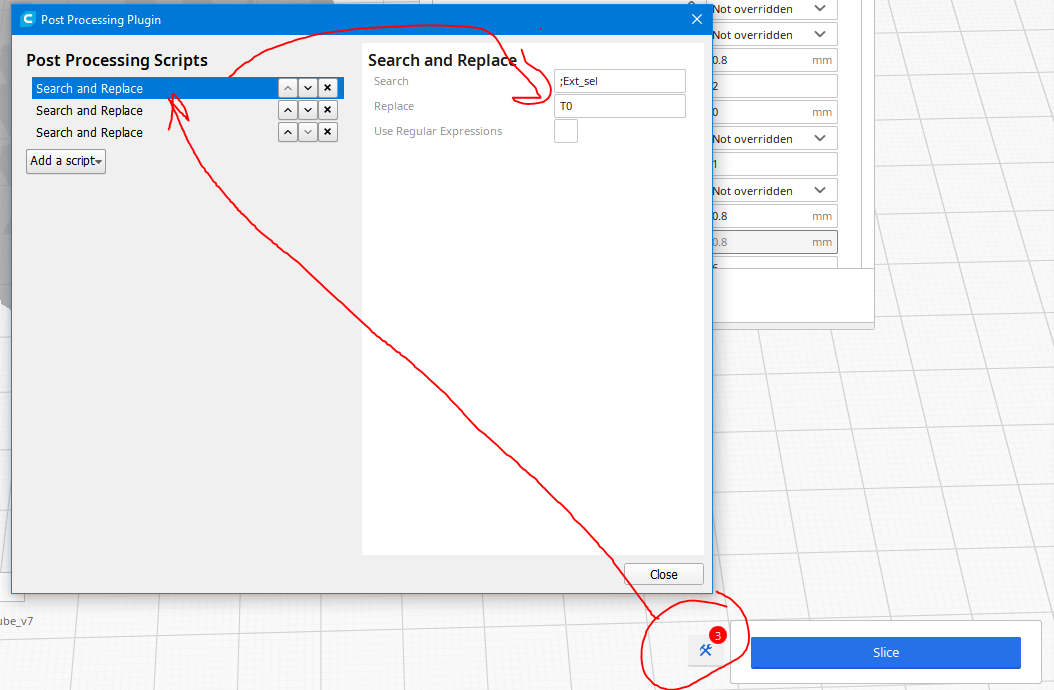

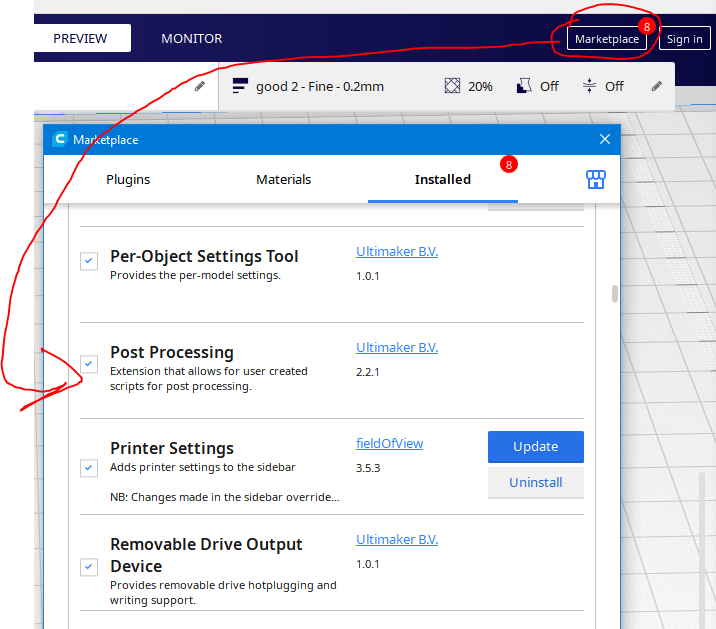

In my homeall.g, I actually need to deselect the current tool using T-1 P0, otherwise if I'm printing with T1, T2, etc, Cura tricks my machine into trying to Z probe with the wrong tool(s). I added the ;Ext_Sel line into my start GCODE, and then use the Post Processing Plugin to manually select the proper starting tool.

