Suggestions for hight precision CoreXY

-

Introduction:

Today I decided that I give up with my delta . I'm so tired. But really. Are two years that I make any sort of modification but I have still problems. This come to be so frustrating that I prefer go to the field with a hoe. Or crush the hoe on the printer...maybe is better.

. I'm so tired. But really. Are two years that I make any sort of modification but I have still problems. This come to be so frustrating that I prefer go to the field with a hoe. Or crush the hoe on the printer...maybe is better.

Now it won't even print flat. Despite how I put the bed , the calibration stay constant even at 0.02 of deviation BUT when I print the bed seem always inclined , if I rise the bed where the print seems too hight and recalibrate the printer > SAME behavior, still print as the bed is inclined.

S6 or S8 don't make any difference. Mesh compensation tried tons of time , reporting a pretty decent flat bed but with no impact on the print.

Duet -wi-fi , Haydn bars, smart effector, disassembled countless times for put it in square, super sturdy carriage , iron core belt (tied not to death) , bed leveled with digital caliper , 7 round different glasses to put on it, 0.9 motors, bondtech extruder , capricorn tube, copper block, and.....a lots of other stuffs. Still problems.

The only part I know , the frame , is a shit. So maybe can be the 3 tower to be bended twisted or whatever, or maybe consumed in some areas, BOH or other magical spites. I don't mind anymore.

Change those part (frame with carriages) with other crappy parts is pointless. Then I should adapt from the start all the enclosure and all the other mods. The final result would be always something not of hight precision. So maybe time to make a change.Needing:

I saw two frame that look interesting:

RailCore II 3D Printer : https://railcore.org/

Or the Motion System and ToolChanger , but this one didn't have 3 motor for auto level the bed and have "just" 200x300x300 part's area.

300x300x300 would be better so for the auto bed leveling . I would go for the RailCore II.

I would like NOT use self printed part but already made precise components.

I'll need to print ASA and ABS (or hotter materials) so I'll build (or adapt) the hot chamber system I already have .

I'll scrap this stupid delta for use all the part I can. Even the smart effector if I can adapt it for the CoreXY.

There are other CoreXY with much sturdy frame out of the box? I would not lose other 2 years for put in line the frame.Availability of the printer, of course. This RailCoreXY seems disappear from the market. Everywhere sold out.

Thanks for the suggestions or argumentations. They will be really appreciate.

-

Have a look at this.

thingiverse.com/thing:3843001 -

The primary determinant of frame sturdiness is the cross sectional size of the members. If you use 20x20 t-slot, don't expect sturdy, even if you add $300 worth of corner gussets. OTOH, if you use some of the money you budgeted for expensive corner gussets and hardware to buy larger t-slot instead, you will get a sturdy frame without all the extra hardware. 40x40 t-slot is pretty rigid stuff for most 3D printer sizes, including 300x300x300 mm print capacity. Adding rigid panels for enclosure can increase overall rigidity a lot, so you might be able to use smaller t-slot than if the printer were open.

If you build a rigid frame and drive the Z axis with a single motor, you probably won't need autoleveling. If you use 3 motors to drive the Z axis, you will need autoleveling because you used 3 motors.

If you're going to print ABS/nylon/PC, etc., you will want to use a kinematic mount for the bed to allow it to expand when heated.

-

@mrehorstdmd said in Suggestions for hight precision CoreXY:

kinematic mount

Ok for the kinematic mount, added to the features to have.

High level Kit (pre-assembled) ?

-

@giostark Definitely study the design of the jubilee. If tool changing is of interest to you.

Railcore is very solid as well.

There is the BLV cube.

Voron2 (a bit needlessly complicated, but nice)

-

I am hoping that somebody will put together a full Jubilee kit with the option of going to a Tim Taylor sized model! <insert manly grunt here>

Being located in Canada makes getting the individual bits VERY expensive due to freight. -

edit:

In Europe I just found this one:

https://www.ratrig.com/3d-printing-cnc/3d-printer-kits/all-3d-printer-kits/rat-rig-v-core-pro-linear-rail-701.html

Did you ever listen of them? Can be they trusted?

