Sovol SV08 Multiple Motion System Upgrade.

-

I think Nema8 might end up working quite well for the Z hoppers.

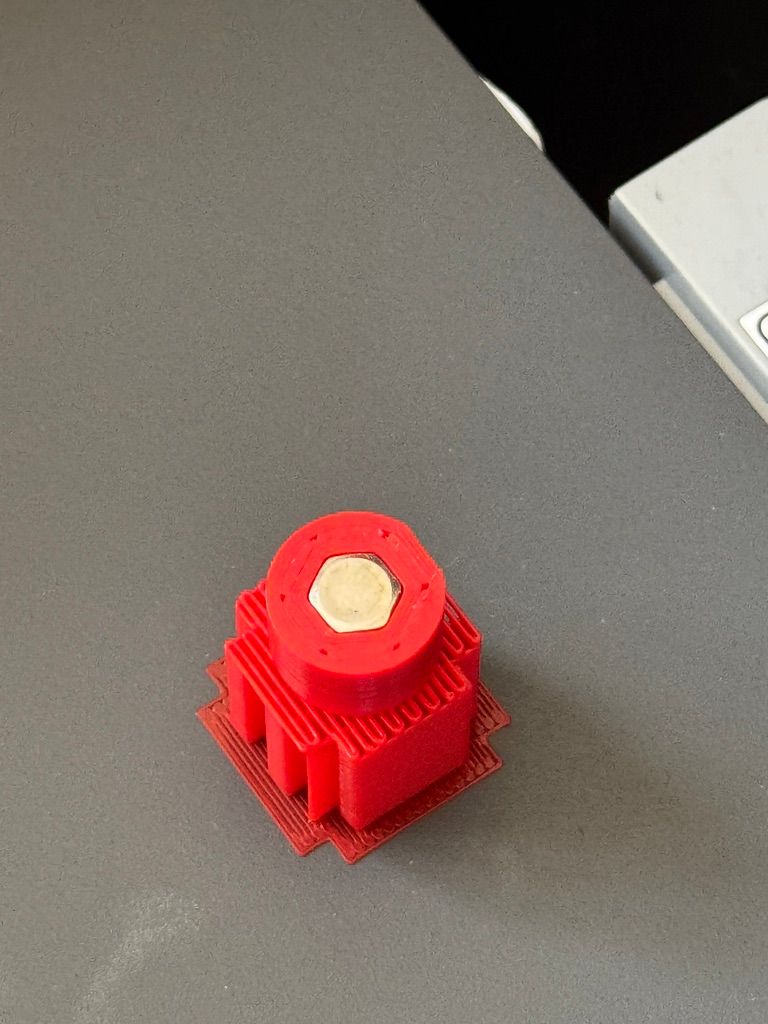

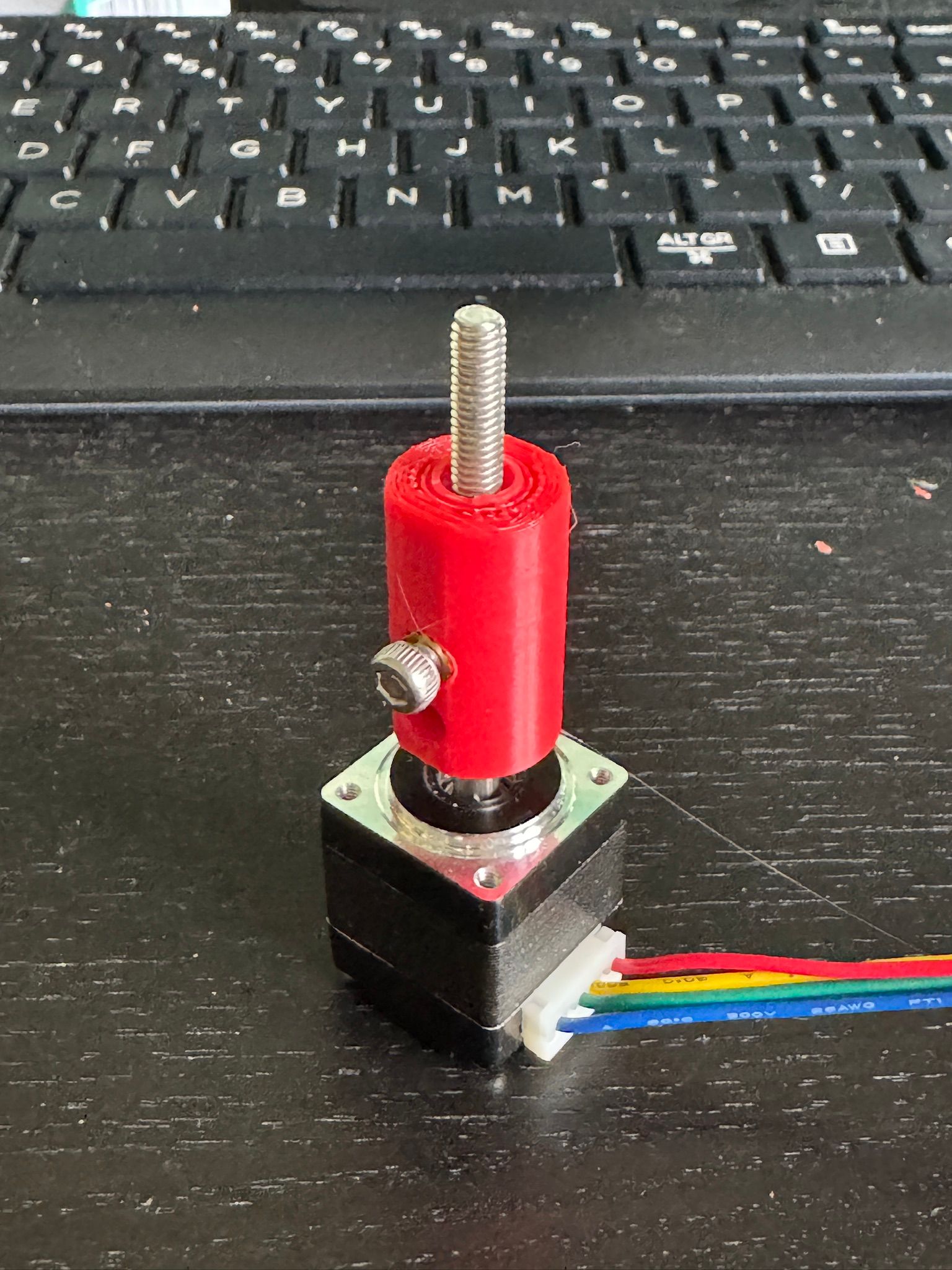

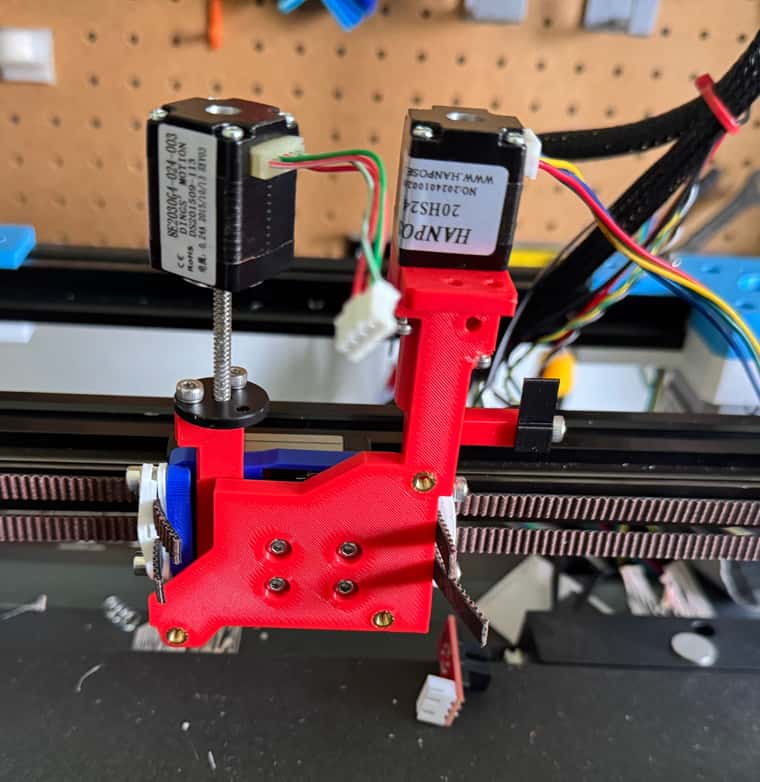

