Scara support ?

-

Looking good!

I guess there is no obvious place to put the electronics for a SCARA printer. On my SCARA printer almost the entire Z axis rotates, so the Duet is mounted on the Z axis to avoid a lot of rotating cables (just like the original electronics that was supplied with the printer). I haven't worked out a good place to put a Panel Due yet - having a touch screen that rotates is not a good option! I don't have a bed for my SCARA printer - I print on blue tape stuck to the desk. You do have a bed so you could put the Duet below that, but you would still need to find somewhere to put the touch screen.

If you are happy with the way the Duet is running your SCARA printer, perhaps you would like to write a post about your machine at http://forums.reprap.org/list.php?185.

In your initial post in this thread, you implied that you were using Smoothieware to run your printer. I'm a little surprised that you decided to risk purchasing a Duet for it, even though homing wasn't implemented in RepRapFirmware at that time. Can you explain your reasons?

Let me know if there is anything else you feel is missing from the SCARA support. I'm still a SCARA novice and I probably have a lot to learn.

-

Smoothieware is a very good firmware

But it is not Arthur Wolf who implemented the support of Scara, it is Quentin Harley which coded the support of Scara for the Morgan on Smoothieware

http://www.morgan3dp.com/

https://github.com/Smoothieware/Smoothieware/blob/edge/src/modules/robot/arm_solutions/MorganSCARASolution.cppI contacted Arthur Wolf and he told me that he did not like mathematics: p

I modified Smoothieware at Fablab, but I still had too many vibrations and my level in c ++ is bad …I had already used your electronics at fablab LABSud for a project which I have no right to speak to date

(I will tell you when I have the right to do it (a 3d printer with 6 extruders).

Since before buying the DuetWifi I had contacted you and you told me that the support of Scara was in progress, I trusted you

Promise I write an article on my scara on forums.reprap

http://forums.reprap.org/list.php?185In my opinion the support of Scara is almost perfect,

It remains to add an automatic calibration system to automatically determine angles in ° by displacements "M669 … A-xx: xx B-yy: yy"Sorry for my brooken English ...

-

Thanks for the explanation. Regarding calibration, you can read how I calibrated my SCARA printer towards the end of https://miscsolutions.wordpress.com/2017/08/27/converting-the-robotdigg-scara-printer-to-duet-electronics/.

-

I've made some improvements to my Robotdigg SCARA printer and blogged about them at https://miscsolutions.wordpress.com/2017/09/24/improving-the-robotdigg-scara-printer/. The latest firmware (1.20 alpha 4) has a few improvements related to these changes:

-

Improved speed of floating point calculations

-

The manual bed levelling assistant can now be used on SCARA printers. I used it to adjust the feet of the printer to get the printing plane about level before I apply mesh bed compensation

-

The power down/power up/resume print facility now allows for a controlled power down, because the resurrect.g file is created any time that you pause the print

This will be one of 3 printers on the Duet3D stand at the TCT show.

-

-

Hello David

Thanks for this update

Power down/power up/resum is really cool !

I hope the TCT show will take you full of new customers !

Nice work on your Scara

This week I have a lot of work, I try to quickly test version 1.20 -

If you are happy with the way the Duet is running your SCARA printer, perhaps you would like to write a post about your machine at http://forums.reprap.org/list.php?185.

Hi David

Post: http://forums.reprap.org/read.php?185,790243I hope that "TCT show" is good for you

-

Nice write-up and video!

One thing you might consider is increasing the bed width or depth to about 450mm. You won't be able to do a 450 X 300mm print, but you will be able to print about 450 X 150mm, which may be useful. When using G29 to probe the bed, you can set up the grid in M557 to cover the entire plate, because points that can't be reached by the head will be skipped automatically.

I did a similar thing with my SCARA printer: I increased the Y axis length declared in the M208 commands from 300mm to 420mm. That allowed me to print a 400mm long submarine at the TCT show.

-

There will be an evolution of my scara,

surely a removable arm that can fit on a table or other support to enjoy the entire surface …

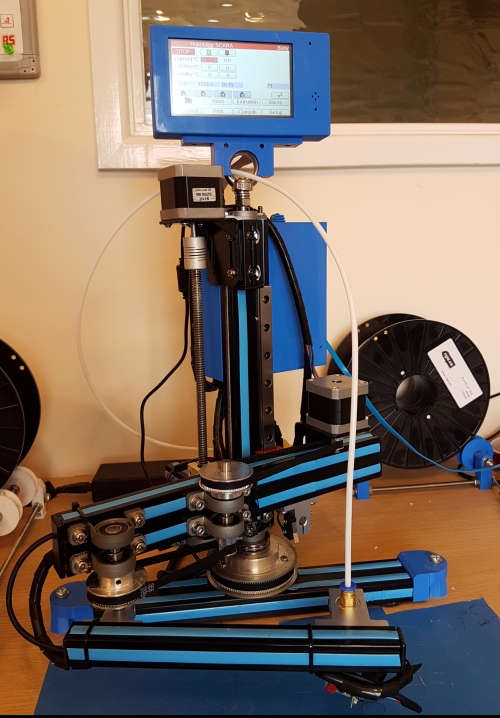

Exemple (Google photo taken at random):

good

==> That allowed me to print a 400mm long submarine at the TCT show.

==> That allowed me to print a 400mm long submarine at the TCT show. -

Hi David, my question about the scara support seems to fit in this thread …

I'm currently using a Duet wifi to control a delta and now also a Duet ethernet to control a Scara. In the latter one I would like to implement a scond Hotend (for the configuration please see the attached sketch). Is it possible to implement the gamma angles in M669. Currently alternating between the hotends is only possible with manual editting M669 Bnnn:mmm according to the gamma angles. Or did I missed something?

-

Currently there is no direct support for a tool-dependent gamma angle offset. However, I think you could implement dual nozzle support in the tool change files like this, provided the distances from the distal joint to the two nozzles are equal:

1. Choose the head reference point, either at one of the nozzles or on an arc from the distal joint midway between them. Define the distal joint homing position based on that choice.

2. In each tpost#.g file, use a G1 command to move the HRP to a known XY position. Then use a G92 command to tell the firmware where the nozzle for tool # is when the HRP is at that position.

3. In the tfree#.g file, do the reverse i.e. send the nozzle to a known XY position and then use a G92 command to tell the firmware where the HRP is.

4. Put T-1 at the start of homeall.g (and homedistal.g if you use it) to make sure that homing is done correctly.