Robotic kinematics

-

@tony73 good morning,

I have the following results of the gear tests:

- if the arm length is 20 cm and the ratio is about 1:10, the weight is maximal 600 g, 1 kg is too much. Otherwise it slips or motor is too weak.

- it helps to shorten the belt length a lot, using deflection pulleys on upper and lower side of belt

- I'll use the steppers as counterweights to minimize this weights

- the counterweights will hinder the arms falling down when powered off

- the speed achieved with a 1:8 ratio without counterweights was Speed 5000 (=5000 degree/min), Accel 1000 (1000 degree/s²), which would be 90 degree/s and, depending on arm length, more than 400mm/s (one axis, the total 5 axes will have a higher speed). Bigger wheel would mean lower speed, but should be more than 200mm/s.

I am currently constructing a belt gear based on what is called ServoBelt, the discussion is here: https://www.cnczone.com/forums/linear-and-rotary-motion/59570-forum.html with the form of a "Rotary ServoBelt" (you can find images googling), using it for all axes. I'll try to avoid planetary gears (backlash) and harmonic drives (expensive and DIY difficult). Using a big pulley (280 mm diameter) without teeth and 20 teeth at stepper gives about 1:22 for axes 1, 2 and 3. Maybe I'll add a 20/60 between stepper and big wheel, giving 1:66.

I'll use different Nema steppers to optimize the counterweights for the different axes.

I will use the teststation to get the exact ratio by multiple wheel rotations.

-

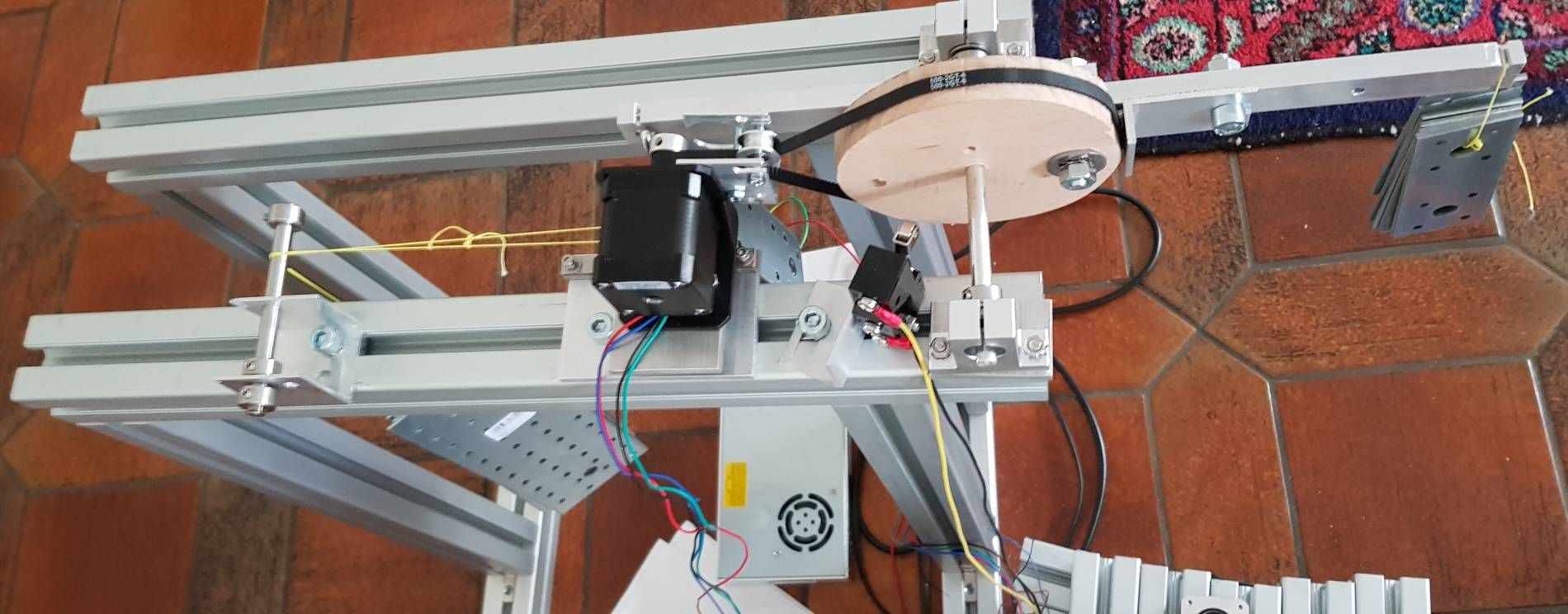

This was my gear teststation

- left is the weight to change the tension of the belt, currently 3 kg. The wire is Spectra fishing line. It does not tear, but the knots are critical. 3kg falling down is not fun.

