heater faults while printing

-

I need help with heater faults during printing.

H2 tune - Warning: Heater 2 appears to be over-powered. If left on at full power, its temperature is predicted to reach 471C.

Auto tune heater 2 completed in 394 sec

Use M307 H2 to see the result, or M500 to save the result in config-override.gH1 tune - Warning: Heater 1 appears to be over-powered. If left on at full power, its temperature is predicted to reach 596C.

Auto tune heater 1 completed in 345 sec

Use M307 H1 to see the result, or M500 to save the result in config-override.ggcode in config reads:

M307 H1 A346.7 C133.1 D4.6 S1.00 V24.7 B0

M307 H2 A458.9 C167.4 D4.7 S1.00 V25.1 B024v 40w cartridge style Chimera hotend.

Basically I'm getting heater faults while trying to print. It doesn't happen all the time which makes it extremely hard to figure out. I've checked the wiring and all seems well on that side. I've not tried to replace a cartridge, as I didn't want to just start throwing money at it. Wondering what else I could try. Parts fan is off while tuning / printing.

-

@gnatman said in heater faults while printing:

V24.7 B0

V25.1 B0that is some variation here. So from that i would conclude that your voltage drops by 0.4 when the bed is on. What is the manufacturer of your power supply and what is the rated power?

can you post a graph of the temperature from the web ui when this error occurs.

Parts fan is off while tuning / printing.

you actually want the part fan on 100% when tuning, beause its on when you are printing.

-

@gnatman To be clear, after completing the heater tuning using M303, did you either paste the resulting parameters into your M307 commands in config.g or use M500 to save them to your config-overide file? If the latter, do you have and M501 command in your config.g file to read those values in?

-

@gnatman it's not unusual to have a highly powered hot end, but when the max predictions go over 500C it would concern me...

What you need here is to re tune using both your cooling and nozzle fans on at a typically running level, and then you need to employ the what I believe is the S parameter during heating... Read the documentation. This will cap the max power output (PWM heater control limits) during tuning/running and would prevent overshoots. For example I would try S0.6 to start and go from there.

Are you using 24V on a 12V cartridge? You can dial most power supplies down to 20V, giving 36% less power to the heaters, while the motors might loose marginally on top speed and not on torque, assuming low resistance.

If the output ever siezes (transistor on full blast)

The PWM won't stop you from hitting hot-end melting temperatures... But the cooling fan and lower mains voltage will.Another note, you can limit the sensitivity of the heater control system, expanding the time or maximum temp deviation parameters

-

@3ddevil said in heater faults while printing:

but when the max predictions go over 500C it would concern me...

that is very common nowadays, specially when the silicon sock is used on the e3d hotends.

i think my prediction was around 700C. -

@Veti said in heater faults while printing:

that is very common nowadays, specially when the silicon sock is used on the e3d hotends.

i think my prediction was around 700C.I had 680C with the 50w heater in mine and a sock, reading through this I note I should re-run with the part coolers on, I'll be curious to see how much it affects things.

Anything over 650C is into the range where Aluminium melts, eg the heat-block

My temp sensor should pack up at 500C+(ish). At which point it should go out of limits and the controller will fault. The only realistic disaster scenario is a short on the heater -ve line and that is dealt with by proper insulation, routing and blind faith. -

As a supporter of a great community I have to advocate for much better care and safety factor. We don't want to be cavalier about numbers that are high enough to start fires because they're well over the flash point.

Aluminum will deform around 350C and above. It's super soft just try to scratch it. Depending on the grade it can become quite pliable. At these temps it will absorb in copper or iron impurities from the thermistor and heater cartridges. This breaks the alloy and can cause it to have a wide melt range (non-eutetic alloy).

So bottom line 400-450C and above is very risky. Many people have had aluminum melt and the remaining cartridge go into overdrive. I know people who lost homes over this.

That's why it's always best practice to get a heater and voltage pair that can not easily or ever exceed 450C. If this means waiting 1-2 extra minutes for heat up that's a small price to pay for your safety.

And btw PLA is flammable napalm so I haven't even included that in this discussion. I recommend petg as it's non-flammable generally.

-

@gnatman said in heater faults while printing:

I need help with heater faults during printing.

Have you read the page about spurious heater faults in the Troubleshooting section of the wiki?

-

@dc42 said in heater faults while printing:

@gnatman said in heater faults while printing:

I need help with heater faults during printing.

Have you read the page about spurious heater faults in the Troubleshooting section of the wiki?

@dc42 Yes, which lead me to posting on here. I had also read a few other posts too.

