Hello, am new here but not a newbie as such.

-

Hi,

Some good friends and very experienced 3dprint industry bods have recommended I look at Duet boards for my various 3dprinters.

Am fed up with crappy marlin and ramps boards, especially after my marlin file for my big 3dprinter recently reset and 2.5 yrs worth of dev settings got lost. Now it won't let me reflash and am so done with wasting my time with Marlin.

Honestly I would like to have an actual chat with someone very experienced with all the modern boards to make some choices. I also have 2 M2 makergear to sort also.

I will be rebraining @FuseDeep ny fast and strong rugged 2m tall 3dprinter and I will be making a 2mx 600mm diameter Polar coordinate machine too shortly.

My website has extensive recent projects and examples of what I do in general:

And my archive site , full of awesome can be found at rgproduct

Please do search me out on LinkedIn: Richard Grant / Experiential Technologist

Happy to help and be helped.

R

-

Welcome!

What are the Specs for the large printer? Specifically the motors/extruders etc that you need to control. that will help with advice on how best to achieve this.

for the polar printer i believe @CNCModeller and @Gregory were both working on polar printers so might be able to give some specific advice.

-

Hi Tony,

Thanks for your email earlier.

Currently wide open, though I do have some decent nema 23 kicking around and some high power 4 amp/coil nema 23 also. But nothing your Duet 2.4 amps would not handle.

The bigger issue is that @Fusedeep runs a trick IGUS gantry and this is a substantial device. I think it is too massive for the fast 3dprint movements (different to pick and place) and when I do complex prints (non vase) it always drifts, I assume losing steps along the way. However I have decided to bin this and move forward with both new boards and probably a lighter gantry set up using hardened rails and carriages from Zapp or similar. However if Duet can print successfully with it then all good. I have been using stepper amp drivers with the ramps set up, Didi I mention I dislike Marlin a lot?

I do not think I would need the amped side of Duet to be honest and am keen to keep it as simple as possible.

Extruder wise will probably go with E3D or a high capacity 0.8mm diameter set up.

I have a 600mm diameter alu base on a bearing (started it 2 yrs back but got sidetracked) for the print bed and interested to hear of current polar use with Duet. Do like polar. so very simple, in some ways...

R

-

Edit. I appreciate my 4 amp specials are outside of the stock Duet board current supply. Nothing about @Fusedeep suggests particularly high current needs for nema 23s so would expect not to need additional drivers.

-

Of course, you'll get a lot of confirmation bias here, towards Duet, because we all have them.

Having said that, I wouldn't really consider any other board for my large or sophisticated printers.

Example: I scratch build a large-ish delta, 600mm Dia, 620 Z, that is now my main workhorse. I wouldn't consider any other controller currently available for that printer. And, I've been very happy with my choice.

Second example: I'm building a toolchanging printer based on E3D's de-facto standard for tool locking. (See the Jubilee on github)

I'm installing a Duet 3 on that, even though they are in Beta. At this moment, it has one "base" Duet 3 board, and two "expansion" Duet 3 boards. The ultimate goal is to eliminate the expansions in favor of "tool" boards (as soon as they are released). This expansion/tool thing is all enabled by the CAN bus connections used in the Duet 3 architecture. A tool will have just power and CAN (and a tube with filament); all heaters, fans, sensors, etc are connected to the tool board that is physically local to the tool itself.

Again, to me, no other choice... these guys are just way ahead of the curve.

-

Thanks Danal, sounds like a useful machine you have there...

I think my first move is to see if a Duet can run the chunky IGUS gantry. if it can, with or without drivers and a breakout board then all good. 450x500x1800 is still a useful machine

This may go hand in hand with my polar build. The brilliant David Price did show me some polar work somewhere for Duet. will take another look, as opposed to delta.

-

@FuseDeep said in Hello, am new here but not a newbie as such.:

Edit. I appreciate my 4 amp specials are outside of the stock Duet board current supply..................

For info, extract from the Duet Generation 3 hardware overview https://duet3d.dozuki.com/Wiki/Duet_3_Mainboard_6HC_Hardware_Overview - quote :

"Six high-current advanced TMC5160 stepper drivers: SPI controlled will all the latest Trinamic features. Maximum motor current 6.3A peak per phase (4.45A RMS)."

You didn't mention the mass of your gantry but also for info, I have two gantries on my machine (actually 3 but the 3rd is for load balancing/force cancelling) and on one gantry the moving mass is around 2Kgs, the other is a tad over 3Kgs. I use Nema 17s rated at 2A but running 1.8A on the lighter gantry and Nema 23s rated at 2.8A but running 2.4A on the heavier gantry. Ohh, and I print at up to 300mm/sec with non-print moves at 350mm/sec with that arrangement.

-

Sounds awesome, thanks for the info.

Honestly, I think it is the ramps board just struggling in general. it never worked properly from day 1 out of vase mode and I have fettled everything 6 times.

Its a substantial gantry with wide 20mm belts and deep teeth, 2 of those on the Y axis!. think it is just too much for this type of application (It was a gift from IGUS).

Bearing in mind my use for a classic large XYZ on @FuseDeep and polar use on the new machine (might call that Beverley as it may have a bevelled gear Z drive) which of the duet boards would be most suitable please?

Want to be able to leave it running standalone and with the screen. reliable and simple to tweak firmware settings is key.

R

-

@FuseDeep said in Hello, am new here but not a newbie as such.:

..................... which of the duet boards would be most suitable please?.....................