- middle the stepper on a hiwin linear guide

- the stepper pulley with two deflection pulleys (they were needed to hinder slipping)

- the big wheel *) without teeth, with a stopper against slippage. This worked very good and allows open loop belts in the future (cheaper and easier to assemble)

- left arm for counterweight

- right arm for weight

- endstop in front

*) the wheel is so "unround", because I tried to round it with a band saw. I cannot recommend band saws for this task. They bend while sawing... I'll use a router for the next wheel.

-

@tony73

Hello, I am currently designing how to proceed with my prototype.I found the following ball gearing based plate:

About 12 EUR for 120 mm or 255 mm diameter, a bit more for 300 mm, material aluminium. With a 20 teeth pulley at the stepper the 255 mm version will give a ratio of about 1:20.If the rings are pressed a bit sideways, they have no play. This should be a good hinge, with being a pulley at the outer diameter at the same time.

I wondered how it is built and how the two rings are assembled together, because there is no seam anywhere. I bought one and here is the solution:

Throught this hole the balls are loaded/unloaded. Interesting. I damaged an allen key trying to open it, so I will bore a second hole.

If quality is too bad, I will replace the balls and hone the inner grooves a bit.My calculations are finished now regarding weights*) and gear ratios needed for the axes, I'll start building it now.

*) more exact: I want the torques of the axes to be 0 in sum for each axis, being torque at right and left of the axes being the same. Most demanding is finding the balance for axis 3.

-

@JoergS5

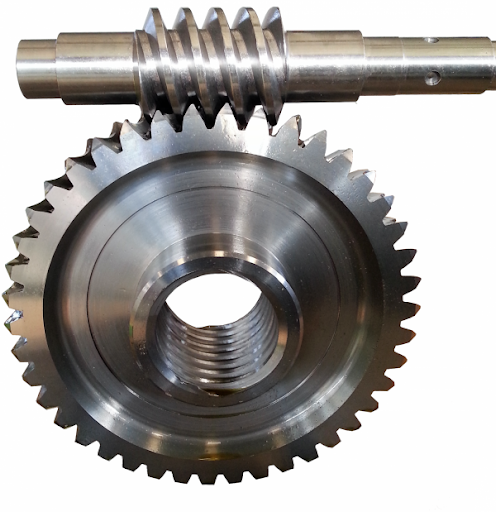

Hi! and very similar to a cross roller bearing, are the balls made of metal or plastic? after the tests you did, what reduction ratio do you want to use for the 5 axes 1/20? I will you use different ratios for each axis? I am designing a worm gear reducer, example:

only a lathe will be needed to build it, with a method that will be simple (as far as possible) with the advantages that when the stepper motor is switched off, the arms will not be able to move and therefore will not fall, the reducer body will also act as a union joint between two arms, the great difficulty is the juxtaposition between the worm and the gear which must be zero! to have no game!

-

@tony73 the balls are steel ball. From what I see, the diameter is similar to the ones in linear guides.

I propose that you use worm drive and I the belt solution and we compare the two solutions and take the better of the two. The worm drive's prevention of falling down is a big advantage. We can mix the two solutions, because they have different advantages and disadvantages. For Axis 1 a belt solution may be best, axis 2 and 3 the worm drive. Axis 1 with the "cross roll bearing clone" has the advantage of an open space in the middle, where wires/filament can be routed through.

I will try 1:20, because the simplicity, but if is not sufficient, I can add the 1:3 resulting in 1:60.

-

@tony73 I tried the hinge with the rotating plate now, it is very stiff:

The play can be finetuned with the screws. I can put the elements even closer together when I get countersunk screws.

Edit: I was receiving other plates now, they have very different quality. The 300 mm diameter one is not round and I will have to rework him. Some have too much play. Some are good. And some don't have the boring holes at the correct position (opposite through the center)...

-

@tony73 I received 225 mm diameter rotation plates now, the resulting robot will look crazy. Maybe it's better to use worm gears. Which ratio do you get with your planned construction?