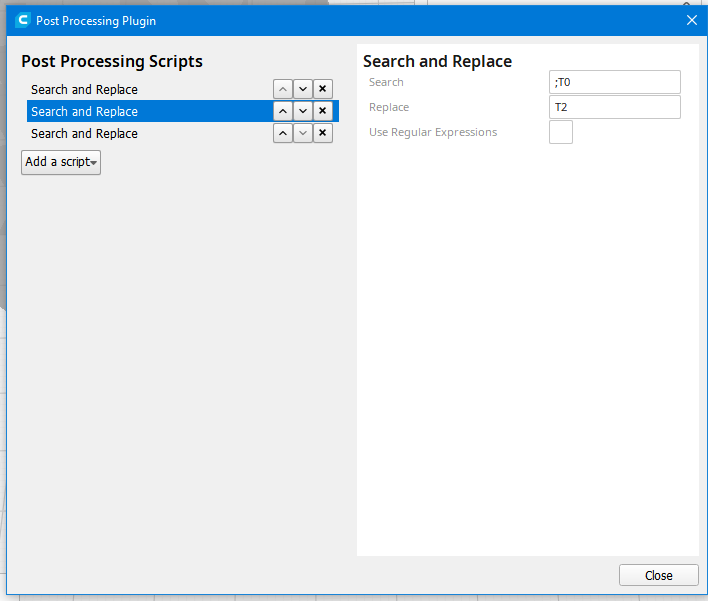

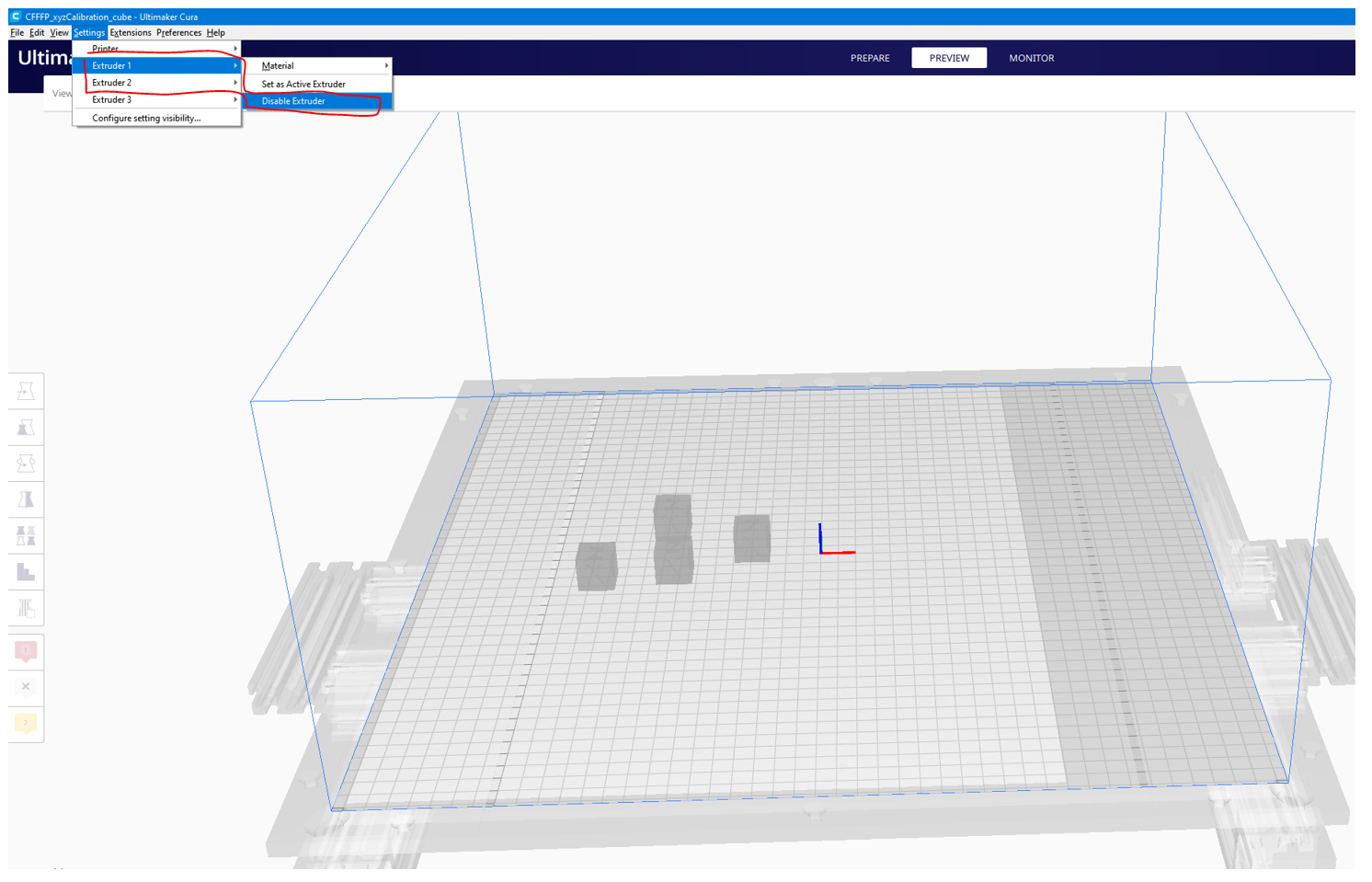

For specifically duplication and mirror modes, I have a SECOND post processing script to change all mentions of T0 or T1 to T2. This one is silly, but I do it instead of creating another tool/extruder in Cura. I slice it for T0 (typically), do my first search and replace script to change ;Ext_Sel to T2 (to specify the tool after my G28 in start GCODE), and then a second search and replace script to change T0 anywhere else to T2 (specifically the FIRST tool mention created by Cura before the start gcode is made, the section in blue from the notepad file a few pictures up).

If not using T2, it must say ";T2" instead of "T2" - or T3 for mirror, etc.I think there are better ways of doing some of that... unfortunately the Duet board and firmware is much smarter and more configurable than Cura....

