Battling sources of vibration and noise

-

@bearer said in Battling sources of vibration and noise:

@arhi said in Battling sources of vibration and noise:

webbing

its what its refered to in more outdoorsy settings at least

I watched adam savage make his new apron last night and he was referring to that strip as webbing so that + theruttmeister calling it webbing makes me assume that's the "common term"

To be honest I don't even know the local term fot that strip

To be honest I don't even know the local term fot that strip

-

@arhi said in Battling sources of vibration and noise:

a proper pillow blocks, fixed bearings and elastic link between motor and the rest of the machine is the main element "big leagues" use that we don't normally see on our printers.

Can you elaborate, I interpret this as a motor with a pulley on its shaft. Connected with an elastic belt? to a second shaft that is supported by these pillow blocks. And from there a second belt (or just the shaft depending on the application) to output the power to wherever it's needed?

-

@Nxt-1 said in Battling sources of vibration and noise:

@arhi said in Battling sources of vibration and noise:

a proper pillow blocks, fixed bearings and elastic link between motor and the rest of the machine is the main element "big leagues" use that we don't normally see on our printers.

Can you elaborate, I interpret this as a motor with a pulley on its shaft. Connected with an elastic belt? to a second shaft that is supported by these pillow blocks. And from there a second belt (or just the shaft depending on the application) to output the power to wherever it's needed?

sorry that was not related to this webbing thing ..

the usual setup on these big expensive machines is

steel frame

on top of steel frame are 2 pillow blocks supporting the threaded rod

sometimes between pillow block and steel frame there is some "plastic" ~1-2mm thick plate (dunno what material it is but feels like plastic). One one side of the rod pillow block is "blind", on other side of the rod, rod protrudes from the pillow block, and have a pulley. Then next to it, parallel to the rod there is a motor with a pulley, two pulleys are linked with timed belt and motor is connected to the steel frame trough dampener (two steel plates connected with hard rubber allowing motor to "dance" and dampening any vibration between motor and frame) so motor-frame link is "soft", and motor-shaft link is "soft", no vibration transfered at all. Shaft-pillow is hard but pillow-frame is again "soft" link .. so the vibration transfer to the chasy is minimalwith the belt systems it's simpler but not much

on each side of the belt is a shaft with a pulley, shaft is supported by 2 bearings on each side of the shaft, one shaft is blind and that side usually have the "block" with 2 bearings and the shaft can slide on the chasy, again that block is connected to the chasy over a "plastic" plate (1-2mm thick). This is used to tighten the belt. If this side is unmovable then there is a third movable pulley that can tension the belt

The other side of the belt loop the shaft is one one side blind and on other side has pulley, again parallel to that shaft is a motor attached to chasy with dampener and a timed belt between motor and the shaft attached to the pulley engaging belt ..sorry for the txt explanation, I'm on vacation and not really visiting these facilities for almost a year due to covid so can't take any pictures but I think I clearly explained how it works.. basically motor is always linked to the "actuator" trough a belt and not directly, and the actuator is always stiff and hold it's own irrelevant to the drive train

-

@arhi Thanks for the write up and enjoy your vacation

While I was cutting the rubber pads for the 2nd version of my top motor bracket a thought came to mind, the couplers. Right now I use rigid couplers between the stepper shafts and the shaft where the pulleys sit on. It could be effective to swap those out for something more flexible.

I have heard multiple people on the forums talk badly about the typical cheap spring like couplers, so I'll avoid those for sure. @kraegar has talked here about quite a few couplers he tested a couple of years ago. I'll see what I can source from where, see what it would cost me and go from there. -

@Nxt-1 well couplers make sense only if the shaft they connect to is fully supported. The common thing I see on 3d printers is a flex coupling between motor and the shaft while shaft is resting directly on the motor and driving for e.g. bed. That's completely useless setup

as not only that you have a spring inside the motor (normally there is a spring washer between back bearing in the stepper motor, that's why your motor shaft moves few mm back and forth) but you add another spring in the coupler

as not only that you have a spring inside the motor (normally there is a spring washer between back bearing in the stepper motor, that's why your motor shaft moves few mm back and forth) but you add another spring in the coupler  ... but if your drive screw is fully supported and will not move (except rotate) than using flex coupler makes sense.

