Pressure Advance seems to not be working.

-

@Samuel235

Just for information, what is the retraction distance and speed? Material? -

@DIY-O-Sphere - Retraction is 4mm at 60mm/s with a prime at 30mm/s and with Rigid Ink ABS in Black.

Edit: Correcting a typo

-

This cube has come out with no visual difference up the seam again. I had the following PA values at the respected layers:

Layer | PA Value 25 | 0.7 50 | 0 75 | 0.9 100 | 0 125 | 1.1 150 | 0 175 | 1.3 200 | 0 225 | 1.5No change at all other than it stopped extruding a little for 6/7 layers during the 1.1 value set of layers (layers 125 to 150).

M122 for this print:

M122 === Diagnostics === RepRapFirmware for Duet 2 WiFi/Ethernet version 2.03 running on Duet WiFi 1.02 or later + DueX5 Board ID: 08DGM-956GU-DJMSN-6J1F4-3SJ6N-1BNBF Used output buffers: 5 of 24 (18 max) === RTOS === Static ram: 25680 Dynamic ram: 94256 of which 308 recycled Exception stack ram used: 492 Never used ram: 10336 Tasks: NETWORK(ready,524) HEAT(blocked,1236) DUEX(suspended,156) MAIN(running,1668) IDLE(ready,160) Owned mutexes: === Platform === Last reset 02:37:52 ago, cause: software Last software reset time unknown, reason: User, spinning module GCodes, available RAM 10312 bytes (slot 1) Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0441f000 BFAR 0xe000ed38 SP 0xffffffff Task 0x4e49414d Error status: 0 Free file entries: 10 SD card 0 detected, interface speed: 20.0MBytes/sec SD card longest block write time: 0.0ms, max retries 0 MCU temperature: min 54.2, current 54.3, max 57.1 Supply voltage: min 24.0, current 24.3, max 24.6, under voltage events: 0, over voltage events: 0, power good: yes Driver 0: standstill, SG min/max 0/1023 Driver 1: standstill, SG min/max 0/243 Driver 2: standstill, SG min/max not available Driver 3: standstill, SG min/max 0/972 Driver 4: standstill, SG min/max not available Driver 5: standstill, SG min/max 9/249 Driver 6: standstill, SG min/max 14/254 Driver 7: standstill, SG min/max 0/255 Driver 8: standstill, SG min/max 0/259 Driver 9: standstill, SG min/max not available Date/time: 1970-01-01 00:00:00 Cache data hit count 4294967295 Slowest loop: 100.31ms; fastest: 0.08ms I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0 === Move === Hiccups: 0, FreeDm: 169, MinFreeDm: 159, MaxWait: 7ms Bed compensation in use: mesh, comp offset 0.000 === DDARing === Scheduled moves: 0, completed moves: 0, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 === Heat === Bed heaters = 0 -1 -1 -1, chamberHeaters = -1 -1 Heater 0 is on, I-accum = 0.0 Heater 1 is on, I-accum = 0.5 === GCodes === Segments left: 0 Stack records: 4 allocated, 0 in use Movement lock held by null http is idle in state(s) 0 telnet is idle in state(s) 0 file is idle in state(s) 0 serial is idle in state(s) 0 aux is idle in state(s) 0 daemon is idle in state(s) 0 queue is idle in state(s) 0 autopause is idle in state(s) 0 Code queue is empty. === Network === Slowest loop: 202.15ms; fastest: 0.08ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) Telnet(0) HTTP sessions: 1 of 8 - WiFi - Network state is running WiFi module is connected to access point Failed messages: pending 0, notready 0, noresp 3 WiFi firmware version 1.23 WiFi MAC address XXXXXXXXXXXXXX WiFi Vcc 3.32, reset reason Turned on by main processor WiFi flash size 4194304, free heap 24592 WiFi IP address XXXXXXXXXXXXXX WiFi signal strength -56dBm, reconnections 0, sleep mode modem Socket states: 0 0 0 0 0 0 0 0How far before the seam point on each layer should PA start to kick in because its literally right on top of the seam that the extruder shows some movement for PA. It doesn't change at all for the corners, its one continuous extrusion from start of layer to the end of the layer. I'm not sure it should really be like that....

-

How fast are you printing? Is Cura limiting your acceleration and jerk?

-

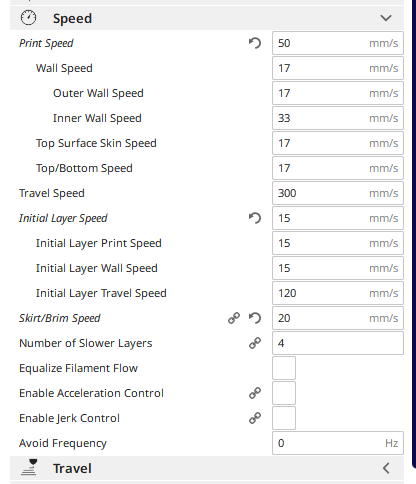

Neither of them are enabled and my speed is what I would class as fairly slow if i'm honest with you.. 17mm/s (i'm only printing a single wall)

-

That's really slow. Pressure advance is meant to reduce the effects of pressure build up. At such low speeds you're not building much pressure.

Try using 2 walls with some amount of infill to increase layer time. 5% will do. And increase your print speeds to something closer to a normal print. 50mm/s or more.

-

I assumed you'd seen this, but maybe not?

-

I have indeed seen that, I'm currently printing another with 5% infil with two walls. Its like I knew what you was going to say haha. My extruder is now behaving a little more like expected, sounds like a machine gun now, but like its skipping steps, I'm running M122's to check for missed steps but seeing nothing. I have brought my Jerk down to 3000 for this test just to stop the extruder exploding while i'm testing for the right PA value, at 3000 it still sounds like its going to explode now.