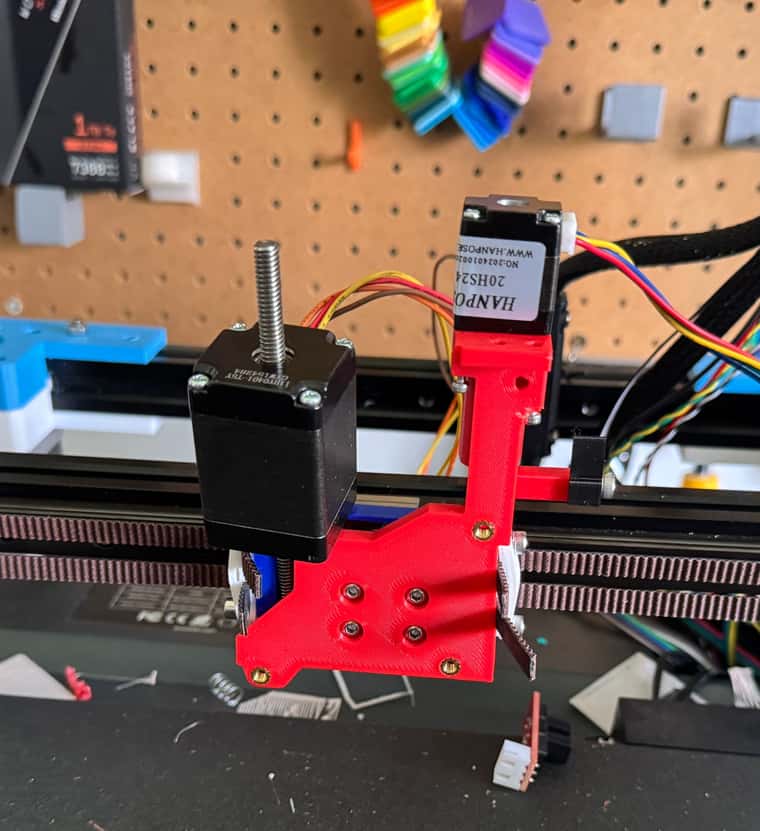

Decided to try and create some sort of lead screw for the existing NEMA8 I got a few weeks ago.

Took quite a few iterations - but ended up doing my first ever 'captive print' - with an M4 Hex Headed Bolt captured inside a coupler print.

As its a bolt rather than lead screw then it is quite sloppy - but might be able to use that as a slight advantage as will hopefully be able to use a single optical end stop for both

