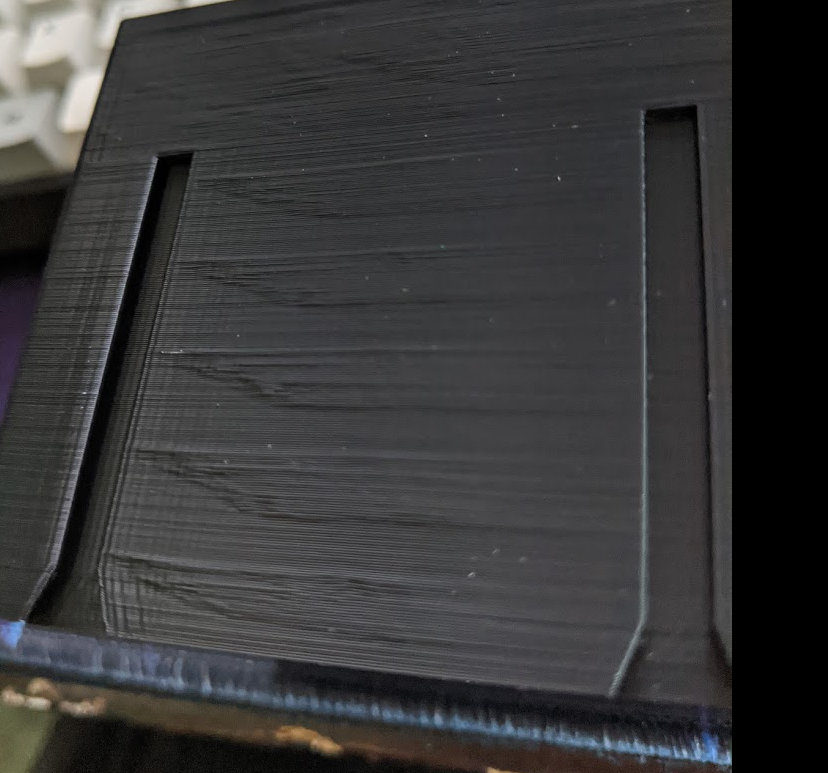

Issue with repeating z pattern on y axis only

-

Having issues with this weird repeating pattern. Its only appearing on the y axis, and I think its because of the directional change. What I don't understand is if its because of the direction change, why isn't it consistent on every layer? Any thoughts? -

What is the spacing between patterns? Is it 8mm, and if so do you have 8mm pitch lead screws? If so, it might have something to do with the Z lead screws. Although that is a pretty strange pattern!

-

each anomaly has a 4mm spacing of good print in between each one. the anomaly in question is 5mm tall.

-

@Turbo can you please include a photo of your printer, with an explanation of where the pattern occurs with relation to the printer?

-

@Leav It is motion based, not Z axis related. Testing another print shows that the sharp direction changes shown in my first image is what causes the pattern, as there is no issue with a print with no sharp changes. What I don't understand is why it follows a pattern, rather than it consistently doing this on every layer.

The printer is a prusa i3 style custom build. Same leadscrew and axis system, with the exception of linear rails on the y axis. Hemera hotend.

-

@Turbo my guess is that something is causing a blob at the corner. The next time the extruder passes over it, it gets knocked upwards/sideways by a few 100um which then messes up the next layer but a little bit further from the corner. Repeat that and you get a diagonal z pattern going upwards and away from the corner (similar to oozing when you have retraction set to low).

I'd first of all check your motion system. If its an i3 style, its easy to see how the x and y sides will be different. Could be some backlash in either one.

Next try playing with accel and jerk settings. Guessing your y axis should be lower than x as its got to move the whole bed.

After you've got them in, try pressure advance. I can see some excess extrusion at the corners. This may be from a mechanical/jerk issue, but a bit more PA might help reduce it.Out of interest is the pattern always at 4mm z spacing? Is it repeatably at the same heights even if you do a print with a smooth section at the bottom?

-

@engikeneer Acceleration, Jerk, and PA have been tuned, and they're quite conservative. Not trying to break any speed records yet. Smooth sections with no sharp direction change result in a smooth surface as expected, no pattern. I don't see the excess extrusion on the corner you're referring too on the print, however it may just be a bad angle of the picture.

-

@Turbo Below is what I was referring to. Circled in red is the artifect on the sharp corner (maybe blob was the wrong word...). To me, this looks like a slight over extrusion at the nozzle slowed down/stopped at the corner (coming out of the screen towards us), then an under extrustion as it starts accelerating to the right. Most likely this just needs a bit more PA.

Also visible is a small amount of ringing marked in green. Likely not an issue, but just wanting to be clear what I am and am not talking about.

I guess to nail it down a bit more, I'd try repeating the print in different orientations (does it only come out on x-surfaces, or is it on Y-surfaces or 45degs too). Maybe also try printing the same object but with a tall raft or other smooth feature on the bottom 5mm. That way you can see if the anomolies occur a set Z-height (so maybe a Z-axis issue) or if it is just after so many layers with sharp corners (so a sharp corner issue that builds up).

Side note on jerk/accel/PA - I actually found when tuning my CoreXY that having slightly higher XY Jerk helped with sharp corners. I think this was because it meant the extruder didn't have to slow down/speed up as much at the corner. Obviously going too high will only cause mechanical issues and make things worse. You may well have already found your machines limits so apologies if I'm saying stuff you already know...

-

@engikeneer now I see what you're talking about, but the picture is kind of misleading. The ringing is pretty bad yes, but that corner isn't as overextruded as the picture makes it out to be.

And yea higher jerk and Accel will help with corners for the reason you give. the corner isnt my issue, its about the repeating pattern

-

@Turbo I guess my point is that it might be the corner artifact & ringing that then leads to the issue, given that you don't get those artifacts following smooth corners. (Edit: though if there isn't much on the corner I'm doubtful if that could be the issue too...)

Do you only get them on the x-face or is it on the y-face too?

-

@engikeneer only on the y faces

-

@Turbo hmm.... my thinking is that there might be a few things at play. The patterns are occurring regularly every 8mm up the print, and your leadscrews do have an 8mm lead (8mm per rev, assuming you're using a standard Prusa Z-axis). This suggests that there may be something going on with the Z-axis as @whopping-pochard mentioned. However, it is also only on the Y-face, following sharp corners suggesting that it is something X-Y motion or extrusion related.

Are you using bed mesh compensation? It could be that there is some small misalignment/issue in your Z-motion which only comes apparent following sharp corners (maybe too fast or two slow). I'm guessing your X & Y jerk/accel settings are quite different which will mean the motion will be different on the Y-face to the X-face. I don't know exactly what the full mechanism would be, but I'm guessing your Y-jerk & accel is lower so the head is moving slower on the Y-face following a sharp corner and there isn't the resolution in your Z-motion to still give smooth zertical motion with a slight binding on the lead screw. It's convoluted and wishy washy I know...

Something else I noted looking closer at your print is that there is a small amount of Z-banding. It's pretty minor so nothing unusual (I'd actually say it's pretty good!), but some of the bands line up with the pattern you are seeing in a regular way, again suggesting it is Z-axis related (though not only a Z-issue).

As I say, the best way to tell will be to try and print the same object again, but with a 4mm tall base at the bottom with rounded edges. If the pattern comes out at the same heights in the two prints, you know it must be (at least partially) Z-axis related.

Final question - which way up did the object print in the picture?