Robotic kinematics

-

@JoergS5

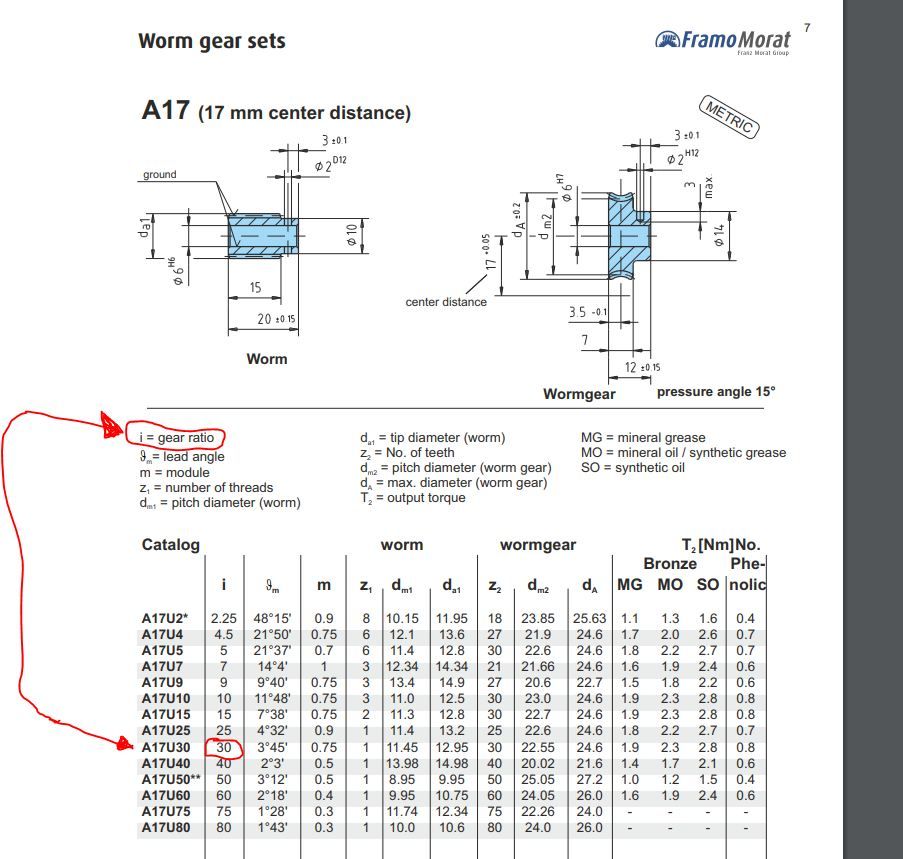

if I understand correctly I should do the 1/30 gear reducer and this would be the calculation for M92 (200 * 30 * 16/360 = 266.6666666667) and could it be suitable for all 5 actuators? -

@tony73 in general yes and the calculation is correct.

But maybe you don't need 1:30 for Axis 5, because the gear will add some weight there. And Axis 4 is always vertical, a lower gear may be sufficient. But if you want to standardize and use the same gear everywhere, you can do it this way. At Axis 1 and 5 I would use only a gear without backlash, because you'll have many direction changes without force up/down.

I would create one worm drive and measure weight, backlash, maximum load and stability/no vibration to all directions, before deciding whether to use it at all axes.

I will try to make Axis 4 and 5 as light as possible, but want to avoid Bowden*). Because I want to create a toolchanger, which is easier to implement with a direct drive extruder.

*) Bowden as counterweight at Axis 3 would be a nice solution with very low weight at axis 5, but I will not use it.

-

This post is deleted! -

@tony73 I am sorry, I don't understand your sentences.

You mean I use wrong material?

What do you mean I protest against using aluminium? I didn't make a statement of material of the worm gear. -

This post is deleted! -

Hi! Sorry for my English ! I said that badly !

your quote: I would create one worm drive and measure weight, backlash, maximum load and stability/no vibration to all directions, before deciding whether to use it at all axes.

idea how to try a screw gear motor!