-

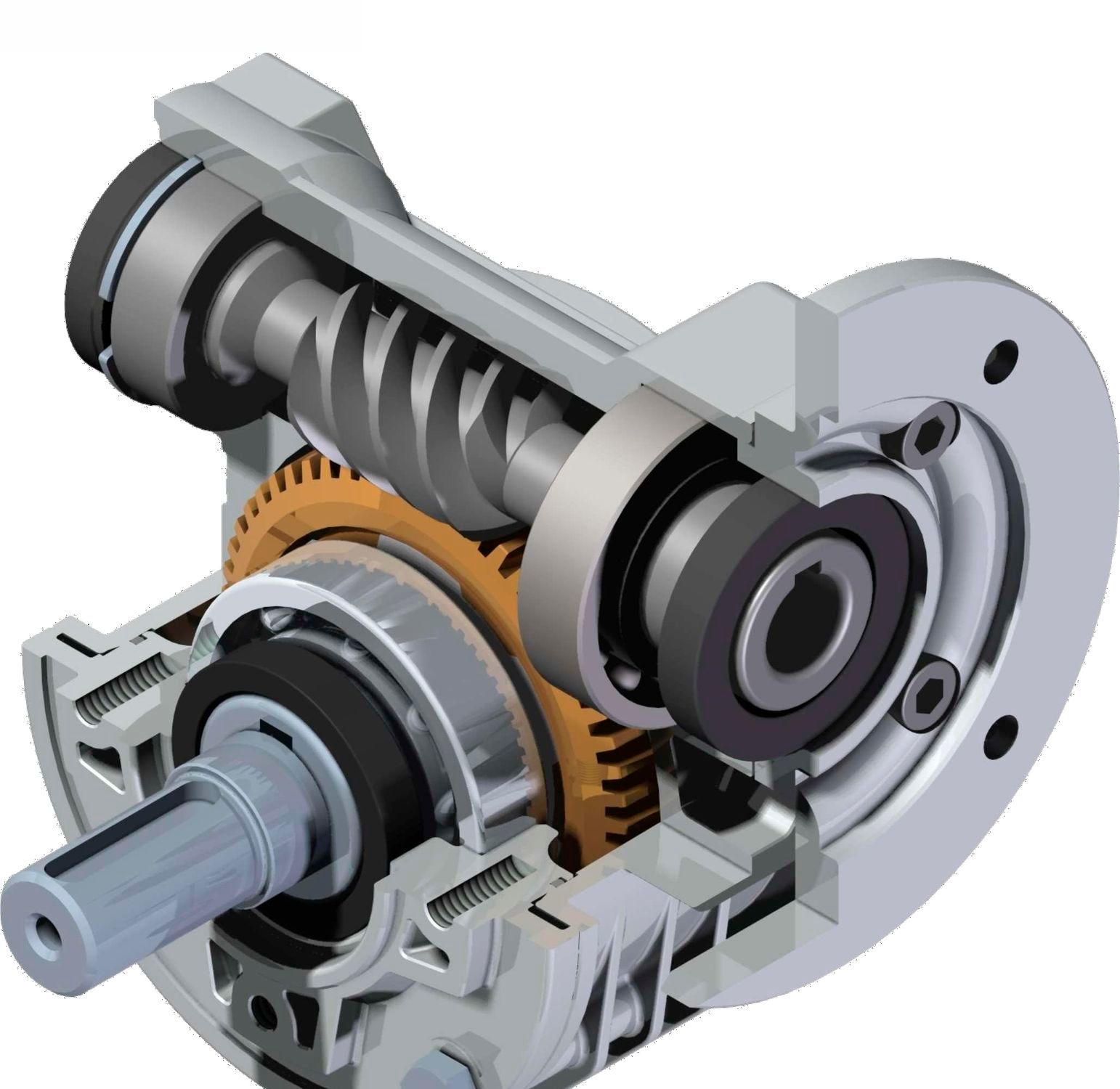

Hi! even if sometimes I don't write, I keep watching your updates! I studied a bit on the various types of worm gearboxes that you made me discover!

the best solution would be this, globoid worm, I tried to understand and designed this

I would like to finish it and print it in abs to understand if the calculations come back, the measurements are mm I would have a smaller footprint! this has pitch 50 teeth about 2.83 (it was a test I didn't care about the pitch) so of reduction of 1/50 I could build it on the lathe, but I have to prepare some things to create the globoid screw (the reduction can be done in various ways 1/20, 1/45, 1/80, 1/100) are examples, you just have to decide the right ratio what can be better, you can make any ratio always small footprint of the reducer! but I don't know which ratio can be the best to use, I will need several different ones for the 5 axes!

I would like to finish it and print it in abs to understand if the calculations come back, the measurements are mm I would have a smaller footprint! this has pitch 50 teeth about 2.83 (it was a test I didn't care about the pitch) so of reduction of 1/50 I could build it on the lathe, but I have to prepare some things to create the globoid screw (the reduction can be done in various ways 1/20, 1/45, 1/80, 1/100) are examples, you just have to decide the right ratio what can be better, you can make any ratio always small footprint of the reducer! but I don't know which ratio can be the best to use, I will need several different ones for the 5 axes!this globoid screw would have contact with at least 6 gear teeth, as opposed to the normal straight screw which only makes good contact on one gear tooth!

