Another Predator

-

Thanks, excellent stuff, I will take a look at all of that.

-

@Carlo said in Another Predator:

These are commented out in the home file for Delta Calibration as per the documentation they are not always commented just at the point of posting.

Just to triple confirm: The running file on the printer is going to end with the carriages (approximately) 5mm below the endstop switches, correct?

-

Hi Danal,

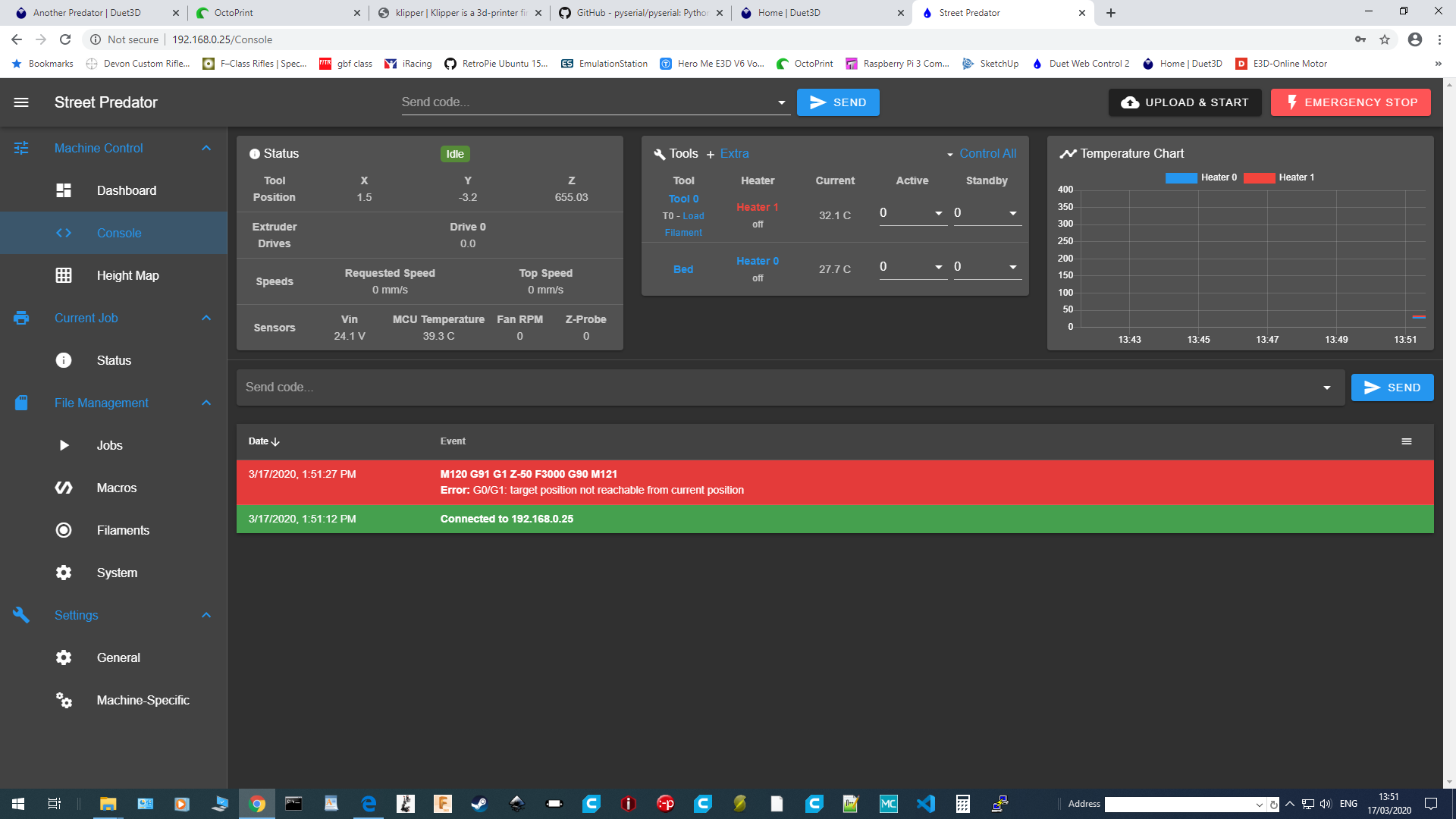

That's what it's supposed to do but I cant confirm as it homes to the below error so it doesn't bounce.

It used to do as intended but I rolled the firmware back redid the configs via the online tool since these errors.

Note* the height Z-50 is myself trying to move the effector after homing.

Not sure this helps.

Thanks I know its a lot to scan through it is appreciated.

-

@Carlo said in Another Predator:

Thanks I know its a lot to scan through it is appreciated.

