Making an epoxy granite machine base

-

FYI - mechanical engineer here

Resonance mode is proportional to mass, so increasing mass is a way to eliminate low-mode resonance (although not always effective). Dampeners (such as epoxy) don't eliminate the resonance energy much (~10%) but that would really only help you trying to limit energy / vibration into your stand (although some will reflect back up into the machine so it does still help).

In my opinion, the limiting factor of your design is the joint between your extrusion and your base plate. The mode of a plate with 80/20 extrusion as you have it is quite low. Increasing the thickness of your base mounting plate will increase your stiffness substantially (increasing your mode away from the motor resonance) as would adding some 90 degree stiffeners to your columns. Make sure you have a large amount of preload on the bolts as well - if you can find it, use a bolted joint calculator online to determine the bolt and the correct force to apply to it. Properly tightening the bolts can drive up stiffness as well.

Cross-beam supports would also substantially increase your stiffness (column to column). I'd advising putting them mid-span for greatest effectiveness, although it might be something of an eye-sore.

-

I have my printer on a fairly solid wooden end table. The printer has some dense closed cell foam for feet. There was still a bit of vibration, so I ended up taking a large weight and using nylon strapping to basically tie the printer down to the table by hanging the weight underneath the table. It looks pretty ghetto, but it worked wonders.

-

@TLAS Thank you for your insights, I will continue with the EG base and feet. After that I will evaluate and about reinforcing the joint between the extrusion and the base plate if needed.

I decided to make some test castings before doing to main job (duh I guess

). The test mold can house four pieces of 75x75x85mm with rounded corners and approximates the actual mold as much as possible.

). The test mold can house four pieces of 75x75x85mm with rounded corners and approximates the actual mold as much as possible.For the 1st batch I made 850g of EG with 10%w epoxy, 90%w fine white sand and 10g of blue dye.

-

wouldn't it be stronger with larger rocks? then again i think i read your

smallestlargest aggregate should be at most 1/3 of the smallest feature in your mold. -

@bearer said in Making an epoxy granite machine base:

wouldn't it be stronger with larger rocks? then again i think i read your

smallestlargest aggregate should be at most 1/3 of the smallest feature in your mold.Well technically my largest aggregate size is at most 1/3 of the smallest feature in the mold

But as I said I will do some experimenting with the materials that I already have and I'll go from there.

But as I said I will do some experimenting with the materials that I already have and I'll go from there. -

Apropos vibrations, here is an active way of dealing with them https://www.youtube.com/watch?v=HS7LvcBowCA

-

@zapta Ah yes, crazy deckingman

. Although it's semantics but I would not call the issue he was dealing with 'vibrations', more like movements. They seem quite low frequency and can be compensated for my a moving mass. This solution is whole lot less practical once you start going up the Hertzes

. Although it's semantics but I would not call the issue he was dealing with 'vibrations', more like movements. They seem quite low frequency and can be compensated for my a moving mass. This solution is whole lot less practical once you start going up the Hertzes

-

@zapta said in Making an epoxy granite machine base:

Apropos vibrations, here is an active way of dealing with them https://www.youtube.com/watch?v=HS7LvcBowCA

How would such a contraption be implemented on a delta.

-

@Phaedrux said in Making an epoxy granite machine base:

@zapta said in Making an epoxy granite machine base:

Apropos vibrations, here is an active way of dealing with them https://www.youtube.com/watch?v=HS7LvcBowCA

How would such a contraption be implemented on a delta.

I leave that to the experts and a separate thread haha

-

@Phaedrux said in Making an epoxy granite machine base:

How would such a contraption be implemented on a delta.

With another delta attached on top, turned upside down, and rotated 180degrees.

