What happens to the temperature inside your nozzle?

-

@fma Regarding the temperature of the cooling air, I think I covered all that in my blog. I was especially careful to note the ambient temperature and the fact that the bed was unheated, so any deflected air might be cooler that if the bed was heated.

I would be hesitant to say that "most people blow way too much air on their parts". I haven't seen the results of any surveys asking people what volume flow rate they use, have you? Is that statement based on any factual data or are just guessing?

Also this statement quote - "When using PLA, you almost don't need to blow air at all, except in specific areas, to preserve small details"

...... is only be true for certain nozzle sizes and slowish speeds. When using larger nozzles and/or printing at high speed, one can lay down a lot of plastic in a very short space of time. If cooling isn't used, then the previous layer will still be at or above the Tg temperature when the next layer is added resulting in the printed part sagging.

-

@deckingman said in What happens to the temperature inside your nozzle?:

@fma Regarding the temperature of the cooling air, I think I covered all that in my blog. I was especially careful to note the ambient temperature and the fact that the bed was unheated, so any deflected air might be cooler that if the bed was heated.

I would be hesitant to say that "most people blow way too much air on their parts". I haven't seen the results of any surveys asking people what volume flow rate they use, have you? Is that statement based on any factual data or are just guessing?

Facts: I meet a lot of people doing 3D printing in my hackerspace and around, and I see what they are doing.

...... is only be true for certain nozzle sizes and slowish speeds. When using larger nozzles and/or printing at high speed, one can lay down a lot of plastic in a very short space of time. If cooling isn't used, then the previous layer will still be at or above the Tg temperature when the next layer is added resulting in the printed part sagging.

Yes, true. That's why I do think that an heated chamber keeping the part at the correct temperature¹ would be a huge improvement, even for PLA. This way, you don't have to bother that much with air flow.

¹ finding that correct temperature would need some experiment, though, and probably change for each filament brand/color/...

-

@fma said in What happens to the temperature inside your nozzle?:

keeping the part at the correct temperature¹ would be a huge improvement, even for PLA

I started my 3d printing "experience" with "difficult to print materials" PP and HDPE (and HDPE800 which is some even higher density polyethylene than normal HDPE and warps even worse), so I'm experimenting with heated chambers for almost a decade. WRT PLA 25-30C is kinda best printing temperature, and temp of the air you blow is best around 25-30C. Blowing hotter air (e.g. 40C) produces very bad prints. Try it yourself. There was a huge issue UP printers had with PLA where the designer made the air that cools the heatbreak work as part cooling too and no matter how much air they pushed the results were terrible. That air was 40-45C. Bringing colder, room temp air, to cool the part solved all the issues. You can find measurements and discussions in lenght on the pp3dp forum.

ABS works great in 70C chamber with 70C air being circulated in the chamber (no need to blow directly under the nozzle, enough to circulate air. I made it usually in the way that first layer of air going from the heaters creates laminar flow over the top layer of the print (never actually visualised the flow but..) and it works ok, problem is hotend's heatbreak, I experimented with a lot of stuff (peltie's, external air trough tubes etc...) and so far water is the only thing that works ok, but those are all hotends I made myself and are not "very good" (single piece aluminium turned on lathe, no multimaterial heatbreak, no interchangeable nozzle ..)... today there are some interesting solutions available that one should try but one needs time

PC is similar only chamber temp 130C works better than 70C.

PP is on the other hand super nasty to print, it's Tg is 0C but I had best print quality with 40-50C chamber and very slow air movement (208C printing temp and slow 8-12mm/sec print speed with pauses on small layers)

cooler nozzle than the block is expected, it is important that low conductivity nozzles are not too long so that temp differential to the tip is not too big. You compensate for the tip temperature by increasing the temp of the heater block. If the nozzle is too long you have to get your block "too hot" and that can damage the filament, but as long as the required heat increase is in the safe zone for the filament you don't have a problem, you just need to temp-tower find the best temp for certain print settings (fan speed, nozzle size, print speed, layer height, extrusion width combo).

-

Thanks for the feedback!

-

@arhi said in What happens to the temperature inside your nozzle?:

Blowing hotter air (e.g. 40C) produces very bad prints.

Yeah, My Up! Mini is not so great for PLA for this reason. Almost considering adding a pump to get outside air for PLA when the conversion is done.

