Heated Chamber BLtouch wiring issues.

-

Hi,

I wired my BLtouch to my Duet2WiFi using H3 and it worked good for a couple month in an enclosure at <40c. No I’ve installed an active heater to get my chamber up to 60c for PC/ABS and now I’ve got issue where my probe will do startup cycle correct but when G29/30 probe doesn’t extend. I tried wiring the power/ground/servo mod all into a 4x2 male header in hopes it would keep a more secure connection but after 1 print it failed again. I’m about to pull my hair out.

Also, if it matters, I do have a 4020 cooling my Duet board with fresh air so the board stay around 40-45c

Is there a way to make use of the z-probe header with the molex connectors on the Duet2 WiFi or is there another suggestion? -

I have heard (no first hand experience) that the BLTouch starts to go squirrly above 50 C.

-

@jens55 said in Heated Chamber BLtouch wiring issues.:

I have heard (no first hand experience) that the BLTouch starts to go squirrly above 50 C.

first hand here .. at 50C it stops working

no clue why (have not try to disassemble it)but op say below 40C, and below 40C it works ok

-

Unless I mis-understood, op says it was working below 40C but is no longer working at 60C

-

Also, maybe there is interference from the heater wiring - is it running parallel to the wiring loom that carries the BLTouch wires ?

-

@jens55 @arhi heater is a stand-alone Wi-Fi InkbirdSmart unit hooked up to a heat lamp. Not duet controlled, yet.

As to the heat with BLtouch, I was aware of the 50c mark. I have been running my G29’s before turning the heater on so temps inside chamber then are usually 25-30c. All good points tho.

I really think this is a wonkey issue with the DuPont connectors. But short or soldering my yellow servo-mod wire directly to the Duet expansion header idk how to solve it -

@jallen810 I tested bltouch, it failed at 50C, I decided not to put it into 50C+ chambers.. there is possibilitiy that after prolonged 50+ it will stop working reliably at room temp too. No idea what's inside, but if they for e.g. use magnets they can get demagnetised permanently..

wrt "securing the wire" the hotsnot goes a long way to secure a wire in a connector (just crimp a pin-receptable on to wire, slide the heatshrink over it, press it on the pin on the expansion connector, secure with hotsnot) and it is not too hard to clean if yuo don't need it any more. other option is to get IDC connector and crip the single (or 3 or ..) wire to it.

In my hot chamber I use precise piezo that's "detachable". It's a very ugly construction but works for me. Z height I detect using a switch (shown to be most reliable to use high quality microswitch). The mesh I do with piezo. I have exposed header on the "head", when I need to do do a mesh calibration, I heat up the bed and get chamber to some "ok to work in" temp (50-60C) and not all the way up (120C) and I attach the mini pcb with amp to the header, the piezo disk hangs on two wires from that pcb, I manupulate that disk "below the nozzle" and start the mesh calibration. Just by hanging by the wires it survives

.. the sensor triggers when nozzle press disk (disk comes between bed and nozzle), it is super ugly, super flimzy but works very very very reliably and very very very repeatable ( this few $ contraption is much more repeatable then my precise pieso orion sensor with fancy pcb and fancy mounting and all the chabang and not very cheap neither) ... after mesh is calibrated I just remove it all and store in a pocket next to printer case.

.. the sensor triggers when nozzle press disk (disk comes between bed and nozzle), it is super ugly, super flimzy but works very very very reliably and very very very repeatable ( this few $ contraption is much more repeatable then my precise pieso orion sensor with fancy pcb and fancy mounting and all the chabang and not very cheap neither) ... after mesh is calibrated I just remove it all and store in a pocket next to printer case. -

