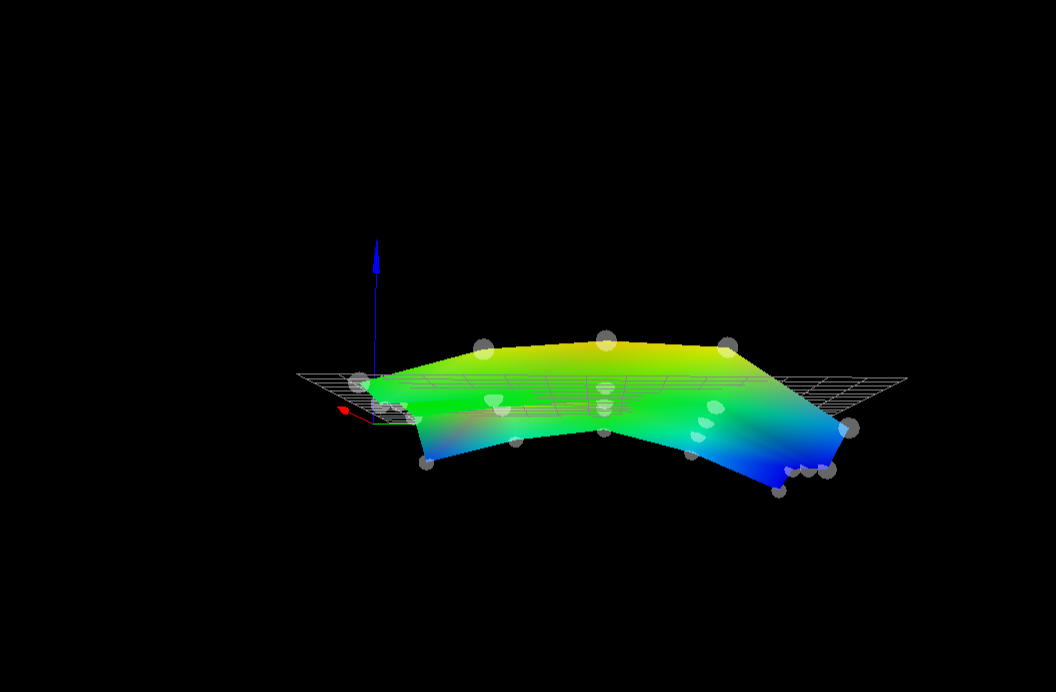

Height map worse than actually is

-

Hey guys!

Below it is my height map. Maximum deviation shows almost 1mm, which is bad! I didn't trust the result so I disabled the mesh compensation and tested using the good old paper. I could see differences of 0.1mm to 0.2mm between 2 points, where the height map shows differences of about 0.6mm. If the height map was correct I could see the 1mm bump using a flat object, like a rule, but there is no difference like this.

I am using a original BLTouch. I tested its accuracy (probing 30 times the same place, moving the head between probes) and its looks totally fine. Below the result:

G32 bed probe heights: -0.439 -0.446 -0.436 -0.449 -0.449 -0.459 -0.454 -0.451 -0.454 -0.469 -0.469 -0.464 -0.451, mean -0.453, deviation from mean 0.010Some other details about my tests:

- I am using Builtak magnetic sheet, but got the same results adding a 4mm glass over it, so I discarded any magnetic interference.

- Probing with 9 or 25 points shows no difference. Same exaggerated discrepancy between points.

- Several G29 were executed with the same outcome.

- All tests were run with the same bed temperature at room temperature. Same room temperature in all tests.

- My paper tests were located exactly on the probed points shown in the pictures.

- Tested area is 270mm x 270mm.

- Leaving mesh compensation enabled and testing the bed with a sheet of paper shows clearly how wrong is the height map.

Machine details:

- Board: Duet WiFi 1.02 or later

- Firmware: RepRapFirmware for Duet 2 WiFi/Ethernet 2.03 (2019-06-13b2)

- Duet WiFi Server Version: 1.23

- Duet Web Control 2.0.4

I run out of ideas. What could be happening?

Thanks!

