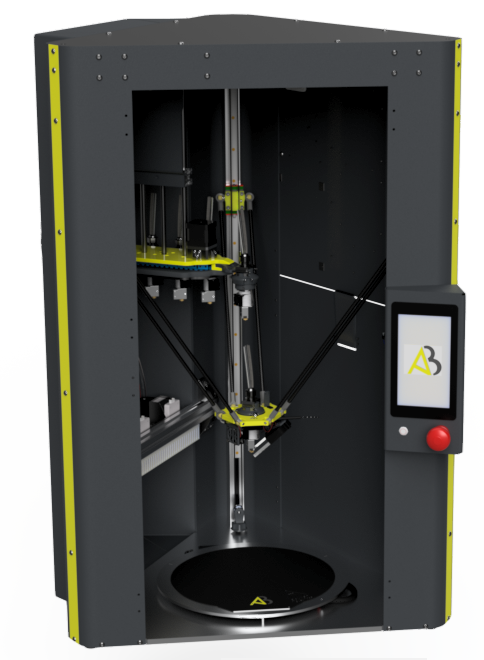

D-PATCH

-

@taconite

That's an option. I had a different idea last night:

I use these two hotend pickup pins as twist&lock pins, too.

The pins would be *U-*shaped and they are mounted into the heatsink-adapter. The tool changer would then connect with the pins and the guides inside the tool changer would twist the pins to unlock the hotend from the Titan housing. I have no idea how to design this twist in Fusion360. But I'll post it in my Blog -

Hey guys,

just a quick update. Here you can see a printed spur-gear with different functionalities.

-

-

So of course the functionalities come with the multi-material print

- reduced friction and therefor wear

- increased strength/stiffness

- flexible material for compliance/dampening of torque peaks

- Sensor element for the detection of wear

-

@taconite thank you for explaining! Do you use some of those BF350 as sensor or something different?

-

Better

conductive filament

conductive filament -

@taconite clever idea!

-

Here you can see some better pictures of the D-PATCH

-

@taconite Happy to see this project alive and well!

-

@taconite would IT be possible to get the Files for rebuilding? Best

-

@HebigT slow and steady

@PCR Sure if there is demand I will put all the files plus BOM on Github (or similar). The one you see is lets say the "maker" version where you need close to no custom parts.

At the moment I work on another version with some improvements (which can be easily implemented in the maker version)

-

@taconite that would be great! I really Love the Idea of a Delta toolchanger!

Best

-

Just saw that you started to sell the D-Patch! Really nice! When is ETA for the "Maker" Edition? Or are you selling the custom parts too? Greetings from someone who was born in bavaria too