In my hot chamber I use precise piezo that's "detachable". It's a very ugly construction but works for me. Z height I detect using a switch (shown to be most reliable to use high quality microswitch). The mesh I do with piezo. I have exposed header on the "head", when I need to do do a mesh calibration, I heat up the bed and get chamber to some "ok to work in" temp (50-60C) and not all the way up (120C) and I attach the mini pcb with amp to the header, the piezo disk hangs on two wires from that pcb, I manupulate that disk "below the nozzle" and start the mesh calibration. Just by hanging by the wires it survives

.. the sensor triggers when nozzle press disk (disk comes between bed and nozzle), it is super ugly, super flimzy but works very very very reliably and very very very repeatable ( this few $ contraption is much more repeatable then my precise pieso orion sensor with fancy pcb and fancy mounting and all the chabang and not very cheap neither) ... after mesh is calibrated I just remove it all and store in a pocket next to printer case.

.. the sensor triggers when nozzle press disk (disk comes between bed and nozzle), it is super ugly, super flimzy but works very very very reliably and very very very repeatable ( this few $ contraption is much more repeatable then my precise pieso orion sensor with fancy pcb and fancy mounting and all the chabang and not very cheap neither) ... after mesh is calibrated I just remove it all and store in a pocket next to printer case.@arhi Do you have some pics and maybe some links to clarify? Or is there a video from one of the 3D Printer YouTubers that you could point me at? I'm by no means married to my BLtouch, it's just what everyone told me was a good solution, and it was until this heat issue struck. I'm about 5min away from buying an EZabl otherwise or trying to get my Sidewinder X1's Z-endstop optical sensor to read my spring steel bed

-

@jallen810 I can take a picture but you are not going to like it

it's really an ugly solution

it's really an ugly solution  ... just need to wait till kids are asleap as need to shift some stuff around in the workshop to get to that machine as it's out of commission attm... expect pictures in 10-15min

... just need to wait till kids are asleap as need to shift some stuff around in the workshop to get to that machine as it's out of commission attm... expect pictures in 10-15min -

@arhi You da man thank you sir!

