slicer scaling behaviour... wild...

-

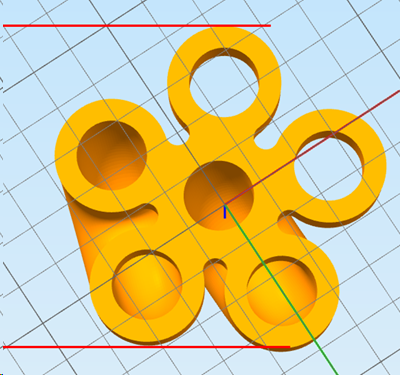

Hi! I need help with simplify3d scaling… I am trying to print figure as below… In the model external size (marked with red) is 29.214mm and internal circle is 6.4 mm.

Once printed in 100% scale external is 28.9 and internal is 5.0

once I adjust scale to 101,08 external prints with tiny difference, but internal is still very small. To print internal in right size I need to use 128% scale

once I adjust scale to 101,08 external prints with tiny difference, but internal is still very small. To print internal in right size I need to use 128% scale  but it drives external size far away…

but it drives external size far away…Which settings should I consider to be changed?

Many thanks!

-

Under Other tab on the Process settings you should have Horizontal size compensation. Change that to 0,7mm

You should be close for the internal diameter.

https://forum.simplify3d.com/viewtopic.php?t=2042But if you made the model, try increasing the dimensions.

-

That's a huge différence; you may have some over-extrusion?

-

At first I also thought of over-extrusion, but then also the outside dimension would be bigger, but it's also smaller.

Something is not completely OK here. -

My bad, I mis-read the outer dimensions!

-

Under Other tab on the Process settings you should have Horizontal size compensation. Change that to 0,7mm

thanks! that is a very strange parameter for me. with test i have figured out that -0.25 mm worked with my 101,08 scale.. however that ratio brought down external size

in my particular case i can live with that, but it is very and very strange...

in my particular case i can live with that, but it is very and very strange... -

Check X and Y steps/mm just to be sure.

-

slicer i guess is a crap... with settings above radial holes are tight as it should be, central one in loose.... in CAD they are all the same..

-

I'm pretty sure you have a hardware/firmware configuration issue... There is absolutely no reason S3D changes holes dimensions depending where they are on the plate.

-

CAD settings are below. as well as motor settings. printer is delta

M569 P0 S1 ; Drive 0 goes forwards M569 P1 S1 ; Drive 1 goes forwards M569 P2 S1 ; Drive 2 goes forwards M569 P3 S0 ; Drive 3 goes forwards (extruder) M350 X16 Y16 E16 I1 ; Set 16x microstepping with interpolation M574 X2 Y2 Z2 S1 ; set endstop configuration (all endstops at high end, active high) M666 X0 Y0 Z0 ; put your endstop adjustments here, or let auto calibration find them M665 R102 L288.17 B75 H152 ; set delta radius, diagonal rod length, printable radius and homed height ; H152 for standart ; H142 for volcano M92 X80 Y80 Z80 ; Set axis steps/mm http://prusaprinters.org/calculator/#stepspermmbelt M906 X1250 Y1250 Z1250 E700 ; Set motor currents (mA) 85% of rated M906 I30 ; Set Idle factor to 30% M201 X1000 Y1000 Z1000 E120 ; Accelerations (mm/s^2) M203 X20000 Y20000 Z20000 E600 ; Maximum speeds (mm/min) M204 P500 T2000 ; Maximum Print and Travel acceleration

-

As @OBELIKS said, re-check M92 values. And as your printer is a delta, re-check the calibration.