We will get it going. I appreciate your patience in re-posting stuff for the "new guy" looking into this.

-

@Carlo Your active high endstops are incorrect, should be M574 X2 Y2 Z2 S1 ; Set active high endstops.

It also looks like you have both RR3 and RR2 configs in your config.g ? file -

@boldnuts said in Another Predator:

@Carlo Your active high endstops are incorrect, should be M574 X2 Y2 Z2 S1 ; Set active high endstops.

It also looks like you have both RR3 and RR2 configs in your config.g ? fileGood catch! Though you mean 'high end' endstops, as in their position on the printer; the S parameter is for active high/low (describes how the microswitch works).

Ian

-

yes correct, which version of the firmware is being used? as it's confusing

-

@droftarts said in Another Predator:

M574 X2 Y2 Z2 S1

Great stuff homing now works and endstops offsets now look... correct also

Quick calibrate returns:

M665

Diagonals 440.470:440.470:440.470, delta radius 221.612, homed height 414.196, bed radius 185.0, X 0.073°, Y 0.055°, Z 0.000°

M666

Endstop adjustments X-0.03 Y-0.29 Z0.32, tilt X0.00% Y0.00%Thank you!

-

Hi Ian,

M115

FIRMWARE_NAME: RepRapFirmware for Duet 2 WiFi/Ethernet FIRMWARE_VERSION: 2.05 ELECTRONICS: Duet Ethernet 1.02 or later FIRMWARE_DATE: 2019-12-13b1If that still needed.

Thanks

-

@Carlo can we see your start gcode from your slicer?, you using G32 (calibrate) before printing?, maybe G29 S1 to load the bed mesh?

-

@boldnuts

I have no start code yet having failed to get a layer down yet didn't want to add any complications,

However I have been doing G92 Z0 with paper G32 before attempting aprint ..I never home after probe and always with heated bed and nozzle, bed @ 70c nozzle @ 220c.