-

It seems that the enclosure temperature should remains 30°C below the glass transition temperature (confirmed by @arhi, which uses 70°C for ABS). So, for PLA, 30°C is the max.

-

@bearer said in What happens to the temperature inside your nozzle?:

@arhi said in What happens to the temperature inside your nozzle?:

Blowing hotter air (e.g. 40C) produces very bad prints.

Yeah, My Up! Mini is not so great for PLA for this reason. Almost considering adding a pump to get outside air for PLA when the conversion is done.

There are upgrades I made for up! / up! plus / up! plus 2 that solve this by separating part cooling fan from heatsink fan and that move heatsink air away from the part being printed, helps a lot makes it totally usable for PLA... I use my mini for ABS and PC only so I never tackled to redesign it's extruder assembly as for ABS/PC/HIPS it works as is ( I only upgraded the bed heater from 18W to 80W so it can actually get to required temp for PC and added printbite surface as original one is utter .. )

-

@fma said in What happens to the temperature inside your nozzle?:

It seems that the enclosure temperature should remains 30°C below the glass transition temperature (confirmed by @arhi, which uses 70°C for ABS). So, for PLA, 30°C is the max.

I disagree. I'm not a chemist and I don't trust "specification" as Tg for some plastic is a number in a book, and name of the plastic filament is made of is a name on a box. What the actual plastic in the box is and what the actual Tg of that plastic is without "measurement" (no clue how to measure) we don't know. As I seen ABS that prints normally at 220C and I seen ABS (e.g. the one from pp3dp) that prints at minimum 260-270C .. those both print on same extruder, same hotend, same sensors... so def are not both "same ABS"..

Furthermore, polypropylene Tg is 0C!! HDPE is below zero, iirc -40C and you need to heat the chamber over 40C to print them so that's like 80 over Tg not below

..

..I'll stick with

- I have no idea what filament require what temperature (bed, nozzle, chamber)

- I have no idea what filament is cooled with what amount of how hot air

- in order to get best results, I test each batch - temperature tower, temperature tower, temperature tower... till I'm satisfied with results

But yes, 100C for PC, 70C for ABS/HIPS and 30C for PLA are values I use for env. if I can

-

@deckingman said in What happens to the temperature inside your nozzle?:

@zapta Those nozzles look interesting. I'd be a bit concerned about the sensor falling out. How is it retained?

In the examples I saw, they hold it in mechanically. Some people mentioned adding a thermal compound.

-

As said, I use little silicone band around it (sticking to itself). It maintains the thermistor, and make a good insulation. And I use their fiber-glass+silicone as final insulation around the ceramic cartridge. This make a very small hotend, allowing to have fan ducts close to the nozzle. Combined to a berd air pump, this allows very accurate air flow.

-

Further results

https://somei3deas.wordpress.com/2020/05/24/quick-and-cheap-diy-nozzle-trainer-socks/

This thread seems to have been hijacked so make of them what you will.........

........... or do your own tests

........... or continue to chat about printers/filaments/heated chambers/life in general,

........... whatever makes you happy.

-

@deckingman said in What happens to the temperature inside your nozzle?:

... whatever makes you happy.

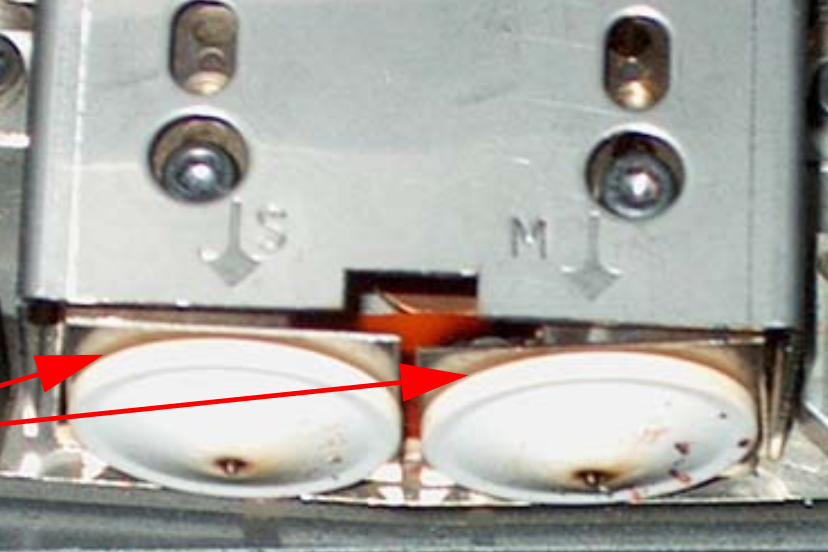

Here is a picture of a ceramic heater and a thermistor in the nozzle that is well covered by a silicon sock. It's compact, symmetric (non need to align) and well isolated. Should handle better deflected air (?). I wonder why this style is not that popular.

