Stepper Motor Vibration

-

@Masterjuggler The spec shows current per phase as 1.5A so you should be using around 1200mA. What do you mean by generating far too much heat? It's normal for stepper motors to run hot and they are normally rated at around 80 deg C. What sort of mass are you trying to move and at what acceleration rate?

-

Ok, "far too much" was strongly worded. I meant a lot more than necessary for what I need them to do, and the noise difference wasn't very noticeable. I am curious to quantify it though, so I'll leave them at 1200 for a bit and hit them with an IR thermometer.

-

The link for your current steppers doesn't open for me. I presume that you are using x16 microsteps with 256 interpolation.

I had a similar problem on my X/Y (though I don't know how your problem sounds) and apparently its was caused by the stepper vibrations amplified by by the aluminum extrusion frame. Placing the X/Y steppers on suspension solved the problem for me. You can try it by removing the belt, removing the stepper, holding it in your hand and command it to turn. If the noise is gone, suspension may help.

ALSO, moving from 1.8 deg to 0.9 deg for X/Y is a good move IMO. I can't comment about the specific steppers you posted.

-

@zapta Not sure why it's not opening for you, I just checked it and it's still fine. In any case, they're the Automation Technology KL17H248-15-4A

Holding an unmounted stepper in my hand is definitely way better than it mounted to my extrusion frame, but I can still feel the step vibrations. I'll have to look into how to better isolate it from the frame. Right now I just have 1/16" cork gasket between the stepper and the printed bracket, maybe some sort of printed TPU pad would be better.

-

@Masterjuggler said in Stepper Motor Vibration:

Right now I just have 1/16" cork gasket between the stepper and the printed bracket, maybe some sort of printed TPU pad would be better.

I use a cork gasket as well and it seems to work ok for me. But there are purpose made dampers as well, such as: https://www.astrosyn.com/product/my23rmdamp-stepper-motor-damper

-

@Phaedrux I've ordered some similar ones, should come in about a week. People who use them seem to think they're the greatest thing since sliced bread, so hopefully I'll see an improvement. In the meantime, I still would like to know if there's any other way to help it through software.

-

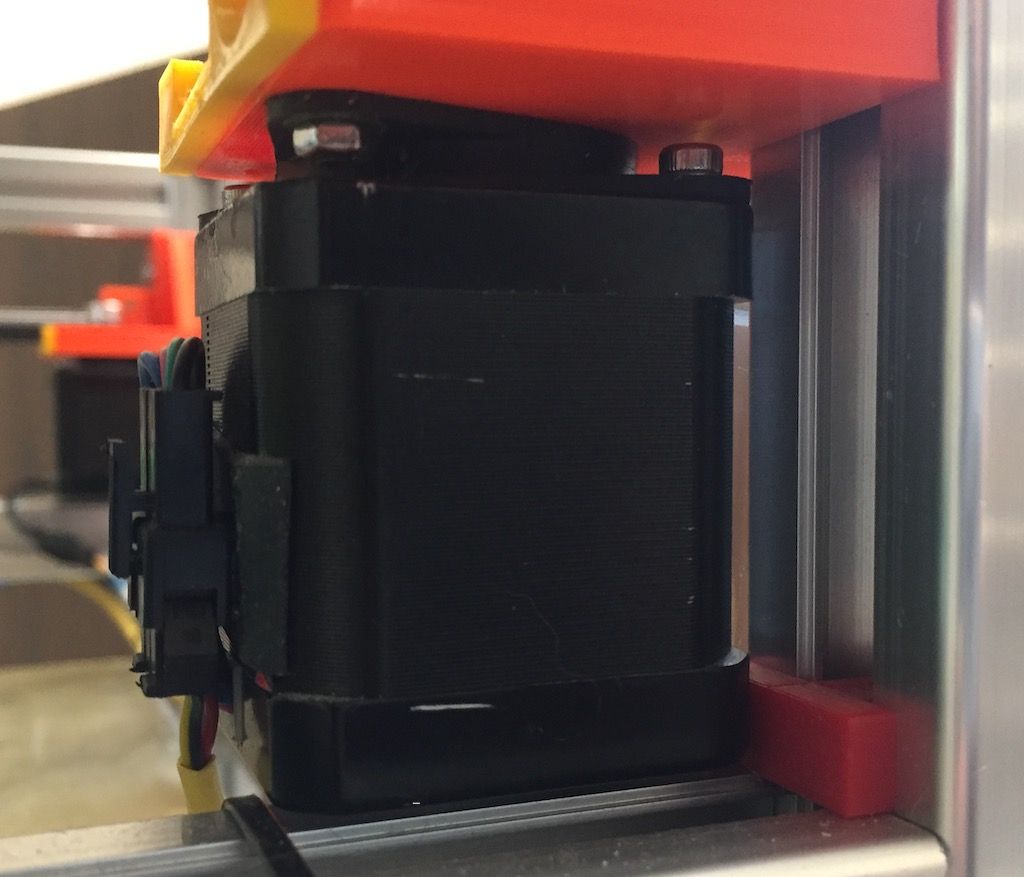

@Masterjuggler, this is how the mount looks like on my HEVO. The red T shape part at the bottom right is printed with TPU and counter balances the pull of the belt to keeps the 0.9deg stepper vertical. My printer is much more enjoyable since I install the suspension.

-

@zapta You're making me excited to have a quiet printer lol. I usually can't run it at night because of the noise.

@deckingman After a three hour print, my steppers at 1.2A seem to have settled at 62C at its hottest point. For some reason I thought they'd be hotter. I'll still try lowering the current until there's an audible change. Really I ought to just print the motor brackets out of nylon for the thermal resistance, but they've worked as PLA for the past few years.

-

@Masterjuggler I found that with very long prints, plastic mounts would soften (even PET-G) and with the belt tension, this could cause the mounts to deform. I used fans and heat sinks to cool the steppers. The fans ran in thermostatic mode by attaching thermistors to the motor bodies with epoxy adhesive. After I got my milling machine, I made new mounts out of aluminium. A side effect of this is that the mount and printer frame act as a giant heat sink and motors run at only a couple of degrees above ambient. Of course, that won't work if you use an insulator between the motor and its mount.

BTW, it is possible for static to build up in belts which could potentially arc across inside the motor and destroy it, as well as the driver. So it's generally recommended to earth the motor if you use an insulated mount. -

I got the stepper dampers, and wow, night and day difference. Without a doubt the best thing since sliced bread. they isolate the steppers from the aluminum extrusion extremely well. According to my uncalibrated phone mic, they brought the noise down from 61dB to 48dB. Not a proper scientific study, but fun to play with.

I brought the stepper current back down to 800mA, I didn't notice any noise difference between that and 1200mA with the dampers.

I also got some sorbothane feet to reduce mechanical vibration transferring to my shelf and walls. Way better than felt feet. My next hurdle are the freaking jet engines I have for fans lol.