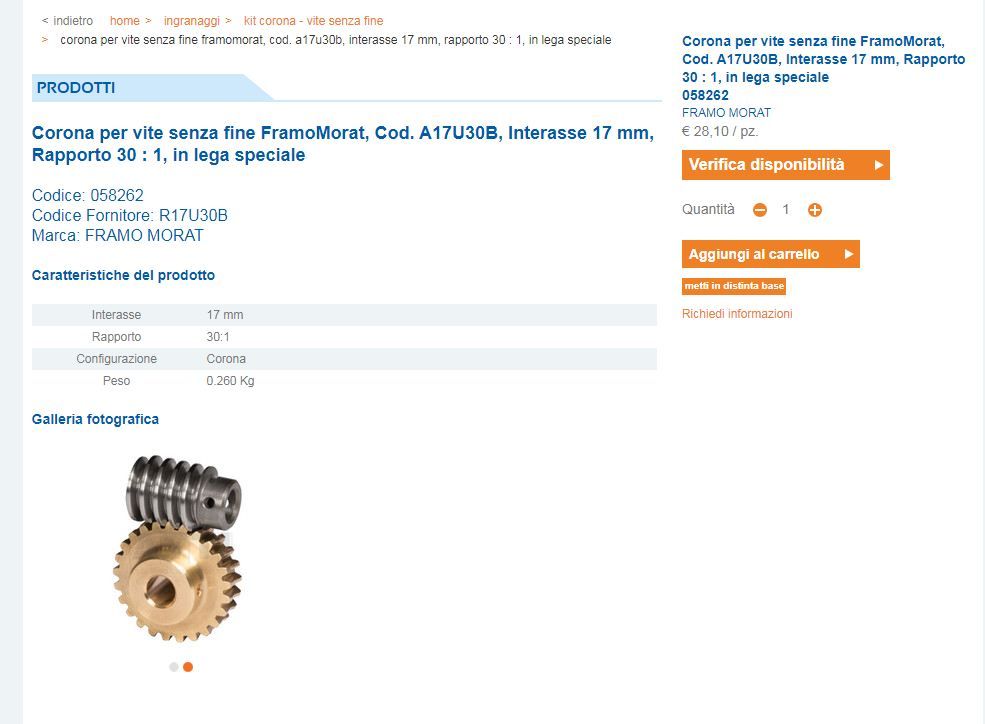

the weight is a bit excessive! 260 grams, but it can be an idea to try the gear motor, for the gear motor structure I would use this!

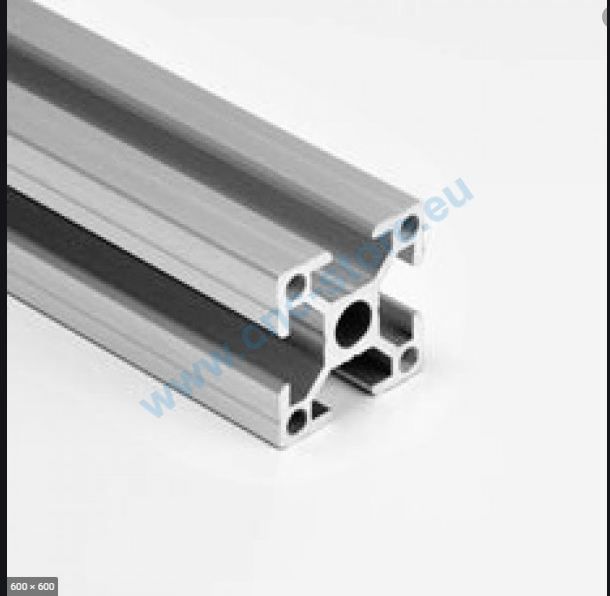

I will do globoid worm gear and cog with lathe, and would like to use aluminum profile for box as proof!

-

@tony73 sounds like a good plan. You made a plan of the worm drive, but without the connection to the arms. If you like, make a plan including this connection and we can discuss.

The output torque T2 in Nm is between 1.8 and 2.8 Nm (depending on lubrication MG/MO/SO), which means:

180 to 280 g with a 1 m arm,

450 to 700 g with 40 cm (arm 2 and 3 in your config),

900 to 1400 g with a 20 cm arm.You will probably need a counterweight at Axis 2, Axis 3 could work without (depends on how many weight you have for Extruder, Hotend, Steppers Axis 4 and 5).

-

do you want to try to make a worm gear reducer to test the robot, or am I wrong to understand?