-

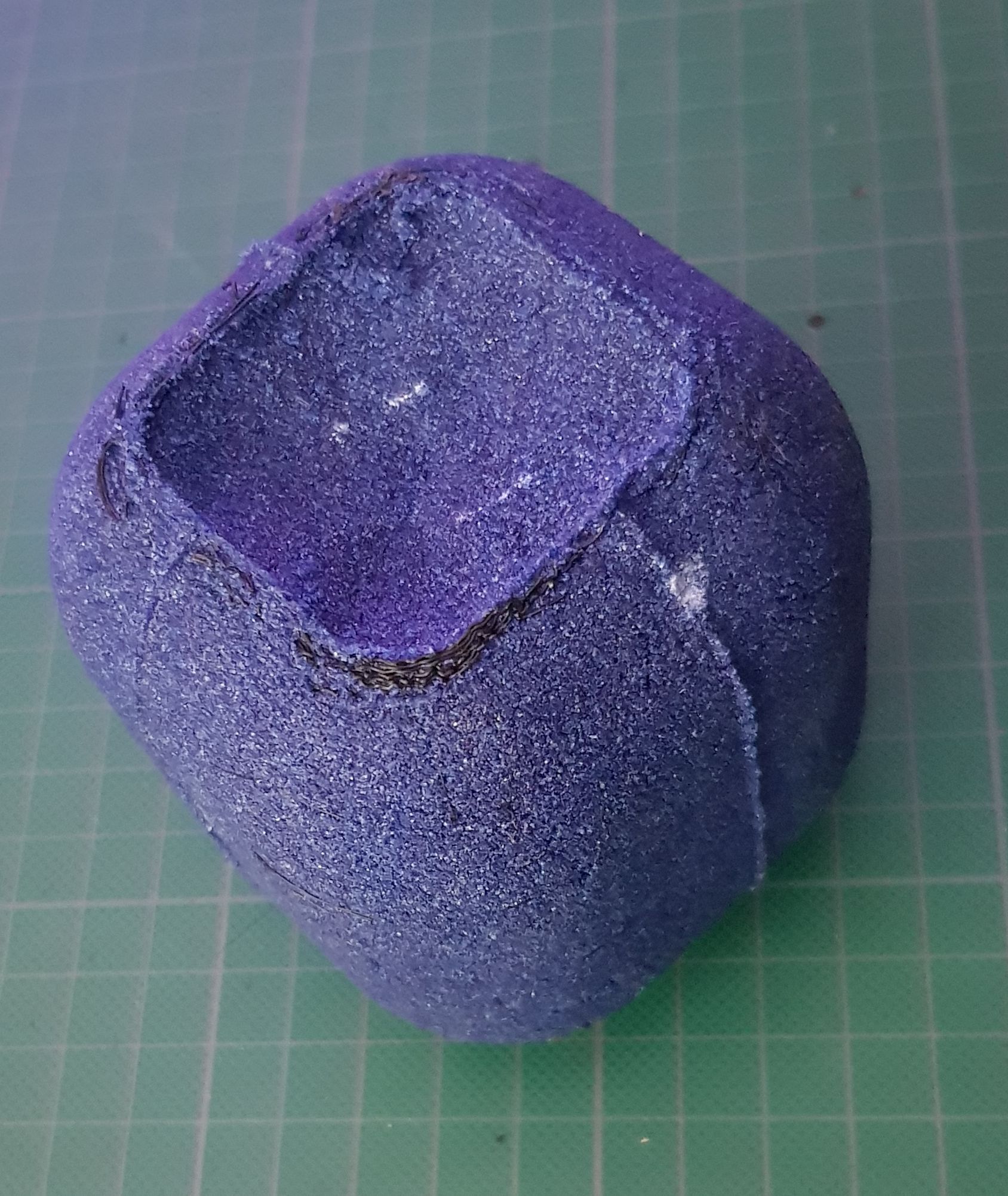

Here is a status update:

I just broke the 1st test piece out of it's mold. That in itself was definitely not easy, but not impossible (the mold only partially survived). For the 1st batch I made EG with 10%w epoxy, 90%w fine white sand and 10g of blue dye. The part in the picture weighs 638g on my scale and has a volume of 372cm^3 according to the cad model, resulting in a density of 1710kg/m^3 for those interested. I should note I only pressed the epoxy as hard as I could with my fingers, so no hammering (yet) and no vibration table.The part seems quite strong, and I have not been able to break or chip it whatsoever by hitting it as hard as I can with a light 200g hammer. I am very happy with how well the dye works. The store I bought it from does not specify what dye it actually is, but seeing how it's priced and what other dyes they offer, I believe it is an iron oxide.

