400mm Delta (Changed topic description)

-

I am playing with configurations

- i have 1/4 inch thick aluminum cheese plate being made, this will allow me to play with different radii

- vs a reprap approach

- 40x40 extrusions set off center so I can mount linear rail on center

- 1.8 steppers, if i need to i will go to .9 - i would rather have more torque and less refinement, so i am starting @1.8

- .08 noz

- 24v

my artemis printer is .09 and my rostock max is 1.8 -

https://www.thingiverse.com/thing:3416307/files

I

-

@wepollock I have some 3.6 permanent magnet steppers in NEMA 17 and 34 sizes that are incredibly fast due to the low inertia and have wondered just how much of a real world difference it would make printing using them for axis motors. I use the 17's for extrusion motors with my Nimbles. The 34 size are a little out of the Duet current range and would probably require external drivers for reliable operation.

-

@alexander-mundy said in 400mm Delta (Changed topic description):

Re TCO: Best I can tell by reading different manufacture sites is the NTE8149 with a cutoff of 152C and holding of 128C would be preferable over the higher temp one. The 128C holding is based on 168 hours continuous and the max temp that is specified is worst case cutoff scenario which is 176C vs 300C for the next higher temp NTE8167. -

i think your going to have to beef up your design a bit. building a big delta is nothing like building a normal sized delta you get all sorts of issues you had not thought of before. it took 2 years of constant trial and error to get my delta finished but its solid as a rock now

-

My current 250mm delta has 2020 corners with 1m verticals and I get great results with it. I figured meticulous assembly as I did with the 250 and going to 2040 1.5m verticals and 2040 top horizontals with 2040 and 2020 bottom horizontals accompanied with a bottom plate (and I thought about a top plate) would be at least as rigid. I have decided to most likely go ahead and increase arm spacing to 80mm. The 500mm CF tubes have arrived and they seem more rigid than the premade 330mm ones from Trick Laser. I second guessed myself using 6mm belt with the longer verticals and have 9mm wide belt and pullies ordered. Do you think I will need cross bracing or other structural improvements or is it simply a matter of geometrical error due to longer extrusion?

-

VBD (Very Big Delta) Questions and Request for input.

-

I designed a Delta Cheese Plate - it's going to let me adjust the delta radius based on performance. I can move the extrusions from 500 inward as needed. The delta cheese plate is rock solid with 40x40mm extrusions.

-

I wired up my power supply, and I noticed that DC is not grounded. Should I hook up negative DC to Green ground (which is mains ground)? I have the DC cables terminated in Wago connectors.. Should I jump ground from my negative wago to green?

-

-

@wepollock said in 400mm Delta (Changed topic description):

Should I hook up negative DC to Green ground (which is mains ground)?

This is generally suggested for safety reasons. The frame and ideally the motors should also be grounded to earth.

https://duet3d.dozuki.com/Wiki/Choosing_and_connecting_stepper_motors

Note: it is highly recommended that the stepper motor casings be grounded, especially in belt-driven printers. Otherwise, motion of the belts causes static charge to build up, which eventually arcs over to the windings. If the motors are screwed to a metal frame, grounding the frame is sufficient.

Just for reference.

https://duet3d.dozuki.com/Wiki/Power_Wiring

https://duet3d.dozuki.com/Wiki/Choosing_the_power_supply

https://duet3d.dozuki.com/Wiki/USB_ground_loops

https://duet3d.dozuki.com/Wiki/Warnings -

Do you plan on mains powered heat? If so you should for sure ground everything metal that you can. DC should also be ground referenced but over many years tinkering with electronics I have run into a couple of odd ball power supplies that didn't like it. I would not use Wago's for anything that carries more than a handful of amps and even then have them in a fire rated box, but that's just me. I do go ahead and use the ones that come in the junction box of recessed can lights but others cut them out. I'd never use them for branch circuit wiring.

Just got done with my arms and took the jig apart. Now to open up the box from Open Builds that arrived.

-

I checked out your monster delta.. WOW..

I plan to go wide not tall. Once I get wide where I want it I can then decide if I want to go tall.It would be great if you could post more pics!

I see you have a hex design?

-

The bed is "mostly" an afterthought at this time because I don't know what that the final geometry of the printer will be. I want to get a rigid platform first, then get the arms on, check if everything is level. I have two sets of arms in development.

(Building the printer is more fun to me that 3d printing. Totally fun! trying stuff.)

