Stringing problem with BMG direct drive and PLA

-

are you 100% sure that you have a semitec thermistor?

-

Now that you mention it, no. I bought a trianglelab v6 hotend, and upgraded the nozzle and heatbreak to genuine e3d parts. They say it is a semitec thermistor, but who knows.

I did try varying the temps from 180c to 225c, and the stringing is worse at lower temps... Now that I'm typing this, it occurred to me that I could still be too low. I'll try switching it to the generic thermistor settings.

-

According to my cheap multimeter thermocouple, the temperature difference is about 30c, if it is to be trusted.

-

Well I tried a print at 240c, so if the temperature really was off, it would fix it. Unfortunately, no luck. Still the same as 215c.

-

and you tried different filament brands?

-

On my BLV printer with a Bondtech BMG and E3D V6 direct drive with their catrtidge thermistor I print my pla at 220, retraction is 1.4mm @ 35mm/s speed, 200mm/s travel speeds and print speeds anywhere from 70-90mm/s. I get pretty much no stringing using prusaslicer with those settings. I have printed Esun, Sunlu and hatchbox PLA filaments. Of course many other types of filaments but for PLA, that is what I use.

I also use pressure advance set at .06.

-

I'm starting to think it might be related to cooling. Watching closely, it doesn't necessarily start to generate a string at a retraction, but only when the nozzle leaves the part during a travel move.

This was printed at 215c, and towards the top I turned retraction to 0 to see what would happen.

A different print:

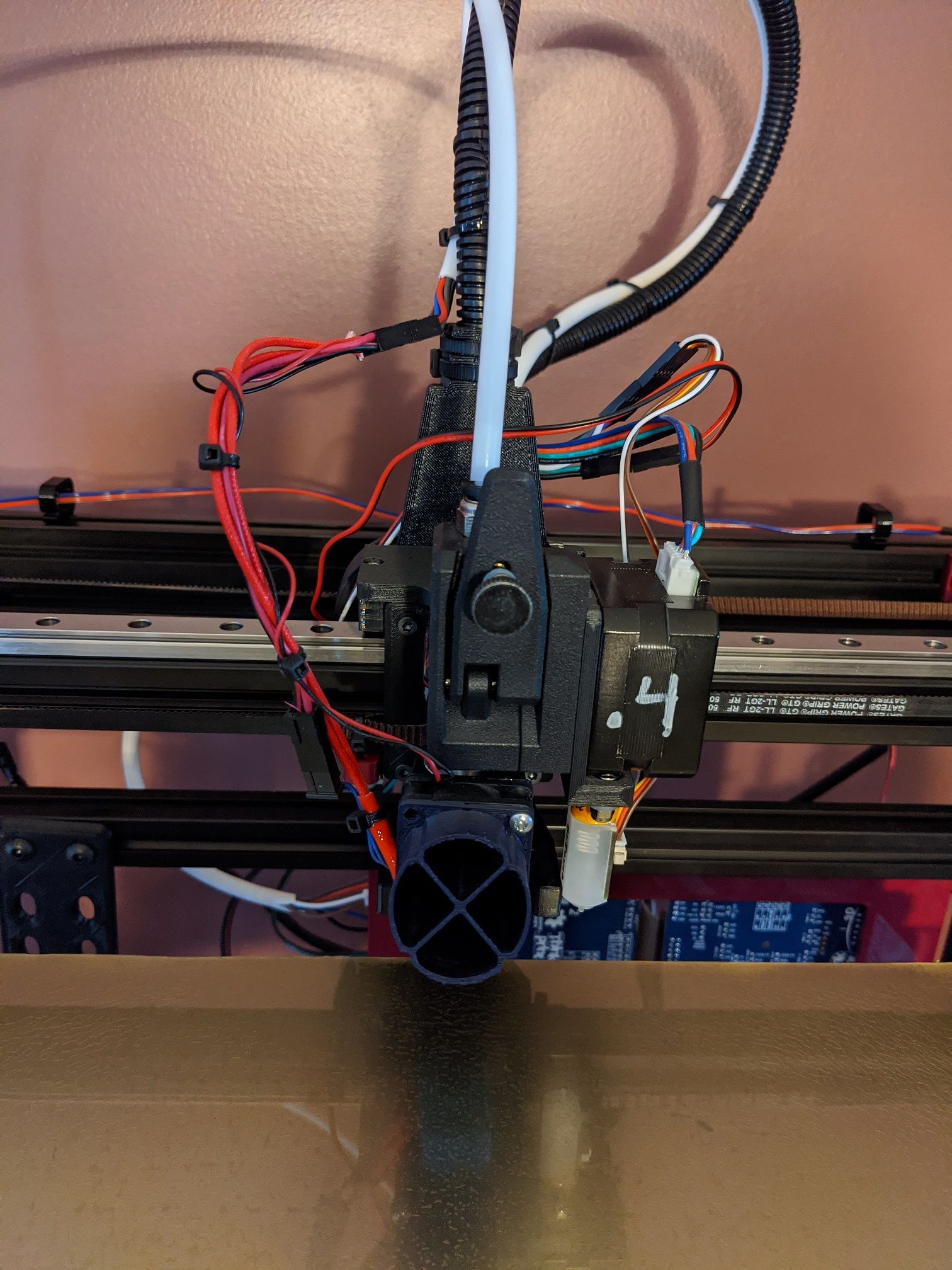

Also, here's a picture of my extruder carriage:

And no, I don't have any other brands of filament to try other than Hatchbox black PLA right now.

-

This is a 12v milwaukee drill stand i printed yesterday with Hatchbox blue pla with the settings I mentioned above.