-

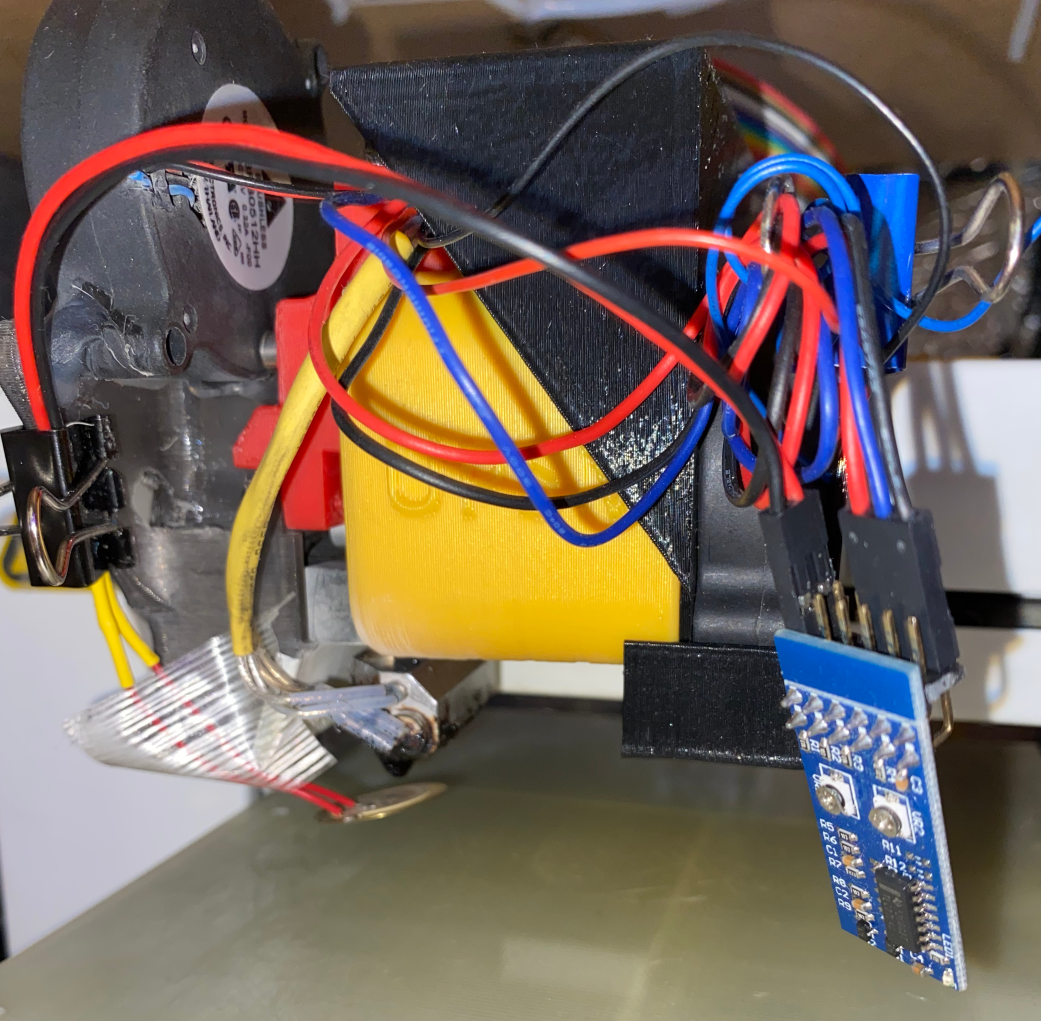

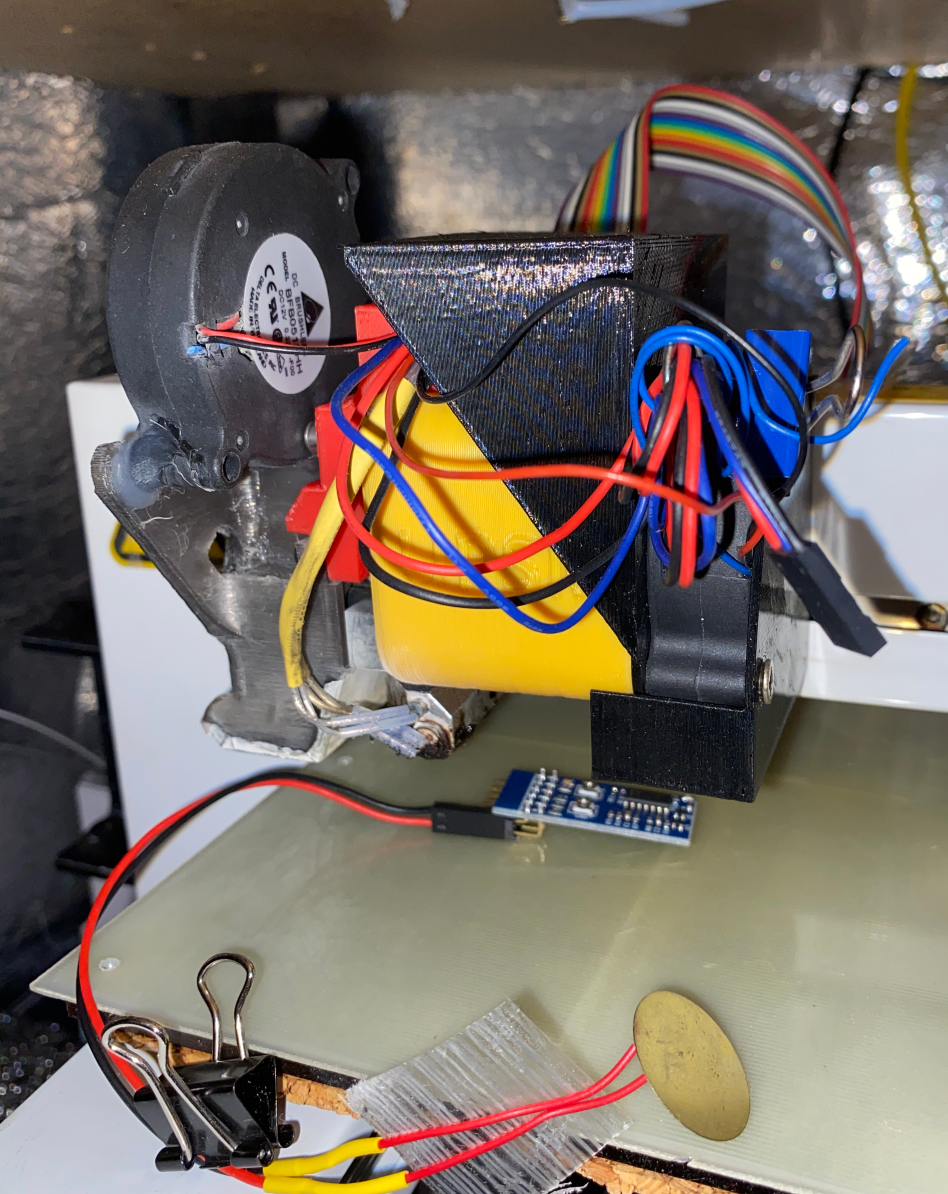

@jallen810 here

as you can see it is a McGiver solution, but works, that header just plugs into el-cheapo PRC board that's an opamp for the piezo disk that's already plugged in and that has "pull to ground" signal output, you see that piezo disk wires are temporary attached with a clip and a piece of tape so that disk is "about below nozzle" the whole contraption will move and disk will be between tip and bed and will trigger ... this, as ugly and flimzy and disgusting as is works amazingly precise.

I have cold air blowing trough the case of that printer keeping all the belts cool, but attm printer is out of comission (otherwise I'd show you video of how it does the mesh calibration) as after almost 10 years a flat cable going to the head is somewhere loosing connection (12V and PT100 wires are dead) so I need to replace it, but it requires a whole printer disassembly to replace it so it's waiting for "free time"

-

and here you see it "disconnected" so printer can work (yes, I know, I should shorten the wires hanging on the extruder but ..) ... the sensor is on the table so you can see what part is disconnected, this I now put in the drawer until next time I need to calibrate mesh... I normally calibrate mesh if I replace the bed or every 2-3 months (and yes, that colorfull flat cable that you see behind, that's what's dead, probbly from being only part of "regular" wiring exposed to heat/cool cycles but it held up many years)

-

@arhi said in Heated Chamber BLtouch wiring issues.:

PRC board

Cool so I would need a piezo and this special board? I google PRR board and couldn't find anything. Is it referred to as something else?

-