Eduardo

Config.g

; Axis Limits M208 X0 Y0 Z-2.2 S1 ; Set axis minima M208 X271 Y270 Z265 S0 ; Set axis maxima ; Z-Probe M307 H3 A-1 C-1 D-1 ; Setup H3 to not be a heater M558 P9 H5 F200 T6000 ; Set Z probe type to switch and the dive height + speeds G31 P25 X17 Y-42 Z1.65 ; Set Z probe trigger value, offset and trigger height M557 X17:271 Y0:228 P5 ; Define mesh grid M376 H2 ; Stop compensation at 2mm height M671 X24:264:264:24 Y17:17:257:257 ; Define positions of bed leveling screwsheighmap.csv

RepRapFirmware height map file v2 generated at 2020-01-10 01:22, min error -0.988, max error -0.026, mean -0.472, deviation 0.268 xmin,xmax,ymin,ymax,radius,xspacing,yspacing,xnum,ynum 17.00,271.00,0.00,228.00,-1.00,63.50,57.00,5,5 -0.829, -0.459, -0.367, -0.595, -0.904 -0.708, -0.234, -0.120, -0.372, -0.726 -0.585, -0.140, -0.026, -0.298, -0.617 -0.639, -0.179, -0.066, -0.283, -0.619 -0.805, -0.362, -0.288, -0.590, -0.988 -

what kind of printer is it?

this looks like x axis bending under the weight.

when the carriage is in the middle the weight bends it slightly and creates a U shape.

-

@Veti thanks for your answer. My printer is a core XY, very similar to the Hypercube evolution. I understand the X might be bent, but my complain is: it is not half bad as the height map shows. My tests shows it. No way it it is 1mm lower in the middle part as it shows.

-

if there is any twist and the probe is not mounted directly under the rail this could result in significant variance as well even without significant deflection down.

-

@nhof could you better explain, please? Do you mean twist on the X axis? Indeed my probe is around 6cm away of the axis (in the -Y direction - I'll take a picture when I get home), but I don't understand how it could amplify the error by a factor of 2.

-

I also configured the probe offset to reflect its actual position.

-

@Cartola said in Height map worse than actually is:

could you better explain, please? Do you mean twist on the X axis?

he means that the hotend is not plane. it rotates slightly as it moves.

as it moves the nozle goes up while the probe does down for example.

this will give you different readings based on the positon that the carriage is at. -

@Veti, got it.

The hotend and the probe is rock solid mounted between them, but I don't know how to "prove" that. Here are some pictures of my hotend:

-

its not the bltouch mount but the entire carriage.

that hermera is quite heavy.

the further it moves to the middle of the bed the further it pushes the lower rod to the back.

that causes the bltouch to move in relation to the nozzle by rotation. -

@Veti I understood the theory, but the rotation can't be that high... I think... 2 * 8mm tempered steel high quality rods. How could I confirm if that is what is happening? Also, the deflection happen equally on X and Y axis.

-

@Cartola said in Height map worse than actually is:

How could I confirm if that is what is happening? Also, the deflection happen equally on X and Y axis.

remove the hermera and try with just a probe.

-

@Veti ok, I will try.

-

@Cartola said in Height map worse than actually is:

2.03 (2019-06-13b2)

Likely unrelated, but you should probably update your firmware, Lots of bug fixes between 2.03 and 2.05.

Have you tried an actual test print to highlight the bed surface and see if the heightmap is actually representative of reality? The curve is exaggerated to highlight the shape.

Print this twice, once with mesh compensation enabled and once with it disabled. Should give you a good idea if things are working properly.

-

Hi @Phaedrux, I added all the versions "just in case"

I could verify the difference using paper, for sure printing would give me the same result.

For everybody that help me - I removed the Hemera and re-run the mesh. Now I don't see the bad results, only the expected axis reflection. You were right! I will re-draw the BLTouch support for Hemera/Hevo to align with the nozzle in the Y axis, this way, even with some rotation, having the BLtouch aligned won't increase the error. Too bad I will lose some print area on X

I hope to have everything fine and uploaded to Thingverse or somewhere else soon!

Thank you all! I will return once I have the updated version.

-

@Cartola

i started off with a hevo as well, but since redone the entire thing.

the smooth rods were always a source of small inconsistencies.

in the end i used the motion setup of the blv cube. its a lot more sturdy and would support the hermera as well.