... but if your drive screw is fully supported and will not move (except rotate) than using flex coupler makes sense.the whole point is that "give" in the coupler, dampener etc. should not in any way affect movement you are trying to control.

BUT!!! BUT, BUT, BUT!! I seen too super expensive fine machines that have belts on pulleys directly on stepper motors and even simple spring belt tighteners ... they are usually slow and use very low acceleration settings but obviosly they too exist

-

@arhi said in Battling sources of vibration and noise:

@Nxt-1 well couplers make sense only if the shaft they connect to is fully supported. The common thing I see on 3d printers is a flex coupling between motor and the shaft while shaft is resting directly on the motor and driving for e.g. bed. That's completely useless setup

as not only that you have a spring inside the motor (normally there is a spring washer between back bearing in the stepper motor, that's why your motor shaft moves few mm back and forth) but you add another spring in the coupler

as not only that you have a spring inside the motor (normally there is a spring washer between back bearing in the stepper motor, that's why your motor shaft moves few mm back and forth) but you add another spring in the coupler  ... but if your drive screw is fully supported and will not move (except rotate) than using flex coupler makes sense.

... but if your drive screw is fully supported and will not move (except rotate) than using flex coupler makes sense.the whole point is that "give" in the coupler, dampener etc. should not in any way affect movement you are trying to control.

BUT!!! BUT, BUT, BUT!! I seen too super expensive fine machines that have belts on pulleys directly on stepper motors and even simple spring belt tighteners ... they are usually slow and use very low acceleration settings but obviosly they too exist

The shaft is well constrained in radial directions and can be in axial with some minor changes so I'm good there. You are right though just about any coupler will add some springy-ness to the system and ideally you'd like to avoid that. Yet there seem to be quite advanced couplers on the market with specs that offer performance far beyond what is needed for a machine like mine.

A big question is can I source decent couplers for a resonable price and from a place that sells to individuals. Places like Misumi are nice but they won't sell to me sadly

I am also not looking to spend like €50 per coupling

I am also not looking to spend like €50 per coupling  I am debating something cheap like these will still offer acceptable performance and backlash

I am debating something cheap like these will still offer acceptable performance and backlash -

@Nxt-1 said in Battling sources of vibration and noise:

I am debating something cheap like these will still offer acceptable performance and backlash

if the screw is held by something cheap like this https://www.123-3d.nl/123-3D-KP8-lager-as-bevestiging-2-stuks-i2161-t9712.html that type of spider connector will work rather good. I tried some original swedish ones that are around 50eur a piece (actually more, you bye each part individually so 2x metal + 1x plastic piece) some super cheap prc ones (3$) and some "medium priced" prc ones (~15$) and tbh they were all performing same. the 3 vs 15$ ones are visually very different but not performance wise, the 15$ vs 50eur .. not even visual difference .. actually prc ones were better as prc ones I could order predrilled to any hole size while swedish ones came with only starter hole to mark the center and you have to drill it yourself

-

@Nxt-1 said in Battling sources of vibration and noise:

@arhi Thanks for the write up and enjoy your vacation

While I was cutting the rubber pads for the 2nd version of my top motor bracket a thought came to mind, the couplers. Right now I use rigid couplers between the stepper shafts and the shaft where the pulleys sit on. It could be effective to swap those out for something more flexible.