-

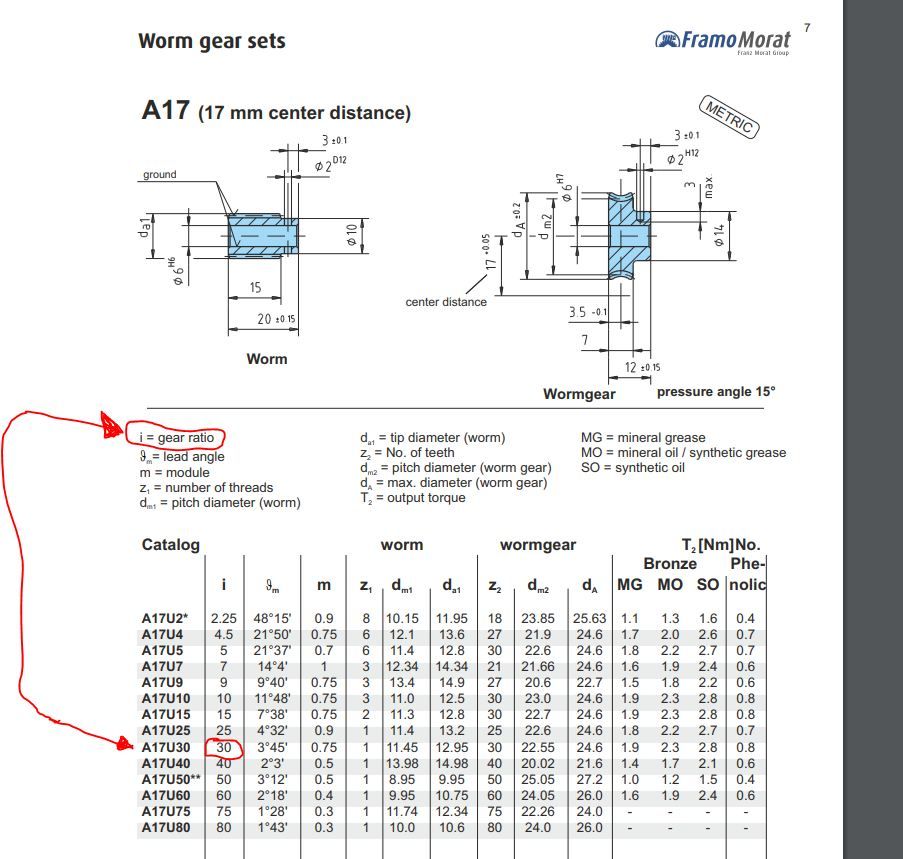

@tony73 a stepper can achieve 1000 rotations/min, which is about 16 rotations per second. But for good torque, in most cases a maximum of about 5 rotations/s are used. This are 5*360=1800 degrees. With a 1:30 ratio, this is 60 degrees per second. The speed depends on the arm length, a 20 cm arm 2 and 3 length which you used means 60 degree for 20 cm rotating, arm2+3 maybe 30 to 35 cm, so 300...350 mm/s. This will probably be more than you can use for the extrusion of the filament. I would recommend using 1:30.

A different aspect is the maximum payload of the gear. Maybe you can research typical maximum payloads for a worm gear. The most critical payload will be for axis 2, because it adds arms 2 until the end, the hotend.

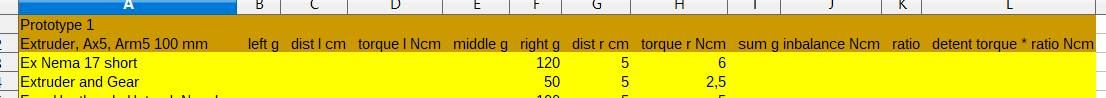

I made me a spreadsheet to calculate the loads (LibreOffice Calc file):

=> please contact me here or with chat if you need the file. It changes rapidly, I don't want to upload it every time it changes.

In the third register is the interesting calculation:

- left g means weight left side of an axis in g

- dist l cm means distance from the axis

- torque Ncm is the torque and depends on distance and weight

- detent torque is when the current is off and should be near 0 for a belt based gear

- CW means counterweight

What can be seen is that the weights of Axis 5 and 4 are critical, because they add to axis 3's and 2's loads, so minimizing is a goal. The weights roughly double with each axis from 5 to 1.

-

@JoergS5

if I understand correctly I should do the 1/30 gear reducer and this would be the calculation for M92 (200 * 30 * 16/360 = 266.6666666667) and could it be suitable for all 5 actuators? -

@tony73 in general yes and the calculation is correct.