-

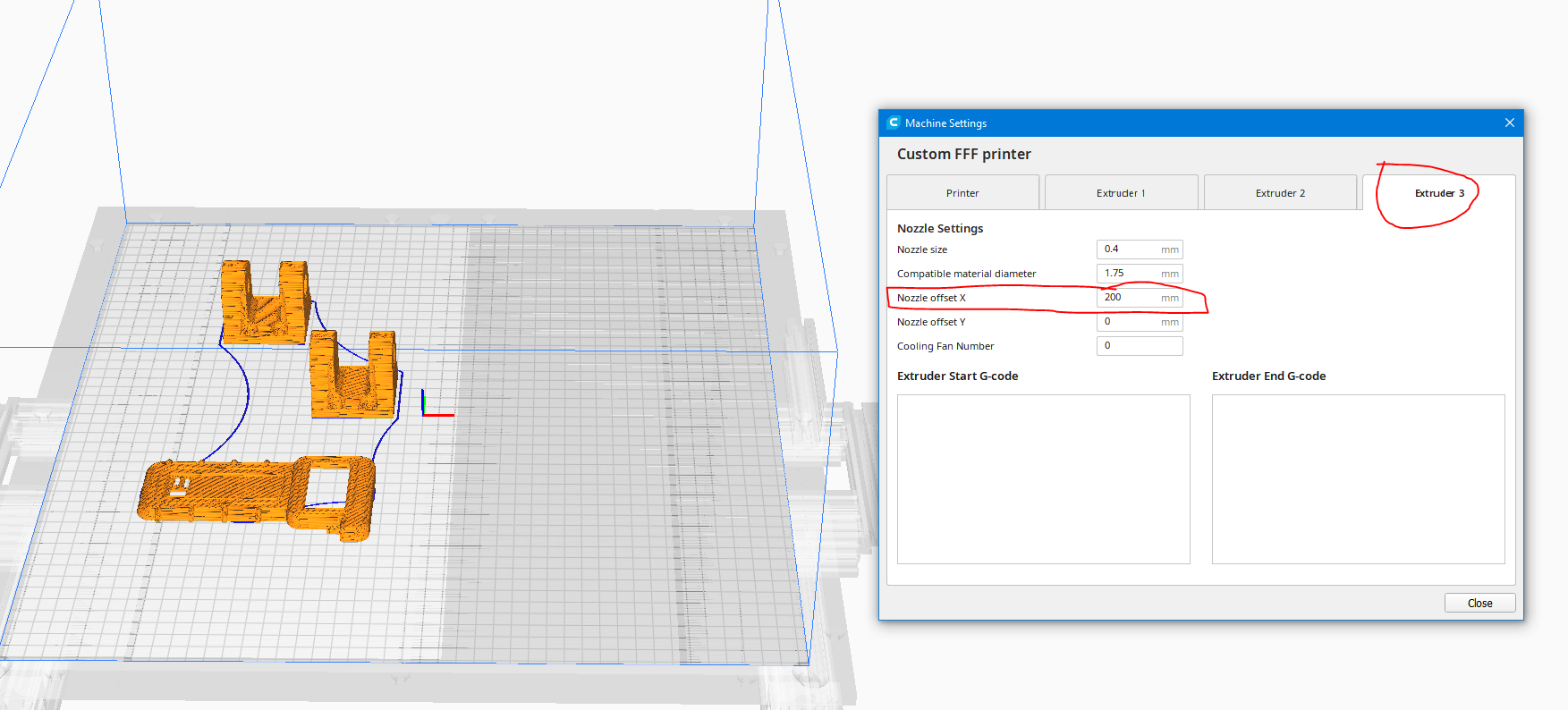

I think a better option is to create a third "extruder" in Cura through the "Machine Settings" window, and selecting a sufficient X or Y nozzle offset to split the bed in half or so, leaving space for the Duet firmware to map the movement to the U-axis.

I have not tried this yet, but I think this would be much easier. An important note - my T2 offset is different than yours, I did not offset the X axis, and instead only offset the U axis. This suggestion with Cura might not work with how you have offset the X and U axis - more investigation needed.M563 P2 D0:1 H1:2 X0:3 ; tool 2 uses both extruders and hot end heaters, maps X to both X and U G10 P2 X0 Y0 U-263.5 S0 R0 ; set tool offsets and temperatures for tool 2Strike that, I hadn't actually selected T2 (Extruder 3) as the print tool. By adding Extruder 3 it split the buildplate for T0/T1, not just T2. When you select T2, it actually makes the entire print surface unusable - wtf Cura.