I have heard multiple people on the forums talk badly about the typical cheap spring like couplers, so I'll avoid those for sure. @kraegar has talked here about quite a few couplers he tested a couple of years ago. I'll see what I can source from where, see what it would cost me and go from there.As @arhi mentions, most people are using those 'spring' couplers in the wrong way. They are specifically made to allow axial travel. So if you use them on a leadscrew, you need bearings that will take the thrust load. Which people don't seem to do very often.

I see them often described as being for Servo motors. I think because they can withstand much higher speeds than disk or spider type couplers (the spiders particularly are going to get hot, and the plastic spider might deform with high loads and speeds.) I seem to remember a nophead post about him destroying spider couplers with high loads... A good coupler should have loading info, you might want to check that given that you are using decent size motors and driving them reasonably fast.Given how easy it is to get dirt cheap spring couplers, I'd personally try those to start.

@arhi said in Battling sources of vibration and noise:

@Nxt-1 said in Battling sources of vibration and noise:

I am debating something cheap like these will still offer acceptable performance and backlash

if the screw is held by something cheap like this https://www.123-3d.nl/123-3D-KP8-lager-as-bevestiging-2-stuks-i2161-t9712.html that type of spider connector will work rather good. I tried some original swedish ones that are around 50eur a piece (actually more, you bye each part individually so 2x metal + 1x plastic piece) some super cheap prc ones (3$) and some "medium priced" prc ones (~15$) and tbh they were all performing same. the 3 vs 15$ ones are visually very different but not performance wise, the 15$ vs 50eur .. not even visual difference .. actually prc ones were better as prc ones I could order predrilled to any hole size while swedish ones came with only starter hole to mark the center and you have to drill it yourself

^ This. Although the hazard with 2 bearings is that if your screw isn't nice and straight it can be much worse than just 1 bearing. But then a nice straight screw isn't that expensive...

-

@theruttmeister said in Battling sources of vibration and noise:

if your screw isn't nice and straight

in reality, I'd go with, if you can't get the straight screw this whole thread is not for you

