Issues with print quality, wall surface rough.

-

Clearly that is better, so you've identified the major config error I alluded to earlier in the thermistor setting, which was identified by DIY.

I can't give you any more tips to dialing it in than I have already. Step by step is the key.

-

@Corexy I think there is still some Z-Binding, what do you think?

-

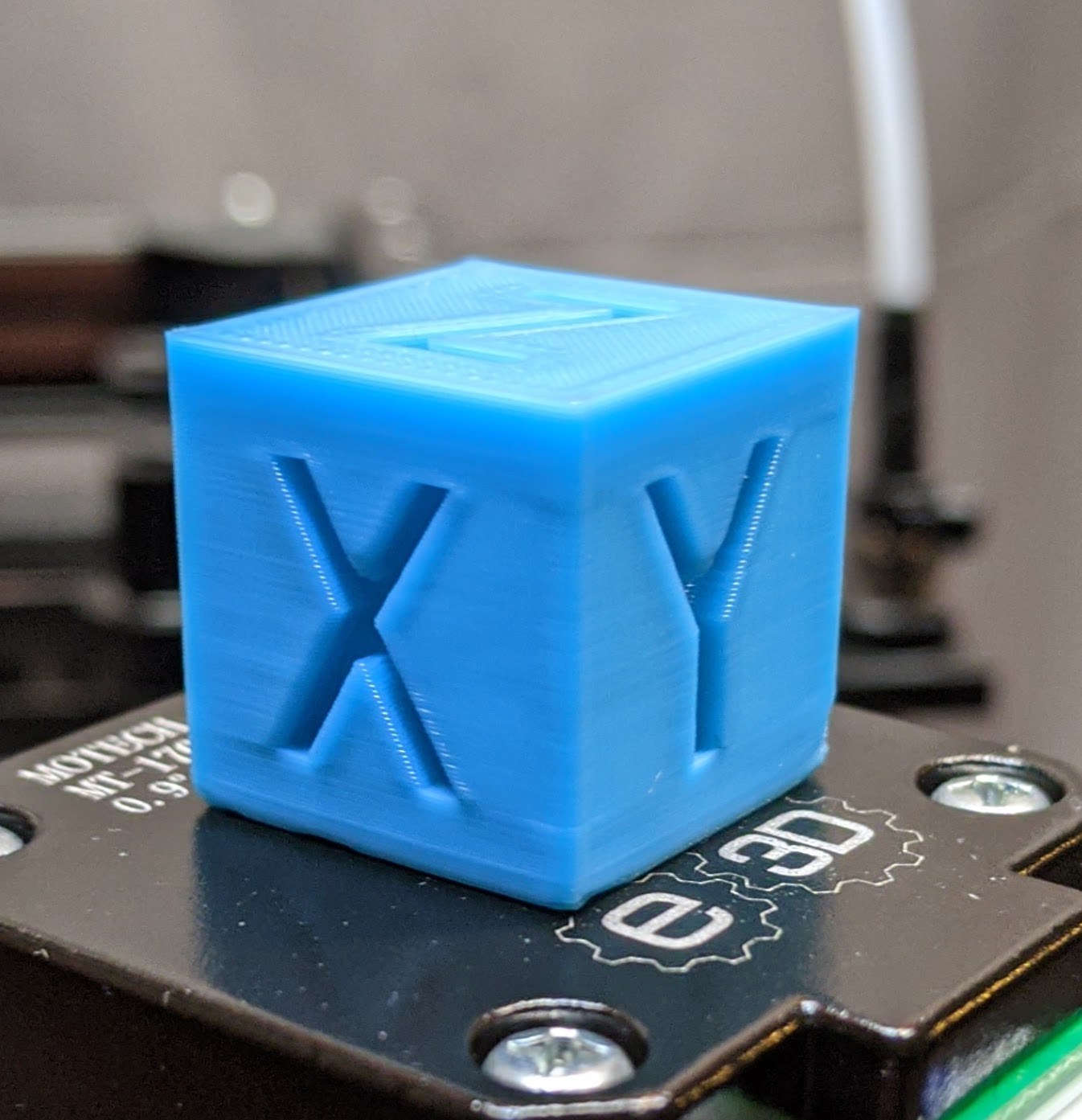

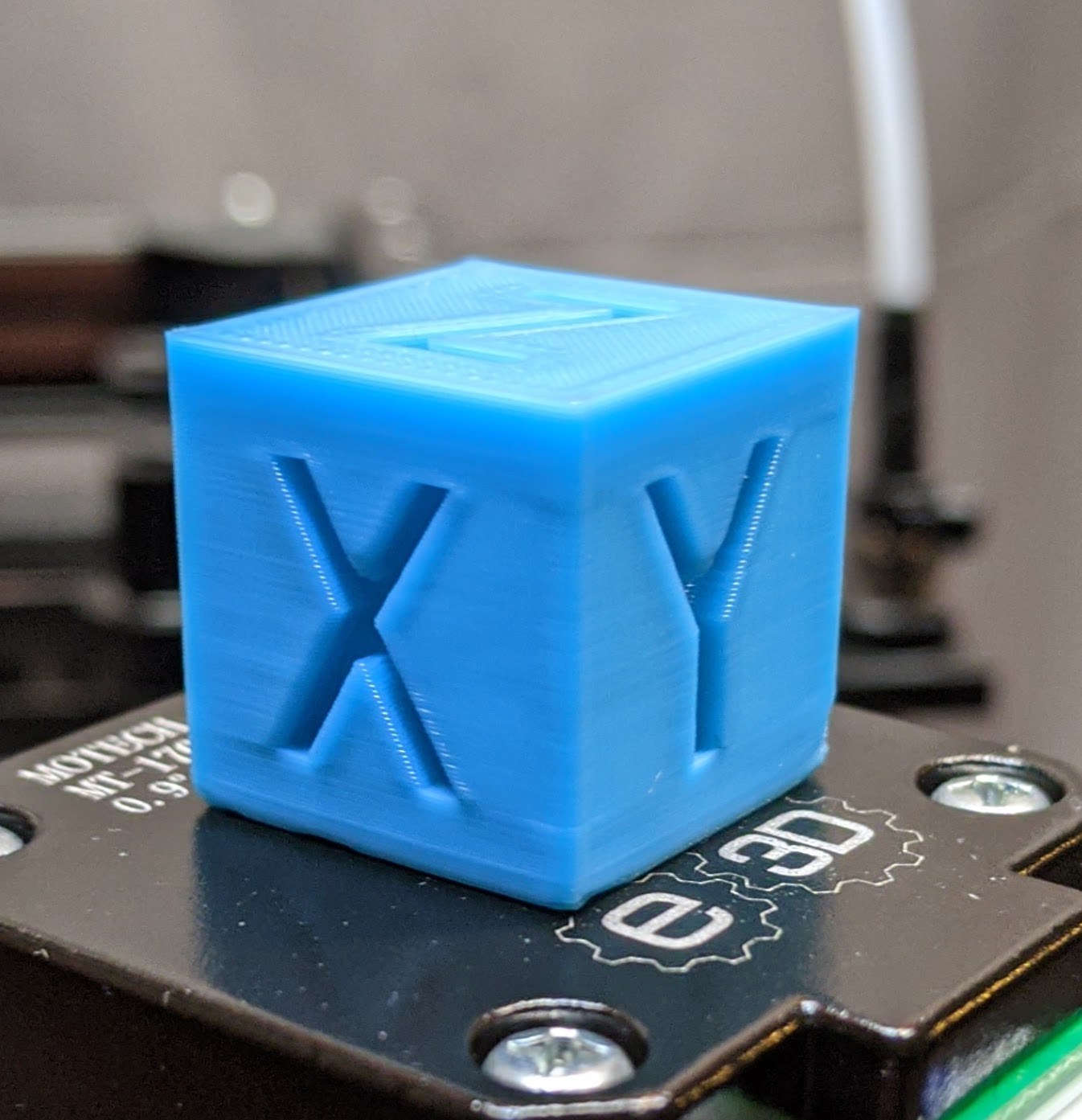

The line above the X could be due to the fact it's an unsupported overhang and is probably being treated as bridging.