But maybe you don't need 1:30 for Axis 5, because the gear will add some weight there. And Axis 4 is always vertical, a lower gear may be sufficient. But if you want to standardize and use the same gear everywhere, you can do it this way. At Axis 1 and 5 I would use only a gear without backlash, because you'll have many direction changes without force up/down.

I would create one worm drive and measure weight, backlash, maximum load and stability/no vibration to all directions, before deciding whether to use it at all axes.

I will try to make Axis 4 and 5 as light as possible, but want to avoid Bowden*). Because I want to create a toolchanger, which is easier to implement with a direct drive extruder.

*) Bowden as counterweight at Axis 3 would be a nice solution with very low weight at axis 5, but I will not use it.

-

This post is deleted! -

@tony73 I am sorry, I don't understand your sentences.

You mean I use wrong material?

What do you mean I protest against using aluminium? I didn't make a statement of material of the worm gear. -

This post is deleted! -

Hi! Sorry for my English ! I said that badly !

your quote: I would create one worm drive and measure weight, backlash, maximum load and stability/no vibration to all directions, before deciding whether to use it at all axes.

idea how to try a screw gear motor!

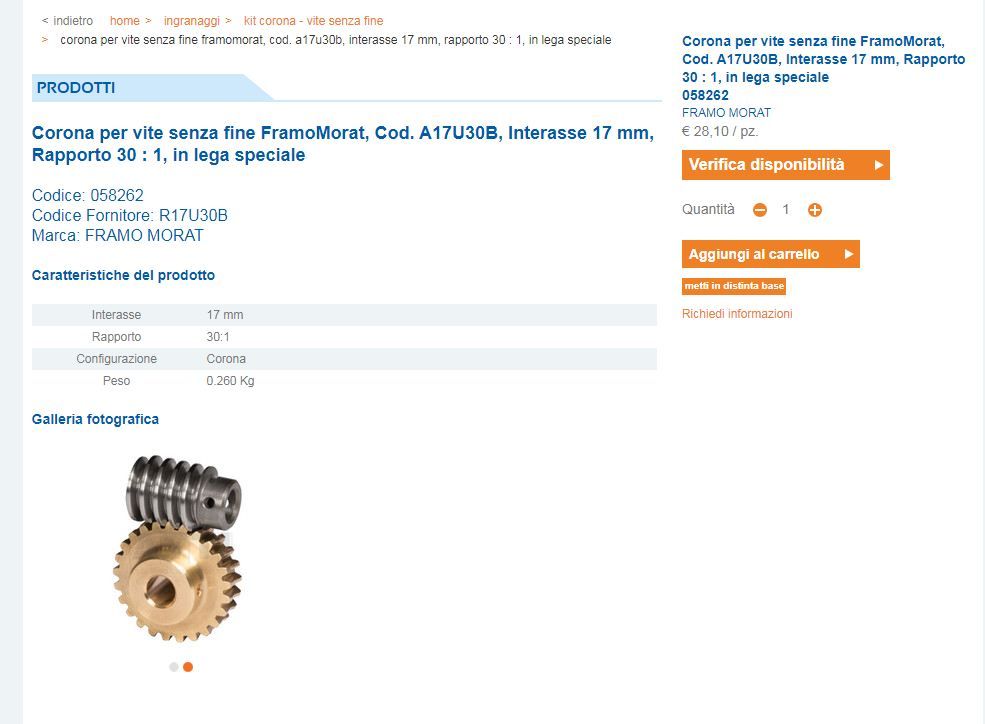

the weight is a bit excessive! 260 grams, but it can be an idea to try the gear motor, for the gear motor structure I would use this!

I will do globoid worm gear and cog with lathe, and would like to use aluminum profile for box as proof!

-

@tony73 sounds like a good plan. You made a plan of the worm drive, but without the connection to the arms. If you like, make a plan including this connection and we can discuss.

The output torque T2 in Nm is between 1.8 and 2.8 Nm (depending on lubrication MG/MO/SO), which means:

180 to 280 g with a 1 m arm,

450 to 700 g with 40 cm (arm 2 and 3 in your config),

900 to 1400 g with a 20 cm arm.You will probably need a counterweight at Axis 2, Axis 3 could work without (depends on how many weight you have for Extruder, Hotend, Steppers Axis 4 and 5).

-

do you want to try to make a worm gear reducer to test the robot, or am I wrong to understand?

-

This post is deleted! -

@JoergS5

ok! I understood ! I'll let you know as soon as I have something built! -

This post is deleted!