-

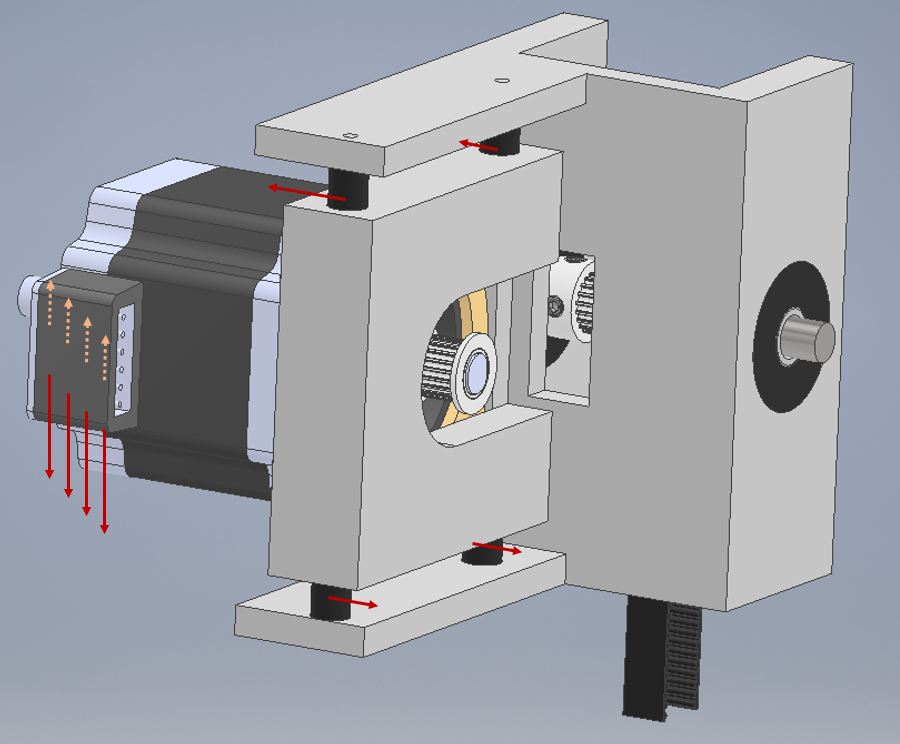

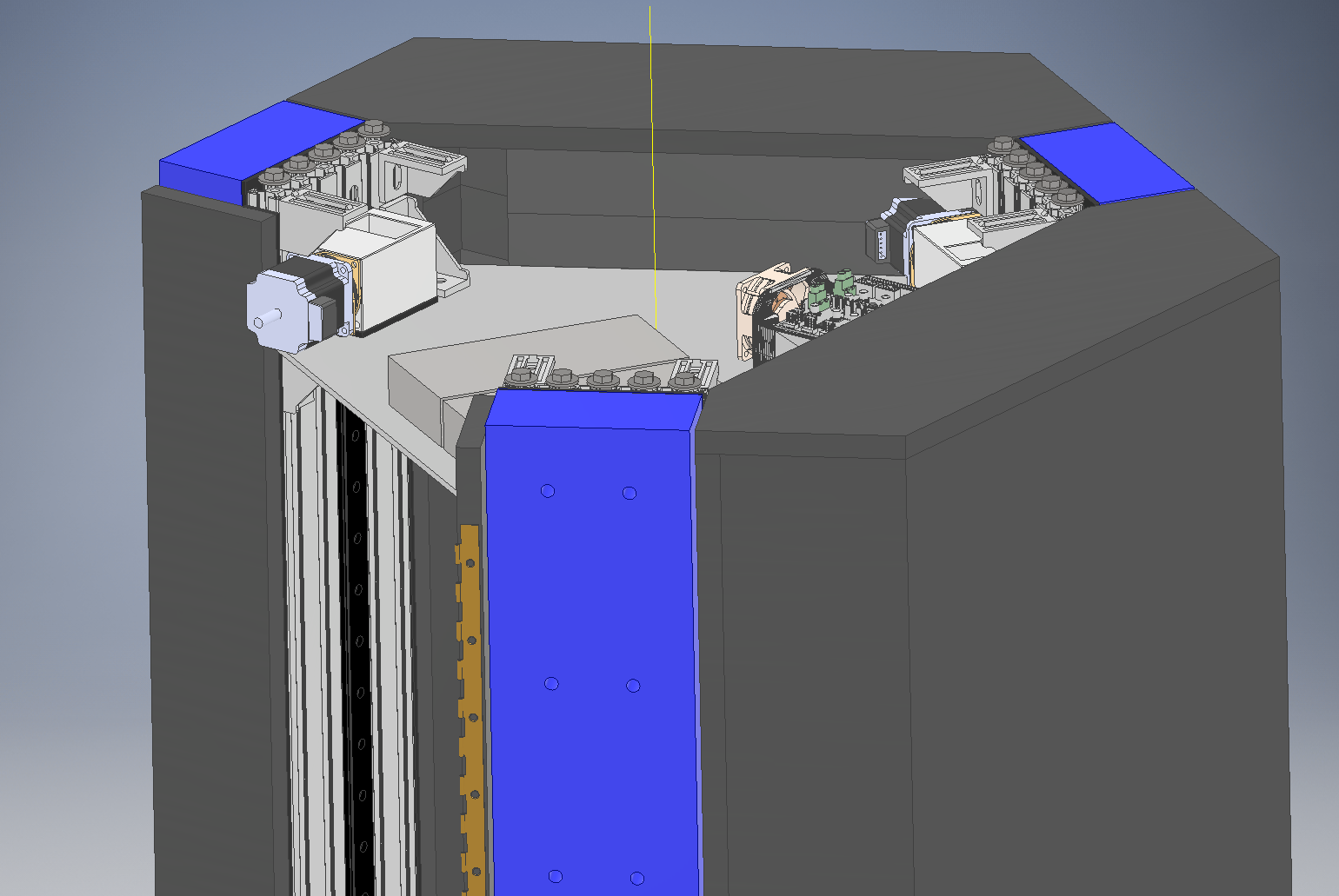

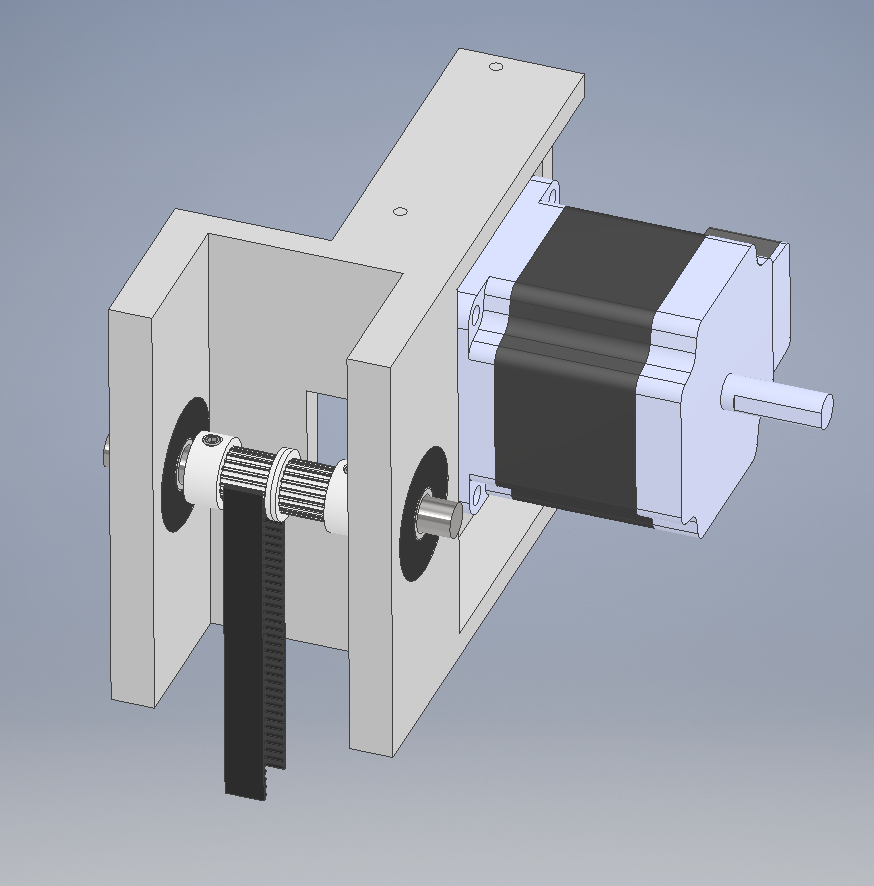

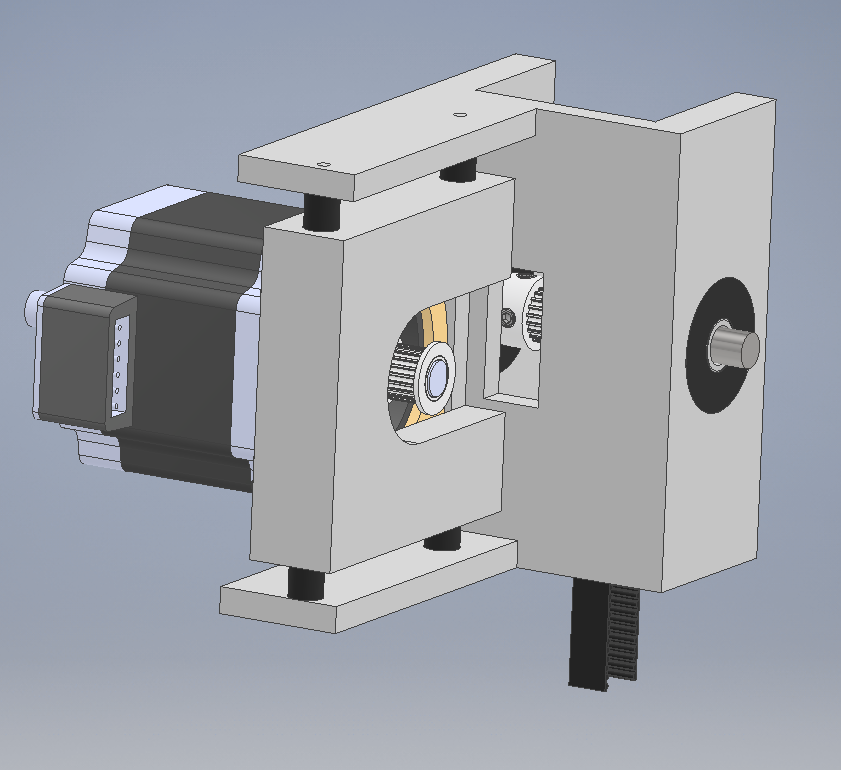

@arhi @theruttmeister The thing is it does not matter whether in what conditions my leadscrews are, because I don't have any. Aha! My machine is a delta, so just belts driving linear rail sliders. Here's a see through view of the motor bracket as I envision it now (and am printing at the moment) and a more overview-y pic of the top of the machine.

I did end up ordering the cheap jaw/spider couplers I linked earlier. I hope the spiders in them are not sloppy, causing a lot of backlash. They should have arrived today, but I have a feeling the shipment will be delay until tomorrow at least.

-

@Nxt-1 said in Battling sources of vibration and noise:

The thing is it does not matter whether in what conditions my leadscrews are, because I don't have any.