(from https://www.deltaprintr.com/)

-

@deckingman said in What happens to the temperature inside your nozzle?:

........... whatever makes you happy.

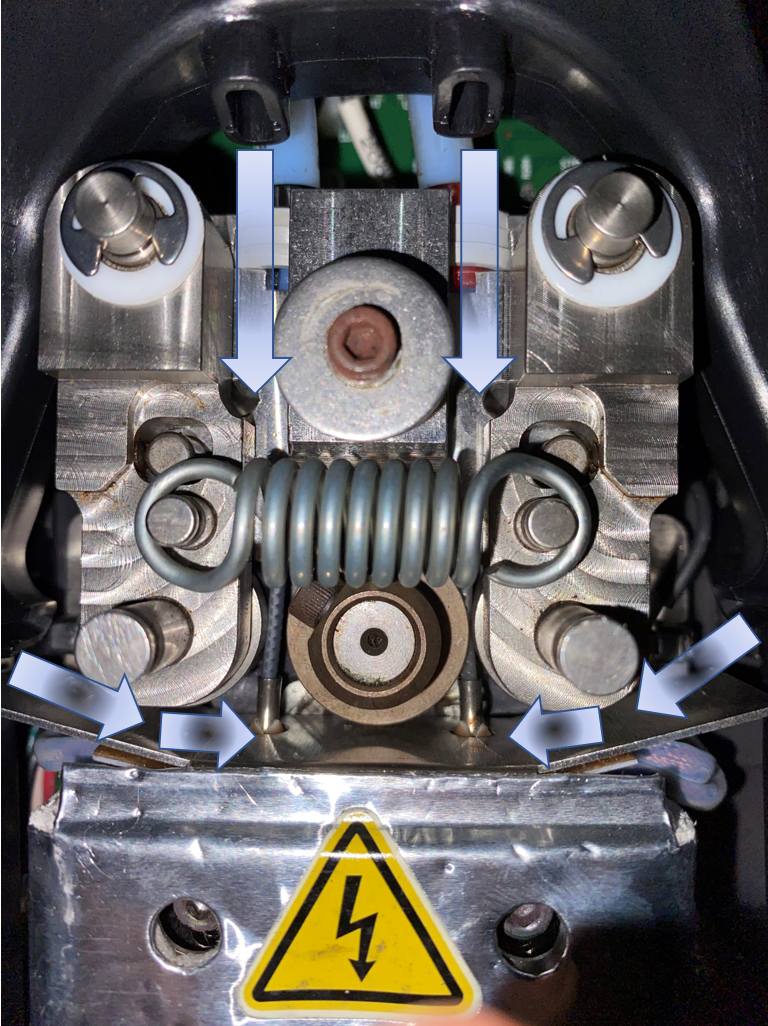

I have a Stratasys BST 1200es in my garage - here is how they separate part cooling and "heatbreak" cooling.

On the print head is an air plenum, where an "umbilical cord/tube" is attached, with the airflow powered by a 120VAC blower fan. This air is drawn from outside of the printer - so assume 25°C or so.

Both the support (left) and model (right) material are extruded with the same DC motor. Some air is directed downward, parallel to the filament, while some is directly just about perpendicular to the filament (right above where it enters the heater).

You can see below that, directly above the heater, there is an angled metal sheet that lines up pretty close to the outlets of the horizontal filament cooling air, controlling the direction of the air and preventing it from passing down towards the print nozzle.

