Suggestions for hight precision CoreXY

-

edit:

In Europe I just found this one:

https://www.ratrig.com/3d-printing-cnc/3d-printer-kits/all-3d-printer-kits/rat-rig-v-core-pro-linear-rail-701.html

Did you ever listen of them? Can be they trusted?

Ok , seems an other Chinese crappy brand. And is expensive too !

Not original linear rail , not auto bed leveling. And looking at some videos the machine dance when go a little fast.

They mount those Chinese rails?!

https://www.youtube.com/watch?v=5phwhocuXWc

The RailCore II is completely an other product.Outstanding...before I have to manage the curse of a crappy delta frame

and when I realize that is time to change , the curse try to keep you with your best enemy making unavailable the substitution

and when I realize that is time to change , the curse try to keep you with your best enemy making unavailable the substitution

BLV cube is available on aliexpress so NEVER buy there again.

The Voron2 didn't have the auto bed leveling. -

@giostark said in Suggestions for hight precision CoreXY:

The Voron2 didn't have the auto bed leveling.

The voron bed is fixed and the X Y gantry is leveled.

-

@giostark said in Suggestions for hight precision CoreXY:

The Voron2 didn't have the auto bed leveling.

if the machine is solid there is no real need for such things imho

-

@bearer Well I did say it was needlessly complex. You know what they say, if you can't make it perfect, make it adjustable.

-

@Phaedrux said in Suggestions for hight precision CoreXY:

if you can't make it perfect, make it adjustable.

absolutely, and then if its reasonably solid it'll stay adjusted which imho is better than autoleveling every print