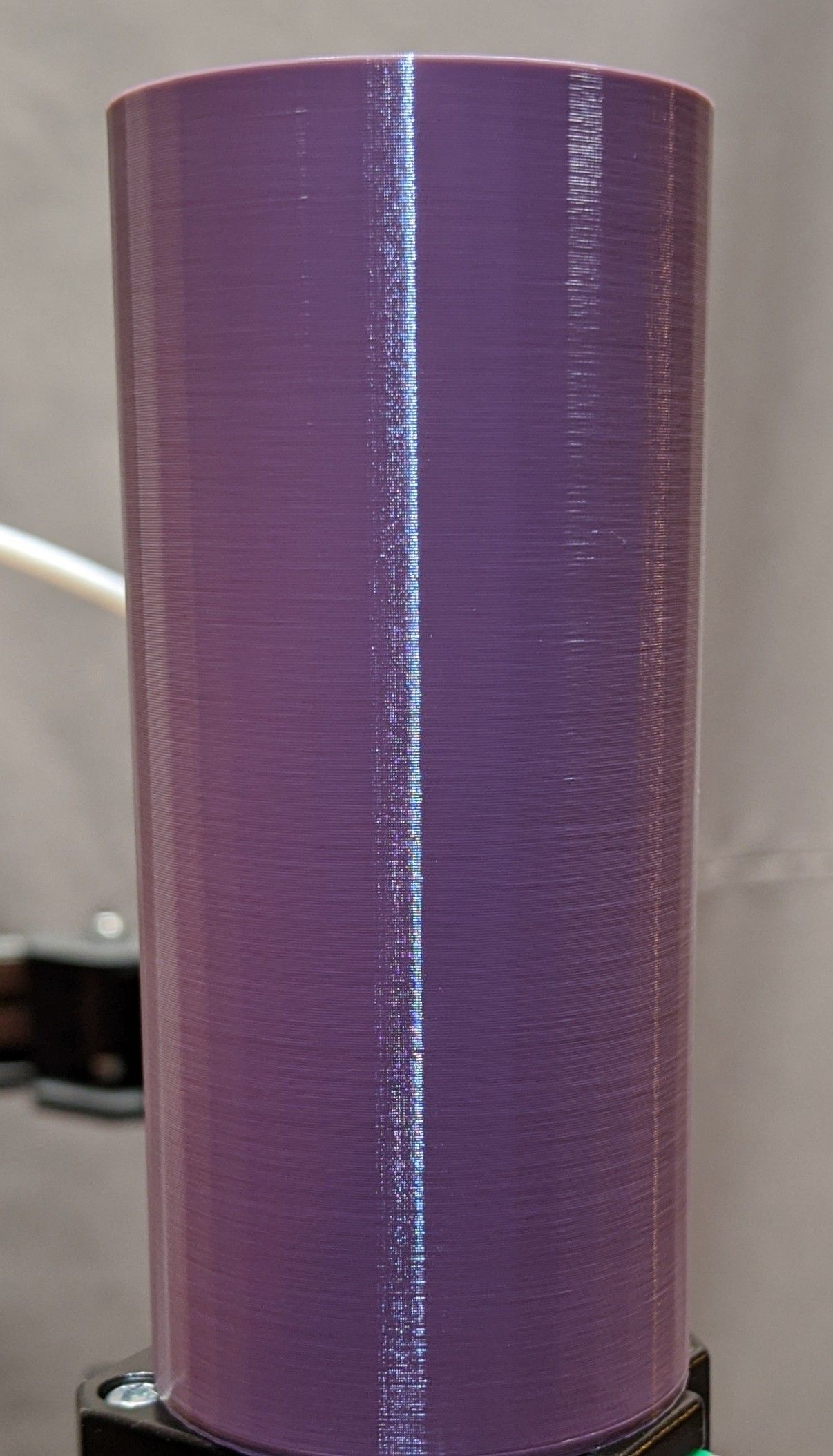

What does a larger vase mode print look like now?

-

@Phaedrux We will find out in a bit, printing a large cylinder right now. I feel like I am very close now, I sure hope so at least.

-

@CorvoDewittV2 said in Issues with print quality, wall surface rough.:

@Corexy I think there is still some Z-Binding, what do you think?

Lol....I think you should go through the steps previously recommended, then print the single walled cylinder in vase mod and that will definitively tell you whether you have a binding Z axis.

If you print your vase mode test with the wrong temp and extrusion multiplier (retraction doesn't matter for this one), you won't see it as clearly as you could.

Seriously...it's like slamming your #$%^ in a door...you'd stop after the first time.

-

@Corexy Ok! I dont know if I have said it but I really do appreciate all of the help. You are awesome and I'm so glad you guys are willing to take time out of your days and help a guy out. I will pass it forward whenever I get the opportunity too.

-

@CorvoDewittV2 said in Issues with print quality, wall surface rough.:

@Corexy Ok! I dont know if I have said it but I really do appreciate all of the help. You are awesome and I'm so glad you guys are willing to take time out of your days and help a guy out. I will pass it forward whenever I get the opportunity too.

No worries at all.

And just to point it out, I am not the guru here. When it comes to your config and tech stuff like that, you've got the right guys here helping you as well. They've already picked up what was suspected in the start (thermistor setting), and now you can start dialing it in.

But I am good at setting up a machine and getting the foundation settings in your slicer right, and have given you steps that will take you straight to a result if you'll listen.

My final point is that you may have some z banding which may be mechanical or due to bed heat, but you need to dial it in now to know.

-

@Corexy I completely understand, and you are right! I can't wait to get this dialed in.

-

@CorvoDewittV2 said in Issues with print quality, wall surface rough.:

@Corexy I completely understand, and you are right! I can't wait to get this dialed in.