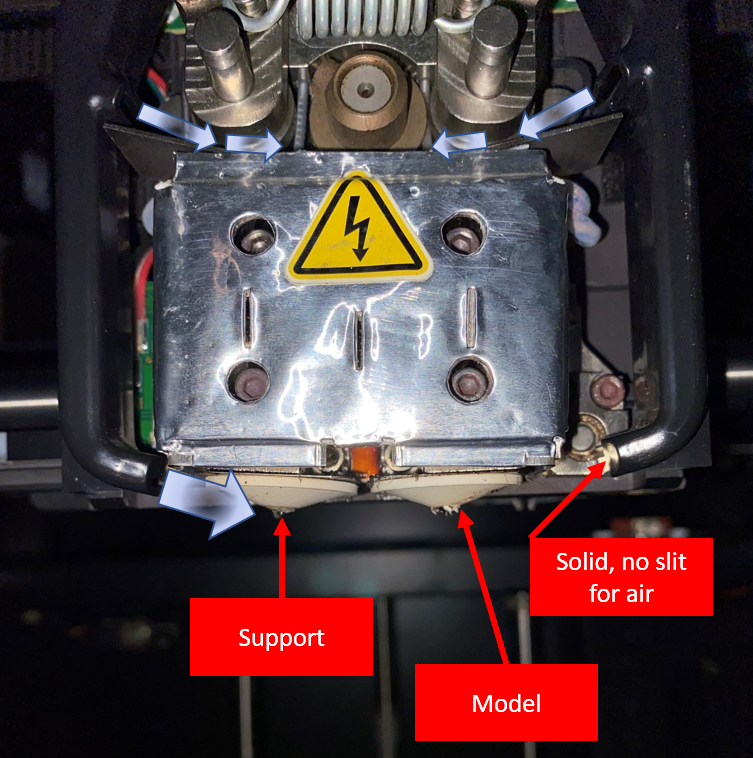

The Dimension series has a heated chamber, set to ~72°C, with the heated air directed over the build plate at roughly the height of the current layer being printed. On the print head air plenum there is a slit on the support side, directing ~25°C air towards the currently printed area. I am unsure if this print cooling air is used only for support or if its for both, as the print head moves depending on what material is selected - if model is selected, it looks like the support nozzle and tip shroud blocks the airflow somewhat. As a note, this blower fan does not turn off except in certain maintenance modes, so the cooling air is not turned off depending on what material is being printed.

The tip shrouds cover a significant amount of nozzle tip, so the impacts of the cooling air (or even blowing chamber air) is limited.

When compared to "reprap" style hotend setups, "heatbreak" cooling flow is quite controlled, the print cooling flow is extremely focused and controlled, and the impact of fluid flow over the nozzle(s) is reduced.

-

@deckingman said in What happens to the temperature inside your nozzle?:

Further results

https://somei3deas.wordpress.com/2020/05/24/quick-and-cheap-diy-nozzle-trainer-socks/

Nice!

One question, did you measure the diamond with and without sock? the temperature at the tip with the fans?

-

@arhi said in What happens to the temperature inside your nozzle?:

One question, did you measure the diamond with and without sock? the temperature at the tip with the fans?

No, I never did. I never thought about it at the time. I don't think anybody thought much about temperatures when socks were first introduced. At that time, it was generally seen as a method of preventing filament from sticking to the nozzle more than anything else. But because of the geometry of the diamond, I wouldn't have been able to get a thermocouple close to the nozzle tip in any case. IIRC, about 6mm or so is about as close as one could get to the tip because it's all 0.4mm diameter from that point to the tip.

-

@deckingman interesting so diamond have long .4mm channels inside there, had no idea.

not sure about that "sticking" part, I first heard about that insulator from bitsfrombytes almost 10 years ago with the silicone tube they were adding over the heater, then I made the silicone insulation all the way down to the tip with car gasket silicone rubber exactly for the reason of protecting the aluminium nozzle from being cooled by the part cooling fan (in those days no fancy ducts, just an 8cm fan blowing all over the place

). I never considered at all the "sticking part" wrt socks, but I would not presume what other ppl toughts were

). I never considered at all the "sticking part" wrt socks, but I would not presume what other ppl toughts were  so you might be right there.

so you might be right there.Anyhow the test with diamond would be interesting considering the size and shape.

On the other hand, I believe you have one SEEK camera at your disposal these days, or you returned it already? Have you tried comparing the visuals with the TC readout? One hint I learned with SEEK as the software auto-range so if your background is too cold you don't see fine changes on the hot nozzle, use the heated plate (I use some old PCB heated bed heated and set to 100C) as the background so your "cold" spots are closer to the stuff you are looking at.