-

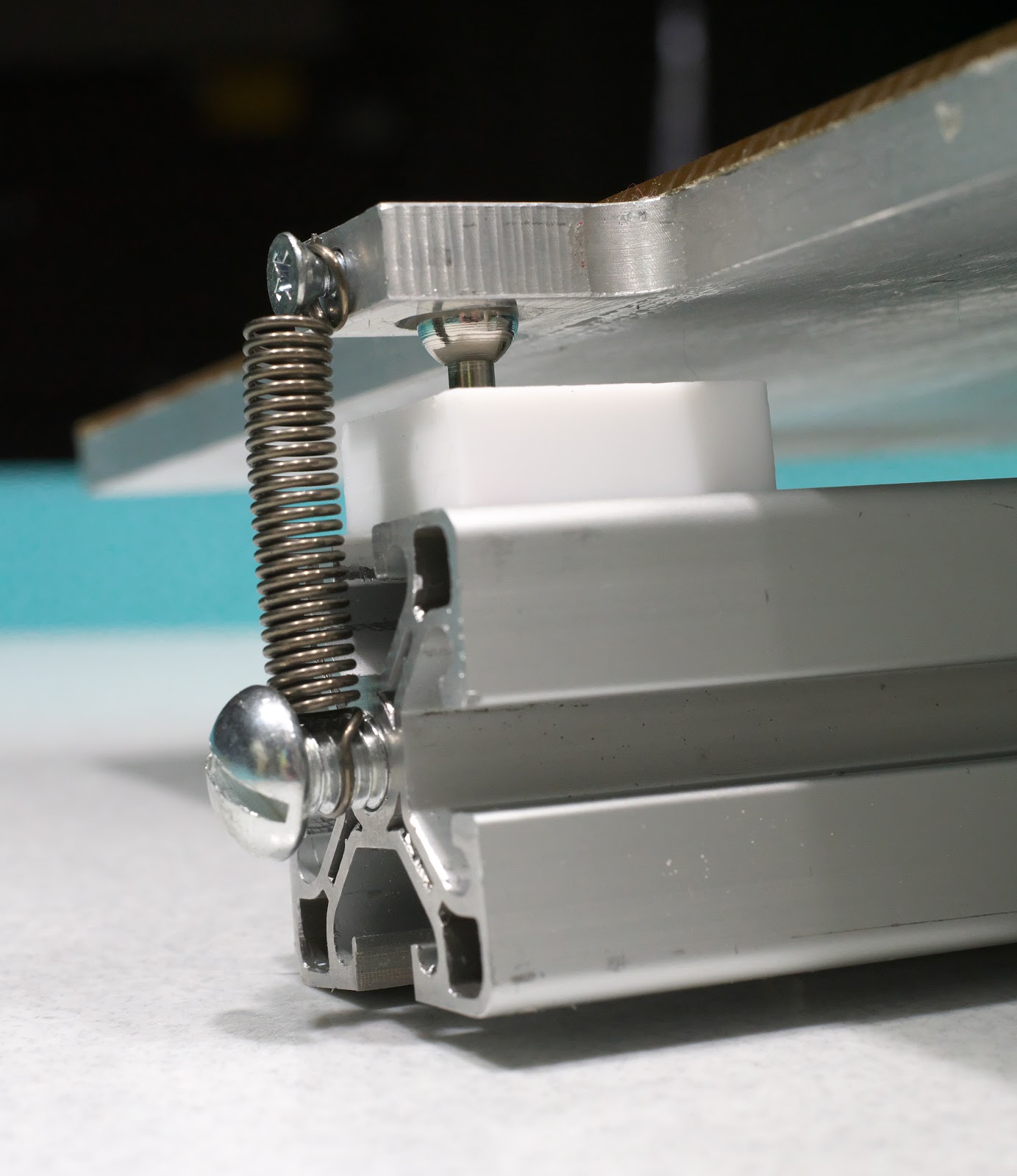

@giostark I don't know of any bed kits that are kinematic, but it isn't too had to DIY.

Start with 3 point support for bed plate- two ball head screws (or acorn nuts), and one "normal" screw:

Put one of the ball heads in a chamfered hole in the plate- this will be the reference adjuster:

And put the other ball head in a chamfered slot. This will be the pitch adjuster. Don't worry, they don't have to be milled- the slot can be cut with a saw and then filed a little to make a smooth edge for the ball to sit in. The plate is going to expand less than 1 mm, so the slot doesn't need to be long.

The third screw, the roll adjuster- just contacts the smooth underside of the plate.

At each screw the plate is free to tilt when you're leveling the bed. At the slot the plate is free to expand in the direction away from the reference screw, and tilt as needed while leveling the bed.

At the roll screw the plate is free to expand in X and Y.

Springs hold the plate down on the support.

See: https://drmrehorst.blogspot.com/2017/07/ultra-megamax-dominator-3d-printer-bed.html

and https://drmrehorst.blogspot.com/2019/04/more-changes-to-ummds-z-axis.htmlOnce you understand the basic concept, you can create this type of mount in many different ways. The slot doesn't have to be milled into the plate- it can be two parallel metal bars that are screwed to the plate. You can also invert the mount and put the ball head screws in the plate and the hole and slot on the support.

Leveling is easy. Adjust pitch, then roll. Done. If the assembly is solid, you won't have to do it again.

-

WOW thanks mrehorstdmd !!!

I'm already entering in this mode...of the CoreXY , I mean.

Hope with a good hardware finally I will get some satisfaction. -

Some one of you know where to found the RailCore II Kit? Or maybe a good used one. It seems sold out everywhere

-

-

We recently made the decision to discontinue doing business with ProjectR3D, this resulted in us also stopping kit sales as some of the kit components come from ProjectR3D. We still have some stock, feel free to reach out to us using the contact page at Filastruder.com.

-

Check the railcore discord. A used rc with first class components ya was posted about 10 days ago.

-

I'm about to re-build a new CoreXY, and I think it will be something cloe to the HevORT:

https://www.youtube.com/watch?v=T-IX8h-ssbs&list=PLY5rp1lSfPHDdxeNpCljgwThos8GBTOFE

I especially like the bed, which allows 5 axis printing:

https://www.youtube.com/watch?v=aL7pEEHTTe4

https://www.youtube.com/watch?v=FsdU0JJdxeQThe problem is they communicate on Facebook

-

Finally , I'm in contact with Peter of Hightemp3D (EU channel). Seems all the stuffs he have are CNC milled components and laser cut parts. Misumi rails, etc etc. Also the kinematic bed will be included, full metal extruder and so on.

I'll update this post with the moving

Then I'll try to keep also the delta. I'll produce by myself the top/bottom frame, then buy new towers and linear rail.

Thanks everyone for the suggestions.

-

@Phaedrux said in Suggestions for hight precision CoreXY:

Voron2 (a bit needlessly complicated, but nice)

OR the Voron VZero. Simpler, compact, stiff and fast.