a) The homing of the Nema8 based Z hopper

b) The X axis

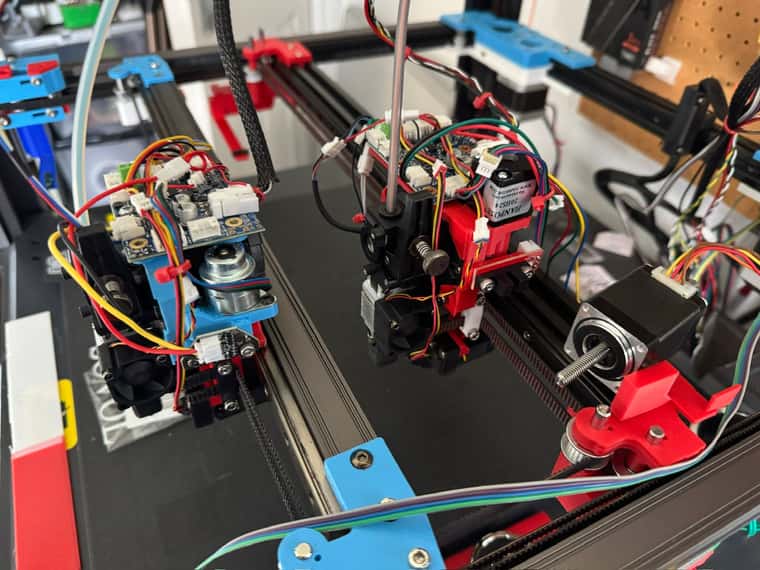

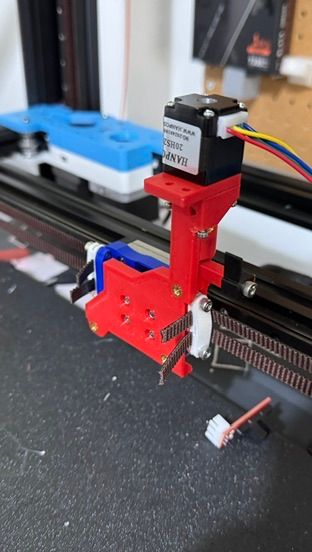

c) Z Axis tapping too.Have replaced Servo on the rear gantry with the Nema8 motor and it is looking good so far.

Comparison photo with the slow soon to be replaced front gantry stepper, rear gantry with almost completely installed NEMA8, with 3 way optical end stop below, plus the NEMA11 motor also included.

Had to move the 1LC tool board about 16mm to the left to accommodate the taller stepper/lead screw combination.

-

@dwuk3d said in Sovol SV08 Multiple Motion System Upgrade.:

As its a bolt rather than lead screw then it is quite sloppy - but might be able to use that as a slight advantage

Vertical slop is a 1st layer killer.

Although it might have advantages with other stuff, you sure don't want to risk bad adhesion to the bed.

Maybe you can add a spring to reduce backlash? -

@o_lampe Thanks will try a spring over the bolt.

Will be interesting to compare the 'bolt' version with the proper lead screw Nema8 version I have ordered.

-

Nema8 motor working quite well as a zlifter on rear gantry - so have ordered a few more for other extruders.

Will create a short video next showing use of a single optical endstop for U,A and Z Axis.

In the meantime - another interesting video from teaching tech with a comparison between Marlin, Klipper and RRF - with another little mention of this project in the RRF section about 9mins30 in.