in your case the shaft secured between two bearing is what needs to be straight and in that case that "cross/web" coupler works awesome. I never had issues with them having any backlash even on a milling machine. The plastic cross in the middle does ware out on the milling machine and develop some backlash (after many hundreds of hours working) and then you replace it (just the plastic part)

-

So today I received the couplers and they look and feel actually quite decent. I installed them on the brackets from my last post, put the bearings in their new rubber sleeves and installed those as well. I took the new assembly for a spin on the machine and the noise was actually considerably worse believe it or not.

After trying out some different combination of rigid couplers, flex couplers, old brackets and new brackets, my conclusion is that the rubber sleeves around the bearings are a bad idea. I have some long time sensitive prints I need to get done so right now I am running the old bracket with the new flex couplers.

I am not really sure where to go from here. I might look into doing something like the double belt arrangement like @arhi mentioned earlier.

-

I use sorbothane (there's various brand names) whenever I need to kill vibration from parts contacting. It actually performs best when slightly compressed as well. This works great for audible noise, but on my delta with dampeners (and bearings to relieve motor shaft tension) I didn't see any visible improvement on my vertical rippling when I applied it any place I could.

I was using a E3D titan extruder (0.9 deg stepper, 16 microstep interpolated) and fine adjustments to that showed some improvements, but moving from a direct drive to a flying extruder resolved all the vertical banding that was left that I was seeing.

-

@Nxt-1

If I had to guess, the rubber is too hard.The tensioned webbing is worth a try though.