-

@zapta said in Suggestions for hight precision CoreXY:

VZero

I'm very tempted indeed, shame its tricky to get 15mm alu locally

(edit: oh my, they have a sourcing guide with aliexpress links for most things, incl alu profile kits and belt/pulley kits. unfortunately hemera is on the way so it'll be a while for a voron)

-

@giostark Hi Sergio

Happy to have you as a customer. The Railcore kit is extremely stable. Only very few 3D printed parts are used so it is long term stable and extremely stiff. At the moment the only 3D printed parts are the feet, electronics enclosure corners, Endstops and BLtouch mount. The BLTouch mount will also soon be aluminum. In the near future there will also be a 135C chamber temperature version of the kit.Peter From HighTemp3D.com based in the EU

-

There is a Kinimatic bed mount system available for the Railcore produced by Mandela Rose Works:

Kinematic Mount -

@jballard86 Yes, thats the one I sell at my EU based shop: https://hightemp3d.com/collections/mandala-rose-work/products/kinematic-mounting-kit-from-mandala-rose-works

-

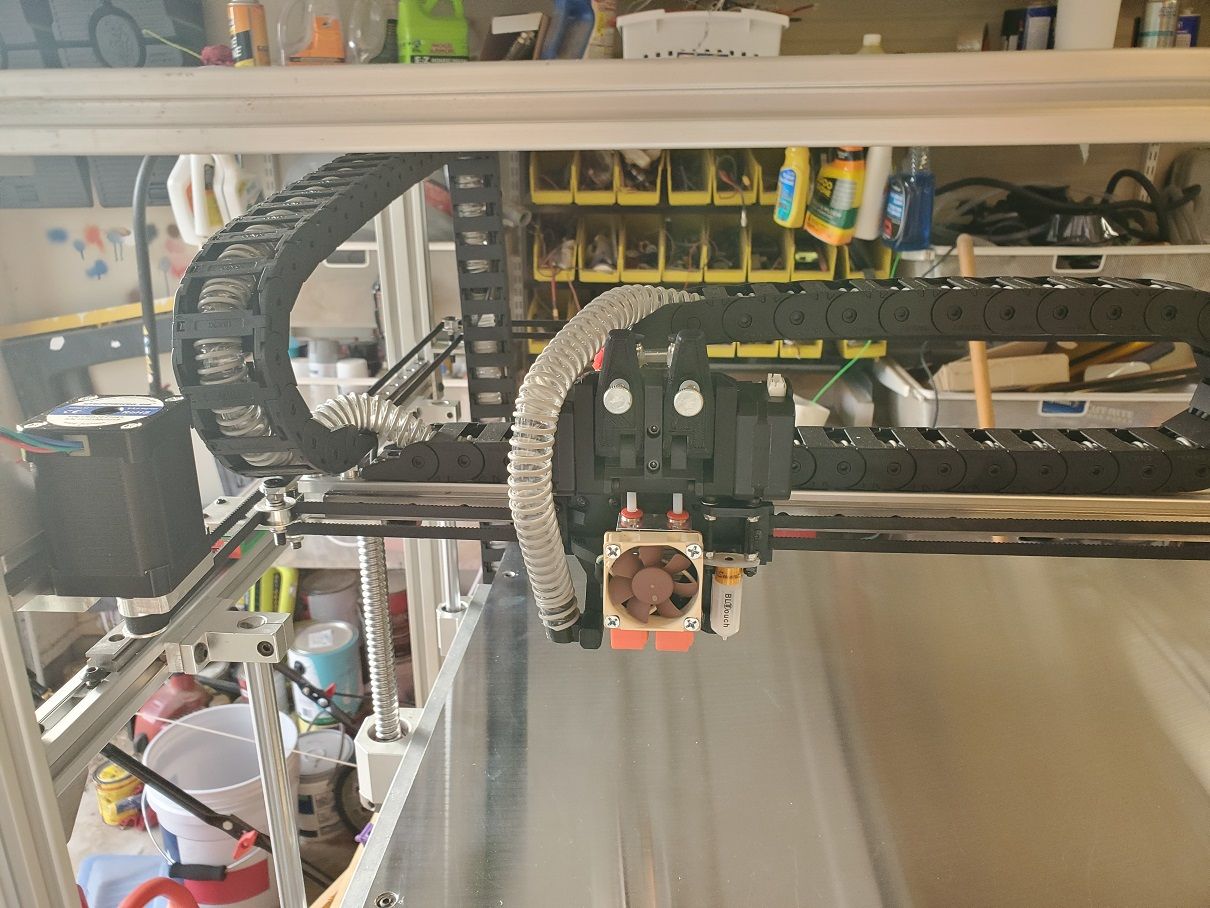

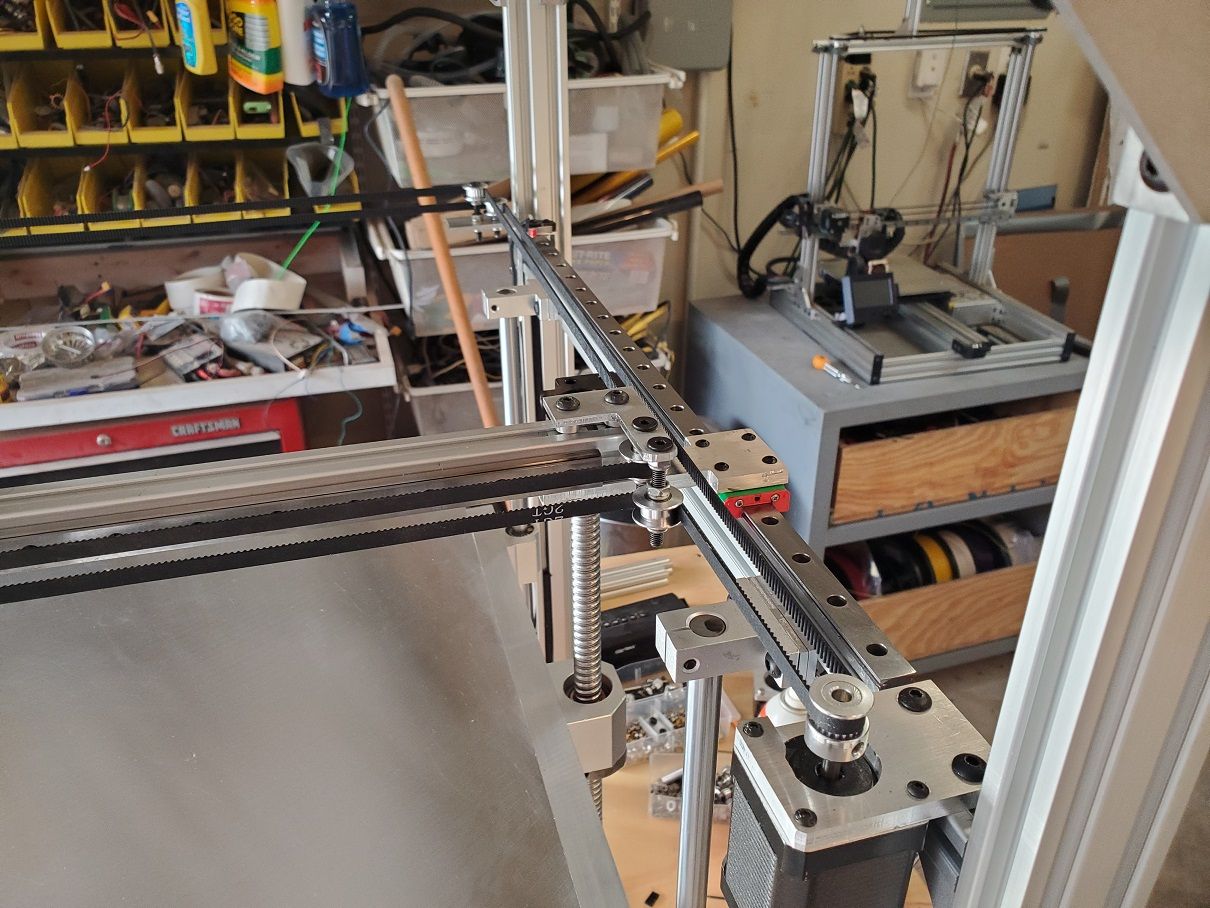

I just finished building a new CoreXY printer with the goal of no 3d printed structural parts at all. The only printed parts are the enclosures for the controller boards and the extruder mount (dual BMG extruders).

I've been 3d printing for several years on both cartesian and corexy. A more rigid printer usually produces better prints. The best improvements were around bed stiffness. I recently went to the 3 independent "true level" setup with a 1/4 thick MIC6 aluminum plate + 1/4 tempered glass. Each z axis motor is controlled by an external stepper and has a 3:1 gear reduction for both higher resolution and higher strength (HERE is a vid of my bed setup). Since this vid, I've added 12mm smooth rods to each ballscrew to improve linear motion.

Attached are a few pics of my printer:

!

!