CR-10S5 Firmware

-

@Veti I dont have any start code.

-

post the start of a g code where the print has been slow

-

;FLAVOR:RepRap

;TIME:13024

;Filament used: 5.97829m

;Layer height: 0.12

;MINX:209.345

;MINY:227.132

;MINZ:0.144

;MAXX:279.794

;MAXY:272.866

;MAXZ:48.914

;Generated with Cura_SteamEngine 4.4.1

T0

M190 S50

M104 S210

M109 S210

M82 ;absolute extrusion mode

M201 X500.00 Y500.00 Z100.00 E5000.00 ;Setup machine max acceleration

M203 X500.00 Y500.00 Z10.00 E50.00 ;Setup machine max feedrate

M204 P500.00 R1000.00 T500.00 ;Setup Print/Retract/Travel acceleration

M205 X8.00 Y8.00 Z0.40 E5.00 ;Setup Jerk

M220 S100 ;Reset Feedrate

M221 S100 ;Reset FlowrateG28 ;Home

G92 E0 ;Reset Extruder

G1 Z2.0 F3000 ;Move Z Axis up

G1 X10.1 Y20 Z0.28 F5000.0 ;Move to start position

G1 X10.1 Y200.0 Z0.28 F1500.0 E15 ;Draw the first line

G1 X10.4 Y200.0 Z0.28 F5000.0 ;Move to side a little

G1 X10.4 Y20 Z0.28 F1500.0 E30 ;Draw the second line

G92 E0 ;Reset Extruder

G1 Z2.0 F3000 ;Move Z Axis upM83 ;relative extrusion mode

;LAYER_COUNT:400

;LAYER:-6 -

Regardless of infill, wall thickness and layer height it prints extremely slow.

-

@Gost101 said in CR-10S5 Firmware:

M201 X500.00 Y500.00 Z100.00 E5000.00 ;Setup machine max acceleration

M203 X500.00 Y500.00 Z10.00 E50.00 ;Setup machine max feedrate

M204 P500.00 R1000.00 T500.00 ;Setup Print/Retract/Travel acceleration

M205 X8.00 Y8.00 Z0.40 E5.00 ;Setup Jerkthose lines must be in the start g code of your slicer. thats why the print is slow.

remove them -

@Veti said in CR-10S5 Firmware:It seems to be moving faster but how do I compensate for the extrusion factor? Lines are becoming to small and separating multiple times in one movement.

-

@Gost101 said in CR-10S5 Firmware:

Lines are becoming to small and separating multiple times in one movement.

is your thermistor set up correctly? are your e steps set up correctly?

-

@Veti Yes they are, just got back to my benchy test print ive been gone for almost 6 hours and cura said that it was a 3 hour print. Turns out the printer is not fast still. What should do?

-

-

did you restart the printer after you made those changes? anytime you are printing an old file you will revert the settings and need to reboot.

-

FYI I think the start code Veti is referring to is in your slicer.

If it is Cura.

Settings - Printers - manage printers

Select your printer and click 'Machine Settings'On that page at the bottom there is a window with Start G-Code

Remove the lines you have been asked to remove.

M201 X500.00 Y500.00 Z100.00 E5000.00 ;Setup machine max acceleration

M203 X500.00 Y500.00 Z10.00 E50.00 ;Setup machine max feedrate

M204 P500.00 R1000.00 T500.00 ;Setup Print/Retract/Travel acceleration

M205 X8.00 Y8.00 Z0.40 E5.00 ;Setup JerkHTH

Paul. -

@Gost101 said in CR-10S5 Firmware:

M203 X500.00 Y500.00 Z10.00 E50.00 ;Setup machine max feedrate

Your screen shot shows the top speed as 8.4mm/s which is basically 500mm/min. So I think you still haven't removed the limiting start gcode from cura. Follow the directions that @PaulHew has given.

Once that change is made it will only apply to newly sliced files. All your previously sliced files will have the slow limits set.

-

@Veti I did reboot it. I did find that in cura and deleted it. lol

-

-

START

M220 S100 ;Reset Feedrate M221 S100 ;Reset Flowrate G28 ;Home G92 E0 ;Reset Extruder G1 Z2.0 F3000 ;Move Z Axis up G1 X10.1 Y20 Z0.28 F5000.0 ;Move to start position G1 X10.1 Y200.0 Z0.28 F1500.0 E15 ;Draw the first line G1 X10.4 Y200.0 Z0.28 F5000.0 ;Move to side a little G1 X10.4 Y20 Z0.28 F1500.0 E30 ;Draw the second line G92 E0 ;Reset Extruder G1 Z2.0 F3000 ;Move Z Axis upSTOP

G91 ;Relative positioning G1 E-2 F2700 ;Retract a bit G1 E-2 Z0.2 F2400 ;Retract and raise Z G1 X5 Y5 F3000 ;Wipe out G1 Z10 ;Raise Z more G90 ;Absolute positionning G1 X0 Y{machine_depth} ;Present print M106 S0 ;Turn-off fan M104 S0 ;Turn-off hotend M140 S0 ;Turn-off bed M84 X Y E ;Disable all steppers but Z

-

And what speeds are set in cura for printing moves?