While I believe it is doable to use this mixture, I would prefer a less porous result. Therefore I will be doing a 2nd and possibly 3rd test piece with 15%w and 20%w epoxy. I will keep this thread updated for those of you that follow here.

-

so the previous picture was just printed parts or?

if your main concern is the surface finish you could use an epoxy compatible gelcoat as a first layer before casting, or introduce even finer aggregate as well.

-

@bearer said in Making an epoxy granite machine base:

so the previous picture was just printed parts or?

The picture with the black parts was indeed just the (empty) printed mold.

-

1710kg/m3 is quite a low density. Fine for the purpose, but it uses quite a lot of expensive epoxy to fill the voids.

I would aim for 2200-2500kg/m3 which is easy to archieve with 3-4 different sizes of aggregate. Cost cannot be an issue; the extra 25kg bags should be as expensive as a single kilogram of epoxy.

-

abs mold acetone vapor smoothed covered with "remover spray"

if you cannot find special remover spray (separator) you can use cooking oil

-

Yesterday evening I made a 800g batch of mix B with 15%w epoxy, 85%w white sand and 7g of blue dye. I did hammer the mix as best as I could (the mold opening is actually quite small and the different mold pieces flex open, so I can't go all sledgehammer on it though

).

).While mix A had a consistency comparable to what I have seen from the so called kinetic play sand, mix B is definitely wetter. Mix B was no so wet that I ran between my fingers but definitely wet enough to be a little runny and, well... cause by brain to flip the switch and think 'hey that's wet-ish'

.

.The epoxy takes about 2-3 days to cure to a usable level, so expect a new update around the weekend. But my gut feeling says that 15%w is going to be what I end up using for the actual pour. Since starting and seeing the mix A test piece I am thinking about closing the mold not just from the bottom and sides, but also from the top. Just to get a better surface finish, and possibly better clamping/compression. Looking at the images from the 1st post in this thread, it can be seen that just a couple straight pieces of wood can perfectly cover the remaining exposed area's.

-

hammering is cool but you really want to vibrate the $hit out of it and you want at least partial vacuum... just a simple vacuum cleaner and a plastic bag will let you get way better results than without vacuuming (having a decent pump is great but difference between nothing and vacuum cleaner is way bigger than vacuum cleaner to mega low vacuum pump

) ... the vibro is easy, you don't need super high frequences or anything special, if you have a sander that's enough or if you have biax (dremel, proxxon, whatever of those small ones) just attach a "bent drill bit" and let it run, attach to the mold or to the tray mold is in and let it run for a while .. combo of vibrator and vacuum will get you to the perfect mixture

) ... the vibro is easy, you don't need super high frequences or anything special, if you have a sander that's enough or if you have biax (dremel, proxxon, whatever of those small ones) just attach a "bent drill bit" and let it run, attach to the mold or to the tray mold is in and let it run for a while .. combo of vibrator and vacuum will get you to the perfect mixture  .. (and even if you don't go the "print abs, smooth with acetone" way if you have abs, you can coat your mold with cooking oil even if PLA, it will help a lot for easier removal

.. (and even if you don't go the "print abs, smooth with acetone" way if you have abs, you can coat your mold with cooking oil even if PLA, it will help a lot for easier removal  but you can check your hw store there are special "remover" sprays for the molds (no clue the real english word, we call them "odvajac" means "separator")

but you can check your hw store there are special "remover" sprays for the molds (no clue the real english word, we call them "odvajac" means "separator") -

@smece I tend agree with your points. On the other hand, as stated before: the mold is already completely printed (in PLA) and is not going to be entirely reprinted just for easier removal. It is a one time use mold after all.