-

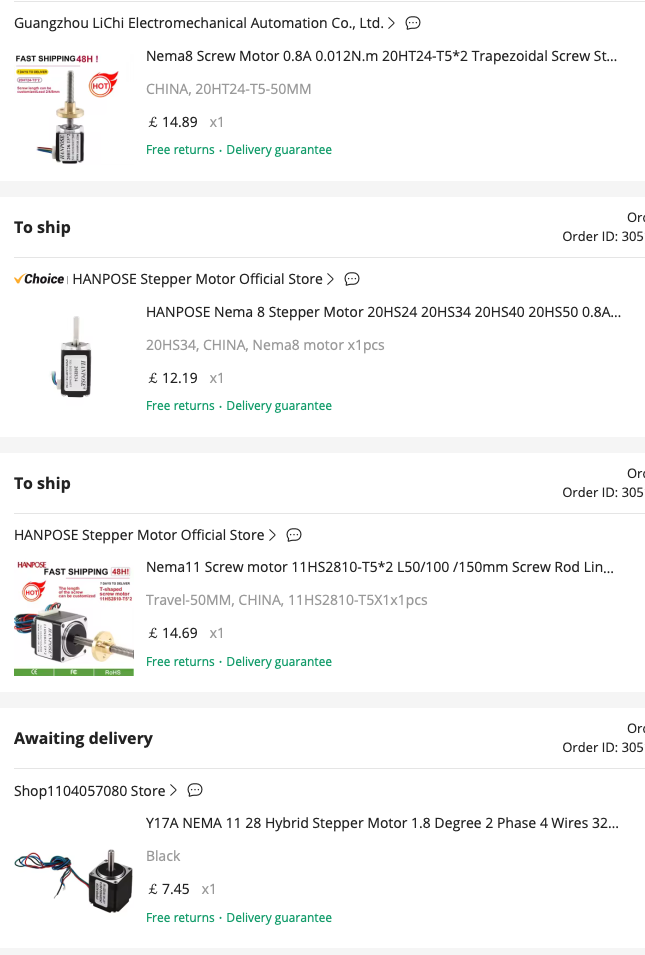

@dwuk3d Initially I was finding that the Nema 8 motors were not powerful enough to reliably lift the gantry.

The Non Lead screw one was I thought rated at 0.4a and the Lead Screw one at 0.24A.

However it looks like on further investigation that the Non lead Screw one is actually rated at 0.8A - and when I set it to 0.6A in Config.g it is working very reliably.

Before I found this out I ordered some smaller (28mm) Nema11-s however as the Nema8's look ok I have ordered two more of those too

Short video attached of Nema8 in operation, and also showing what may or may not be a good idea - using the same (very cheap) optical sensor for

- MicroZ (A Axis)

- U Axis

- Z Axis tapping

In order to swap the 122.io2.in pin between the 3 axis - I found I had to first swap the other axis to dummy IO pins - so that they would release 122.io2.in - so that it could be assigned to the correct axis using M558 commands.

-

Little time saver GCode command created,

M98.1 - For running Macro's - without needing to specify the full path, or .G suffix

M98.1 A"ClearAllocs"

Instead of

M98 P"0:/macros/ClearAllocs.g";m98.1.g - Run Macro if exists(param.A) var P ="0:/macros/"^{param.A} if fileexists(var.P) M98 P{var.P} else var P2 =var.P^".g" if fileexists(var.P2) M98 P{var.P2} else echo "M98.1 Macro file not found",{var.P} else echo "M98.1 Macro Parameter A not found" -

Got a bit distracted today by the BondTech INDX - which looks like a very interesting Nozzle Changing solution - although I suspect it might end up being a bit expensive to be practical for my Proof of Concept.

