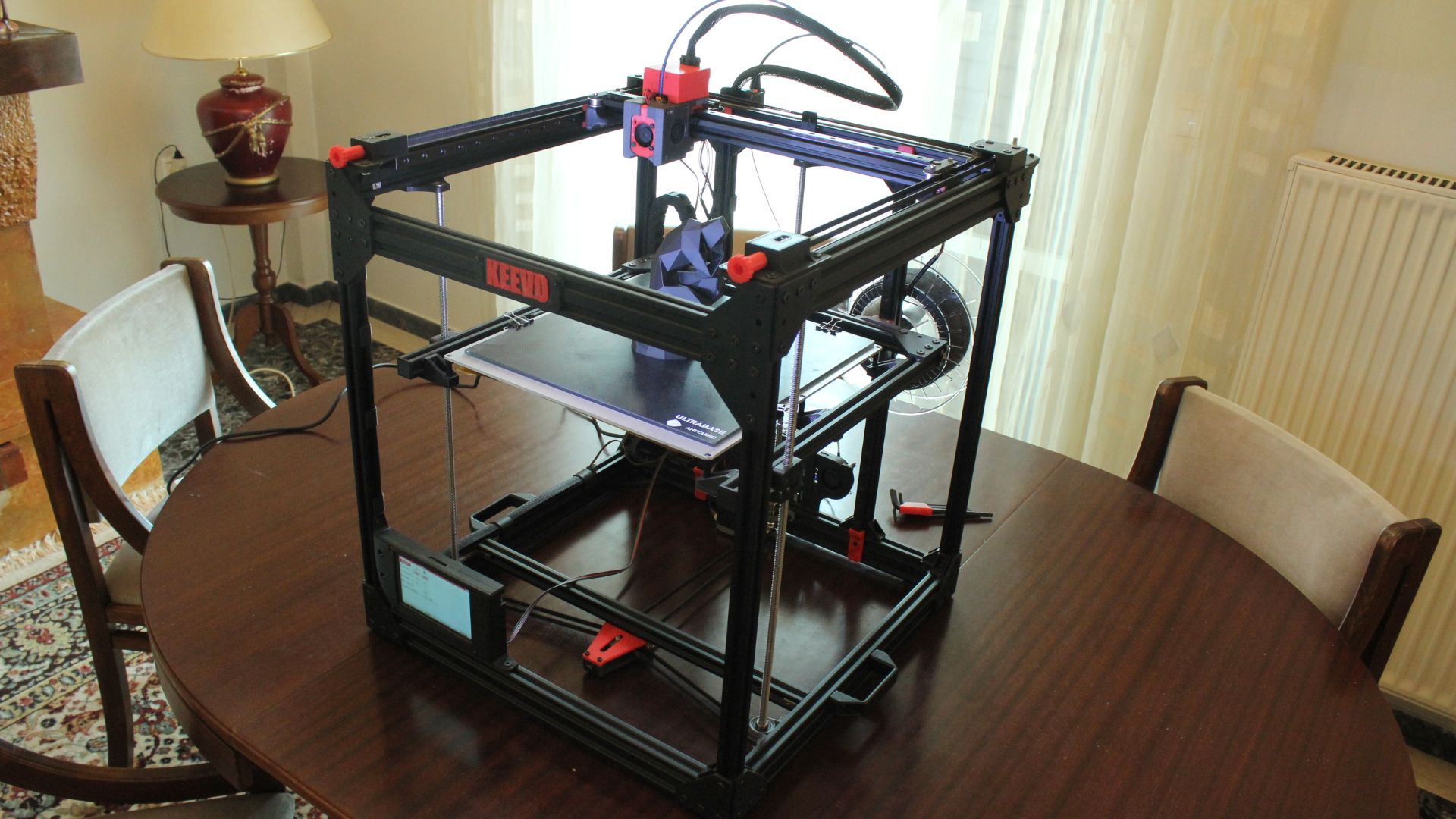

KEEVO Printer (corexy)

-

Hello again,

I just wanted to share with you the last build I made, which of course uses Duet

(KEEVO = Cube in Greek)