-

This post is deleted! -

@JoergS5

ok! I understood ! I'll let you know as soon as I have something built! -

This post is deleted! -

This post is deleted! -

@tony73 I want to sort the ideas I had and delete the unsorted blogs:

- please don't feel obligated to build a worm drive now to help with building the prototype. The worm drive may not work, but getting experience with it is worthful of course.

- from my gear tests, I think it is best to use as big last wheel as possible, because of the forces involved and precision sideways, leading the arm into the intended direction and stability into the intended direction.

- counterweights should be avoided or they should be near the axis, for better acceleration and low wobbling, an exception will be axis 2, which has the burden of arms 2 to 5 and extruder and the biggest leverage

I've calculated all for a solution with belt based gears and found solutions where they are in balance when powered off. I build it now.

There are two robots which impress me and I'll try some of their ideas: Kuka KR 700 and bytronic 5ARA (UK company, R12 from ST Robotics similar).

-

@tony73 said in Robotic kinematics:

to use aluminum profile for box as proof

this is a good idea: using aluminium profiles for a part of the prototype. I have already many parts with wrong holes in it, the profiles will spare some money for testing where the holes shall be. I am currently using aluminium profiles to construct Axis 1.

I rebuilt axis 2, 3 and 4 yesterday, proceeding with axis 1, then finish the hotend.

-

@JoergS5

Hi! i looked at robot arm R12 and it looks great for using pulleys and belts! which one are you building the kuka kr 700 or R12? -

@tony73 I am trying the counterweight idea of R12. I install two steppers left of axis 3 for axis 3 and axis 4, and one big Nema 23 left of Axis 2 for axis 2. With the help of aluminium profiles it was very easy to install axis 1. Arm 2 length is 270 mm, arm 3 is 230 mm, arm 4 is 180 mm and arm 5 is 100 mm.

The Kuka KR 700 is similar to what I built to run in R1 mode without a stepper for Axis 4. This is useful for users who want to use 4 steppers for the axes and 1 stepper for the extruder, so in total 5, because the Duet boards often have 5 drivers (and according to the article which I mentioned somewhere above the precision is better).

-

@JoergS5

good morning! do you have photos to see the work you are doing? -

@tony73 at weekend I can post them.

I am sorry, I had to make a little creation pause to rethink the design ideas. But I promised an image, here it is:

The weights are balanced, so the detent torque (torque of stepper when he is turned off) is higher than the arm falling weight. I am currently planning the gears near the rotation plate and a construction to fix the open belt at the rotation plate. Below the third little rotation plate will be installed the axis 5 stepper and the extruder+hotend.

The big rotation plate and axis 1 plate are 250 mm diameter (1:20 with 20 teeth pulley), the small ones 120 mm (1:8). The gears will add additional 1:2 (20/40) or 1:3 (20/60). Arm 2 is 270 mm (between the axes), arm 3 is 230 mm (between the axes), arm 4 will be about 180 mm. The Axis 2 stepper is Nema 23, but not because of force, but because of weight. Axis 3 and 4 steppers left of axis 3 are Nema 17. A disadvantage is that the belt for stepper 4 to axis 4 is long, the tension will be critical. The aluminium extrusions are all 45x45 format, the horizontal one is 70 cm long. print area will be larger than 40x40x40 cm.

Next tasks

- design gear with good belt tension

- fix open belt at rotation plate

- how to route wires and filament

- build axis 5 and extruder/hotend part

- install endstops

- three point calibration solution for axis 1

- starting a simple CNC machine to bore precise holes

I follow some design principles

- standardize the holes if possible to 1 cm / 2 cm raster (rotation plates have other distances of the holes as exception)

- modular as much as possible so the elements can be tested isolated

- as simple as possible, but at the same time as precise as possible

-

This post is deleted! -

@JoergS5

Hi! how is work on the robot? thanks for the preview photo! I have little time in this period, I would have changed my mind about the gearbox, I did a quick test and tried to do a harmonic drive the test is in nylon type material, the gearbox is 36/1 flexible bell 70 teeth, fixed gear 72 teeth . made with lathe and divider, the flexible bell is about 33 mm in diameter, if I can calculate the perfect size of the teeth, to have zero play, I will do everything in metal with subsequent hardening. 36/1 in M92 gives an even result, I remember you said it would reduce the margin of error! 200 * 36 * 16/360 = 320