@jallen810 it is precisionpiezo clone from aliexpress or original one I don't remember i have 4 or 5 originals and 4 or 5 ones from aliexpress ... I have both original and prc versions 1.x so old ones. New 2.x are supposedly better but I prefer the old ones.

this is PRC version: https://www.aliexpress.com/item/32832426899.html

original of this type of pcb

https://www.precisionpiezo.co.uk/product-page/universal-piezo-z-probe-pcb-v2-x-for-1-2-3-or-more-piezosNow, I suggest you go for original, price is more/less same but with original you get superb support from PP guy's while with PRC version you get nothing. Also original is properly soldered and tested, PRC version I had to "touch up" few of them to get working

this is the kit I'd use "today" if I'm buying for new printer to use in this type of fashion I'm using here.

https://www.precisionpiezo.co.uk/product-page/copy-of-precision-piezo-universal-z-probe-kit

mind, in "not enclosed" printers like my ender5 I use their

https://www.precisionpiezo.co.uk/product-page/precision-piezo-orion-kit

embedded in the printhead .. and while it's super convenient, I kinda prefer that mcgyver way

-

I am impressed with your solution! I have several piezo sensors kicking about as I first tried that solution before gong to the BLTouch. I really liked the idea of not having to set the offset - the measurement as taken was perfect. Alas, it wasn't all cream and honey. There was a big fat fly right smack dab in the middle paddling around in the cream and honey. The problem was (IMHO) the way the piezo was mounted to the hot end. The piezo was incredibly accurate and unbelievable sensitive .... but while some spots produced a perfect sense result, in other spots the bed was pushed down by a huge amount before the sensor would trip. It was utterly useless!