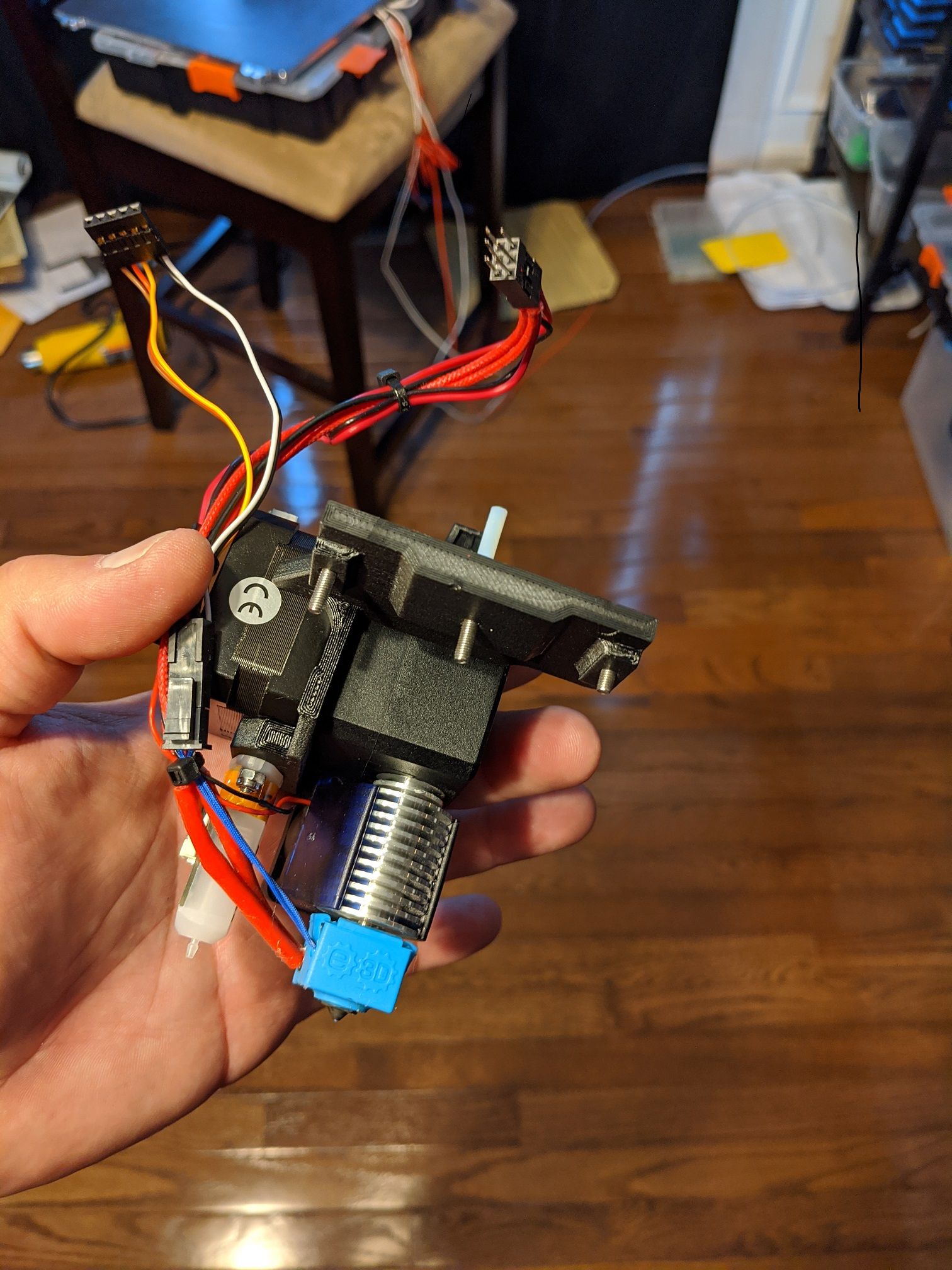

And this is my custom designed quick swap extruder setup I have on both of my BLV cubes. I know my wiring isn't neat by any means but it works perfectly

-

Interesting. I use nearly the exact same settings as you do, but the main difference I think is the part cooling. You have a single fan blowing from one side, and I have two fans blowing from both sides at an angle. I think what may be happening is that there is turbulence where the two airstreams converge on my duct, and this causes the heat to build up. I might try redesigning my cooling duct so that the two airstreams are more aligned.

Also, I really like your quick change toolhead. Very compact.

-

My fan blows on 3 sides actually. I designed the duct based on the original and it has an opening on the back and on both sides. I need to re-design it to flow more air though as the openings are very small. I'll see if I can get a picture.

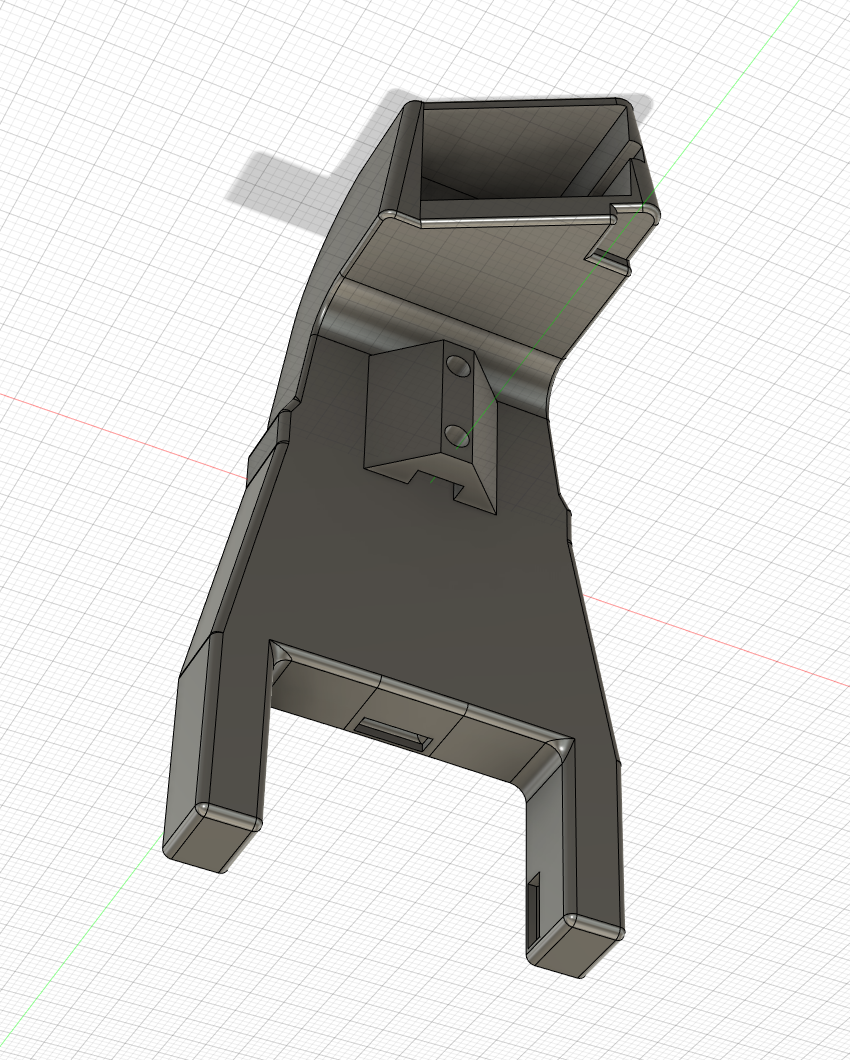

EDIT: It was easier to just do a screenshot from fusion360.