I still have the outer wall set to 17mm/s, I might need to change it to configure PA though, so might need another print after this before I see any difference in the print.

-

Print has just completed with the following settings

Speed Settings:

M566 X700 Y700 Z60 E2000 ; Set maximum instantaneous speed changes (mm/min) M203 X18000 Y18000 Z3000 E15000 ; Set maximum speeds (mm/min) M201 X2000 Y2000 Z250 E1800 ; Set maximum accelerations (mm/s^2) M204 P1500 T2000 ; Set printing acceleration and travel accelerationsCurrent Settings:

; Drive currents M98 P"/macros/print_scripts/xy_current_high.g" ; XY (AB) currents high M98 P"/macros/print_scripts/z_current_high.g" ; Z currents high M906 E1600 ; E current M906 I30 ; idle current percentagePA Values:

Layers | PA Value 0 - 25 | 0.3 25 - 50 | 0.0 50 - 75 | 0.4 75 - 100 | 0.0 100 - 125 | 0.5 125 - 150 | 0.0 150 - 175 | 0.6 175 - 200 | 0.0 200 - 225 | 0.7Results:

Conclusion:

If PA is now functioning correctly, I have something else to be dealing with, more than likely retraction prime amount. I'm not really convinced by any of the PA values here but if I had to choose one, I would have to say 0.5 performed the best. I was hoping the severity of my seam was due to PA, but it seems (no pun intended) that its not helped me at all really. I imagine it will serve a huge part in correct infil lay down though, you can see on the rear of the print (side with no seam) that on the PA=0 layers you are unable to see where the infil joins the walls, so thats a huge positive from this exercise.Time to start troubleshooting other settings to help me with hiding the seam, most prints will have their seam on a corner, but sometimes the seam is out and visible (round objects) and I would like to dial that in if possible.

-

That crap in the last image is most likely to be caused by un-retracted travel. If you are using combing, you really need to set the max comb distance with no retract setting to something like 10, 20, etc.

-

If you correct for the coasting issue mentioned you may get some better results on the seam from higher PA values than 0.7. I'd also try upping the extruder acceleration a bit. Say 3000ish.

-

Also, as pressure advance increases the amount of retraction needed decreases, so even though it's noisy, some of that noise can be reduced after you find the PA value by retuning your retraction amount. You can also probably reduce the retraction speed a bit.

-

@burtoogle - I do have combing enabled, but its set to 10. Your branch of Cura freezes up when its idle for about an hour or so, I have to keep reopening it up when I get back to testing a new set of slicer dependant settings. Not a problem, just thought I would let you know

@Phaedrux - I have changed my retraction to 3mm at 40mm/s. I will increase the extruder acceleration now as you suggest. Would you go lower than 3mm, I can test this out myself but while I print a test with these new settings just thought I would ask.

-

@Samuel235 said in Pressure Advance seems to not be working.:

@burtoogle - I do have combing enabled, but its set to 10. Your branch of Cura freezes up when its idle for about an hour or so, I have to keep reopening it up when I get back to testing a new set of slicer dependant settings. Not a problem, just thought I would let you know

What OS and HW are you running Cura on? I haven't had any other reports of my builds freezing.

-

@burtoogle - Windows 10 on 8GB RAM, i5-3570K @3.4GHz (stock, not OC'ed) with a AMD Vega 56. If you need any specific information, please feel free to contact me privately to avoid clogging this thread up, more than willing to chat.

-

@Samuel235 said in Pressure Advance seems to not be working.:

I do have combing enabled, but its set to 10.

I dislike combing, I'd much rather retract at all times.

-

@Phaedrux - Combing has now been disabled, i'm joining the dark side!

-

I'm getting a little confused between M201 and M204, the duet gcode page is saying that M201 is per axis acceleration and M204 is for printing overall, will only the lowest value get used when it comes to printing?

-

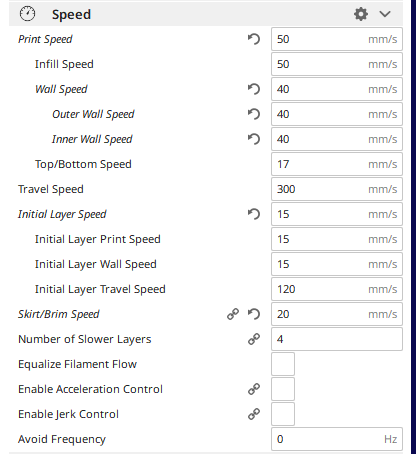

M201 sets the maximum value for all cases. M204 is optional and gives a bit finer control by separating print and travel moves and lets you use higher acceleration on travel moves. This can be controlled in the slicer now as well with much finer grained control still.

It comes down to preference where and how you set those values. And as long as you're aware it doesn't really matter. Some people like to use M201 in config.g and leave it at that with acceleration set the same for all moves. Or maybe use M204 and split print and travel. And others like me use the slicer to have fine grained control over each move type. I use faster for travels, medium for internal areas, and lower for external surfaces. Cura is best for this. PrusaSlicer has more limited control over acceleration and no control of jerk.

-

More to the point maybe. I'm not sure which will take precedence. If M201 sets a limit at 1000, and M204 sets print moves at 500 and travel at 5000, I'm not sure if M201 will override the M204 or if M204 just sets the new limit.

Even if using M204 you'd still need to use M201 to set the values for all axis since M204 only applies to XY movement I believe.