I spent a LOT of time getting it to work right before I gave up to preserve my sanity.

With your solution, which I am sure could be made 'pretty' you have the best of all worlds - you got accuracy, no offset to figure out (and to change every time you change nozzles) and something that works everywhere on the bed.

I am puzzled/surprised that it works so well because I was under the impression that the piezo disc needed to flex in order to generate an output. In your setup the piezo is flat on the bed before the nozzle touches it and generates the output pulse. I am also a bit surprised you don't get noise issues / false triggers as the nozzle comes down and there is the settling of the piezo against the bed.

Anyway, I like it and might try to emulate along those lines but prettier because we all know that prettier works better

-

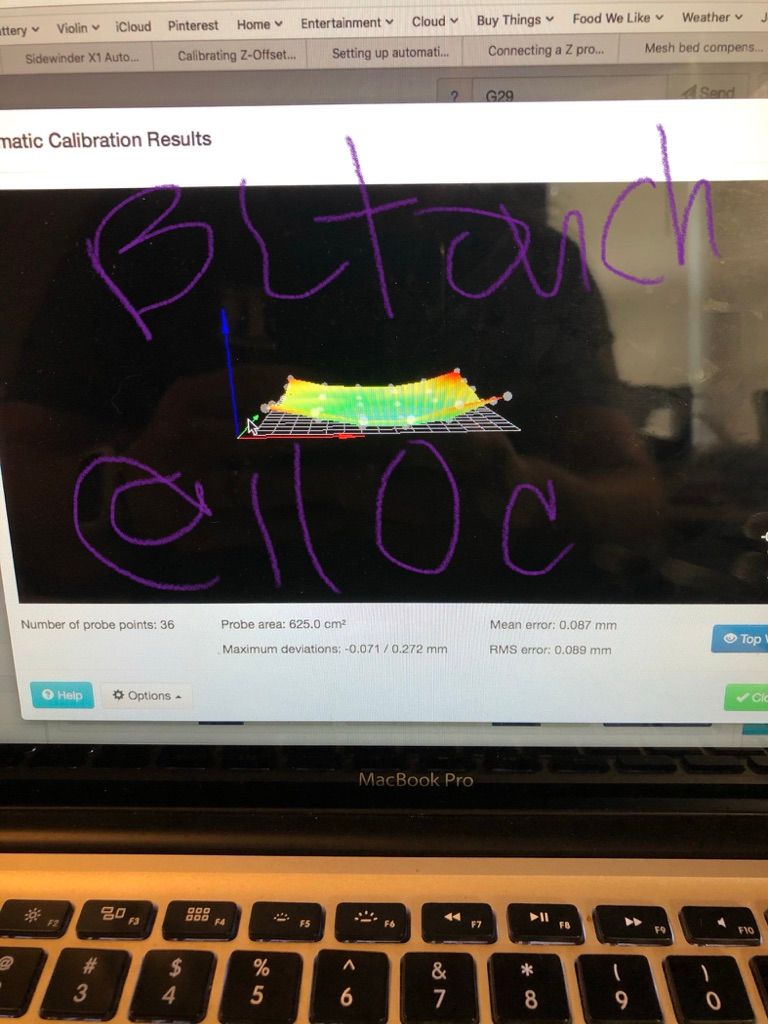

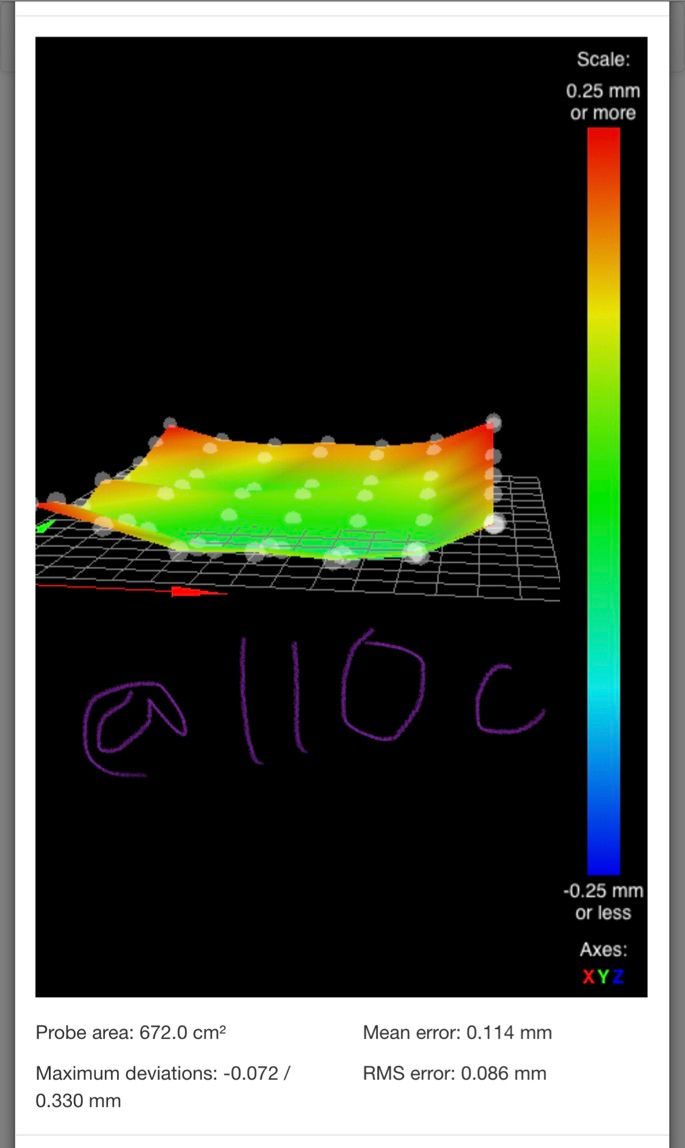

Update: So on the off chance it worked I tried cutting my Artillery Sidewinders Z-endstop off and put in on my probe mount to see if it would work. It's a SunX GL-8H NPN-NO inductive sensor so I wired it up as such and here are the results. It's rated up to 70c so ill try it and see how it holds up over time. Only concern is the 2.5mm max sense distance

If it fails I may try one of these SICK engineering hi temp 8mm distance M12 probesBLtouch at 100mm/min speed:

GL8H @600mm/min probe speed:

-

Hi everyone, I'm sorry for my English but I'm Italian and I use Google translate

I had many problems related to bltouch and the high temperature (> 80 °), in practice I noticed that the stick being made of plastic, it embarks.

If you've ever bought an inexpensive bl-touch, you may have noticed that the stick is made of aluminum, which doesn't mess with temperature.

The simple solution I found:- take original bltouch stick (plastic), cut the magnet and keep it for later.

- take aluminum stick, remove magnet and hold stick.

- with pliers, squeeze the stick to create the thickness that stops the stick from falling (the precise height of the enlargement, see Original Stick).

-limate the face of the magnet to be attached and the face of the stock to be attached. - attaches original magnet with aluminum Stick, using Attack (they must be perfectly aligned).

- now put all this, in the original bl-touch.

PS. I shortened the aluminum stick to make it lighter, I don't know if it is essential.

-

@babetto-matteo i don't know how the pictures are attached sorry

-

@babetto-matteo You should be able to copy and paste or drag and drop the image into the post window.