-

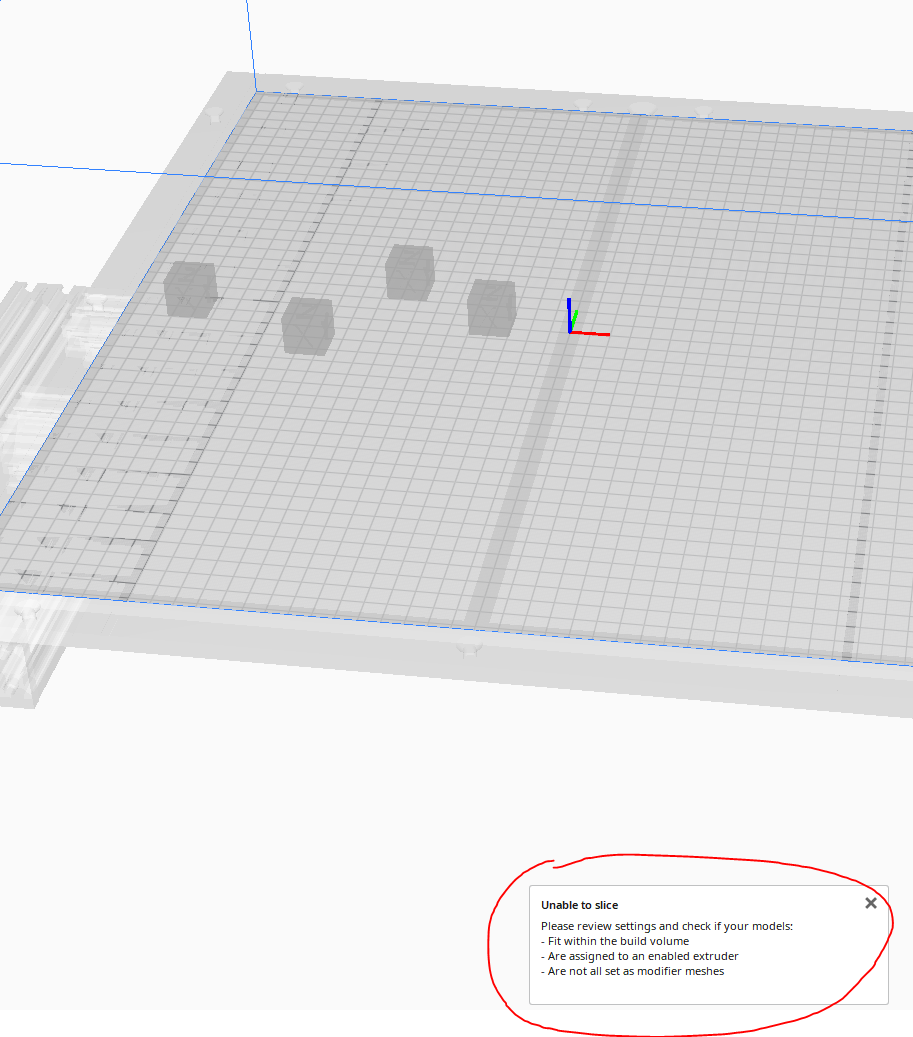

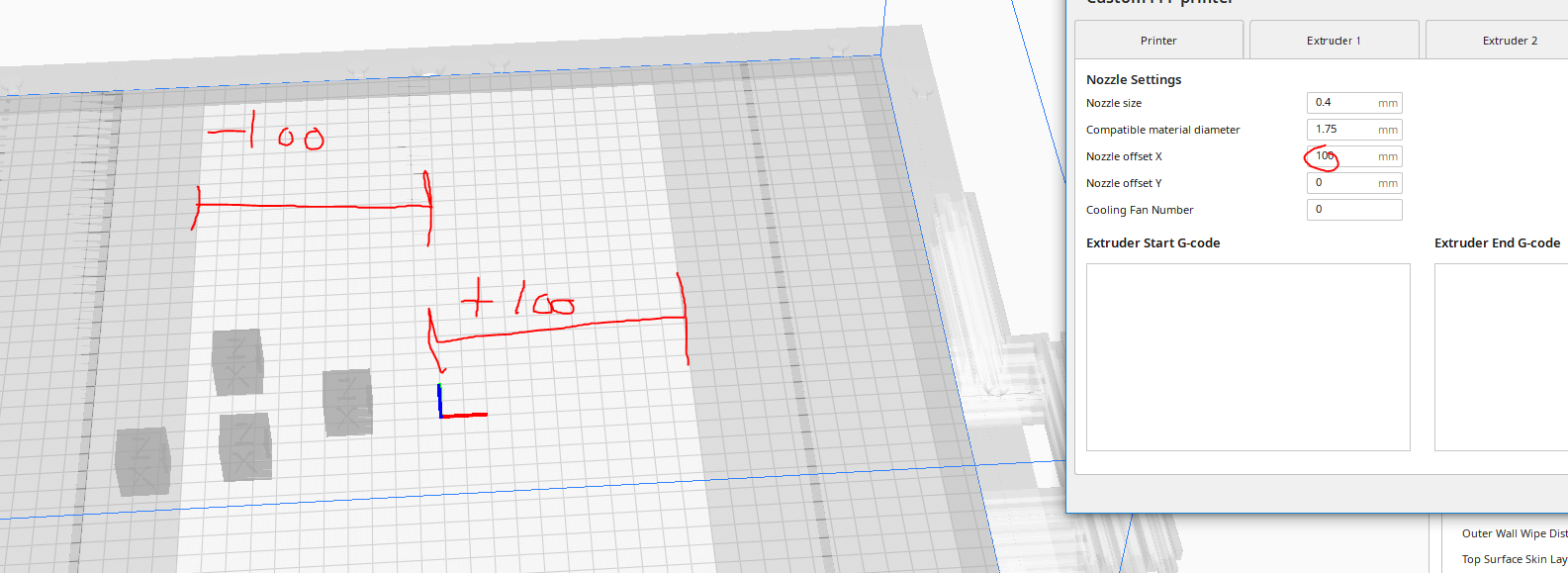

Getting closer, but still not quite right. Some funky stuff going on in the background w/Cura.

With "Origin at Center" the previously entered X offset applies starting at the origin... but only if tools T0 and T1 (extruder 1 and 2 in cura) are disabled. Whatever you enter - such as 100mm, is for only one direction, therefore the overall width would be 2x (200 mm for example).

However, any combination of having T0, T1 active, with T2 both active as well disabled, results in the right hand side available build surface being truncated by whatever the X offset is set to (loss of 100mm. If the offset was -100mm, it happens to the left side of the bed, as expected). I don't understand the reasoning why... If T2 is disabled, why is the offset being applied? Is Cura really assuming that T2 will always travel during printing (a single gantry/print head), and thus must limit that offset amount? I think that is shortsighted... but perhaps the alternative is as well. I just tried expanding the machine X total print width from 450mm to 650mm in Cura (double the X offset in T2) which solves the T0, T1, T2 combo issue, but then that totally messes up the T2 only print area. Stumped for now........

-

@sebkritikel This is a rather complicated method. I do not think that a beginner and an ordinary consumer can handle it.

And why are you against bcn3d Cura? it was designed specifically for IDEX printer -

@dc42 the developers of Duer3D and RepRap were able to create such complex software and nevertheless do not have detailed instructions for setting up an IDEX printer, the process of slicing, extruder selection, initial and final GCode, Slicer selection and much more are not described. Perhaps I missed something and such an instance exists?

-

@dc42 I also have one question. I am going to use Duet equipment in my invention and further replicate it, can I get support from the software developers in my printer settings?

-

@DE-TechArt said in Creating a new IDEX 3D Printer with Duet 2 WIFI:

@dc42 the developers of Duer3D and RepRap were able to create such complex software and nevertheless do not have detailed instructions for setting up an IDEX printer, the process of slicing, extruder selection, initial and final GCode, Slicer selection and much more are not described. Perhaps I missed something and such an instance exists?

Have you read https://duet3d.dozuki.com/Wiki/ConfiguringMultipleIndependentXcarriagesCartesian#Section_Configuring_tools and the section on tool changing after? If so, what do you think is missing?