I do not see how I can vacuum the entire mold and printer, keep in mind that the base will be cast in place on the machine. Also, while I did not try, I don't think that attaching a simple dremel or alike to a ~40 kg mold will do much useful. -

@Nxt-1 said in Making an epoxy granite machine base:

@smece I tend agree with your points. On the other hand, as stated before: the mold is already completely printed (in PLA) and is not going to be entirely reprinted just for easier removal. It is a one time use mold after all.

well for one time is irrelevant, you can lightly coat it with oil to easier remove it but even that you don't have to ... I was mostly thinking about the test pieces if you are going to do more of them so you don't need to make new mold for every test, for the final one it's irrelevant

I do not see how I can vacuum the entire mold and printer, keep in mind that the base will be cast in place on the machine.

huge garbage bags and vacuum cleaner .. works on a casted bathtub, should work on your printer too

just attach some temporary styrofoam blocks on any sharp bits that might tare the bag when you vacuum it

just attach some temporary styrofoam blocks on any sharp bits that might tare the bag when you vacuum itAlso, while I did not try, I don't think that attaching a simple dremel or alike to a ~40 kg mold will do much useful.

oh yes it will do a lot in combo with vacuum cleaner, it will shake all the bubbles out .. even the small dremel

... better if you have something bigger but even the dremel will do magic

... better if you have something bigger but even the dremel will do magicI'm not an expert or anything but my fam. had a "gheto manufacturing"

(no proper tools, everything bodged, wooden molds, everything as cheap as you can imagine ) for 2 years produced thousands of bathtubs, kitchen sinks, countertops etc etc out of that stuff and I helped from time to time so catched few things along the way ..

) for 2 years produced thousands of bathtubs, kitchen sinks, countertops etc etc out of that stuff and I helped from time to time so catched few things along the way .. -

Dear diary, today (well yesterday) I

fucmessed up.Well damn the 1st

Yesterday I went to town on the mold for the second test piece I made. As expected, getting the mold off was not easy, I was quite happy when the 1st mold piece started to give. To my surprise the EG cuboid split in two pieces, each half staying nicely in their side of the mold. My childish nature made sure that the 1st thing to come across my mind was, oooh touch it. So I did, and the EG felt dry but kind of sticky and not very stiff. All due to my impatience and to short drying time was my tough. Well damn (1).

Well damn the 2nd

That being that I was browsing on the webpage from the store where I got the epoxy from. By true coincidence I stumble across one of their video's about mixing epoxy and decide to watch it just for the fun of it. One of the things the host talks about is mixing ratio's, 100:43 ratio results in 100 units of part A and 43 units of part B. Immediately I realize that's different from my interpretation. My logic was to make 100 units in total you need 43 units of part B, leaving 57 units for part A. I get out my calculator, Matlab and drawing board and start solving some differential equations, contour integrals and invert some matrices. Low and behold the calculations are right, in my mixtures I used about twice as much part B as needed. Well damn (2).

It all comes together

That being that I continue watching the video and the host starts talking about wrong mixing ratio's. "Too much part A leaves you with a dry but not as strong result, while too little results in a sticky and gummy-ish part. Combining this info, damn (1) and (2) leads my to conclude that by using half as much part A as I needed by mixture was way to gummy (and indeed sticky), therefore it split in two while releasing it. I assume the 1st test piece survived because the lower percentage of epoxy in the EG maybe reduced the effect, but I don't know that for sure.

After all this, it is safe to say that my two test pieces are not very representative. On the other hand, I do feel like I have got a decent idea of how the material feels and what epoxy/sand ratio's are viable. So I don't think I am going to print a new test piece mold for more experiments before doing the actual cast.