-

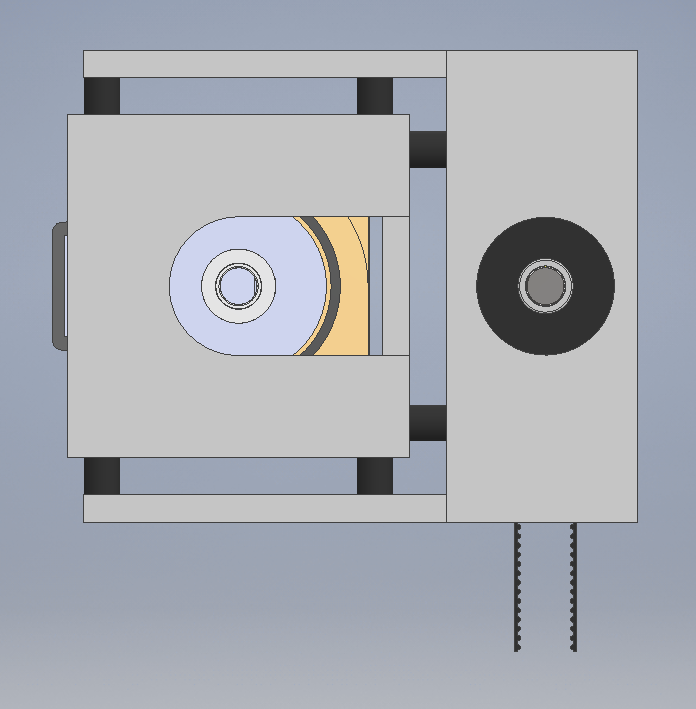

I just did a quick-ish mockup of how I understood what was suggested by @arhi earlier.

All the dark black solids you see are made of rubber. In this configuration, the bearings supporting the intermediate shaft are mounted in the thick rubber washers again. The motor is mounted to the same Astrosyn style face-dampers that I use now. A printed squarish part is bolted to the other side of those dampers. This that part is in turn supported by 6 type B circular dampers.

What do you guys think, there for sure is a lot of rubber in there. I did not go for any rubber sheeting or something like Sorbothane, because is't certainly not cheap and I don't have great (fast) sources for those at the moment.

-

@Nxt-1 I'd look at adding support to the back end of the motor. I would most likely mirror the front motor mount, utilizing the two mounts on the bottom and the two mounts on the side. For initial testing I'd leave off the entire top set as I think it might over-constrain - but it all depends of the hardness / elasticity for the items your using.

Since you're looking into this configuration, it is worth noting that changing the drive ratio will effect the resonate frequency, as well as steps per mm. Might be fun, and worth a shot, to play with it. -

-

@Nxt-1 dunno if the rubber housing for bearings holding main shaft are necesary and if they will add ringing or not.

the motor in this configuration is normally on the dumpener, so there is rubber between motor and that bracket so none of the motor vibrations are transfered to the frame directly

-

First of all thank you all for the replies, nothing excites me more then waking up in the morning an seeing 3 new post haha

@Kolbi Any specific reason to further support the back of the motor? I can think of two possible reasons. One, to counteract the moment loads due to belt tension and second to try to reduce vibrations from that side. The issue with constraining the back side is that I lose the effectiveness of the face damper I believe. And I don't have a second set of face dampers at hand sadly

Love to hear your thoughts.

Love to hear your thoughts.

Then again, I might lose the top dampers as you said (I need some vertical space anyways to fit in the machine) and move them to the back.On the topic of changing drive ratios, yeah it nice to have the option. Although I must admit I am not sure if I'd want to really change it up. Going with a lower steps per mm get me into trouble with back emf and going the other way I lose resolution. 'They' got me cornered

@theruttmeister It sure is a lot

@arhi Good point, seeing how my last attempt at using rubber for those bearings went, I might try a rigid mount first.

-

@Nxt-1 IMO, the shown configuration, the top, and bottom mounts will have constant shear stress, which will lessen their effectiveness and in this case, might cause more vibrations to resonate as the back end of the motor is unrestrained, and will shorten the lifespan. I would move the two mounts from the top to the rear-bottom of the motor. Of course, the hardness of these mounts is unknown to me, but this is just general.

Also, with the configuration, it gives you the advantage to easily change the drive ratio. If more vibration/noise is experienced at slow stepper motor speeds and lessens at higher speeds, you could change the drive ratio which could reduce the over/undershooting from the driver-motor arrangement.