Robotic kinematics

-

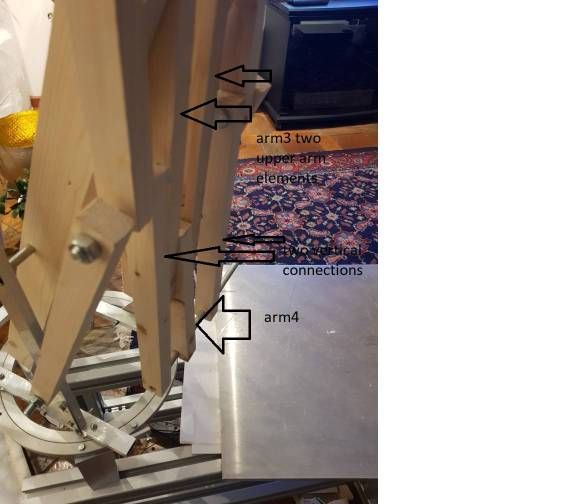

I thought until today that a parallelogram structure with R1 mode would be the best solution. But when arm3 is in line with the vertical arm4 (always when arm 3 is vertical too), the vertical arm4 is very unstable, similar to a singularity:

Mathematically arm 4 stays vertical, but every part has a few micrometers play. Arm 4 can rotate some mm because of that.

Unfortunately the regions where arm 3 is vertical is at a lot of places (a cone from bed Z0 towards axis 1 high Z). This limits the precision advantage of R1 mode. I'll concentrate on R0 mode now, with actuator 4 for axis 4.

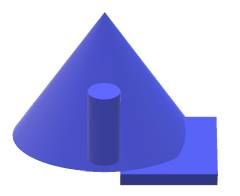

Problematic conic area where arm 4 can rotate with xy inaccuracy (if axis 5 rotates, this area is even bigger):

Kuka KR700 has a different solution for the arm elements which fixes the 4th axis, this may still be an option for a R1 mode. I let R1 remain in the firmware, but will not build robots with R1 mode for some time. This means, Duet 2 and Mini 5+ need an extension board for 6 actuators.

The Type 1 prototype has 8 actuators:

- 5 for the 5 axes

- 1 for extruder

- 2 to calibrate axis 1, standing on 3 columns, 1 of them fixed, 2 of them to be calibrated by actuator with differential screws.

For Type 1, Duet 3 and Mini 5+ are used together with the 3HC board, Mini 5+ using one of 3HC's drivers for the Nema 23 of axis 2 with 3.5 A.

-

This post is deleted! -

This post is deleted! -

This post is deleted! -

This post is deleted! -

This post is deleted! -

This post is deleted! -

@tony73 and all, I will proceed with the robot implementation from March 2nd, with the following priorities:

- finish prototype with an implementation to be able to print

- migrate firmware to

tag 3.2.2 (some libraries 3.2)3.3 - test firmware code

- describe homing and implement the functionality which is described in documentation, but is missing

- describe sample config for Duet 2, Duet 3 and Mini 5+

- try a servo iHSV57 with 1XD card for axis 2, compare precision with stepper solution

- document how to build the prototype

- review print results, gather ideas for improvement, summarize lessons learned

- after that, I start developing the 6 axis robot

If someone has an additional topic for the first steps to proceed, please tell me.

-

@JoergS5

Hi! how are you? About a month ago I bought a used harmonic drive, the 14 - 50 complete with body and cross roller bearing. I found that when it is mounted on a robot, with the engine off, with a large load, the joint can fall, but it is not a problem because the load should be very large !!! the ratio of 14 - 50, that is 1 to 50 creates a very big brake! I tell you this because I did not know that a harmonic drive could rotate with the engine off, I was amazed to see this thing! I'll put you a video link of a guy showing this behavior, on a 3d printed robot! ľ articulation that rotates is a 14 - 50 like mine !!

https://m.youtube.com/watch?v=766F_8LPM9c -

@tony73 nice to hear from you. Now I know I am not alone

I'll try to speed up the topic. -

@JoergS5

I'm very pleased to hear from you too, I waited so as not to disturb you but I'm here !!! and i want to do what i can to help you and get to make a robot arm with duet !!! -

@JoergS5

Hi ! what is the current situation on the robot? have you started building a new one?

-

@tony73 I have some time next weekend, I gather my activities and make images or change the descriptions. I'll strip down https://forum.duet3d.com/topic/20209/robot-type-1-45-cm-belt-gear-direct-drive-r0 to a minimum (only describing the construction, some images, videos, 3D print results), if you need information from there, please copy it. I have not received any feedback as to whether the information on craft and safety is of use to anyone, so I would like to remove that. Safety information always has the risk that it could be wrong. That's why I better remove it again. (Especially in #6).

-

@joergs5

good morning! have you done any other tests? is there any news? -

@tony73 please give me a few additional days. I am currently building three robots, one for Duet 2, one Duet 3 and one Mini 5+, so I can better compare the different construction ideas. I was not able to buy Maestro, they are out of stock (I wanted to see the performance for the board without FPU). If someone builds a Maestro supported robot, please tell me whether the performance of the kinematics is sufficient. I'll post an update after next weekend. I can currently only proceed at the weekends.

-

@joergs5

all the time you need! no problems! I'm just trying to figure out where you are, so let's keep in touch! I have recovered several reader heads (vhs)! I'm putting together a robot with these! let's see how it will go! -

@tony73 thats good. I expect that they run very smooth.

Looking around, there are a lot of motors which could be used as actuators, eg I gathered the last defect electric teeth brushes, they have powerful motors, and small. Could be used for toolchangers or to generate vibration.

-

@3DPotter you asked (in chat) about https://www.aliexpress.com/item/32976011942.html?spm=a2g0o.productlist.0.0.68797987WMLq56&algo_pvid=46319237-5fa5-4dc3-8552-8bf06331e261&algo_expid=46319237-5fa5-4dc3-8552-8bf06331e261-0&btsid=0b0a555f16170320625218222eb53f&ws_ab_test=searchweb0_0,searchweb201602_,searchweb201603_ for using it with the robot kinematics. I think it can work with R2 mode, please check the documentation in https://duet3d.dozuki.com/Wiki/Configuring_RepRapFirmware_for_a_FiveAxisRobot?revisionid=HEAD

R2 mode means the axis 4 is always vertical, and there is no axis 5, a rotation of the hotend. So the configuration is with 3 actuators (steppers), like in the description of the product.If you are not used to compile firmware, I can provide you a binary, if you tell me the duet hardware you're using. We can discuss how to setup the config file also.

I should add that the firmware is still in beta and may contain errors (which I will fix when I have become aware of them). It is not part of the production firmware yet.

-

@joergs5 Thankyou for the help. I am trying to configure the robot using 3 motors and the duet 2 wifi. Additionally the limit switches are normally closed. the main thing I need it ow to configure the kinematic line and the compiled firmware since I am unfamiliar with compiling.

-

@3dpotter to create a configuration file, please start with the RRF configurator in https://configtool.reprapfirmware.org/Start

This gives you a start config for the 3 steppers, endstops, extruder and optionally probes and bed heater. From this point you can modify it with the robot specific config, mainly the M669 line.

I'll give you a binary for Duet 2, based on RRF release 3.1. You should install 3.1 from production and only replace the bin file from me after uploading the package. Binaries are available in https://github.com/Duet3D/RepRapFirmware/releases

Maybe I can make a 3.2.2 binary also, I'll have to check it.