How to ground steppers

-

@change3d-gmbh said in How to ground steppers:

@Nxt-1 You could use the existing screws on top of the motor to connect the ground with a connector like this:

This is my backup, as it would mean using the screws as a conductor trough the bracket in which the motor is mounted. It's probably just fine tough. Depending on what people come up with, this is what I'll do.

@mrehorstdmd said in How to ground steppers:

Are the metal brackets and screws that mount the motors on the grounded metal frame of the printer insufficient?

The black bracket is not conductive due to the anodizing on there.

-

I've "fixed" a lot of glitchy CNC machines by grounding. I have NOT had to do this with 3D printers... but... I've had less hands on with other people's printers.

Things I've learned with CNC:

- Bond metal frame components frames across joints. Even bolted joints. A short jumper.

- As already mentioned, file or sand through anodizing on aluminum frames. Including clear (silver).

- Run all ground wires (other than joint jumpers) to a single point, creating a physical "star" configuration. Use a long bolt and stack the crimp-on rings.

Star ground configuration is probably the most important point to achieve stability. - If you have SHIELDED cables, ground ONE END, not both. Normally, the end that is physically closer to the "center of the star".

"Only one end of a shield" is the second most important point. This is also the hardest thing to get people to actually do, it just seems counter-intuitive. - NEVER use a shield in place of a ground wire.

- Do NOT connect the star ground bolt to Earth ground*. Normally. (See below).

- If the machine runs stably, keep "star center" isolated from Earth... if it still glitches, then do consider connecting them. Double and triple check that this is done safely, abolutely no chance of the star ground and/or frame encountering anything that is Mains "hot".

A "star" ground with each wire back to a given central point, that technique has stabilized quite a few CNC machines that were having problems.

.

*Terminology: Earth = Ground Pin in Wall Plug in US, Ground Pin in Mains plug in UK, etc.

-

I don't understand well : the star ground is connected to COM (0V) on power supply, or earth which come from main plug ?

Have you a schematic ?

-

What's your main motivation, safety? Signal integrity?

-

@zapta said in How to ground steppers:

What's your main motivation, safety? Signal integrity?

I am grounding my frame for safety and the steppers to prevent any chance of static change buildup.

-

@pipersw said in How to ground steppers:

I don't understand well : the star ground is connected to COM (0V) on power supply, or earth which come from main plug ?

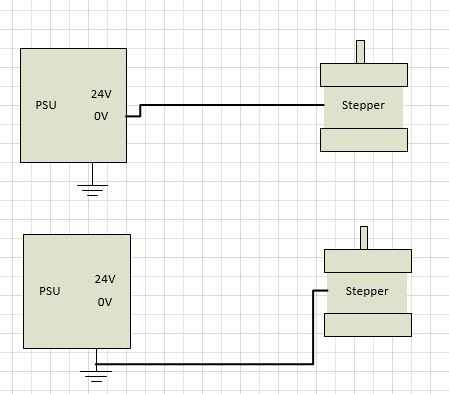

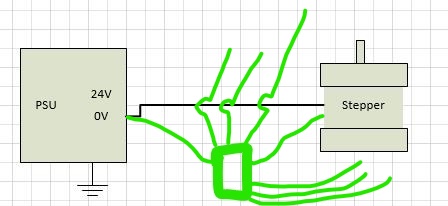

Step 1 is a common point to which ALL grounds connect, including 0V on the power supply.

Step 2, only if required (and this is very rare) connect "Earth" (mains) to that same common point.

Have you a schematic ?

A schematic won't reflect a star ground. A schematic will have ground symbols all over it. A star ground system is physical, not logical.

Like this. The green rectangle is a bolt. (Where the free end of the extra green lines are other steppers, other electronics, whatever needs a ground).

-

Also... what are you trying to accomplish? You said "Safety" and "static charge".

There are literally millions of 3D printers that do not have any special grounding for the stepper motors, and they all work great. Static does not appear to be an issue for anyone else.

Safety? Do you have a mains powered heat bed? In that case, I do recommend grounding the frame, particularly the part of the frame on which the heat bed sits. That is all that is needed for safety. On the other hand, a 12V or 24V bed requires nothing special. Grounding the case of the power supply is sufficient.

So, again, what are you trying to accomplish?

-

@danal Yes I do have a mains powered heatbed, and mains wiring running around my printer in a metal frame. Grounding steppers is recommended in the Duet documentations fyi.

Anyways, I was not really looking to start a thread on the necessity of stepper grounding. Only on how to do it best if you choose to.@Danal one note on your schematic, often the psu 0V terminal and the earth ground are internally connected. As is the case in the psu I am using.

-

If your goal is simply to prevent static buildup then I would use copper tape to connect the stepper frame to the printer frame. Even an ultra-high impedance connection can bleed a static charge just fine, so you don't need to do anything heavy duty.

To be honest if you crank down the screws hard enough (or use a biting washer on one of the holes for each mate) you will be grounded. The connection doesn't need to be great - they put 1meg resistors in anti-static wristbands. http://www.circuitnet.com/experts/87211.html

If you want a low impedance ground connection then you can slip a ring terminal under one of the mounting screws and run it to either the frame or the grounding bus depending on how concerned about ground loops you are. Note that grounding your steppers like this will make you look absolutely insane to most people.

-

@691175002 said in How to ground steppers:

make you look absolutely insane to most people

Yeah like that wasn't already the case.

-

@nxt-1 I see the diagram of your psu, and the 0V and earth are not connected. Have you take a measurement of resistance between 0V and earth ?

So, with a 220V heatbed, I have to connect the earth to the frame under the bed only, and steppers case to 0V in star configuration ?

-

@pipersw said in How to ground steppers:

@nxt-1 I see the diagram of your psu, and the 0V and earth are not connected. Have you take a measurement of resistance between 0V and earth ?

I misread the diagram, there is capacitor from 0V to mains earth, not a DC path