Ok , seems an other Chinese crappy brand. And is expensive too !

Not original linear rail , not auto bed leveling. And looking at some videos the machine dance when go a little fast.

They mount those Chinese rails?!

https://www.youtube.com/watch?v=5phwhocuXWc

The RailCore II is completely an other product.Outstanding...before I have to manage the curse of a crappy delta frame

and when I realize that is time to change , the curse try to keep you with your best enemy making unavailable the substitution

and when I realize that is time to change , the curse try to keep you with your best enemy making unavailable the substitution

BLV cube is available on aliexpress so NEVER buy there again.

The Voron2 didn't have the auto bed leveling. -

@giostark said in Suggestions for hight precision CoreXY:

The Voron2 didn't have the auto bed leveling.

The voron bed is fixed and the X Y gantry is leveled.

-

@giostark said in Suggestions for hight precision CoreXY:

The Voron2 didn't have the auto bed leveling.

if the machine is solid there is no real need for such things imho

-

@bearer Well I did say it was needlessly complex. You know what they say, if you can't make it perfect, make it adjustable.

-

@Phaedrux said in Suggestions for hight precision CoreXY:

if you can't make it perfect, make it adjustable.

absolutely, and then if its reasonably solid it'll stay adjusted which imho is better than autoleveling every print

-

@giostark I don't know of any bed kits that are kinematic, but it isn't too had to DIY.