Deep breath...slow down...step by step (in the right order) is the key.

-

-

This is the most frustrating part. This is a print off the ender 3 pro I have. I've spent less that half on that printer that I have on the v core.

-

Please take pictures of the final layer of the extrusion multiplier cube, the complete retraction test and the single walled cylinder in vase mode (full height 100-150x300 tall, you could do that in 0.3mm layer height to save time if you like.

Clearly this is getting a lot better. Are you using bang bang temp control on the bed? AFTER you've done the setup prints it might be worth asking Phaedrux how to use PID control there. No use asking me about that.

What was this digital protractor jigger you used to set up your frame? Are they expensive and do you have a link to one?

-

No sense retyping the wheel

https://duet3d.dozuki.com/Guide/Ender+3+Pro+and+Duet+Maestro+Guide+Part+4:+Calibration/40

-

@Phaedrux said in Issues with print quality, wall surface rough.:

No sense retyping the wheel

https://duet3d.dozuki.com/Guide/Ender+3+Pro+and+Duet+Maestro+Guide+Part+4:+Calibration/40

You know I've used bang bang on the bed of my Duet/Zortrax for 4 years...it's just got the built in thermistor that came with the Keenovo mat.

Would I benefit from PID? I certainly see some minor Z banding there. I always chased it mechanically.

-

@CorvoDewittV2 said in Issues with print quality, wall surface rough.:

This is the most frustrating part. This is a print off the ender 3 pro I have. I've spent less that half on that printer that I have on the v core.

I've got bad news for you...that's a bit ordinary for an E3 Pro. I've got one too with BMG extruder, Capricorn tube/fittings and a stock hot end/fans with a printed fan shroud, and it knocks out the best prints I've ever done or even seen...regularly.

When you've done tweaking this one, you need to go and do the 3 steps on that one too.

If you don't mind paying for Simplify 3D, they have a built in profile that works pretty well for that model too.

-

@Corexy I did the 2/3 steps. 96 is the extrusion multiplier and 190 is the temp. It looks no different. There is a mechanical issue. My guess is the lead screws. But honestly do I really want to throw more money at this printer? If I was able to tune in the ender 3 with much less fiddling, then why would I keep fiddling with this one? I'm sorry im just upset. I've spent every day for 2 months and over 2k on this printer.

-

Also just noticed that sometimes when I start a print it will not set the extrusion multiplayer. So got to figure that out now. Must be something with the start gcode. I sometimes get an error that no tool is selected but it it heats up the only one I have so IDK.

-

@CorvoDewittV2 said in Issues with print quality, wall surface rough.:

@Corexy I did the 2/3 steps. 96 is the extrusion multiplier and 190 is the temp. It looks no different. There is a mechanical issue. My guess is the lead screws. But honestly do I really want to throw more money at this printer? If I was able to tune in the ender 3 with much less fiddling, then why would I keep fiddling with this one? I'm sorry im just upset. I've spent every day for 2 months and over 2k on this printer.

OK, so those temp/EM numbers sound quite reasonable. Run with those. Have you done the retraction test yet?

So where's the pics of the 100x300 single walled vase mode cylinder? Do that please next.

The other cylinder you posted above looked much better, why be upset? You're moving in the right direction.

You're not going to get better prints from this printer, you get much larger prints due to the build volume.

You haven't eliminated the bed temp causing the banding yet, but just do the cylinder next and put the picture up here so people can help you.

And please tell me about this electronic protractor...I might use one.

No use flipping out mate. You've got to keep your shirt on, take the curlers out and move through the steps. It's frustrating but victory is sweet in the end. If you want to see frustration, go back through my posts to when I first converted a Zortrax to Duet...I drove everyone mad. Now I've used it for 4 years and it's pounded out tonnes of top prints. It's a total work horse.

Cylinder pic next please!

-

@Corexy Its a Wixey Digital Protractor, about $60 US.

I have the 8 inch one from woodworking, but for printer building I would prob get a smaller one. I'll pick this back up tomorrow. Maybe I need to lower my expectations a bit too.

-

@CorvoDewittV2 said in Issues with print quality, wall surface rough.:

Also just noticed that sometimes when I start a print it will not set the extrusion multiplayer. So got to figure that out now. Must be something with the start gcode. I sometimes get an error that no tool is selected but it it heats up the only one I have so IDK.

Extrusion multiplier is set in the slicer, at least that's how I do it. I'll save a profile in the slicer for a specific roll/material, which has all my preferred settings for that material. The only thing I have in the config file is Esteps, which I'll check and change as required when I change rolls.

My understanding is that Duet will always start a print at 100% flow, but that will be 100% of the flow/EM setting you entered in the slicer.