https://youtu.be/BCmGoP0uNlM?si=9z8oPViQpQ6cfGIo

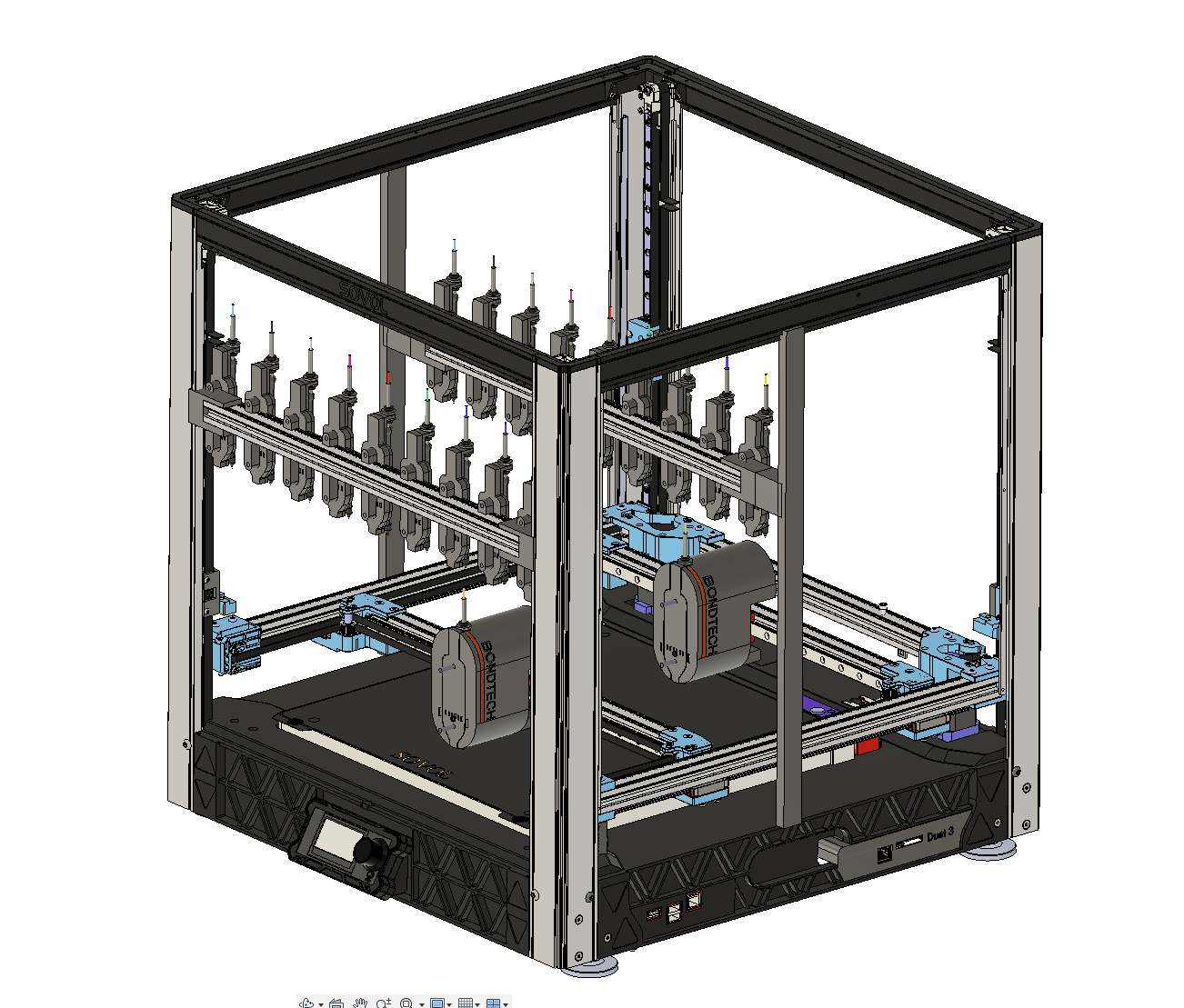

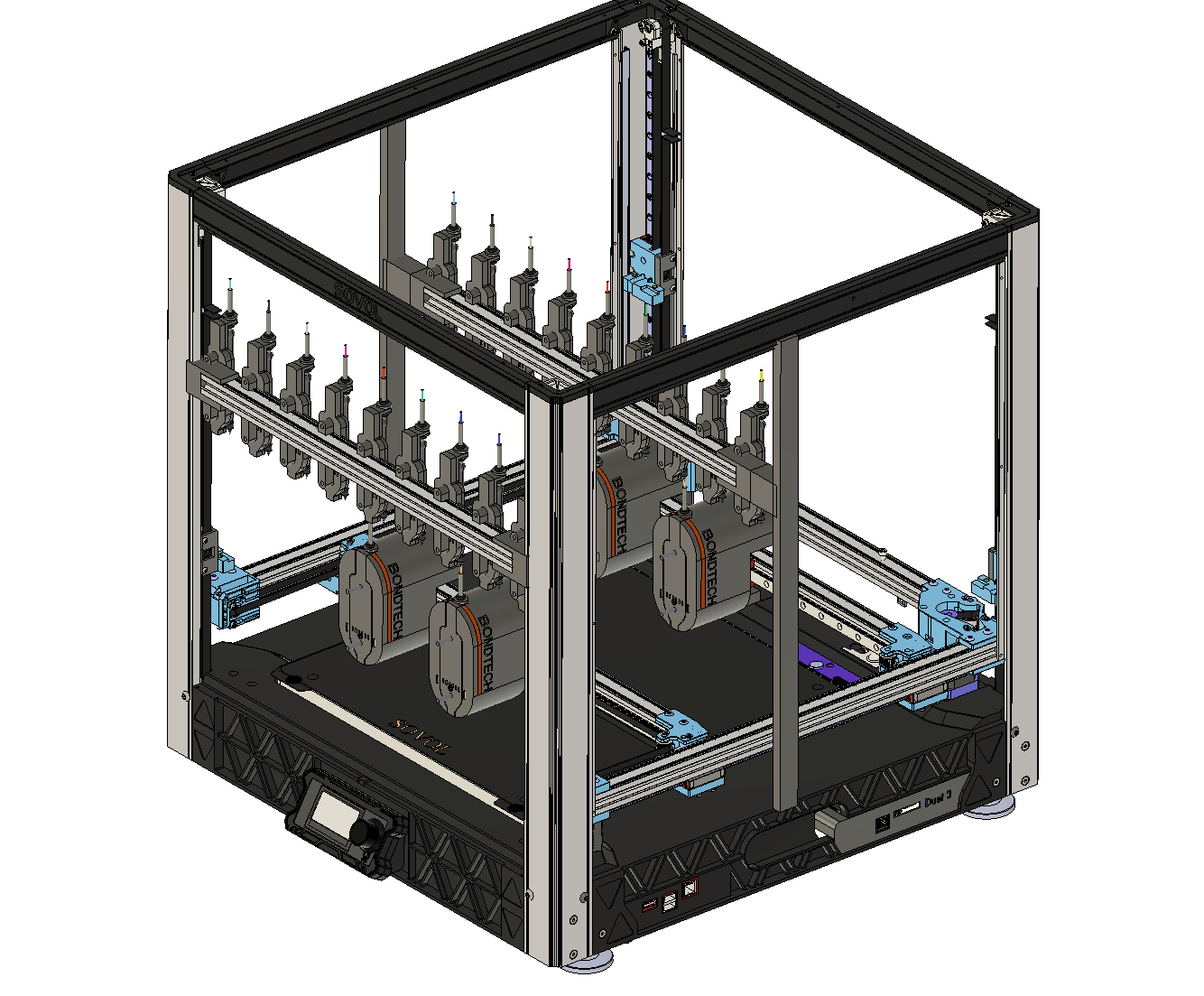

Double Gantry SV08 - with 9 way INDX on each gantry - for parallel tool changes and parallel printing

Double IDEX version ultimate parallel printing / multi colour solution

-

@dwuk3d I played around with multicolor prints, but they all looked like (R)designed by Toys'R'us.

It was hard to find decent colors and mixing hotends where a fail, too. -

@o_lampe thanks for all of your input on my project.

I've not tried any colour mixing - but agree that it would be good if they come up with a really good way of doing full colour printing without needing masses of different pre-coloured filaments.

The ink injection method recently featured by teaching tech looks like it has some potential - but I was put off trying it by the slightly washed out look, and high postage costs quoted for the prototype.

I've tried a few different non mixing methods such as Prusa MMU2, Mosaic Palette and IDEX plus combinations- but didn't really have anything I wanted to print until I decided to start doing ship modelling, plus when Bambulab finally came out with a reliable solution that can produce some surprisingly detailed results

- lots of stuff about my multi colour printing stuff here if anyone is interested https://forum.bambulab.com/t/cruise-ship-print/5122

The multi colour challenge I am trying to address is print time - as even tool changers are quite slow when you have 1000s of colour changes in a model - especially when the printing and tool changing are single threaded.

I'm also though trying to get the print time of big objects single or multi colour down too without needing them to be split into multiple parts.