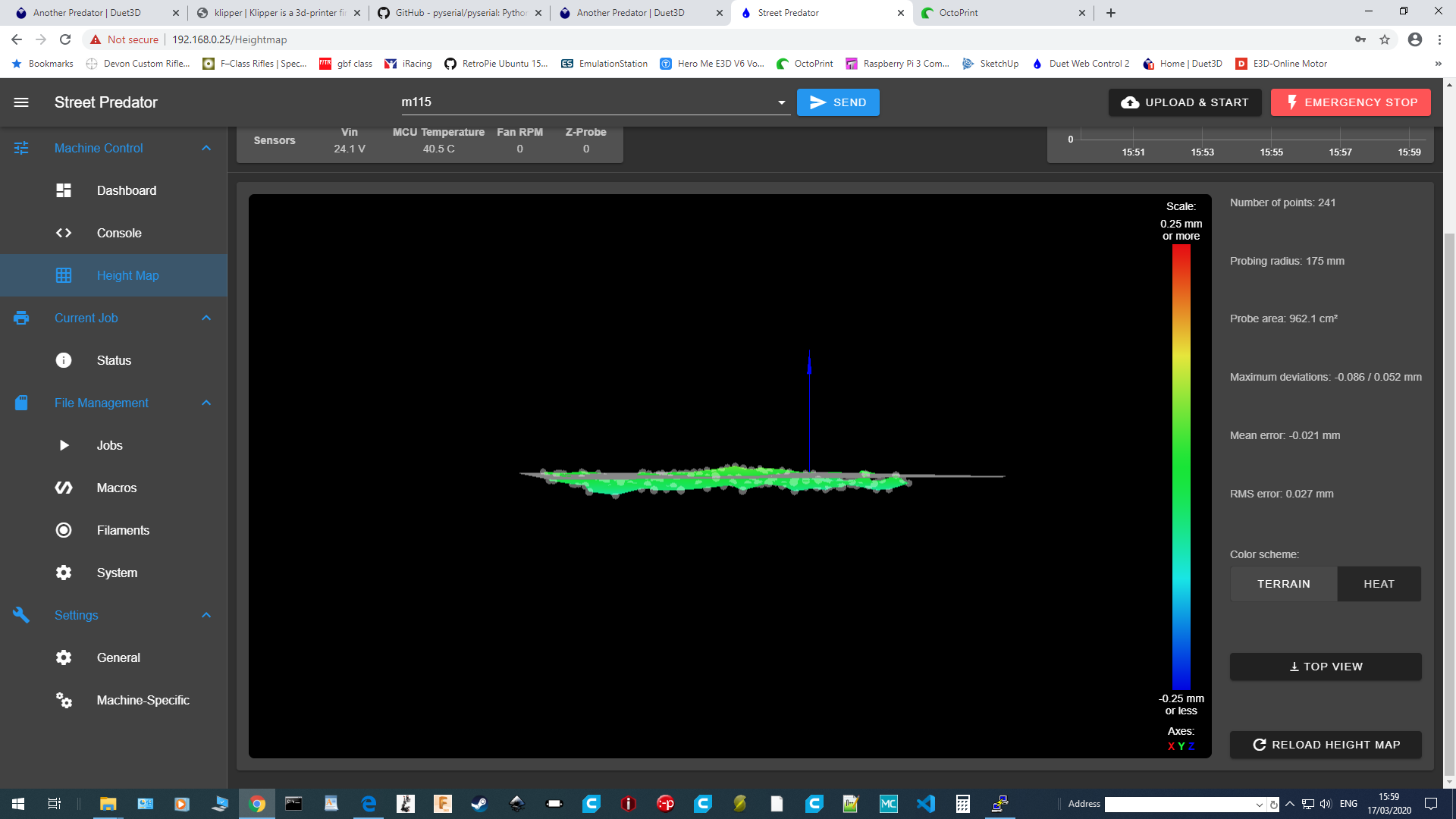

I have done the mesh but don't use it .. more to know it's flat..ish I think?? height maps are above in previous post.If that help ?

Thanks

-

You need to run G32 in your start gcode before every print and it might be a good idea to run G29 to load the bed mesh as well, then recall it with G29 S1

-

@boldnuts said in Another Predator:

You need to run G32 in your start gcode before every print

YES!

This is one of the big keys to running a delta. Let it find the bed, every time.

-

I'll try the mesh I do G32 before every print attempt.

dc42 commented a well built delta doesn't need bed mesh so not wanted to ..because I want a well built delta printer

Thanks

-

-

Yes, that's great. Very flat. RMS error .027.

You can probably skip mesh, if you wish. I would still run a simple probe before every print to set bed height. They run very quickly, in the grand scheme of things.

Here's my bed.g (invoked by G32 in slicer startup code). Note: The M106 commands turn off (and back on) the hotend fan. Mine vibrates enough to cause false triggers. It doesn't hurt for it to be off for the one minute or so all the probes take.

Build one for you here http://escher3d.com/pages/wizards/wizardbed.php The big key is to do a 6 or 8 factor, so as not to adjust diagonal rod length. (Do NOT do a 7 or 9, at least not before every print). More info here: https://duet3d.dozuki.com/Wiki/Calibrating_a_delta_printer#Section_Setting_up_the_bed_g_file

; bed.g file for RepRapFirmware, generated by Escher3D calculator ; 16 points, 8 factors, probing radius: 280, probe offset (0, 0) G28 M106 P1 S0 G30 P0 X0.00 Y280.00 Z-99999 H0 G30 P1 X140.00 Y242.49 Z-99999 H0 G30 P2 X242.49 Y140.00 Z-99999 H0 G30 P3 X280.00 Y0.00 Z-99999 H0 G30 P4 X242.49 Y-140.00 Z-99999 H0 G30 P5 X140.00 Y-242.49 Z-99999 H0 G30 P6 X0.00 Y-280.00 Z-99999 H0 G30 P7 X-140.00 Y-242.49 Z-99999 H0 G30 P8 X-242.49 Y-140.00 Z-99999 H0 G30 P9 X-280.00 Y-0.00 Z-99999 H0 G30 P10 X-242.49 Y140.00 Z-99999 H0 G30 P11 X-140.00 Y242.49 Z-99999 H0 G30 P12 X0.00 Y140.00 Z-99999 H0 G30 P13 X121.24 Y-70.00 Z-99999 H0 G30 P14 X-121.24 Y-70.00 Z-99999 H0 G30 P15 X0 Y0 Z-99999 S8 G29 S1 M106 P1 S1 I0 F500 H1 T40 -

I need to try something as mesh didn't work...Did probe then ran mesh then ran probe then invoked G29 S1 and loaded the print file and,

I'll play with the probe G31 Z height a little I guess ? ...changed the print file got sick of the other one.

Also I've just redone my bed file I'll try that first before making any other changes

Thanks -

@Carlo Any reason you didn't baby step down 0.1 or 0.2mm or so? After all this, that would tell you if it's just a probe height problem.

Ian

-

How does the effector actually probe?

Example: The smart effector flexes the circuit board just slightly when the nozzle presses on something, and a strain gauge reads this to trigger the probe output. The strain gauge is a long "spiral" (spiral triangle) of very thin circuit traces that surround the mounting point of the hot end. Because of all of this, the Z offset for a smart effector probe is often right at -0.1

What does your hotend do? Piezo? Slight movement? Etc. What offsets have you used?

-

This post is deleted!