Generally our documentation covers setting up the Duet to work as transparently as possible with slicing software. However, setting up the slicing software is beyond our control, with so many options, though we will try to support you to get it working. With Duet customers building a huge range of exotic and wildly different machines, we are not able to create documentation for every conceivable permutation.

Ian

-

@DE-TechArt said in Creating a new IDEX 3D Printer with Duet 2 WIFI:

@sebkritikel This is a rather complicated method. I do not think that a beginner and an ordinary consumer can handle it.

And why are you against bcn3d Cura? it was designed specifically for IDEX printerCura is complex software, and has the capacity to create machine profiles for your customers to use. Have you tried creating a machine profile, extruder profiles, and print settings to match the capabilities of your machine? You can post on their forums for help potentially on creating Cura profiles for mirror/duplication mode, as that is more specific to Cura than Duet.

https://github.com/Ultimaker/Cura/wiki/Adding-new-machine-profiles-to-Cura

https://github.com/Ultimaker/Cura/wiki/Definition-Files-Explained

Example: https://github.com/Ultimaker/Cura/blob/master/resources/definitions/ultimaker_original.def.jsonFor my IDEX machine, I have been (slowly) creating the appropriate Cura definition files, and hope to one day make it seamlessly work with mirror and duplication modes, but I am not there yet.

The Duet electronics hardware, RepRapFirmware, and community here are excellent at creating machines with intricate macros, amazing kinematics - but some effort is on the individual 3D printer designer to put all of the final touches in place.

You can certainly experiment with the BCN3D Cura, but keep in mind a few things.

- It is a "fork" of a much older version of Ultimaker Cura

- It is designed for use with their custom version of the Marlin Firmware, not RepRapFirmware

https://github.com/BCN3D

https://github.com/BCN3D/Marlin

https://github.com/BCN3D/BCN3DSigmax-FirmwareHere is the start of a GCODE file made by BCN3D Cura for mirror mode. Marlin GCODE

;FLAVOR:Marlin ;TIME:8871 ;Filament used: 1.69044m ;Layer height: 0.15 ;Extruders used: T0 0.4 T1 0.4 ;BCN3D_FIXES ;Generated with Cura_SteamEngine 2.1.5 T0 M190 S60 M104 S190 M104 T1 S190 ;Fixed T1 temperature M109 S190 M109 T1 S190 ;Fixed T1 temperature M82 ;absolute extrusion mode ;Sigma ProGen 2.2.0 (Build 14CJ1301) ;BCN3D Fixes applied ; - Fix start GCode ; - Fix Acceleration/Jerk commands ; - Z Hop At Layer Change G21 ;metric values G90 ;absolute positioning M204 S600 ;set default acceleration M205 X12.5 Y12.5 ;set default jerk M107 ;start with the fan off G28 X0 Y0 ;move X/Y to min endstops G28 Z0 ;move Z to min endstops G1 Z5 F200 ;safety Z axis movement T1 ;switch to the right extruder G92 E0 ;zero the extruded length G1 F47.4 E15 ;extrude 15mm of feed stock G92 E0 G4 P2000 ;stabilize hotend's pressure T0 ;switch to the left extruder G92 E0 ;zero the extruded length G1 F47.4 E15 ;extrude 15mm of feed stock G92 E0 G4 P2000 ;stabilize hotend's pressure M605 S6 ;enable mirror mode M92 E510.9 M500 G4 P1 G4 P2 G4 P3 ;LAYER_COUNT:80 ;LAYER:0 M107 M204 S1175 M205 X9.38 Y9.38 G0 F3600 X31.809 Y179.29 Z0.2 M204 S470 ;TYPE:WALL-OUTERM605 S6 ;enable mirror mode

Is how the BCN3D printers know to switch to Mirror or duplication mode, however that is a custom command created by BCN3D, and not used in any other printer.

As far as additional hardware help - happy to be of assistance, however I do not know exactly how items like your fans are wired, what steps you have tried to troubleshoot problem areas, etc.