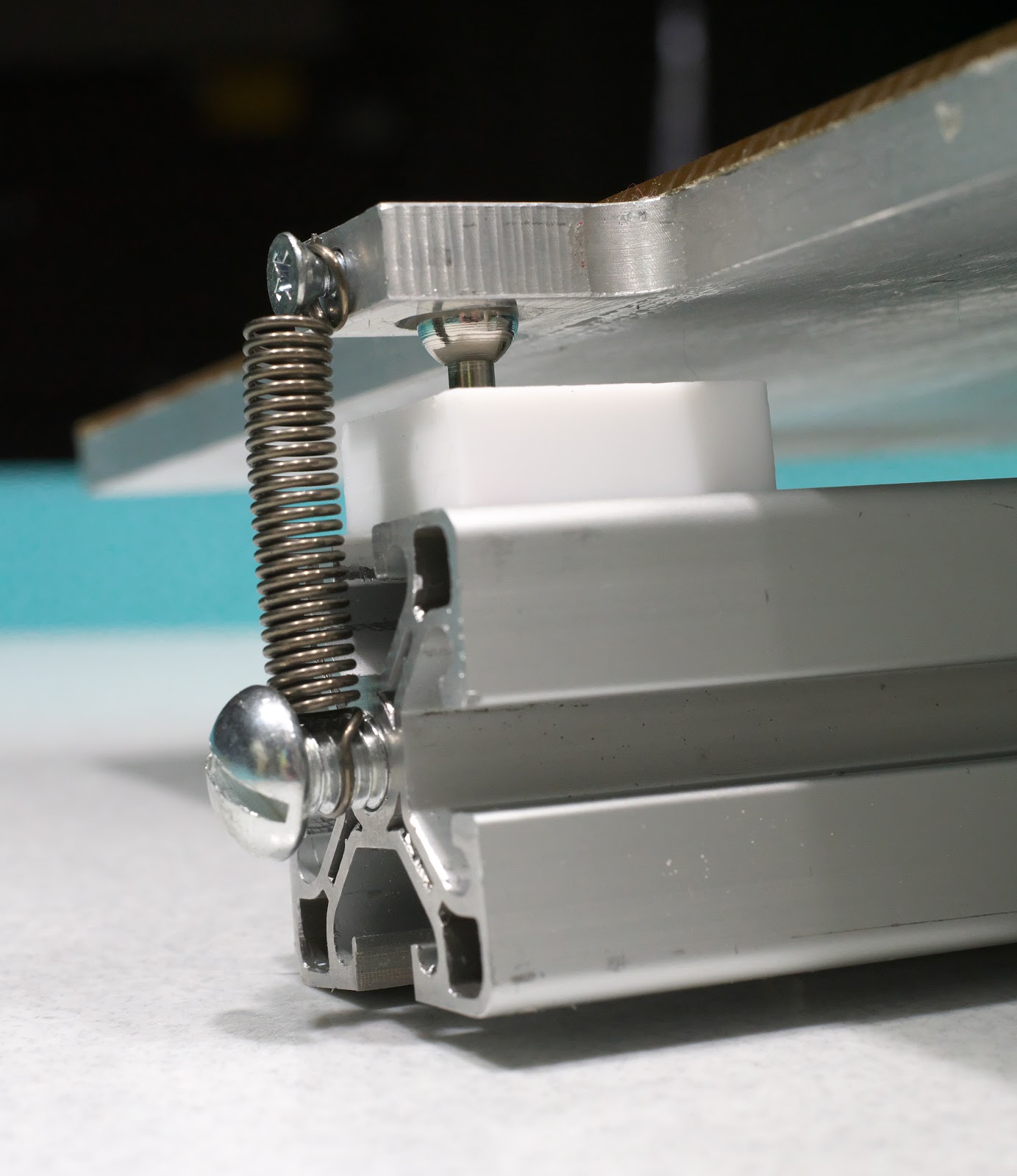

Start with 3 point support for bed plate- two ball head screws (or acorn nuts), and one "normal" screw:

Put one of the ball heads in a chamfered hole in the plate- this will be the reference adjuster:

And put the other ball head in a chamfered slot. This will be the pitch adjuster. Don't worry, they don't have to be milled- the slot can be cut with a saw and then filed a little to make a smooth edge for the ball to sit in. The plate is going to expand less than 1 mm, so the slot doesn't need to be long.

The third screw, the roll adjuster- just contacts the smooth underside of the plate.

At each screw the plate is free to tilt when you're leveling the bed. At the slot the plate is free to expand in the direction away from the reference screw, and tilt as needed while leveling the bed.

At the roll screw the plate is free to expand in X and Y.

Springs hold the plate down on the support.

See: https://drmrehorst.blogspot.com/2017/07/ultra-megamax-dominator-3d-printer-bed.html

and https://drmrehorst.blogspot.com/2019/04/more-changes-to-ummds-z-axis.htmlOnce you understand the basic concept, you can create this type of mount in many different ways. The slot doesn't have to be milled into the plate- it can be two parallel metal bars that are screwed to the plate. You can also invert the mount and put the ball head screws in the plate and the hole and slot on the support.

Leveling is easy. Adjust pitch, then roll. Done. If the assembly is solid, you won't have to do it again.

-

WOW thanks mrehorstdmd !!!

I'm already entering in this mode...of the CoreXY , I mean.

Hope with a good hardware finally I will get some satisfaction. -

Some one of you know where to found the RailCore II Kit? Or maybe a good used one. It seems sold out everywhere

-

-

We recently made the decision to discontinue doing business with ProjectR3D, this resulted in us also stopping kit sales as some of the kit components come from ProjectR3D. We still have some stock, feel free to reach out to us using the contact page at Filastruder.com.

-

Check the railcore discord. A used rc with first class components ya was posted about 10 days ago.

-

I'm about to re-build a new CoreXY, and I think it will be something cloe to the HevORT:

https://www.youtube.com/watch?v=T-IX8h-ssbs&list=PLY5rp1lSfPHDdxeNpCljgwThos8GBTOFE

I especially like the bed, which allows 5 axis printing:

https://www.youtube.com/watch?v=aL7pEEHTTe4

https://www.youtube.com/watch?v=FsdU0JJdxeQThe problem is they communicate on Facebook

-

Finally , I'm in contact with Peter of Hightemp3D (EU channel). Seems all the stuffs he have are CNC milled components and laser cut parts. Misumi rails, etc etc. Also the kinematic bed will be included, full metal extruder and so on.

I'll update this post with the moving

Then I'll try to keep also the delta. I'll produce by myself the top/bottom frame, then buy new towers and linear rail.

Thanks everyone for the suggestions.

-

@Phaedrux said in Suggestions for hight precision CoreXY:

Voron2 (a bit needlessly complicated, but nice)

OR the Voron VZero. Simpler, compact, stiff and fast.