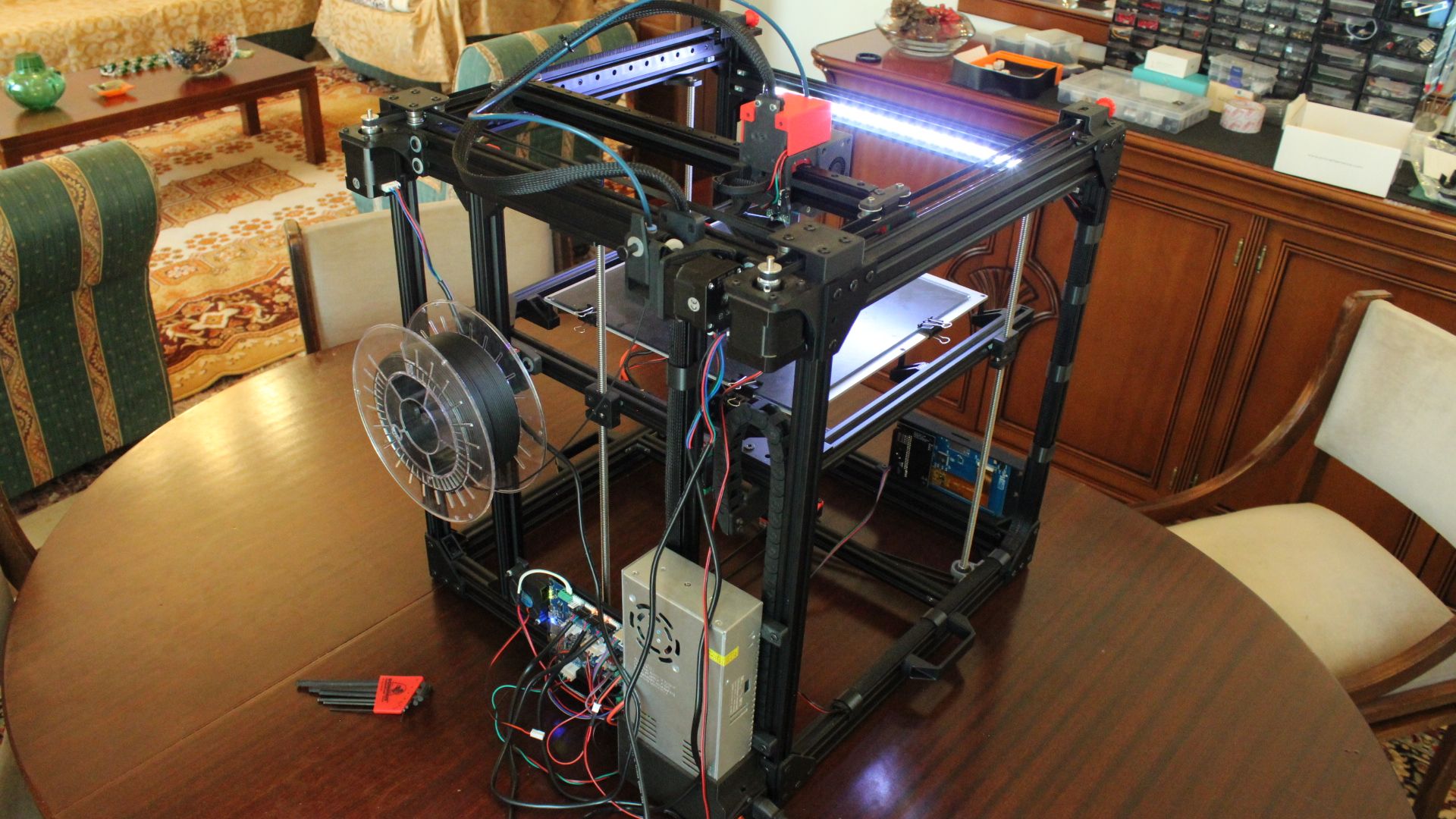

(yeah the cables need some management)It is also posted on Thingiverse -> https://www.thingiverse.com/thing:4129443

Any feedback is welcome of course!

Also, regarding the 3 leadscrews (which are only really mounted on the bottom), do you think that the forces from the Z belt will bend the leadscrews in the long run. I don't really see any bending though. It can be seen more clearly in this video which was the previous version (an hbot without duet and other stuff, but z axis is the same) -> https://www.youtube.com/watch?v=K0pcGKAQ4eA

Cheers

-

@nuverian said in KEEVO Printer (corexy):

do you think that the forces from the Z belt will bend the leadscrews in the long run

Unlikely.