-

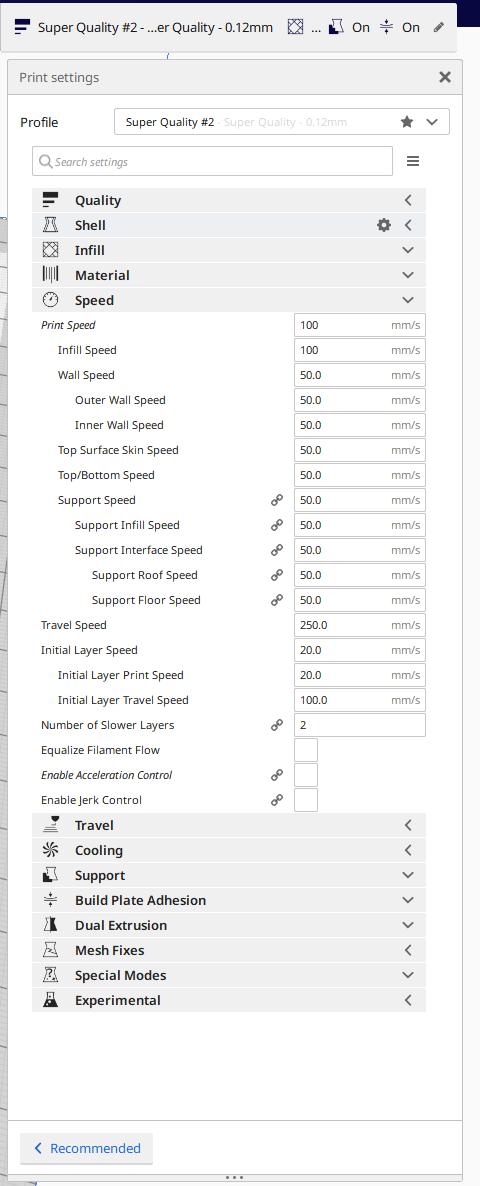

@Phaedrux For this profile it is:

-

@Phaedrux Regardless of any adjustments to this, it still takes a long time to print. Even after the changes made.

-

Can you post a gcode file somewhere for us to see? And perhaps your current config.g file as it is right now?

-

Heres the benchy file: Benchy GCode

;config.g ; Created by Gost101 on Saturday, September 28th, 2019 at 18:00 (6:00PM for Civs). ; This firmware discussion can be found on duet fourm: https://forum.duet3d.com/topic/11964/cr-10s5-firmware/37 ; Contact gost1017@gmail.com for more help. ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"A.C.E." ; set printer name M669 K0 ; select Cartesian mode ; Network M551 P"SpaceForceHu2020!!" ; set password M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S1 ; X physical drive 0 goes forwards M569 P1 S1 ; Y physical drive 1 goes forwards M569 P2 S0 ; Z physical drive 2 goes backwards M569 P2 S0 ; Z physical drive 2 goes backwards M569 P3 S0 ; E physical drive 3 goes forwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z400.00 E408.30 ; set steps per mm M566 X500.00 Y500.00 Z30.00 E1500.00 ; set maximum instantaneous speed changes (mm/min) M203 X10800.00 Y9000.00 Z300.00 E3000.00 ; set maximum speeds (mm/min) M201 X1000.00 Y1000.00 Z500.00 E3000.00 ; set accelerations (mm/s^2) M906 X950 Y950 Z850 E900 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0:500 Y0:500 Z0:500 ; set axis maxima ; Endstops M574 X1 Y1 Z1 S1 ; set active high endstops ; Z-Probe M558 P0 H5 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed M557 X15:215 Y15:195 S20 ; define mesh grid ; Heaters M305 P0 T100000 B3950 R4700 ; set thermistor + ADC parameters for the heated bed M143 H0 S120 ; set temperature limit for heater 0 to 120C M305 P1 T100000 B4725 C7.060000e-8 R4700 ; set thermistor + ADC parameters for heater 1 M143 H1 S550 ; set temperature limit for heater 1 to 550C ; Fans M106 P0 S0 I0 F500 H-1 ; set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off M106 P1 S1 I0 F500 H1 T45 ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S40 ; set initial tool 0 active and standby temperatures to 40C ; Custom settings are not defined