-

@Veti said in heater faults while printing:

@gnatman said in heater faults while printing:

V24.7 B0

V25.1 B0that is some variation here. So from that i would conclude that your voltage drops by 0.4 when the bed is on. What is the manufacturer of your power supply and what is the rated power?

can you post a graph of the temperature from the web ui when this error occurs.

Parts fan is off while tuning / printing.

you actually want the part fan on 100% when tuning, beause its on when you are printing.

Sure, I can post a graph in another post and tag you. I'm currently trying to run a tune now with the part fan on. I generally do not use my part fan when printing.. I print with petg not that it matters.

I'm not sure who the manufacture is of the psu. I purchased a hevo kit from Lin on alliexpress. so it's whatever psu they offer on the 24v side of things.

-

@deckingman Correct, I actually copied the values from config override and pasted them into the config file. as I do not have the M501 command so cannot execute the M500 command to save it.

-

@gnatman said in heater faults while printing:

@dc42 said in heater faults while printing:

@gnatman said in heater faults while printing:

I need help with heater faults during printing.

Have you read the page about spurious heater faults in the Troubleshooting section of the wiki?

@dc42 Yes, which lead me to posting on here. I had also read a few other posts too.

Then you should know that there are two different sorts of heater fault, and you can control the detection of one of them using M570. But you haven't told us which type of heater fault you are getting, or what M570 settings you are using.

-

@dc42 Sorry missed the link within the wiki. M570 H2/H1 S120 currently.. we will see what it does now.

-

so @dc42 with the above M570, it ran fine during that print. I was just about to print another and I received the heater fault again

Error: Heating fault on heater 1, temperature excursion exceeded 15.0°C

Resume state saved -

@gnatman said in heater faults while printing:

@dc42 Sorry missed the link within the wiki. M570 H2/H1 S120 currently.. we will see what it does now.

I suggest you read https://duet3d.dozuki.com/Wiki/Gcode#Section_M570_Configure_heater_fault_detection because your M570 command is not correct except for very old firmware.

-

@dc42 M507 H1 P120 T20 S120

ok, does this look more current? -

Now this is odd. Huge drop in the graphic when it was sent to "print" and the head moved!!https://i11.photobucket.com/albums/a170/Z28Kid/Screen Shot 2019-10-17 at 7.40.53 PM_zpscvxyztdk.png

-

the link does not work. you can upload pictures directly to the forum.

-

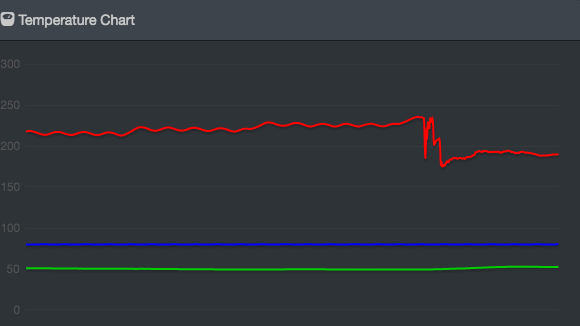

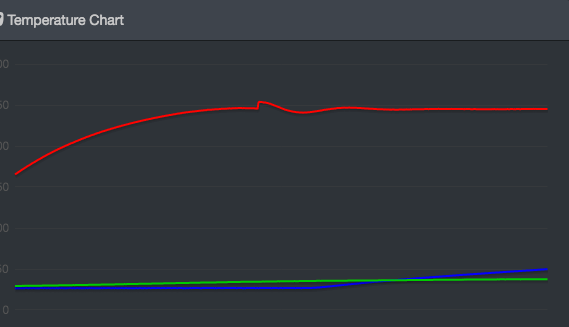

Sorry thats the button I was looking for last night. This was shortly after when the print head moved and it was starting to print. durning tunes the graph is smooth.

sitting idle there is a little hickup

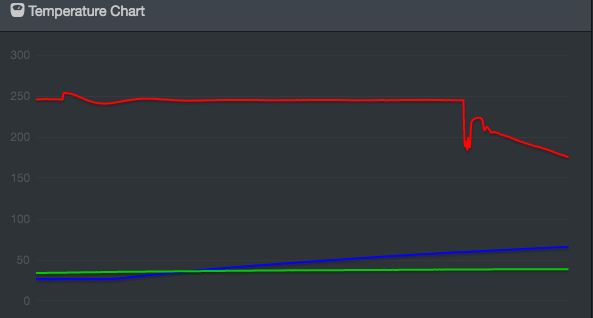

This as soon as I went to home z.

-

It seem a voltage drop from your power supply. Check V_IN while the issue occur.

If you have sense pins on your psu, wire them with cable cross to V_IN board, I see a very good regulation since I have made the modification.