Printing great, artifacts in one place

-

Hi There,

The printer is working fantastically well compared to what it was

, however I have encountered another issue. The location of where the printer starts is left on the printed part (see photo). Any suggestions? I originally thought it was heat so printed at various temps, this is selection of 15 cubes I printed. The two in the middle printed best @ 195 degrees C and the material is PLA (Filamentive). As you can see the tapering on the cube in the foreground was removed by the use of fans.

, however I have encountered another issue. The location of where the printer starts is left on the printed part (see photo). Any suggestions? I originally thought it was heat so printed at various temps, this is selection of 15 cubes I printed. The two in the middle printed best @ 195 degrees C and the material is PLA (Filamentive). As you can see the tapering on the cube in the foreground was removed by the use of fans.

Any idea how to cure the corner issues?

Best,

Andy

-

I think what you're referring to is the layer seam. It's a tricky issue.

https://mattshub.com/2017/07/19/layer-seams/

A few things to check to try and make it less noticeable...

Increase your extruder and Z axis speeds a bit to make it more responsive to limit any potential pausing between layers which can reduce unwanted oozing.

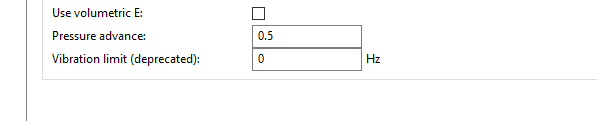

Try enabling and calibrating your pressure advance value.

Sometimes it can help to change your perimeter order from inside out to outside in, but this will be very model dependant.

Also keep in mind that simple shapes like squares and circles are worst case scenarios for the slicers seam hiding algorithm. A more complex model will have more places that the seam transition can be hidden. Even then, it'll be up to you to choose which seam hiding algorithm to choose for each model. Sometimes it's best to randomize it, sometimes it's best to keep it aligned to one spot, and sometimes it can be best to choose nearest corner option to reduce travels, especially for very oozy filaments.

Which slicer are you using?

-

Hi There,

I am using Slic3r, not looking to change to another till I have it all working. Did consider Simplify 3d.

I will try what you suggest and report back

Best,

Andy

-

Hi There,

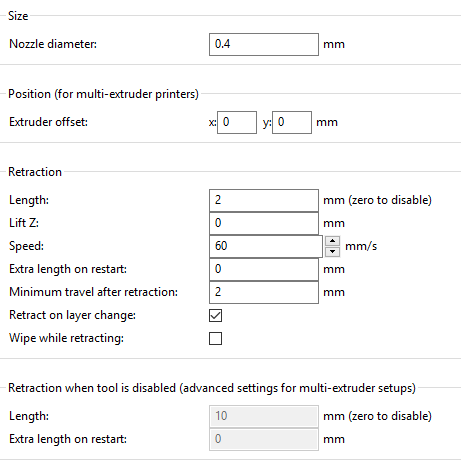

Printed the three files attached using different settings, the third came out significantly better. See images attached for settings and test files. I used the Pressure Advance in the Slic3r rather than the Duet3d, is this wise?

My hot end is an E3d Volcano with their bowden set up.

Best,

Andy

-

I'm not really sure how Slic3r 1.2.9 is implementing the pressure advance algorithm. It looks like it's making it's own extruder moves. Personally I would try both the slicer implementation and the Duet implementation and use which ever looked the best.

From your gcode it looks like you are using slicer 1.2.9. Consider upgrading to the more recent 1.3.1 release. There have been some significant improvements compared to the ancient 1.2.9 release. https://slic3r.org/download/

Also consider trying the Prusa Edition of Slic3r which has many improvements of it's own. https://github.com/prusa3d/slic3r/releases

A volcano with a bowden setup will be even more prone to ooze than a traditional hotend, so I think your results from test3 are quite good.