I think massive printers like the Elegoo Orangestorm Giga would really benefit from having 4, 9 or even 16 heads.

-

Still working on Z hoppers - taking longer than I expected to get working well.

I've moved the Z hopper off of the tool board holder onto the main extruder holder - which has the advantage that it doesn't need to be offloaded when I get to the tool changer stage. Will need two sets of wires going to each extruder - one for the Z Hopper, and one for the Tool with the 1LC board and PTFE.

Not completely sure they will be strong enough - they are not very heavy - so I could put a 2nd one on the other side - and run them in parallel - with double the current. Would also be better to be lifting from both sides - but does seem a bit excessive to have 2 motors.

Another option is to switch the 'lead bolt' from M4 0.7mm pitch to M3 0.5mm pitch - as that will increase the gearing.

Size comparison with the larger NEMA11 motor - I'm still waiting for shorter ones to be delivered.

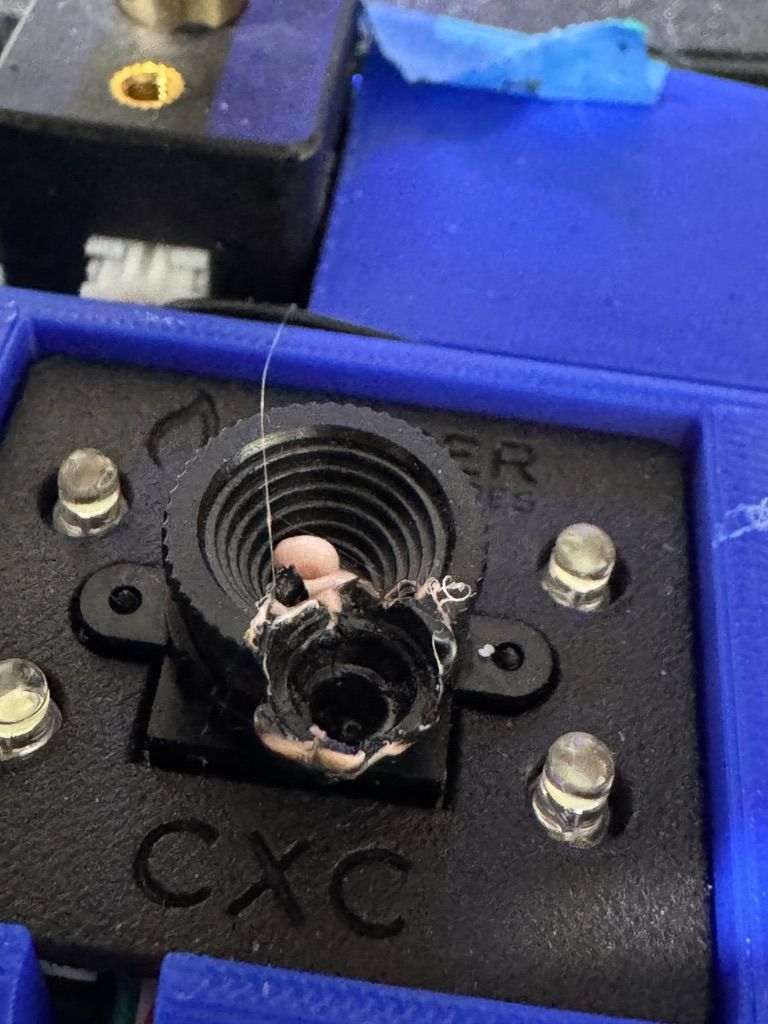

Also had a nasty accident with my alignment camera - accidentally took the gantry down to 5mm nearly over the top of it.

Luckily it still seems to workNew 3.6.0.rc1+3 looks like it solves my motion system non release issue - so should hopefully be able to proceed with further testing now on that version. Will be good to turn on head avoidance, plus will probably switch the XY gantry into M596 P0 now that the UV no longer has the servo on it.