PT100 temp questionable

-

Do you have this problem with both hot ends? The theory I was formulating was that you have a partial nozzle blockage, needing a high temperature to overcome it.

-

Hi DC,

Yeah no difference between the 2.... having a bit of another issue where my machine is bouncing the carriages of the Endstops even though they are triggering ? And keep getting changing tool and can’t do anything until that goes to idle unless I hit Estop though nothing has changed in my config from earlier so I’ll give it go over tomorrow morning and try a print at normal temps out of interest I know you have used the printbite what bed temp have you used for PLA lower than usual?

-

I run the bed heater at 70C for PLA, however I know there is a drop of about 10C across the 4mm glass + PrintBite, so that actual bed surface temperature is more like 60C.

-

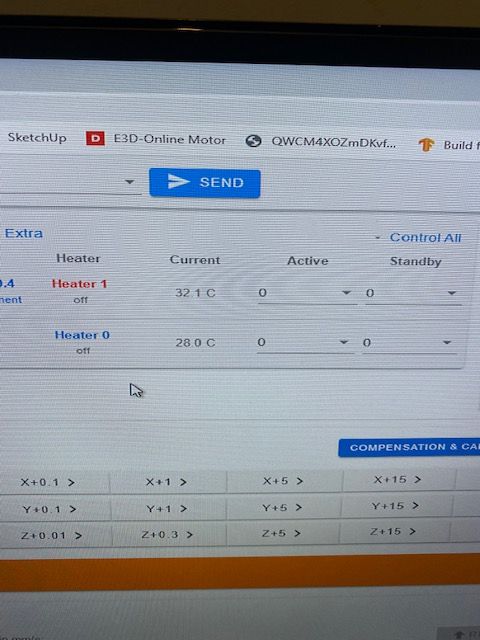

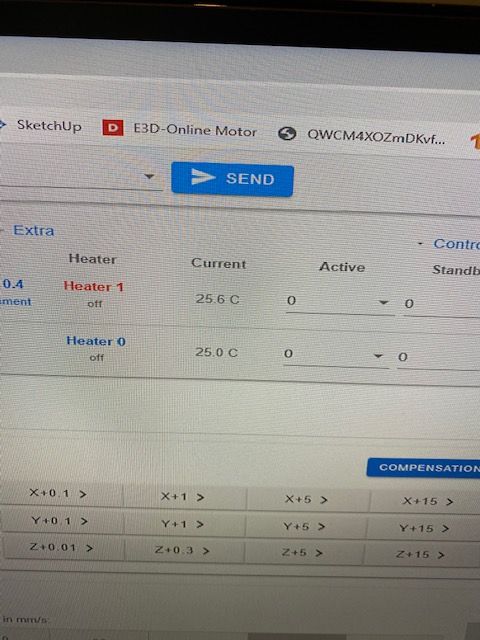

So after a few odd things going on last night couldn't find anything obvious in the wiring...but the temp for the hotend is now exactly the same as the ender 3 hot end and bed which is 0.5/6c of this bed ? now I never touched the daughter board just the endstop plugs to see if there was a loose connection which there doesn't appear to be though I was tugging on the board so not sure whats going on ...not that I did previously..possible there is a poor solder joint ? cant see anything obvious.

Yesterday evening

This morning

I'll just see if that changes over time

Thanks for your help much appreciated.

C -

Printing @210c though hot end temp doesn't seem very stable which is gonna be reflected in the quality but a step forward.

-

@Carlo said in PT100 temp questionable:

Printing @210c though hot end temp doesn't seem very stable which is gonna be reflected in the quality but a step forward.

Have you run heater tuning?

-

Yes and its in my config,M307 H1 A221.0 C100.7 D2.0 S1.00 V24.0 B0 ; disable bang-bang mode

The hot end temp is more stable when the part cooling fan is on little over 1c change fan not on 7/8c just straight up and down 205 ish to 212 ish @210 but the part has printed and not terrible my retraction is bang on:) but it is warped and I could see that happening as it printed the initial layers.

Hot end 210 bed 70 bed temp .1c shift temp chart straight line hot end a bumpy line smoother towards the end when the fan was on more and higher speed. -

Sometimes it helps to tune the D parameter by hand. If you get regular oscillations, increase D. If the temperature recovers slowly in response to changing loads (e.g. the fan turning on), reduce D.

-

-

@Carlo

I re ran the PID and now have a completely new set of values though I had run it yesterday when the temps were off

so now very stable hot end temps so as long as it stays like this all good...how do you mark the posts as solved ?Appreciate the help as always

C