Impossible to say with the limited information provided. You know more about your application than anyone else, so take a look at the specs for each board and see which one will do want you want. Generation 2 is the mainstream product (either wifi or ethernet) generation 3 is more specialised and suited to applications that require a large number of stepper drives (>12) and or higher current ones.

-

Can you give more information about this IGUS cantry and the motor(s) you are currently using to drive it?

-

The original igus steppers were rated at five point something amps. apparently. Its the 600 x 600 room with the very deep top beam:

I got a lot of conflicting info early on, so swapped them out for some decent regular nema 23.

Am pretty sure it is just too chunky and have given up on it. I'll try it on a duet and if not swap it for a buzz automation set up. It's wasted too much of my time time at this point tbh.

Substantially quicker and cheaper to change the gantry than keep chasing my tail. especially now with losing the painful marlin settings.

R

-

I can't post the url to the gantry as it is flagging as spam. Is there a way round it please?

-

It's an IGUS drylin room gantry 600x600 with some very expensive steppers (330 each remarkably). It can work beautifully but has never liked complex prints.

-

weird, posting URLs should work, probably the anti spam being super cautious because you are a new user. try with spaces in the url

-

co.uk/info/drive-technology-drylin-gantries?

gclid=EAIaIQobChMI48r9pO7a5Q

IVRLTtCh2PLwnnEAAYASAAEgIIpfD_BwE

-

the DLE-RG-0001

-

yes! sorry, should have said.

h ttp:// shop.3 dfilap rint. com/blog/2017/08/

-

annoyingly igus does not provide any information about the stepper motors with encoders used on that gantry. you say you replaced them anyway? what with (model number?)

-

-

@FuseDeep said in Hello, am new here but not a newbie as such.:

o

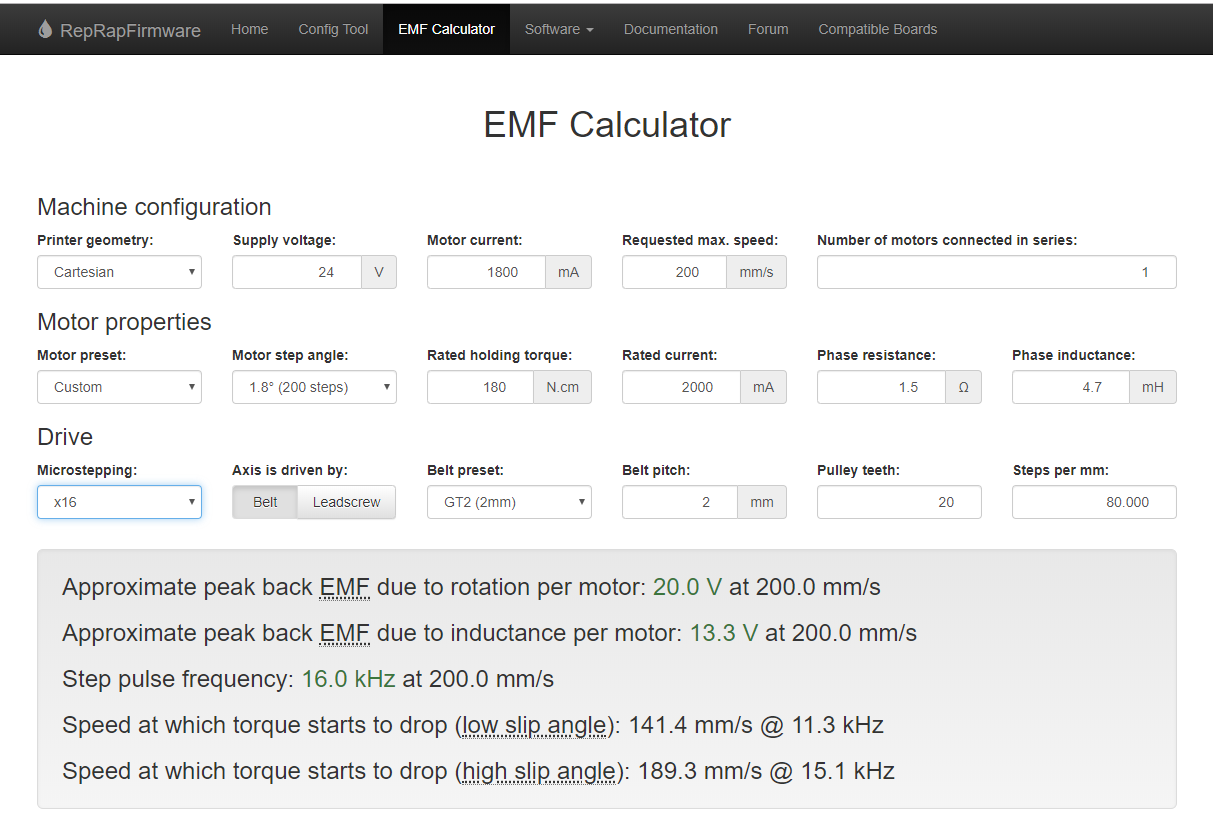

have a look at the specs of thse motors when plugged into the EMF calculator:

You will need to put the correct information for your machine in there

For more info see:

https://duet3d.dozuki.com/Wiki/Choosing_and_connecting_stepper_motors#Section_Considerations_when_choosing_stepper_motorsany you can try different values in the tool to see how motor properties effect your maximum speed achievable.