Nice looking printer.

-

@Phaedrux Hey thanks!

Great printer you have as well

Similar Z concepts. I see you use two bearings (as far as I understood). Was that for the same reason and for peace of mind?

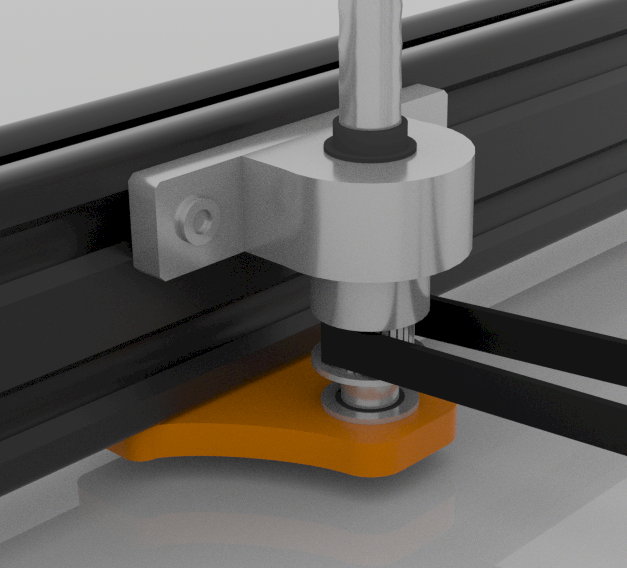

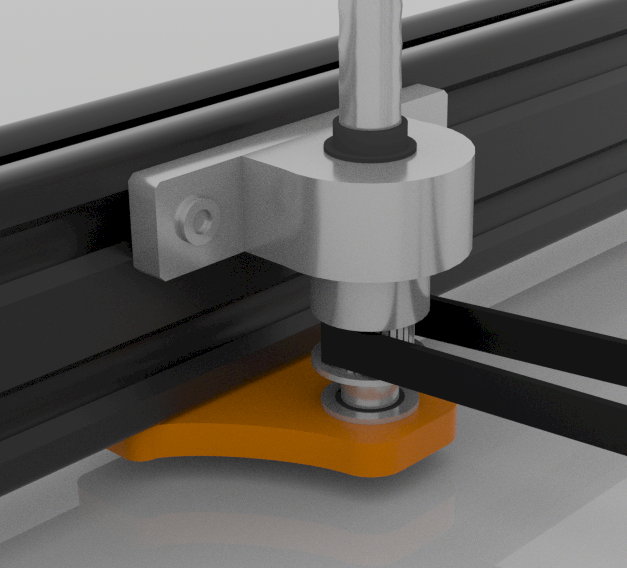

Similar Z concepts. I see you use two bearings (as far as I understood). Was that for the same reason and for peace of mind?I also don't think it will be a problem, but what I was thinking is adding a counter bearing on the bottom so that when the belt pulls, the leadscrew won't budge. Something like this mockup:

Maybe an overkill, maybe not

-

Yes, the double bearing block was mostly to help keep the lead screw stable vertically, but also would help counter and pulling forces from the belt tensioner.

-

@nuverian said in KEEVO Printer (corexy):

@Phaedrux Hey thanks!

Great printer you have as well

Similar Z concepts. I see you use two bearings (as far as I understood). Was that for the same reason and for peace of mind?

Similar Z concepts. I see you use two bearings (as far as I understood). Was that for the same reason and for peace of mind?I also don't think it will be a problem, but what I was thinking is adding a counter bearing on the bottom so that when the belt pulls, the leadscrew won't budge. Something like this mockup:

Maybe an overkill, maybe not

Double shear is nearly always better than single shear.

-

The screw is 8mm diameter and you're pulling on it with the same belt that's pulling on the 5 mm motor shaft. If it's OK to do that at the motor shaft, it's probably OK at the larger diameter lead screw.

You could easily fabricate a two-bearing mount for the lead screw as a single piece either from rectangular aluminum tubing or by printing a part with a tang that fits in the t-slot. I did this in my sand table (the brown part):

The two pieces that make up the pulley mount are aligned by bosses. The bearings press-fit tightly into the top and bottom pieces.

-

Thanks for your comments.

I ended up adding a counter bearing on the bottom to help with the belt forces, as well as a collar on the leadscrew above the pillow bearing to help with vertical/gravity forces.