-

@zapta said in What happens to the temperature inside your nozzle?:

................. I wonder why this style is not that popular.

Perhaps it's because it would be awkward and time consuming to swap between nozzles? It would certainly put me off buying one, but I can understand that it might be a good choice if one only ever used one size and one material nozzle.

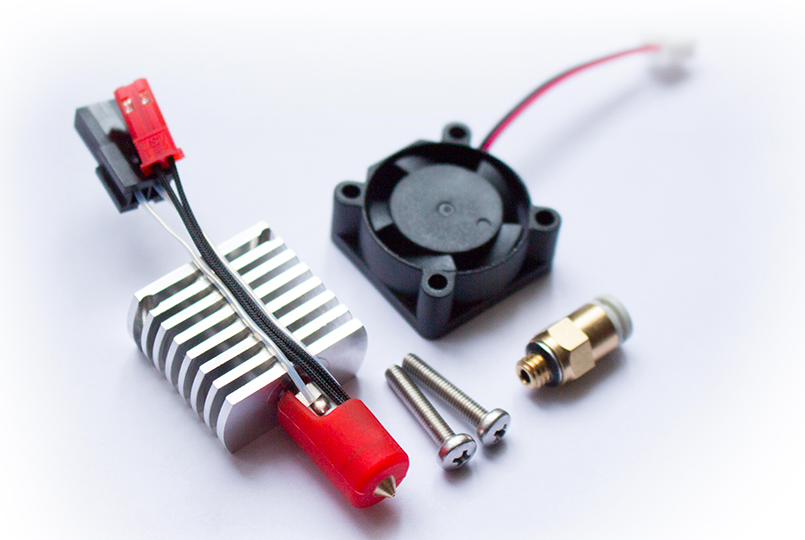

One of the design criteria I set myself for the hot end I'm trying to develop is that it should be possible to swap nozzles quickly and with one hand. That comes from having used Diamond hot ends for too long, which are a complete PITA to change! I keep 3 or 4 complete assemblies (both 3 and 5 colour and 0.5 and 0.9mm) and swap between them that way, because it's a lot quicker than stripping out all the heat sinks, heater, thermistor, and fans but it's an expensive option.

-

@arhi I can't remember the exact dimensions but on the Diamond, there is certainly a straight section of 0.4mm diameter for each input, then another section of 0.4mm after the 3 (or 5) inputs combine into 1.

Anyhow the test with diamond would be interesting considering the size and shape.

That's not going to happen - or at least, I'm not going to do it. The only reason I did these tests is that I'm still waiting for new heat break assemblies, so this hot end had never had any filament loaded making it easy to fit a thermocouple. All my Diamonds have been used so will have some filament inside which will prevent me from fitting a t/couple.

On the other hand, I believe you have one SEEK camera at your disposal these days..........

No. Somebody kindly lent me an Android IR camera to try, but I couldn't get either of my 'phones to recognise it, so I never did use it and eventually returned it.

-

@arhi said in What happens to the temperature inside your nozzle?:

............not sure about that "sticking" part,..........................

Take a look at E3D's site here - https://e3d-online.com/v6-silicone-socks-pack-of-3?gclid=CjwKCAjw2a32BRBXEiwAUcugiMm2wsjorPLcI7CLM3so2Kr4-myU_22T1Y84cdnPi5TtHYfmyT51SRoC_kgQAvD_BwE

They still make a big thing about their socks being designed to stop sticky plastics from building up on the nozzle, and then they go on to talk about temperature benefits too. My memory ain't what it was but I'm fairly sure when they first introduced them, it was all about preventing "sticky" filaments from building up on the nozzle. The limiting of temperature drops due to part cooling fans was a kind of "accidental side effect".

-

@arhi Well blow me down.

I just took a gander at that old post of mine (June 2017) about making a sock for the diamond https://somei3deas.wordpress.com/2017/06/15/making-an-insulating-sock-for-the-diamond-hot-end/

I didn't put a thermocouple inside the nozzle but I did test with and without sock, with and without part cooling fans, just using the "normal" hot end thermistor. Here is what I wrote:

"Without the sock and with the print bed at 1mm from the nozzle tip, putting the print cooling fans on at 100 % gave a 2.1 degree drop in hot end temperature before it recovered. With the sock fitted, there is no discernable change in temperature with respect to the operation of the print cooling fans".