Once the geometry is solidified I will do initial testing w/o a heater.

I am considering a bunch of options - I don't know the final diameter of the printer

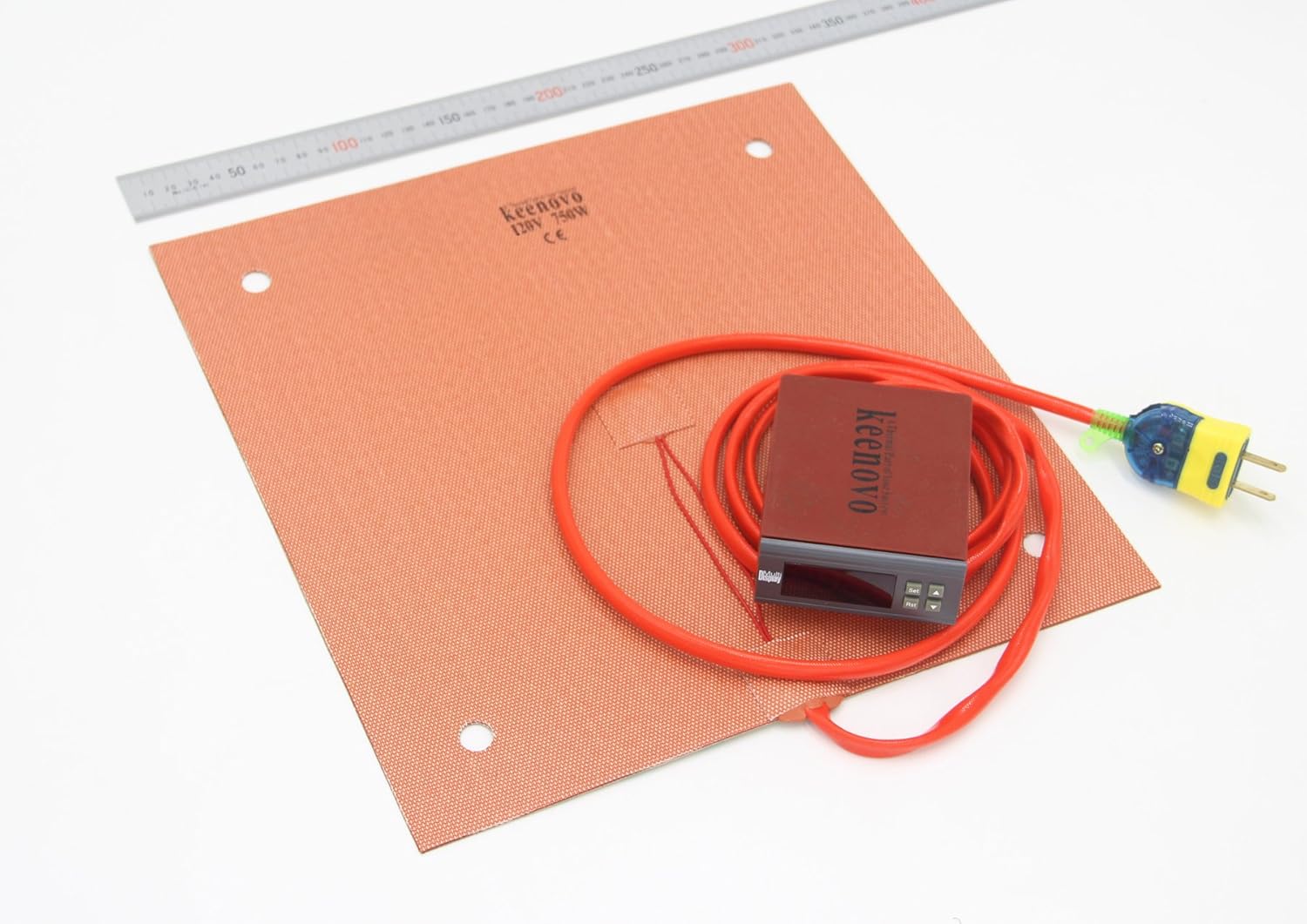

---(thinking about) separating the heater from the printer entirely with a keenovo solution

-- also thinking about http://www.zyltech.com/zyltech-3mm-400x400-heated-bed-kit/

--The Wago 221's are rated to 20 amps.

--I am not going to run a DC heated bed through them (low voltage is higher amps)

--I will run the heated bed through an SRR